Cracking a skill-specific interview, like one for Shingle Replacement, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Shingle Replacement Interview

Q 1. What are the different types of asphalt shingles?

Asphalt shingles are the most common roofing material in North America, and they come in a variety of types, each with its own characteristics and lifespan. The main categories are:

- 3-Tab Shingles: These are the most economical option, featuring a simple three-tab design. They are easy to install but tend to have a shorter lifespan than other types.

- Architectural Shingles (Dimensional Shingles): These offer a more upscale look, with thicker, heavier construction and a more textured surface. They provide better durability and weather resistance than 3-tab shingles. They often mimic the look of wood shakes or slate.

- Luxury Shingles: These represent the highest tier in asphalt shingles. They are thicker, heavier, and more durable than architectural shingles, featuring enhanced designs and colors. They often come with enhanced warranties.

- Laminated Shingles: These shingles are made of two or more layers bonded together, offering greater durability and a more dimensional appearance compared to 3-tab shingles.

The choice of shingle type depends on budget, aesthetic preferences, and the expected lifespan of the roof. For instance, a homeowner looking for a budget-friendly solution might opt for 3-tab shingles, while someone aiming for a long-lasting, aesthetically pleasing roof might choose luxury shingles.

Q 2. Explain the process of properly installing asphalt shingles.

Proper asphalt shingle installation is crucial for a long-lasting, leak-free roof. The process involves several key steps:

- Preparation: This includes inspecting the existing sheathing, ensuring it’s sound and free from rot or damage. Any necessary repairs should be completed before installation begins. This also includes the proper installation of underlayment, a waterproof membrane that protects the roof deck.

- Starter Course: A starter course of shingles is installed along the eaves to provide a straight, even base for the remaining shingles. This ensures a neat and aligned look.

- Shingle Installation: Shingles are installed in overlapping rows, starting from the bottom and working upward. Each shingle overlaps the one below it to ensure proper weather protection. Nail placement is critical; nails should be placed in the designated spots to ensure the shingles are securely fastened.

- Flashing: Flashing, which is a thin metal sheet, is installed around chimneys, vents, and other roof penetrations to prevent water leakage. Careful attention to flashing details is very important.

- Ridge Cap Installation: The ridge cap is the final layer of shingles, installed along the peak of the roof. It protects the roof’s highest point from the elements.

Throughout the installation process, it’s vital to maintain consistent shingle alignment and secure fastening to ensure a waterproof and aesthetically pleasing finish. A poorly installed roof can lead to leaks, premature shingle failure, and costly repairs down the line. Therefore, it is important to hire a skilled and experienced roofing professional.

Q 3. How do you determine the square footage of a roof?

Determining roof square footage is essential for accurate material estimation and budgeting. The most common method involves breaking the roof down into simple geometric shapes (rectangles and triangles) and calculating their individual areas, then summing them up.

For a simple rectangular roof: Measure the length and width of the roof, multiply them together (length x width), and this gives the square footage.

For a more complex roof with multiple sections: Divide the roof into individual rectangular and triangular sections. Calculate the area of each section separately. For rectangles, use length x width. For triangles, use (base x height) / 2. Add up the areas of all sections to get the total square footage.

Example: A rectangular roof section measures 20 feet by 30 feet. Its area is 20 ft x 30 ft = 600 square feet. A triangular section has a base of 10 feet and a height of 15 feet. Its area is (10 ft x 15 ft) / 2 = 75 square feet. The total area would be 600 + 75 = 675 square feet.

Remember to account for all sections of the roof, including dormers and other projections. For very complex roofs, it’s advisable to use professional measuring and estimation services.

Q 4. What safety precautions are necessary when working on a roof?

Roofing work is inherently dangerous. Safety precautions are absolutely paramount. These include:

- Fall Protection: Always use a safety harness and anchor points when working at heights. This is non-negotiable. Never work on a roof without proper fall protection.

- Proper Footwear: Wear sturdy, non-slip work boots with good ankle support to prevent slips and falls.

- Ladder Safety: Ensure ladders are placed on a stable, level surface and extend at least 3 feet above the roofline. Always have a spotter when using a ladder.

- Head Protection: Wear a hard hat to protect against falling objects.

- Eye Protection: Use safety glasses to protect against debris and flying particles.

- Weather Conditions: Never work in inclement weather such as rain, snow, or strong winds. Postpone work until conditions improve.

- Proper Tools: Use the right tools for the job, and ensure they are in good working order.

- Buddy System: It’s always best to work with a partner to enhance safety and provide assistance if needed.

Prioritizing safety ensures the well-being of the workers and prevents accidents that can result in serious injuries or fatalities. A thorough risk assessment should always be undertaken before commencing any roofing work.

Q 5. Describe your experience with different shingle brands.

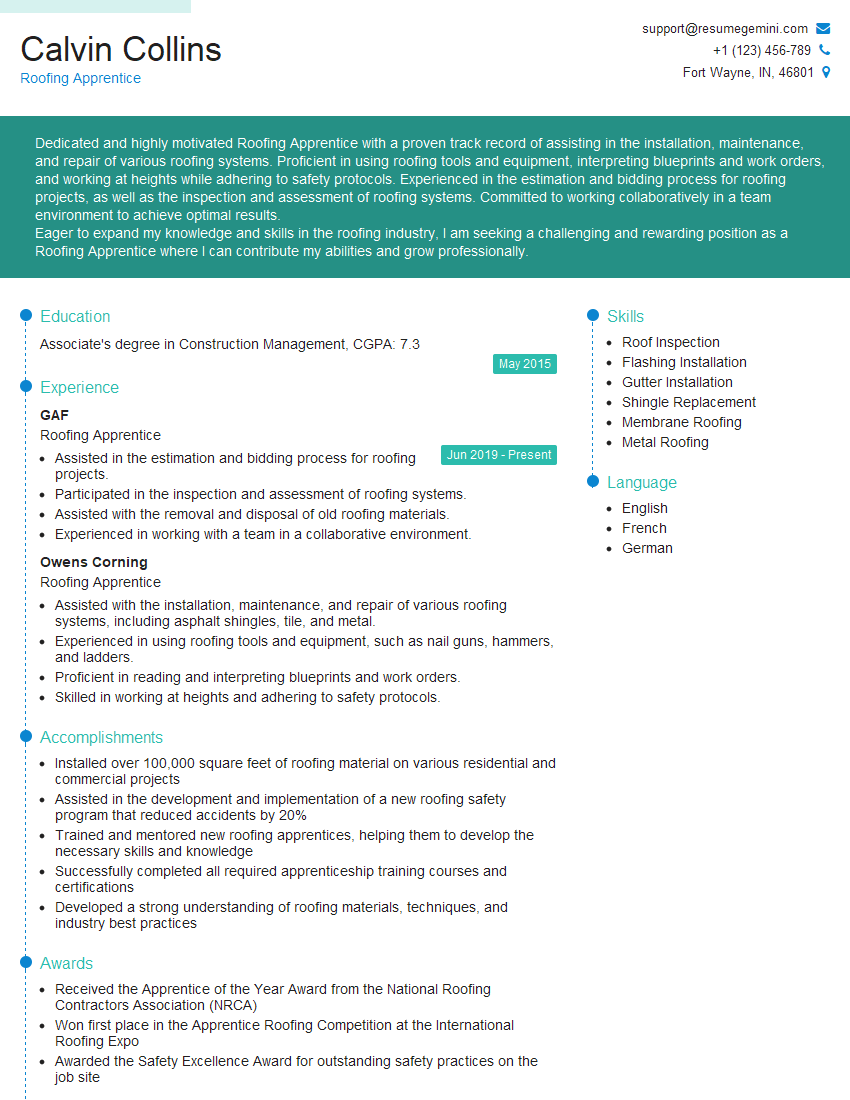

Throughout my career, I’ve worked with numerous shingle brands, including Owens Corning, CertainTeed, GAF, and IKO. Each brand offers a range of products with varying qualities, price points, and warranties. For example, Owens Corning’s Duration shingles have a reputation for excellent durability, while CertainTeed’s Landmark shingles are a popular choice for their aesthetic appeal. GAF’s Timberline HDZ shingles are well-regarded for their weather resistance. IKO also produces a wide selection with varying levels of performance.

My experience with these brands allows me to select the appropriate shingle for a given project based on the client’s budget, the specific climate, and the overall aesthetic goals. Understanding the nuances of different brands allows for more informed decisions, which ultimately contributes to a successful and long-lasting roofing project. I’ve also found that understanding the warranty options offered by each brand is incredibly important for the homeowner.

Q 6. How do you handle damaged or missing shingles during a repair?

Handling damaged or missing shingles during a repair involves a systematic approach. First, I would assess the extent of the damage to determine the best course of action. For minor damage, such as a few cracked or curled shingles, simply replacing the affected shingles is often sufficient. This requires carefully removing the damaged shingles, ensuring that the surrounding shingles aren’t further damaged in the process.

For more extensive damage or missing shingles, the underlying sheathing needs to be inspected. If any underlying damage is found (rot, water damage, etc.), it must be repaired before new shingles are installed. New shingles should always match the existing ones to maintain a uniform appearance. In the event that the exact shingle is unavailable, I work with the homeowner to select the closest match or explore options to replace several surrounding shingles to better blend a slight mismatch.

In all cases, proper sealing of the new shingles is crucial to prevent water penetration. High-quality roofing cement is used to ensure a waterproof seal around the edges and nails.

Q 7. What are the signs of a failing roof?

A failing roof often shows several telltale signs. These can include:

- Missing or Damaged Shingles: Noticeable gaps or damaged shingles are clear indicators of a problem, which should be addressed promptly to prevent further water damage.

- Leaks: Water stains on ceilings or walls are undeniable evidence of leaks. This might require investigating multiple areas of the roof to determine the leak’s source.

- Granule Loss: A significant loss of granules from the shingle surface indicates that the shingles are deteriorating and approaching the end of their lifespan. This is often seen as a build-up of granules in gutters.

- Curling or Cupping Shingles: Shingles that curl upwards or cup downwards indicate moisture damage or degradation of the shingle material.

- Sagging Roofline: A sagging roof can signal structural problems or excessive moisture buildup.

- Moss or Algae Growth: Excessive moss or algae growth can indicate poor ventilation, potentially leading to increased moisture buildup and shingle deterioration.

If you notice any of these signs, it’s crucial to have a roofing professional inspect your roof to assess the damage and recommend appropriate repairs or replacements. Ignoring these problems can lead to extensive and costly repairs later on.

Q 8. Explain the importance of proper underlayment.

Proper underlayment is crucial for a long-lasting and leak-free roof. Think of it as insurance for your roof. It acts as a secondary barrier, protecting your home from water damage in case the shingles fail. Without it, even a small leak in your shingles could lead to significant damage to your roof deck and interior.

There are different types of underlayments, each with its own benefits. Synthetic underlayments are becoming increasingly popular due to their durability and resistance to tears. They often offer superior water resistance compared to traditional felt underlayment. Felt underlayment is less expensive but can be more susceptible to tearing during installation, especially on complex roof designs.

In my experience, I always recommend using a quality synthetic underlayment, particularly in areas prone to heavy rain or snow. This extra protection is a small investment compared to the potential cost of repairing water damage.

Q 9. How do you deal with different roof pitches and angles?

Roof pitches and angles significantly impact shingle installation. Steeper roofs require extra precautions to prevent shingle slippage, while lower-pitched roofs might need additional measures to ensure proper water runoff.

For steeper roofs, we often use extra sealant and more meticulous fastening techniques to secure the shingles. We might also employ specialized roofing nails with longer shanks to penetrate the decking properly. On lower-pitched roofs, we pay close attention to the shingle overlap to prevent water penetration. We might even consider incorporating additional flashing around valleys and chimneys to reinforce water diversion.

I’ve worked on roofs with angles ranging from near-flat to extremely steep, and adapting my techniques to each unique situation is essential for a successful installation. Understanding the nuances of different roof geometries is paramount to a professional roofer.

Q 10. What are the common causes of shingle blow-offs?

Shingle blow-offs are a frustrating and costly problem. They are usually caused by a combination of factors, not a single event. Strong winds are the primary culprit but the shingles’ installation quality plays a huge role.

- Inadequate fastening: Using too few nails or improperly driven nails allows wind to lift shingles.

- Poor shingle overlap: Insufficient overlap leaves gaps that wind can exploit.

- Damaged or deteriorated shingles: Old, brittle, or damaged shingles are more vulnerable to wind.

- Lack of proper sealing: Gaps between shingles or where they meet flashing allow wind to enter and lift them.

- Missing or inadequate underlayment: This leaves the roof deck exposed to wind and rain.

Preventing blow-offs involves using the correct number and type of nails, ensuring proper shingle overlap, using high-quality sealant, and inspecting the underlayment for any damage.

Q 11. Describe your experience with roof ventilation.

Proper roof ventilation is critical for extending the life of your roof and preventing costly problems like ice dams in colder climates and excessive moisture buildup. It’s like having a good respiratory system for your roof.

I always assess the existing ventilation system during my inspections, looking for adequate intake vents at the soffit and exhaust vents at the ridge or peak. Proper balance is key—you need sufficient airflow to prevent moisture buildup without creating excessive pressure that could lift shingles. In many cases, adding or upgrading ventilation is a crucial part of a shingle replacement project. Sometimes adding ridge vents is more effective than relying solely on soffit vents.

I’ve seen firsthand the damage caused by poor ventilation – mold, mildew, rot, and premature shingle failure. Addressing ventilation issues proactively saves homeowners considerable money in the long run.

Q 12. How do you ensure proper shingle overlap?

Proper shingle overlap is fundamental to a watertight roof. Imagine shingles as overlapping scales on a fish; each scale protects the one beneath. The manufacturer’s specifications clearly define the required overlap for each shingle type. This varies depending on the shingle design and the roof’s pitch.

I meticulously measure and ensure consistent overlap during installation. I typically use a measuring tool or a chalk line to maintain uniform spacing. Inconsistent overlap leads to gaps which are points of vulnerability to water intrusion. I also pay special attention to the starter course and the hip and ridge installations where precise alignment and proper overlap are essential. Ignoring proper shingle overlap compromises the entire roof’s integrity.

A consistent and accurate overlap isn’t just about aesthetics; it’s a key element of structural stability and water resistance.

Q 13. What tools and equipment are essential for shingle replacement?

Shingle replacement requires specialized tools and equipment for efficient and safe work. Safety is always my top priority, and the right tools contribute to that.

- Safety equipment: Hard hats, safety harnesses, gloves, and safety glasses are non-negotiable.

- Measuring tools: Tape measures, chalk lines, and squares for precise measurements and marking.

- Cutting tools: Utility knives, circular saws, and shingle cutters for precise cuts.

- Fastening tools: Roofing nailers (pneumatic or battery-powered) for efficient and consistent nailing.

- Lifting equipment: Depending on the project scale, we might use scaffolding, ladders, and possibly a crane for heavy materials.

- Removal tools: Pry bars and shovels to safely remove old shingles.

- Other essential tools: Roofing cement, sealant, and various other accessories to support the installation.

Having the right tools not only improves efficiency but also enhances safety and minimizes the chance of errors during the installation process.

Q 14. Explain your experience with ice and water shield installation.

Ice and water shield is a critical component, particularly in areas experiencing freezing temperatures and snow accumulation. It protects the vulnerable areas of your roof, acting as a safeguard against ice dams and leaks. Think of it as a highly waterproof underlayment for the most susceptible parts of your roof.

I typically install ice and water shield on all low-sloped areas, valleys, around chimneys and vents, and along the eaves. It’s a self-adhering membrane that forms a continuous waterproof barrier. The installation requires attention to detail; overlaps must be meticulously sealed to ensure complete protection. Proper installation is crucial since this layer is your last line of defense against water infiltration in these vulnerable areas.

I’ve seen the devastating consequences of neglecting ice and water shield installation – extensive water damage and costly repairs. Its cost is insignificant compared to the potential damage it prevents.

Q 15. How do you handle unexpected issues during a shingle replacement job?

Unexpected issues are part and parcel of any roofing job. My approach is proactive and methodical. First, I thoroughly assess the situation. Is it a simple fix like a damaged shingle discovered after tear-off, or something more complex like unexpected structural damage or unforeseen weather conditions? For example, if I discover rotted sheathing during tear-off, I’ll immediately document it with photos and discuss it transparently with the homeowner. We’ll discuss the best course of action, which might involve halting the shingle replacement temporarily while addressing the sheathing issue. This avoids costly mistakes down the line. My experience allows me to troubleshoot quickly and efficiently. I have a robust network of subcontractors – structural engineers, carpenters – that I can tap into if necessary, ensuring the project stays on track. Communication with the client is paramount throughout this process. I keep them informed every step of the way.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with different roofing materials besides shingles?

While my expertise lies in shingle roofing, I have experience working with other materials. I’ve worked on projects involving tile roofs, particularly Spanish tile. I understand the intricacies of installation, including underlayment and flashing requirements, which differ significantly from shingle installations. I’ve also assisted on projects involving metal roofing, learning about its advantages (durability, longevity) and the specialized techniques needed for proper installation. This broader experience provides me with a valuable perspective and helps me offer comprehensive advice to clients, even if their project goes beyond traditional asphalt shingles. For example, understanding the challenges of tile roof repairs helps me better assess the potential costs and benefits when recommending a shingle replacement vs. tile repair.

Q 17. How do you calculate the cost of a shingle replacement project?

Calculating the cost of a shingle replacement is a multi-faceted process. It’s not just the material cost. I begin by performing a thorough roof inspection to determine the square footage, the condition of the existing underlayment, the need for repairs to the decking (sheathing), and any other potential issues. Then, I’ll factor in the cost of materials, including shingles, underlayment, flashing, nails, and any necessary supplementary materials like drip edge. Labor costs are calculated based on the project’s complexity and the number of workers required. I also include a contingency for unexpected issues, typically around 10-15%, to cover any unforeseen complications. Finally, permits and disposal fees are factored in. I present a detailed, itemized estimate to the client, ensuring transparency and clarity. For example, a client might have a 20-square roof; I’ll multiply the square footage by the cost per square of shingles, underlayment etc. and add labor and contingency costs. This provides a clear understanding of where their money is going.

Q 18. Describe your experience working with clients and managing expectations.

Client communication is essential. I aim to build a strong rapport with each client, beginning with a thorough consultation to understand their needs and expectations. I explain the process clearly, answering all their questions patiently. I provide realistic timelines and keep them updated throughout the project. If unforeseen issues arise, I communicate them immediately, explaining the impact and potential solutions. Transparency is key to managing expectations. For example, I’ve had clients who were initially hesitant about the cost of additional underlayment. Once I clearly explained the benefits—increased lifespan, improved weather protection—they were much more understanding. Positive communication helps build trust, leading to satisfied customers.

Q 19. What is your experience with different types of roofing fasteners?

My experience encompasses various roofing fasteners, including galvanized roofing nails, stainless steel nails, and specialized fasteners for specific shingle types. The choice of fastener depends on the shingle material and local building codes. Galvanized nails are common for asphalt shingles, offering sufficient corrosion resistance. Stainless steel nails provide superior corrosion resistance in areas with high humidity or coastal conditions. I always ensure that the nails are appropriately sized and driven straight to prevent shingle damage. I also use appropriate sealing washers, especially when working with high-profile shingles. Understanding the properties of each fastener is crucial for ensuring the long-term integrity of the roof. Improperly installed fasteners can lead to leaks or premature shingle failure.

Q 20. What is your knowledge of building codes and permits related to roofing?

Knowledge of building codes and permits is crucial. I am familiar with local and state building codes concerning roofing, including requirements for shingle type, underlayment, ventilation, and wind resistance. Before starting any project, I verify all necessary permits are obtained. I meticulously document my work, ensuring it complies with all regulations. I understand the consequences of non-compliance, such as project delays, fines, or even legal issues. For example, I’m aware of the specific wind resistance requirements in hurricane-prone areas and ensure the shingles and installation methods meet these standards.

Q 21. How do you ensure the quality of your workmanship?

Quality workmanship is my priority. I use only high-quality materials from reputable suppliers. I adhere to strict installation procedures, ensuring each shingle is properly aligned, nailed, and sealed. I perform regular quality checks throughout the process, addressing any imperfections immediately. I take pride in my work and strive for perfection. After completion, I conduct a thorough final inspection to ensure water tightness and overall aesthetics. I am confident in the longevity and durability of my work. A crucial aspect is also proper cleanup after the project. Leaving the job site clean and free of debris is a sign of professionalism and respect for the client.

Q 22. What are some common problems you encounter during shingle installation?

Common problems during shingle installation often stem from inadequate preparation or unforeseen circumstances. One frequent issue is encountering damaged or improperly installed underlayment. This can lead to leaks and premature shingle failure. Think of the underlayment as the roof’s raincoat – if it’s torn or improperly overlapped, the whole system is compromised. Another challenge is dealing with inconsistent nail placement. Nails that are too short, driven crookedly, or spaced incorrectly can result in shingles lifting or blowing off in high winds. Imagine trying to build a house of cards with uneven support – it’s unlikely to stand! Finally, improper flashing around chimneys, vents, and valleys is a major source of leaks. Flashing acts as a waterproof seal, and any gaps or improper installation will let water in. It’s like leaving a hole in a dam – eventually, the water will break through.

- Damaged Underlayment: Carefully inspect and replace any damaged sections before shingle installation.

- Inconsistent Nail Placement: Use a nail gun with consistent pressure and always check for proper spacing and penetration.

- Improper Flashing: Use high-quality flashing materials and ensure proper overlap and sealing around all penetrations.

Q 23. How do you handle difficult or complex roof designs?

Complex roof designs require meticulous planning and execution. I approach these projects by first creating a detailed plan, often involving scaled drawings and 3D models (if necessary). This helps visualize the entire process, especially when dealing with multiple angles, valleys, hips, and ridges. For instance, on a mansard roof, the intricate angles require precise cutting and placement of shingles to ensure watertightness. I use specialized tools and techniques like custom-cut flashing and different shingle types to manage complex areas. Communication is key – I regularly consult with the homeowner and potentially a structural engineer to ensure the plan is feasible and safe. Safety is paramount, and I always employ appropriate fall protection and scaffolding systems for complex roof geometries.

Step-by-step, this usually involves:

- Detailed Assessment: Thoroughly examine the roof structure and identify all complex areas.

- Plan Development: Create a comprehensive plan outlining materials, tools, and specific installation techniques.

- Careful Execution: Install shingles methodically, paying close attention to detail and using appropriate tools.

- Regular Checks: Frequently inspect the work for accuracy and make adjustments as needed.

Q 24. How do you manage your time effectively on a roofing project?

Effective time management is crucial in roofing. I use a combination of techniques to ensure projects are completed on schedule and within budget. Prior to starting any project, I create a detailed schedule, breaking down the work into manageable tasks with realistic timelines. I factor in potential delays due to weather or material availability. Daily, I prioritize tasks based on urgency and complexity, focusing on critical path activities first. I maintain open communication with the homeowner to keep them informed of progress and any potential delays. My team and I also utilize efficient work methods, including using appropriate tools and minimizing wasted movement. For example, we pre-sort shingles and materials to minimize time searching for the right component on the roof. The adage ‘measure twice, cut once’ is especially relevant; preventing mistakes saves significant time later.

Q 25. Describe your problem-solving skills in a roofing context.

Problem-solving is an integral part of roofing. I approach challenges systematically. Let’s say we encounter unexpected rot in the sheathing during a shingle replacement. My first step is a thorough inspection to determine the extent of the damage. Then, I carefully assess the repair options, considering factors like cost, time constraints, and the long-term structural integrity of the roof. This might involve selective sheathing replacement, reinforcing existing structure, or even consulting a structural engineer for more complex repairs. Finally, I clearly communicate the findings and repair options to the homeowner, obtaining approval before proceeding. I prioritize finding solutions that are both effective and cost-efficient. Documentation is key – I keep records of all decisions and repairs made, aiding future maintenance and warranty claims.

Q 26. What are your strengths and weaknesses as a roofing professional?

My strengths lie in my meticulous attention to detail, my problem-solving abilities, and my effective communication skills. I am also adept at managing a team and ensuring the safe and efficient completion of projects, even under pressure. A weakness I constantly work on is delegating more effectively. I sometimes take on too much responsibility, which can sometimes slow down the project in the long run. To address this, I’m actively working on building my team’s skills and trusting them to handle aspects of the work independently. I am also continually reviewing processes and workflows to make the most effective use of everyone’s time.

Q 27. How do you stay updated on the latest roofing technologies and practices?

Staying updated in roofing involves continuous learning. I regularly attend industry conferences and workshops to learn about new products, techniques, and safety regulations. I subscribe to trade publications and online resources to stay informed about the latest innovations. I also actively participate in online forums and communities dedicated to roofing professionals, engaging in discussions and sharing best practices. Moreover, I maintain relationships with manufacturers’ representatives, who often provide training and information on new products. This ensures that I am constantly improving my skill set and delivering the highest quality workmanship.

Q 28. Explain your experience with warranty claims related to roofing.

I have extensive experience handling warranty claims. My approach focuses on thorough documentation. From the initial assessment and material selection, I maintain meticulous records, including photos, material invoices, and a detailed description of the work performed. This documentation serves as critical evidence should a warranty claim arise. When a claim is filed, I promptly address it, thoroughly investigating the cause of the issue. Open communication with the homeowner and the manufacturer is paramount. If a defect is indeed covered under warranty, I work diligently to ensure a timely and fair resolution for the homeowner, often coordinating repairs with the manufacturer to ensure proper materials are used and the work is done to the same high standard as my initial installation. A transparent approach helps to build and maintain trust with my clients.

Key Topics to Learn for Shingle Replacement Interview

- Understanding Roofing Systems: Familiarize yourself with different types of roofing systems, their components, and their lifespans. This includes understanding the differences between asphalt shingles, architectural shingles, and other roofing materials.

- Roof Inspection and Assessment: Learn how to properly inspect a roof for damage, identify necessary repairs, and determine the extent of shingle replacement needed. Practice identifying common roofing problems like damaged flashing, leaks, and granule loss.

- Shingle Installation Techniques: Master the proper techniques for installing different types of shingles, including underlayment application, starter courses, and shingle overlapping. Understand the importance of proper nailing and sealant application.

- Safety Procedures and Regulations: Demonstrate knowledge of OSHA safety regulations for working at heights and handling roofing materials. Be prepared to discuss safe work practices and fall protection measures.

- Estimating and Project Management: Learn how to accurately estimate the materials and labor needed for a shingle replacement project. Understand project scheduling and the importance of adhering to deadlines.

- Problem-Solving and Troubleshooting: Be ready to discuss how you would approach and solve common challenges encountered during shingle replacement, such as unexpected weather conditions, material shortages, or complex roof designs.

- Customer Communication and Service: Highlight your ability to effectively communicate with clients, understand their needs, and address their concerns throughout the project lifecycle. Emphasize the importance of professionalism and customer satisfaction.

Next Steps

Mastering shingle replacement skills opens doors to rewarding career opportunities with excellent growth potential within the construction industry. To maximize your chances of landing your dream job, it’s crucial to create a compelling and ATS-friendly resume that highlights your qualifications effectively. ResumeGemini is a trusted resource that can help you build a professional resume tailored to showcase your expertise in shingle replacement. Examples of resumes optimized for this field are available through ResumeGemini, ensuring your application stands out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.