Are you ready to stand out in your next interview? Understanding and preparing for Sensory Color Analysis interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Sensory Color Analysis Interview

Q 1. Define metamerism and explain its significance in Sensory Color Analysis.

Metamerism is a phenomenon where two colors appear identical under one light source but different under another. Imagine two sweaters – one appears perfectly blue in your living room, and the other, a cleverly mixed combination of other colors, looks exactly the same. However, take them outside under sunlight, and the ‘true blue’ sweater maintains its color while the other reveals its underlying composition. This difference in spectral power distribution (SPD) is crucial in sensory color analysis because it highlights the limitations of relying solely on visual matching.

In sensory analysis, understanding metamerism is essential because it impacts color consistency and quality control. Manufacturers need to ensure that their product’s color remains consistent across different lighting conditions. For example, a car manufacturer wouldn’t want a blue car to appear a different shade in a showroom versus under harsh sunlight. Metamerism tests help identify these discrepancies and aid in developing color formulations that are more stable across lighting variations.

Q 2. Describe the Munsell color system and its applications.

The Munsell color system is a color space that organizes colors based on three perceptual attributes: hue, value (lightness), and chroma (saturation). Think of it as a three-dimensional color sphere where hue is the angle around the circle (red, yellow, green, blue, etc.), value is the vertical height (from black to white), and chroma is the distance from the neutral axis (how intense or dull the color is).

Each color is represented by a unique notation like 5YR 7/4, which signifies a yellowish-red (5YR), a value of 7 (lightness), and a chroma of 4 (saturation). This system’s strength lies in its intuitive visual organization, making it ideal for practical applications.

- Applications: The Munsell system is widely used in soil science (classifying soil colors), art and design (color specification and matching), textile and paint industries (quality control), and even geology (describing rock colors).

Q 3. Explain the difference between additive and subtractive color mixing.

Additive and subtractive color mixing are two different approaches to creating colors. Additive color mixing involves adding light of different wavelengths. Think of a projector; shining red and green light together creates yellow.

- Additive: Starts with black (absence of light) and adds light to create colors. The primary additive colors are red, green, and blue (RGB).

Subtractive color mixing involves removing wavelengths from white light using pigments or dyes. Think of mixing paints; mixing blue and yellow paints creates green. The pigment absorbs certain wavelengths of light, leaving the remaining wavelengths to reflect, creating the perceived color.

- Subtractive: Starts with white (all wavelengths of light) and subtracts wavelengths by absorbing certain colors. The primary subtractive colors are cyan, magenta, and yellow (CMY), often with black (K) added to improve depth (CMYK).

The difference is fundamental: additive mixing involves light, while subtractive involves pigments or dyes. The results differ, with additive mixing creating brighter and more vibrant colors than subtractive mixing.

Q 4. What are the limitations of using just spectrophotometric data to assess color?

Spectrophotometric data, while providing objective measurements of a color’s spectral reflectance or transmittance, cannot fully capture the complexity of human color perception. Here’s why:

- Metamerism: Spectrophotometric data alone can’t predict how colors will appear under different illuminants, as it doesn’t account for metameric pairs.

- Individual Differences: Human color vision varies, influenced by age, genetics, and even current health. Spectrophotometry ignores this individual variability.

- Contextual Effects: Surrounding colors can influence our perception of a target color (simultaneous contrast), a factor spectrophotometry doesn’t account for.

- Observer Variation: Subjective aspects of color, such as pleasantness or perceived similarity, are not captured.

Therefore, relying solely on spectrophotometry leads to an incomplete and potentially misleading assessment of color, particularly in sensory analysis, where human perception is paramount. Integrating instrumental measurements with sensory evaluations provides a more complete understanding.

Q 5. How does lighting influence color perception and how can this be controlled in a sensory evaluation?

Lighting significantly impacts color perception. The same object will appear different under incandescent light (yellowish), fluorescent light (bluish), or daylight (more balanced). This is because the spectral distribution of light influences which wavelengths are reflected and reach our eyes.

In sensory evaluation, controlling lighting is crucial for consistency and reproducibility. Standard illuminants, like D65 (simulating average daylight), are used to minimize variations due to lighting. Color evaluation booths or light cabinets that maintain controlled illumination and color temperature are essential tools for precise color assessment, preventing biased sensory results.

Q 6. Explain the concept of color constancy and its importance.

Color constancy refers to our remarkable ability to perceive the color of an object as relatively constant under different illuminants. Even though the spectral composition of the light reflected from an object changes dramatically under different light sources, our visual system compensates, allowing us to perceive the color consistently. For instance, a red apple remains red whether it’s viewed indoors or outside under direct sunlight.

The importance of understanding color constancy in sensory evaluation is clear: without this ability, sensory evaluation would be highly unreliable. The concept highlights the subjective aspect of color perception and the need to standardize viewing conditions and instructions in sensory assessments. Without considering it, we risk misinterpreting the results.

Q 7. Describe different methods for measuring color and their relative strengths and weaknesses.

Several methods exist for measuring color, each with strengths and weaknesses:

- Spectrophotometry: Measures the spectral reflectance or transmittance of a sample. Highly accurate but expensive and requires technical expertise. Provides detailed information about the sample’s color but ignores human perception.

- Colorimetry: Measures color using tristimulus values (X, Y, Z), simulating human color vision. More affordable than spectrophotometry but less detailed.

- Visual Colorimetry: Human observers visually compare a sample to standard colors. Simple and inexpensive, but subjective and prone to observer variability. Useful for quick assessments and quality control.

- Imaging Colorimetry: Uses digital cameras and specialized software to capture and analyze color. Convenient, high-throughput, but accuracy depends on camera calibration and software settings.

The best method depends on the specific application and the desired level of accuracy. For high-precision applications, spectrophotometry is preferred. For quality control or rapid assessments, visual or imaging colorimetry may suffice.

Q 8. What are the key factors influencing individual color perception?

Individual color perception is a complex process influenced by a multitude of factors, extending beyond the simple functioning of our eyes. It’s a fascinating interplay of biology, psychology, and even the surrounding environment.

- Physiological Factors: This includes the individual’s specific cone cell distribution in the retina (responsible for color vision). Some people have more or fewer cones of a certain type, leading to variations in color sensitivity. Age also plays a role; as we age, the lens of the eye yellows, subtly shifting our perception of colors.

- Psychological Factors: Our past experiences, cultural background, and even our current emotional state significantly affect how we interpret colors. For example, the color red might evoke feelings of excitement in one person but anger in another, based on their personal associations. This is heavily studied in the field of color psychology.

- Environmental Factors: The lighting conditions under which a color is viewed are crucial. A color that appears vibrant under bright sunlight might look dull under incandescent light. The surrounding colors also play a role; a color will appear different depending on its context.

- Individual Differences: Beyond the aforementioned factors, there’s inherent individual variability. Just as we all have unique fingerprints, our color perception is uniquely personalized. This makes sensory color analysis so critical; we need to account for this natural variation to obtain reliable results.

For example, a winemaker might perceive a subtle shift in the hue of their red wine that signifies a difference in the ripening of the grapes, a nuance that a less experienced individual might miss entirely. This highlights the importance of expertise and calibrated instruments in objective color assessment.

Q 9. How would you design a sensory evaluation experiment to assess the acceptability of a new product’s color?

Designing a sensory evaluation experiment for a new product’s color requires a structured approach ensuring objectivity and reliability. We need to minimize bias and account for individual variations in color perception.

- Define Objectives: Clearly state the purpose. Are we assessing overall color acceptability, specific color attributes, or comparing it to a competitor? This guides the entire experiment design.

- Panelist Selection: Recruit a panel representative of the target consumer group. Consider factors like age, gender, and any known color vision deficiencies. Pre-screen panelists for color blindness using standard tests.

- Sample Preparation: Ensure consistent presentation of the product under controlled lighting conditions. Use standardized lighting booths to maintain uniformity across samples.

- Experimental Design: Employ a suitable experimental design. A balanced incomplete block design (BIBD) is often preferred to manage the number of samples and minimize evaluator fatigue. This design ensures each color sample is compared with every other color sample an equal amount of time.

- Data Collection: Use a structured rating scale (e.g., hedonic scale from 1 to 9, representing dislike to like) to capture the panelists’ acceptance of the product’s color. Employ appropriate statistical analysis (e.g., ANOVA) to assess the significance of differences between the color samples.

- Data Analysis: Analyze the data considering potential variations among panelists. Calculate descriptive statistics (mean, standard deviation) to understand the overall perception, and inferential statistics to determine if differences are statistically significant.

For instance, when assessing the acceptability of a new shade of lipstick, you might compare it against existing popular shades, using a 9-point hedonic scale to gauge consumer preference. The statistical analysis will help you determine if the new shade is significantly more or less acceptable than the existing ones.

Q 10. Explain the difference between hue, saturation, and lightness.

Hue, saturation, and lightness (or value/brightness) are the three fundamental attributes of color, often represented in color spaces like L*a*b* or HSL. They describe a color comprehensively, similar to how latitude, longitude, and altitude describe a location on Earth.

- Hue: This refers to the pure color – the chromatic quality that we identify as red, green, blue, yellow, etc. Think of it as the basic color name. Hue is represented as a position along a color circle (e.g., 0° for red, 120° for green).

- Saturation: This represents the intensity or purity of a hue. A highly saturated color appears vivid and intense, while a low-saturated color appears dull or washed out. Imagine a bright red versus a pale pink; both have the same hue (red), but differ greatly in saturation.

- Lightness (or Value/Brightness): This describes the perceived amount of light in a color. A high lightness value means a bright or light color, while a low lightness value means a dark or deep color. For example, a light gray has high lightness, while a dark gray has low lightness, regardless of their hue.

Consider a sky-blue color. Its hue is blue, its saturation might be medium (not overly vivid but not pale either), and its lightness is relatively high because it’s a bright shade of blue. By changing these three attributes, you can create a vast range of colors.

Q 11. What is a color difference formula, and why are different formulae used?

A color difference formula is a mathematical equation that quantifies the difference between two colors. It’s essential in quality control and color management to ensure consistency across various stages of product development and manufacturing. Different formulae are used because of their varying performance across different color spaces and applications.

- Different Formulae, Different Purposes: Common formulae include CIE76, CIE94, CMC(l:c), and ΔE*ab (often simplified as ΔE). Each formula is designed to model the perceived difference between colors differently, accounting for the non-linearity of human color perception. CIE76, for example, is simpler but less accurate, particularly for colors with low saturation. Later formulas such as CIE94 and CMC(l:c) attempt to address this.

- Color Spaces: The choice of color difference formula often depends on the color space used (e.g., CIE LAB, XYZ, RGB). Different color spaces represent color data differently, hence necessitating the use of specific formulae to accurately calculate color differences within each space.

- Application Specificity: Some formulae are more suitable for certain applications. For example, CMC(l:c) is known to be better at predicting perceived color differences in textiles than others because of its weights to chroma and lightness.

Imagine a food manufacturer adjusting the color of a food product. They might use a specific color difference formula (like ΔE*ab) to quantify how much the color changes with different production techniques and ensure the final product meets the desired color specification.

Q 12. How do you interpret a color difference (ΔE) value?

A color difference (ΔE) value represents the magnitude of the difference between two colors. It’s a single number that summarizes the perceived difference, making it easy to compare various color variations. The interpretation of a ΔE value is often based on thresholds or just noticeable differences (JNDs).

- Thresholds: A common threshold is ΔE ≤ 1.0, which typically indicates a difference that is undetectable by the average observer under normal viewing conditions. ΔE values between 1 and 2 might be perceptible to some individuals, while values above 2 are generally considered noticeable. Values above 3 signify a significant and readily apparent color difference.

- Context is Key: The acceptability of a ΔE value depends heavily on the application. In some industries, like pharmaceuticals, extremely small color differences must be controlled, while in others, a higher ΔE might be acceptable. The visual impact of ΔE values depends on the actual colors being compared; a small ΔE can create a noticeable difference in certain color regions.

- Formula Dependence: The interpretation also depends on the color difference formula used. A ΔE of 2.0 calculated using CIE76 might correspond to a different perceived difference than a ΔE of 2.0 calculated using CIE94 or CMC(l:c).

For example, in the textile industry, a ΔE above 2 might be unacceptable for matching dye lots, as the color difference would be too noticeable to the consumer. In food processing, a ΔE between 1 and 2 might be acceptable if the color change is imperceptible to consumers.

Q 13. Describe different types of color vision deficiency and their impact on sensory color analysis.

Color vision deficiency (CVD), often incorrectly referred to as color blindness, refers to the reduced ability to distinguish between certain colors. Several types exist, each affecting the perception of colors differently. These deficiencies significantly impact sensory color analysis because they introduce biases that must be considered.

- Protanopia & Protanomaly: These involve reduced sensitivity to red light. Protanopia is a complete lack of sensitivity to red, while protanomaly is a reduced sensitivity.

- Deuteranopia & Deuteranomaly: These affect green light sensitivity, similarly to protanopia and protanomaly, respectively.

- Tritanopia & Tritanomaly: These are rarer conditions affecting blue light sensitivity.

The impact on sensory color analysis is significant. If panelists with CVD participate in an evaluation, their responses might differ from those with normal color vision. This can lead to inaccurate conclusions about color acceptability. Therefore, it is crucial to identify and screen panelists for CVD using standardized tests to ensure the integrity of the analysis.

For example, a new blue food dye being tested would result in skewed data if only testing it on a protanopic and deuteranopic group, as they might not accurately differentiate shades of blue.

Q 14. How do you handle inconsistencies in color perception among panelists in a sensory evaluation?

Inconsistencies in color perception among panelists are inevitable due to the inherent variability in individual vision and psychological factors. Several strategies can help manage these inconsistencies in sensory evaluation:

- Larger Panel Size: Increasing the number of panelists helps to average out individual variations and obtain a more robust estimation of the mean. The larger the sample size, the less likely outliers will significantly affect the average outcome.

- Statistical Analysis: Employ appropriate statistical techniques to identify and manage outliers and account for variation. Analysis of variance (ANOVA) can assess the significance of differences between color samples, while considering the variations between panelists.

- Pre-screening and Training: Before starting the evaluation, screen panelists for color vision deficiencies and provide training on the evaluation procedure and the use of rating scales to ensure standardization.

- Calibration: Use standardized lighting conditions and calibrated instruments (spectrophotometers, colorimeters) to minimize the influence of environmental factors on color perception. These instruments will objectively measure color, independently of human perception.

- Repeated Measurements: Have panelists repeat the assessments at different times or under slightly different conditions to check for consistency and identify unreliable responses.

For example, a discrepancy in scoring amongst panelists might be caused by inconsistent lighting, which can be addressed using a controlled lighting environment and potentially repeating the experiment.

Q 15. Explain the concept of color space and describe different color spaces used in digital applications.

A color space is a mathematical model that describes the range of colors that can be represented. Think of it like a coordinate system for colors. Each point in the space corresponds to a specific color. Different color spaces prioritize different aspects of color, such as perceptual uniformity (how evenly spaced colors appear to the human eye) or the ability to accurately reproduce colors on specific devices.

Several color spaces are commonly used in digital applications:

- RGB (Red, Green, Blue): This is an additive color model used for displays like monitors and televisions. Each color is represented by a combination of red, green, and blue light intensities, typically ranging from 0 to 255.

(255, 0, 0)represents pure red,(0, 255, 0)pure green, and(0, 0, 255)pure blue. - CMYK (Cyan, Magenta, Yellow, Key/Black): This is a subtractive color model used for printing. It works by subtracting colors from white light. Each color is represented by the amount of cyan, magenta, yellow, and black inks used.

- HSV (Hue, Saturation, Value): This is a more intuitive color space for humans, representing color in terms of its hue (color shade), saturation (color intensity), and value (brightness). It’s easier to visualize and manipulate than RGB or CMYK.

- LAB (L*, a*, b*): This is a device-independent color space designed to approximate human color perception. ‘L*’ represents lightness, ‘a*’ represents the green-red axis, and ‘b*’ represents the blue-yellow axis. It’s crucial for color consistency across different devices and printing methods.

The choice of color space depends on the application. For example, RGB is ideal for screen displays, while CMYK is necessary for print production, and LAB is essential when ensuring color accuracy across various media.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are some common color-related issues encountered in product development?

Color-related issues are frequent in product development and can significantly impact the final product’s quality and customer perception. Some common problems include:

- Metamerism: Two colors that appear identical under one light source may look different under another. This is a major concern for products viewed in various lighting conditions.

- Color Drift: Colors can change over time due to factors such as light exposure, temperature fluctuations, or chemical reactions in the materials. This is particularly problematic for products with long shelf lives.

- Color Differences Between Batches: Variations in raw materials, production processes, or even the equipment used can lead to inconsistencies in color across different production runs.

- Device-to-Device Color Mismatch: A design that looks perfect on a monitor might appear different when printed or displayed on another device due to variations in color profiles.

- Subjective Color Perception: Color perception is influenced by individual differences in vision and personal preferences. What one person considers ‘red’ might slightly differ from another’s perception.

Addressing these issues requires a thorough understanding of color science, appropriate color management tools, and rigorous quality control procedures.

Q 17. How would you ensure the consistency of color across different production batches?

Maintaining color consistency across production batches is critical for brand identity and customer satisfaction. Here’s a multi-faceted approach:

- Standardized Raw Materials: Sourcing raw materials from reliable suppliers with consistent color characteristics is paramount.

- Precise Color Measurement: Utilizing spectrophotometers to precisely measure and document the color of each batch ensures objective comparison and identification of deviations.

- Color Management System (CMS): Implementing a CMS throughout the production process helps standardize color profiles and workflows, ensuring consistent color reproduction across all stages.

- Regular Calibration and Maintenance: Equipment, such as printers and spectrophotometers, should be regularly calibrated and maintained to ensure accurate and repeatable results.

- Color Standards: Using established color standards like Pantone or RAL provides a common reference point for everyone involved in the production process. This helps ensure everyone is working with the same ‘definition’ of a specific color.

- Statistical Process Control (SPC): SPC involves monitoring the color of each batch statistically to detect any trends or shifts outside the acceptable range, allowing for timely adjustments.

By combining these techniques, we can significantly reduce variations and ensure consistent color across production batches. For example, in a textile manufacturing plant, regular spectrophotometer measurements against a Pantone standard would allow prompt adjustments if color drift occurs.

Q 18. What are some advanced techniques used in color measurement and analysis?

Advanced techniques in color measurement and analysis enhance accuracy and efficiency. These include:

- Spectrophotometry: This involves measuring the spectral reflectance or transmittance of a sample, providing a detailed profile of its color characteristics. It’s far more precise than visual assessment.

- Color Difference Calculations: These calculations, such as Delta E (ΔE), quantify the difference between two colors, enabling objective comparisons and setting tolerances for acceptable variations.

- Image Analysis: Digital image analysis can be used to assess color uniformity across large areas or batches of products, identifying potential inconsistencies automatically.

- Multispectral Imaging: This technique uses a wider range of wavelengths than traditional methods, enhancing the identification of subtle color variations and detecting flaws undetectable by the human eye.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms can be used to analyze large datasets of color information, predict potential problems, and optimize color reproduction processes.

These techniques provide a far more scientific and quantitative approach to color analysis than traditional methods, allowing for more precise control and consistency.

Q 19. Describe your experience with color management software.

I have extensive experience with various color management software packages, including X-Rite i1Profiler, Datacolor SpyderX, and Adobe Color Engine. My expertise includes profile creation for various devices (monitors, printers, scanners), color transformation between different color spaces, and the implementation of color management workflows within various design and production environments. For instance, I’ve used X-Rite i1Profiler to create custom ICC profiles for a client’s printing press, significantly improving the color accuracy of their printed materials, minimizing waste and increasing customer satisfaction by ensuring print consistency with on-screen designs.

I’m proficient in using these tools to diagnose and resolve color discrepancies, ensuring accurate color reproduction across different media and devices. My experience also encompasses training other personnel on using these tools effectively within a workflow.

Q 20. How would you troubleshoot a color problem during the manufacturing process?

Troubleshooting a color problem during manufacturing involves a systematic approach:

- Identify the problem: Precisely define the color issue (e.g., metamerism, color drift, batch inconsistency). Use spectrophotometric measurements to quantify the deviation.

- Isolate the source: Determine the stage of production where the problem originates (raw materials, processing, equipment, etc.). This might involve testing materials and inspecting the production process.

- Analyze the data: Examine colorimetric data to determine the magnitude and nature of the color difference (Delta E values). This helps assess the impact on the final product and inform corrective actions.

- Implement corrective actions: Adjust raw materials, process parameters, or equipment settings based on the analysis. This might involve recalibrating equipment, changing a dye concentration, or replacing a faulty machine part.

- Verify the solution: Measure the color of the corrected batches to confirm the issue is resolved and the color falls within acceptable tolerances.

- Document the process: Thoroughly document the problem, the analysis, and the corrective actions taken. This helps prevent similar issues in the future and aids continuous improvement.

For instance, if a batch of paint appears too yellow, we’d use a spectrophotometer to measure its color, compare it to the standard, identify if the issue stems from a raw material or process, adjust the formulation accordingly, and remeasure to verify the correction.

Q 21. How familiar are you with different color standards (e.g., Pantone, RAL)?

I’m very familiar with various color standards, most notably Pantone and RAL. Pantone is widely used in the graphic design, fashion, and textile industries, while RAL is prevalent in the architectural and industrial sectors. I understand the differences between their color systems, their respective color libraries, and how to effectively utilize them to achieve consistent color reproduction. I also have knowledge of other standards, such as those specified by different industries.

Understanding these standards is essential for ensuring accurate communication and color consistency across different parts of the supply chain. For example, when working with a client, specifying a Pantone color code ensures everyone is working from the same reference point, regardless of the materials or technologies involved. A deep understanding of these systems allows for efficient and accurate color specification and communication.

Q 22. How would you communicate color specifications effectively to a manufacturer?

Communicating color specifications effectively to a manufacturer requires precision and clarity. It’s not enough to say ‘make it blue’; you need to provide objective, measurable data. The best approach utilizes a standardized color system, such as CIELAB (L*a*b*), which describes color in terms of lightness (L*), red-green opponent (a*), and blue-yellow opponent (b*). These numerical values can be obtained using a spectrophotometer.

I would provide the manufacturer with a color standard, either a physical sample of the exact color or digital color data in a universally accepted format like a spectral data file (.txt or .csv). This allows them to match the color consistently throughout production runs. I’d also include tolerances (a range of acceptable variation around the target color) to account for slight differences in materials or manufacturing processes. Think of it like a recipe – the target color is the ideal dish, and the tolerance accounts for minor ingredient variations that still result in a similar final product. Finally, I would clearly define the measurement conditions (e.g., illuminant, observer) used to obtain the color data to ensure consistent results.

For example, I might specify a CIELAB color of L* = 60, a* = 10, b* = 20 with a Delta E tolerance of 2. This means the acceptable range of color variation is within a Delta E of 2 from the target color. This ensures consistency and avoids costly rework.

Q 23. Explain your experience with various color measurement instruments (e.g., spectrophotometers, colorimeters).

My experience with color measurement instruments is extensive. I’ve worked extensively with both spectrophotometers and colorimeters, understanding their strengths and limitations. Spectrophotometers, like the X-Rite i1Pro or Konica Minolta CM-700d, are precision instruments that measure the spectral reflectance or transmittance of a sample across the visible spectrum. This detailed spectral data allows for precise color calculations and accurate color communication. Colorimeters, such as the X-Rite ColorMunki Design, are simpler and more portable, providing CIELAB values directly. They are useful for spot checks and less demanding applications where high-precision spectral data isn’t necessary.

The choice of instrument depends on the application. For critical color matching, like in automotive paint or textile production, the accuracy of a spectrophotometer is crucial. In less demanding scenarios, like initial color evaluation or quality control checks in less stringent processes, a colorimeter offers a more cost-effective and efficient solution. I’m proficient in using these instruments, understanding calibration procedures, and interpreting their outputs, including metamerism indices. Understanding metamerism is key, as it helps anticipate and control color matches that appear identical under one light source, but may vary under another.

Q 24. Describe a time you had to resolve a color-related issue. What steps did you take?

During a project involving the development of a new line of children’s toys, we encountered a significant color issue. The initial batch of plastic parts arrived with a noticeable color shift from the approved sample. This was crucial because the slight color difference in the plastic rendered the toy visually unappealing and possibly problematic from a child safety perspective.

My first step was to use a spectrophotometer to objectively quantify the color difference between the approved sample and the produced parts. This provided numerical data, specifically the Delta E value, showing the magnitude of the discrepancy. Then, we investigated the possible causes. We worked closely with the manufacturer to review their production process, examining factors such as the batch of raw materials, processing temperature, and the instrument calibration for the molding process. It turned out there was a minor variation in the plastic resin formulation batch.

Our solution involved carefully analyzing the spectral data to identify the exact nature of the color shift and collaborating with the supplier to correct the resin formulation. After implementing these corrections, subsequent production runs yielded parts that met the required color specifications, ultimately avoiding significant delays and financial losses.

Q 25. What are your strategies for minimizing bias in sensory color evaluations?

Minimizing bias in sensory color evaluations is paramount. We employ several strategies to achieve this. Firstly, we use a large and diverse panel of evaluators to reduce the influence of individual biases. A diverse group minimizes the impact of individual preferences or perceptual differences related to color vision variations. Secondly, we use standardized lighting conditions to ensure consistent viewing and avoid variations in perception due to different light sources. Think about how a color looks different under fluorescent lights versus sunlight.

Thirdly, we employ randomized presentation order of samples to prevent order effects and bias from visual fatigue. Fourthly, we provide clear, concise instructions and training to evaluators to ensure everyone understands the task and scoring criteria. Lastly, we use blind testing, meaning the evaluators are unaware of the sample identities during evaluation. This helps to eliminate preconceptions and ensures unbiased judgment. By implementing these strategies, we work towards obtaining objective and reliable results, minimizing the risk of subjective influences on the final assessment.

Q 26. How do you use sensory color analysis data to inform product design decisions?

Sensory color analysis data plays a crucial role in informing product design decisions. The data gathered from our sensory evaluations, combined with instrumental color measurements, provides a comprehensive understanding of how consumers perceive colors. This helps us make informed decisions regarding color choices that align with specific brand identities or appeal to target audiences.

For example, if sensory analysis reveals that a particular shade of blue evokes feelings of trust and reliability, this knowledge might influence the color selection for a financial institution’s branding. Conversely, data showing that a specific green tone is associated with freshness and health could inform the choice of color for food packaging. Essentially, we use the data to bridge the gap between objective color measurements and subjective consumer preferences. The combination provides powerful insights for achieving effective product design.

Q 27. Describe the different types of color blindness and how they impact color perception.

Color blindness, or color vision deficiency, encompasses various types, primarily affecting the ability to distinguish certain colors. The most common types are:

- Protanopia: Reduced sensitivity to red light.

- Deuteranopia: Reduced sensitivity to green light.

- Tritanopia: Reduced sensitivity to blue light.

These deficiencies arise from variations in the cone cells in the retina, which are responsible for color vision. The impact on color perception varies depending on the type and severity of the deficiency. Individuals with protanopia might confuse reds and greens, while those with deuteranopia might experience similar difficulties. Tritanopia is less common and affects the discrimination between blues and yellows.

Understanding these variations is critical in sensory color analysis. We need to consider the potential impact of color blindness on the target consumer base. For example, using red and green together for critical information might be problematic, as a significant portion of the population may not distinguish these colors effectively. We might opt for alternative color combinations to ensure accessibility and effective communication across all individuals, considering that color perception plays a large part in product appeal and information perception.

Q 28. What are some ethical considerations when conducting sensory color analysis?

Ethical considerations are crucial in sensory color analysis. First and foremost, ensuring informed consent from all participants is vital. Participants must understand the study’s purpose, procedures, and potential risks or discomforts before participating. We must also maintain the anonymity and confidentiality of their responses. Their data should be protected and handled responsibly, adhering to data privacy regulations.

Another crucial aspect is avoiding manipulative or coercive practices. Participants should never feel pressured to provide responses that don’t reflect their true perception. Finally, we should strive to minimize any potential psychological or emotional distress that might arise from the study. This includes carefully considering the selection of colors, particularly if they might have strong emotional connotations. By adhering to ethical guidelines throughout the entire process, we aim to ensure the validity and integrity of our research, upholding responsible practices in the field of sensory color analysis.

Key Topics to Learn for Sensory Color Analysis Interview

- Color Perception and Physiology: Understand the human visual system’s interaction with color, including opponent process theory and color constancy.

- Color Appearance Models: Familiarize yourself with CIELAB, CIECAM02, and other relevant models, and their application in predicting color appearance under different lighting conditions.

- Color Measurement and Instrumentation: Learn about spectrophotometers, colorimeters, and their role in objective color assessment. Understand color difference calculations (e.g., Delta E).

- Color Psychology and Aesthetics: Explore the emotional and psychological impact of color, and how cultural factors influence color preferences.

- Color Communication and Standardization: Grasp the importance of standardized color communication systems (e.g., Pantone) and their role in maintaining consistency across different stages of product development.

- Practical Applications: Be prepared to discuss real-world applications, such as product design, quality control in manufacturing, marketing and branding, and digital image processing.

- Problem-Solving in Color Analysis: Practice identifying and resolving color discrepancies, considering factors like metamerism and observer variations.

- Advanced Topics (for senior roles): Explore areas like color management systems (CMS), color space transformations, and advanced colorimetric calculations.

Next Steps

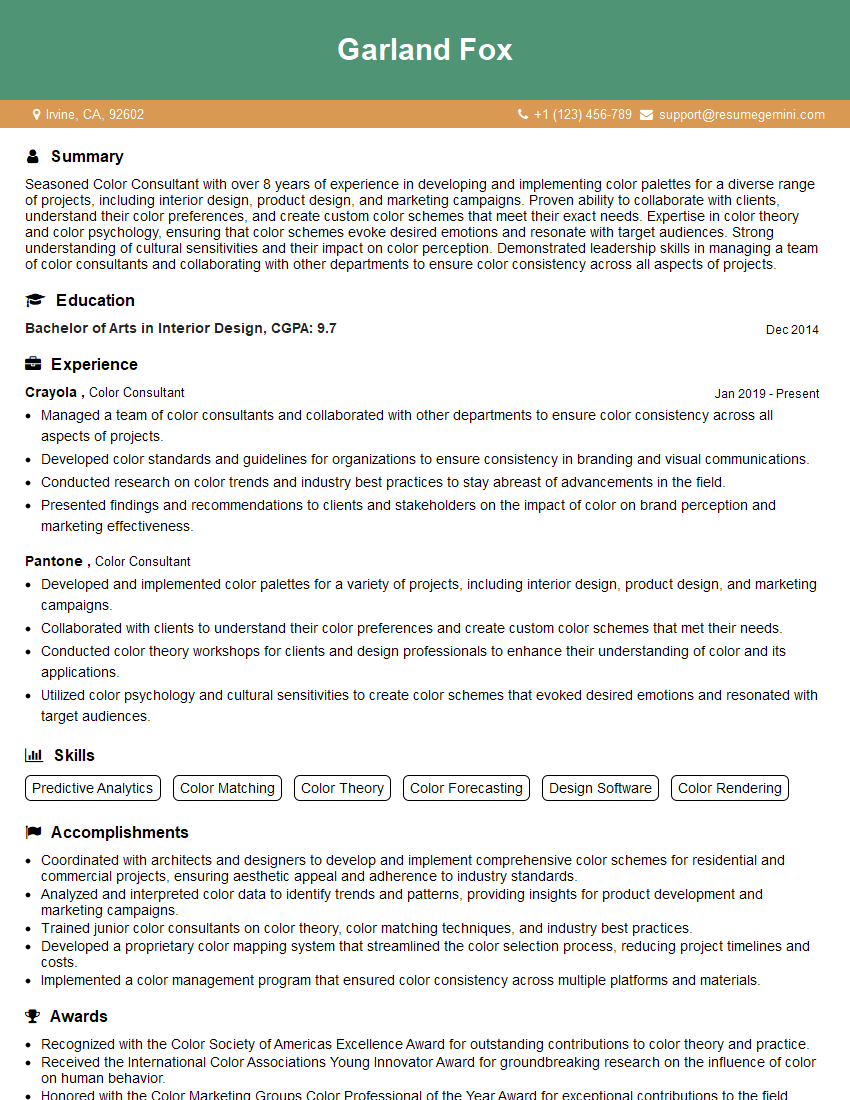

Mastering Sensory Color Analysis opens doors to exciting careers in diverse fields, offering opportunities for innovation and creative problem-solving. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to highlight your unique skills and experience in Sensory Color Analysis. Examples of resumes tailored to this specific field are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.