Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Solder and Copper Work interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Solder and Copper Work Interview

Q 1. What types of solder are commonly used, and what are their applications?

Solder comes in various types, each suited for specific applications. The most common are lead-based and lead-free solders. Lead-based solders, while offering excellent wettability and strength, are increasingly phased out due to environmental concerns. Lead-free solders, often containing tin, silver, and copper, are environmentally friendlier but may require higher soldering temperatures and specialized fluxes.

- Lead-tin (Pb-Sn) solder: This classic solder is known for its ease of use and excellent wetting properties. Different ratios of lead and tin alter melting points, making them suitable for different applications like electronics (60/40 Sn/Pb) or plumbing (50/50 Sn/Pb). However, their use is declining due to toxicity.

- Lead-free solder (Sn-Ag-Cu): These alloys, typically containing tin as the primary component with additions of silver and copper for strength and improved properties, are becoming the standard. Their higher melting point demands more precise temperature control during soldering.

- Silver solder: Containing a significant percentage of silver, these solders offer higher strength and melting points, suitable for applications requiring higher temperature resistance, like jewelry making or specialized plumbing.

The choice of solder depends heavily on the materials being joined, the required strength of the joint, and environmental regulations.

Q 2. Explain the process of soldering copper pipes.

Soldering copper pipes involves creating a strong, leak-proof joint. The process typically uses capillary action, where solder is drawn into the joint by surface tension. This requires meticulous preparation of the pipe ends.

- Preparation: Clean the pipe ends thoroughly, removing any dirt, grease, or oxidation. This is often done with sandpaper or a wire brush, ensuring a bright, shiny surface for optimal solder adhesion.

- Fitting: Insert the fitting onto the pipe, ensuring proper alignment and a secure fit.

- Flux application: Apply a suitable flux to the pipe ends and the fitting. Flux cleans the surfaces, improves solder flow, and prevents oxidation.

- Heating: Apply heat using a propane torch or other suitable heating tool, focusing on the joint area. The heat melts the solder, and capillary action draws it into the joint.

- Soldering: Feed solder into the heated joint until it flows completely around the fitting, filling all gaps.

- Cooling: Allow the joint to cool naturally without disturbing it, ensuring a strong and leak-proof bond.

Different types of copper pipe (Type L, M, K) might require slightly different techniques, but the core principles remain the same. Always ensure adequate ventilation when using propane torches.

Q 3. Describe different soldering techniques (e.g., capillary action, wave soldering).

Several soldering techniques exist, each optimized for specific applications.

- Capillary Action: This is the most fundamental soldering technique, relying on the surface tension of molten solder to draw it into a gap between two components. Think of it like water rising in a thin tube – the solder is similarly drawn into the narrow space between the copper surfaces.

- Wave Soldering: Primarily used in electronics manufacturing, this technique involves passing a printed circuit board (PCB) over a wave of molten solder. The solder is pumped to form a wave that coats the PCB components, providing a rapid and efficient soldering process. It’s ideal for high-volume production.

- Dip Soldering: The entire component, often a small electronic part, is dipped into molten solder for complete coating. This is effective for batch processing and creating uniform solder joints.

- Iron Soldering: This is a common manual soldering technique using a soldering iron to melt solder and apply it to the joint.

The selection of technique is driven by factors such as the scale of the operation, the complexity of the assembly, and the type of components being joined.

Q 4. How do you prepare copper surfaces for soldering?

Proper surface preparation is crucial for successful soldering. Copper oxidizes quickly, forming a layer that prevents solder adhesion. This oxide layer must be removed before soldering.

- Cleaning: Begin by removing any dirt, grease, or oil from the copper surface using a solvent like acetone or isopropyl alcohol. This ensures that the solder can properly wet the surface.

- Abrasion: Use fine-grit sandpaper (around 220-grit) or a wire brush to remove any oxide layer. The goal is to reveal the bright, clean copper underneath. A dull, dark surface indicates the presence of copper oxide and needs more attention.

- Fluxing: After cleaning, apply a suitable flux to the prepared surface. Flux cleans any residual oxides and aids in solder flow, ensuring a strong and reliable bond.

Proper cleaning is critical; incomplete cleaning will result in weak or nonexistent solder joints.

Q 5. What are the safety precautions when working with solder and fluxes?

Soldering, while seemingly straightforward, demands attention to safety.

- Ventilation: Always work in a well-ventilated area, especially when using lead-based solder or fluxes that produce fumes. These fumes can be toxic.

- Eye protection: Wear safety glasses to protect your eyes from molten solder splatter and fumes.

- Heat protection: Use heat-resistant gloves and clothing to avoid burns from hot tools and molten solder.

- Proper tools: Use tools in good condition, avoid damaged or frayed equipment.

- Lead-based solder: Avoid lead-based solder if possible due to its toxicity, and ensure proper disposal of any waste.

- First Aid: Be aware of first aid procedures for burns and solder splashes. Have a first aid kit readily available.

Safety is paramount. Neglecting these precautions can lead to serious injury or health problems.

Q 6. What are common soldering defects, and how can they be prevented?

Several common soldering defects can arise from improper technique or preparation.

- Cold Solder Joint: A weak joint resulting from insufficient heat or poor solder flow. It appears dull and lacks a smooth, shiny surface. This can be prevented by ensuring proper heating and sufficient solder application.

- Insufficient Solder: The solder joint is too small or insufficient to adequately fill the gap between the surfaces, resulting in weakness. This is prevented by applying sufficient solder to achieve complete joint coverage.

- Oxidation: The presence of oxide on the copper surface inhibits solder adhesion. Thorough cleaning is crucial to prevent this.

- Solder Bridges: Accidental solder connections between adjacent components or pads. This is often seen in electronics and is prevented by careful solder application.

Careful preparation, proper technique, and attentive observation during the process minimize defects.

Q 7. How do you choose the appropriate solder for a specific application?

Solder selection depends on several factors:

- Base Metals: The type of metals being joined dictates the solder’s melting point and composition. For example, different solders are used for copper than for aluminum.

- Operating Temperature: If the joint will be exposed to high temperatures, a higher-melting-point solder is necessary.

- Strength Requirements: Applications requiring high strength benefit from stronger solders, such as silver solders.

- Environmental Considerations: Lead-free solders are increasingly preferred due to environmental regulations and health concerns.

- Ease of Use: Some solders are easier to work with than others. Factors like melting point and wettability influence ease of use.

Consider these factors carefully. A poorly chosen solder can lead to joint failure and necessitate rework, causing significant time and cost overruns.

Q 8. Explain the concept of solder joint strength and its importance.

Solder joint strength refers to the mechanical integrity of the connection between two or more metal parts achieved through soldering. A strong solder joint is crucial because it dictates the reliability and longevity of the entire assembly. A weak joint can lead to failure, causing malfunctions, safety hazards, or even catastrophic damage, depending on the application.

Several factors influence solder joint strength: the type of solder used (its composition and melting point), the cleanliness of the surfaces being joined, the amount of solder applied, the temperature profile during the soldering process, and the presence (or absence) of appropriate flux. For example, a joint made with lead-free solder often requires a higher temperature and more precise control than one using leaded solder. Insufficient solder can result in a weak, unreliable connection, while excessive solder may lead to cold joints or bridging.

Think of it like building a brick wall: each brick represents a component, and the mortar (solder) holds them together. If the mortar is weak or improperly applied, the wall will crumble. Similarly, a weak solder joint will compromise the functionality and lifespan of an electronic device or other soldered assembly.

Q 9. What are the different types of fluxes used in soldering, and their purposes?

Fluxes are crucial in soldering because they clean and prepare the metal surfaces for proper wetting by the molten solder. They remove oxides and contaminants that would otherwise prevent a strong bond. Different fluxes serve different purposes, based on the metals involved and the soldering process:

- Rosin flux: This is a common, relatively mild flux often used for electronics. It’s relatively easy to clean up and leaves minimal residue. However, it may not be effective with heavily oxidized surfaces.

- Water-soluble flux: This type of flux is easily cleaned with water, making it suitable for applications where cleanliness is paramount. It’s often more aggressive than rosin flux and can handle more heavily oxidized surfaces.

- Activated flux: These fluxes contain more aggressive chemicals to remove stubborn oxides. They are useful for difficult-to-solder materials but require thorough cleaning afterward to prevent corrosion.

- No-clean flux: This is designed to leave minimal residue that is generally considered non-corrosive, reducing the need for post-soldering cleaning. However, it’s important to select a no-clean flux that is compatible with the application to prevent long-term issues.

The choice of flux depends heavily on the application and the materials being soldered. In high-reliability electronics, for instance, a no-clean flux or a water-soluble flux is preferred to prevent corrosion. For less critical applications, rosin flux may suffice.

Q 10. How do you troubleshoot a bad solder joint?

Troubleshooting a bad solder joint involves a systematic approach. First, visual inspection is critical. Look for:

- Cold solder joints: These appear dull, grayish, and lack a smooth, concave meniscus. They indicate insufficient heat or poor wetting.

- Dry joints: These show little or no solder between the components. The cause is often insufficient solder or inadequate cleaning.

- Insufficient solder: A small amount of solder creates a weak connection, vulnerable to stress.

- Excess solder: Too much solder can cause bridging (short circuits) between adjacent components.

- Cracks in the solder: These indicate stress on the joint, often due to thermal cycling or mechanical shock.

If a visual inspection isn’t enough, you can use a multimeter to check for continuity (a short circuit) or an open circuit. If a short exists where it shouldn’t, there’s a bridging problem. An open circuit indicates a weak or broken connection. Using a magnifying glass can provide a clearer view of small defects. Sometimes, it’s necessary to desolder the joint, clean the surfaces, and resolder, using proper technique and appropriate flux.

Q 11. What is the difference between soldering, brazing, and welding?

Soldering, brazing, and welding are all joining processes that use heat, but they differ significantly in the melting temperatures involved and the types of materials used:

- Soldering: Joins metals using a filler metal (solder) that has a lower melting point than the base metals. The process relies on capillary action to draw the solder into the joint. Typically used for joining smaller components.

- Brazing: Similar to soldering, but uses a filler metal with a melting point above 450°C (842°F) but below the melting points of the base metals. It often requires higher temperatures and more precise control than soldering. Used for stronger joints in larger assemblies.

- Welding: Melts the base metals together, forming a continuous structure. The filler metal, if used, has a similar or higher melting point than the base metals. Creates the strongest joint of the three methods but requires specialized equipment.

An analogy is using glue, epoxy, and welding two pieces of wood together. Glue (soldering) is weakest, epoxy (brazing) is stronger, and welding is the strongest.

Q 12. Describe your experience with different types of soldering irons/equipment.

My experience encompasses a range of soldering equipment, from basic soldering irons to more advanced stations. I’m proficient with:

- Temperature-controlled soldering irons: These provide precise temperature control, essential for lead-free soldering and working with sensitive components.

- Soldering stations with adjustable temperature and power: Offering greater precision and versatility for various soldering tasks. I’m familiar with different tip types (e.g., chisel, cone, knife) and their applications.

- Hot air rework stations: Used for desoldering surface-mount components and repairing complex assemblies. These require a higher level of skill and understanding of heat transfer.

- Soldering guns: These are less precise but effective for larger tasks like joining thicker wires or joining components not sensitive to heat.

I have worked with various types of solder, including leaded and lead-free, understanding the differences in their melting points and the implications for the soldering process. Experience with all of these tools allows me to adapt to different projects and choose the best equipment for each job, optimizing efficiency and quality.

Q 13. How do you ensure consistent solder joint quality?

Consistent solder joint quality hinges on several key factors:

- Proper surface preparation: Cleanliness is paramount. Thoroughly cleaning the surfaces to be joined removes oxides and contaminants, ensuring proper wetting by the solder.

- Appropriate flux selection: Choosing the right flux for the metals and application ensures efficient cleaning and wetting.

- Precise temperature control: Maintaining the correct temperature is critical. Too low, and the solder won’t melt properly; too high, and it can damage components or cause excessive heat damage.

- Correct soldering technique: This includes the application of heat, the addition of solder, and the timing of the process. Proper technique ensures even heat distribution and capillary action.

- Proper handling of components: Avoid excessive stress or force on sensitive components during the soldering process.

- Consistent processes and procedures: Implementing standard operating procedures and regular equipment calibration are essential for maintaining consistent quality.

Regular practice, attention to detail, and ongoing refinement of techniques contribute significantly to consistently achieving high-quality solder joints. I regularly calibrate my equipment and maintain a clean and organized workspace.

Q 14. What are the implications of using improper flux?

Using improper flux can have serious consequences:

- Poor wetting: The solder won’t adhere properly to the metal surfaces, resulting in weak or unreliable joints.

- Corrosion: Residue from some fluxes can be corrosive, leading to long-term failures of the soldered assembly.

- Component damage: Aggressive fluxes can damage sensitive electronic components.

- Short circuits: Flux residue can act as a conductive path between components, causing short circuits.

- Difficult cleaning: Some fluxes are difficult to remove, leaving residue that interferes with subsequent operations or testing.

In critical applications, such as aerospace or medical devices, the consequences of improper flux can be severe. Always choose the appropriate flux for the application and follow manufacturer recommendations for cleaning.

Q 15. Explain the importance of proper ventilation when soldering.

Proper ventilation is paramount when soldering because the fumes produced, especially with leaded solder, can be toxic. Lead fumes, in particular, are highly dangerous and can cause serious health problems like lead poisoning. Even lead-free solder fluxes can release irritating or potentially harmful gases.

Imagine baking a cake without ventilation – the kitchen would fill with steam and potentially unpleasant smells. Soldering is similar; without proper ventilation, harmful fumes accumulate, impacting your health and the quality of your work. A well-ventilated workspace, achieved through exhaust fans, open windows, or a dedicated fume extraction system, is essential for safety and ensuring a clean working environment.

- Always work in a well-ventilated area.

- Consider using a fume extractor, especially when working with large projects or leaded solder.

- Ensure fresh air circulation to prevent buildup of harmful fumes.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle different copper thicknesses and gauges when soldering?

Handling different copper thicknesses and gauges requires adjustments in technique and equipment. Thicker copper requires more heat and a more powerful soldering iron to achieve a proper melt and joint. Thinner gauges, conversely, need less heat and a more delicate touch to avoid melting the copper completely.

For example, when soldering thick copper bus bars, I might use a higher wattage iron and a larger solder tip to distribute the heat evenly, avoiding localized overheating. With thinner copper wires used in electronics, I would opt for a lower wattage iron with a fine tip, ensuring precision and control. Preheating larger copper components can also be helpful to ensure even heat distribution and prevent damage. Flux is crucial in both cases, improving the flow of solder and aiding in a strong, clean joint.

Think of it like cooking; you wouldn’t use the same heat for searing a steak as you would for gently simmering a sauce. Different gauges of copper need different levels of heat and precise application for optimal soldering results.

Q 17. What are your experiences working with different types of copper alloys?

My experience encompasses a wide range of copper alloys, each presenting unique challenges and requiring specific soldering techniques. I’ve worked with oxygen-free copper (OFHC), which is prized for its high conductivity and used extensively in electronics and high-frequency applications. This alloy typically solders well but requires attention to avoid oxidation. I’ve also worked with brass and bronze, which contain zinc and tin, respectively, altering the soldering process due to their differing melting points and potential for oxidation.

For instance, with brass, the zinc content can cause it to oxidize easily, necessitating the use of a strong, active flux to clean the joint and ensure proper wetting of the solder. Bronze, with its tin content, generally solders more easily than brass but still requires careful temperature control to avoid damage.

Understanding the properties of different copper alloys is critical for successful soldering. Choosing the right flux, solder type, and soldering technique is crucial for each alloy to achieve a reliable and durable joint.

Q 18. What is the significance of temperature control in soldering?

Temperature control in soldering is absolutely crucial for several reasons. Overheating can damage delicate components, melt the base metal, or create brittle joints prone to failure. Underheating, conversely, results in poor solder flow, weak joints, and incomplete connections.

Using a temperature-controlled soldering iron allows precise control, enabling the user to achieve the optimal temperature range for the specific solder and base metal being used. This ensures a clean, strong, and reliable joint. For instance, lead-free solder typically requires higher temperatures than leaded solder, so a temperature-controlled iron is essential for reliable soldering with this material. Monitoring the temperature prevents overheating, making it suitable for delicate electronics and components.

Think of it like cooking with a precise oven temperature control – it’s essential for achieving the perfect result each time. In soldering, temperature control translates to consistency, quality, and longevity of the joint.

Q 19. Describe your experience with soldering delicate components.

Soldering delicate components requires exceptional precision and a steady hand. I’ve worked on surface mount devices (SMDs) and intricate circuit boards where even a slight slip can ruin the component or the entire assembly. Here, a low-wattage, fine-tipped soldering iron is essential, along with proper magnification, good lighting, and a stable work surface.

Flux is especially critical in these situations, as it helps the solder flow evenly and prevents bridging between closely spaced components. I employ techniques such as pre-heating the component and using a small amount of solder to avoid heat stress and ensure a precise connection. I sometimes use solder paste for fine work, enabling better control over the solder placement and minimizing the risk of bridging or overheating.

Imagine assembling a miniature clock – every component is tiny, and a mistake can have significant repercussions. Soldering delicate components necessitates the utmost care, patience, and skill.

Q 20. How do you clean solder splatter and residue after soldering?

Cleaning solder splatter and residue is essential for maintaining a clean workspace and ensuring the integrity of the soldered joint. For solder splatter, I often use a small brush and some isopropyl alcohol to remove any loose particles. For stubborn splatter, a fine steel wool pad can gently remove the residue. For solder residue on the joint itself, I utilize specialized solder wick or a brass cleaning brush, ensuring that no remaining solder obstructs the circuit.

The choice of cleaning method depends heavily on the substrate and components. For delicate electronics, I might use a specialized cleaning fluid and a soft brush to avoid damaging the components. It’s important to allow the solder to cool completely before attempting cleaning to avoid accidental movement or damage to the newly formed joint.

Cleaning is akin to finishing a painting; it’s the final step that reveals the quality of the craftsmanship. A thorough cleaning process makes the completed project look professional and ensures the longevity of the work.

Q 21. What is the difference between lead-free and leaded solder?

The primary difference between lead-free and leaded solder lies in their composition. Leaded solder contains lead, typically 60/40 tin/lead, which makes it easier to work with due to its lower melting point and superior flow characteristics. However, lead is toxic and its use is increasingly restricted due to environmental concerns and health hazards.

Lead-free solder typically consists of tin, silver, and copper alloys. They require higher soldering temperatures and often need more flux to achieve proper wetting and flow. The higher melting point and different flow characteristics of lead-free solder require more expertise to solder reliably. While environmental benefits are significant, lead-free solder can require more skill and attention to detail to achieve consistent results.

The choice between lead-free and leaded solder depends largely on the application and regulatory requirements. Many industries have transitioned to lead-free solder due to its environmental benefits and regulatory pressures, but leaded solder may still be appropriate in specialized applications.

Q 22. How do you maintain your soldering tools?

Maintaining soldering tools is crucial for consistent, high-quality work. It’s like keeping your chef’s knives sharp – neglecting them leads to frustration and poor results. My routine involves several key steps:

- Cleaning the Iron Tip: After each soldering session, I thoroughly clean the iron tip using a wet sponge or brass wire brush to remove solder residue. This prevents oxidation and ensures a smooth, clean transfer of heat. Think of it like wiping down a hot pan immediately after cooking to prevent sticking.

- Tip Tinning: Regularly tinning the tip (coating it with a thin layer of solder) protects it from oxidation and improves heat transfer. It’s like applying a protective layer to a delicate tool.

- Storage: I store my iron in its stand to prevent accidental damage or burns. Keeping the tip clean and tinned also helps prevent premature wear.

- Solder Wire Management: I keep my solder wire organized and stored in a dry place to maintain its quality and prevent oxidation. This is like storing your spices correctly to maintain their flavor.

- Regular Inspection: I periodically inspect the iron’s cord and plug for any signs of damage or wear, ensuring its electrical safety.

This diligent maintenance routine ensures my tools remain in optimal condition, allowing for precise and efficient soldering every time.

Q 23. Describe your troubleshooting skills related to soldering issues.

Troubleshooting soldering issues requires a systematic approach. I start by identifying the symptom – a cold joint, a burnt component, excessive splatter, etc. Then, I investigate potential causes.

- Cold Joints: These are caused by insufficient heat, poor joint preparation, or contaminated surfaces. I check the iron’s temperature, clean the surfaces, and ensure proper flux application.

- Burnt Components: This usually points to excessive heat or prolonged exposure. I use a lower temperature setting, improve heat dissipation with a heat sink, and reduce the soldering time.

- Solder Bridges: These occur when solder flows unexpectedly between adjacent components. I use a smaller tip, improve joint positioning, and apply flux carefully.

- Poor Solder Flow: This might be due to oxidation, dirty surfaces, or improper flux. I clean the surfaces thoroughly and use fresh flux.

I often utilize a magnifying glass to examine the joint closely for signs of contamination or poor bonding. Documenting my troubleshooting steps is important, helping me understand recurring problems and optimize my processes. It’s a process of elimination, always checking the basics first.

Q 24. What are some common challenges faced in soldering, and how do you overcome them?

Common soldering challenges stem from several factors:

- Oxidation: Copper and other metals oxidize, hindering solder adhesion. I overcome this by thoroughly cleaning surfaces with a wire brush or sandpaper and applying flux. Flux cleans the surface and helps the solder flow smoothly.

- Heat Dissipation: Heat can dissipate quickly from small components, resulting in cold joints. I use heat sinks to direct heat to the joint and prevent damage to nearby sensitive components.

- Improper Flux Application: Insufficient or excessive flux can lead to poor solder flow or residue. I learn the right amount and type of flux for the application.

- Incorrect Temperature: Too low a temperature leads to cold joints, while too high a temperature can damage components. I carefully select the appropriate temperature for the solder and components involved.

My approach to overcoming these challenges is a combination of preventative measures and on-the-spot solutions. Preparation is key; a clean workspace, appropriate tools, and a methodical approach are crucial for avoiding common issues.

Q 25. How do you determine the correct amount of solder to use?

Determining the correct amount of solder depends on several factors: the size of the joint, the type of components, and the required strength. It’s not about using the maximum amount but rather the optimal amount to achieve a strong, reliable connection.

I usually use just enough solder to completely fill the joint, creating a smooth, concave meniscus. Think of it like filling a small cup – you don’t overfill it; you fill it just enough to achieve a full, even surface. Excessive solder can lead to cold joints or shorts. Practice and experience play a crucial role in accurately judging the right amount.

For small joints, a tiny amount is sufficient, while larger joints require more. Always prioritize a strong, visually pleasing connection over an excess of solder.

Q 26. Describe your experience with soldering in various positions (e.g., overhead, below).

My experience with soldering in various positions has honed my dexterity and problem-solving skills. Overhead soldering, for example, requires careful hand positioning and a steady hand to avoid drips or burns. I adjust my posture and utilize specialized holders or clamps to maintain a safe and efficient work posture.

Soldering below, often encountered in tight spaces, demands precision and patience. I often use magnifiers and utilize specialized tools for better access and visibility. I practice using different angles and adjust my tool positioning to ensure the optimal heat transfer. It’s about adapting my technique to the constraints of the situation.

Throughout my experience, adapting to various positions has sharpened my skills and made me more versatile and efficient in diverse soldering tasks.

Q 27. Explain your understanding of different types of copper fittings.

Copper fittings are essential in plumbing, electrical work, and other applications. There’s a wide variety, each with its own strengths and weaknesses.

- Compression Fittings: These fittings use compression rings to create a watertight seal. They’re easy to install and require minimal tools.

- Flare Fittings: These fittings involve flaring the end of the copper tube and fitting it into a flared fitting. They offer a reliable and robust connection.

- Solder Fittings: These are joined using solder, creating a strong and permanent seal. This requires more skill and specialized tools, but it results in a robust, leak-proof connection, especially beneficial in higher pressure applications.

- Push-to-Connect Fittings: These are simple and quick to install, requiring no tools and only a push-to-connect mechanism.

Understanding the properties of each fitting – its suitability for pressure, temperature, and the required installation technique – is critical for selecting the right fitting for a given application. Choosing the wrong fitting can lead to leaks or failure, so proper selection is paramount.

Q 28. What safety measures do you take when working with high-temperature soldering?

High-temperature soldering poses several safety risks, so I adhere to rigorous safety protocols:

- Proper Ventilation: Soldering fumes can be toxic, so I always work in a well-ventilated area or use a fume extractor. This prevents inhalation of harmful substances.

- Eye Protection: I always wear safety glasses or a face shield to protect my eyes from solder splatter and potential chemical burns.

- Heat Resistant Gloves: Gloves provide protection from burns while handling hot components and tools.

- Fire Safety: I keep a fire extinguisher nearby and am aware of potential fire hazards related to hot surfaces and flammable materials.

- Proper Clothing: I wear clothing that covers my skin to reduce the risk of burns and protects from molten solder splashes. Loose clothing should be avoided.

- Work Area Cleanup: I always clean up my work area after soldering, ensuring that all hot components have cooled down to prevent accidental burns or fires. This includes disposing of solder waste properly.

Safety is paramount. Neglecting these precautions can lead to serious injury. I treat every soldering task as potentially hazardous and always take the necessary steps to mitigate any risks.

Key Topics to Learn for Your Solder and Copper Work Interview

- Soldering Techniques: Mastering various soldering methods (e.g., through-hole, surface mount, reflow) and understanding the differences between lead-free and leaded solder.

- Copper Fabrication: Familiarize yourself with different copper forming techniques such as bending, shaping, and joining. Understand the properties of copper and how they impact fabrication processes.

- Safety Procedures: Demonstrate knowledge of safe handling procedures for soldering irons, fluxes, and other materials. Highlight your understanding of PPE and workplace safety regulations.

- Troubleshooting Common Issues: Be prepared to discuss common soldering problems (e.g., cold joints, bridging, overheating) and how to effectively troubleshoot and rectify them.

- Electrical Principles: Possessing a fundamental understanding of electrical conductivity, circuitry, and the role of solder in electrical connections is crucial.

- Material Selection: Demonstrate knowledge of selecting appropriate solder types and fluxes based on the application and materials being joined. Understanding the implications of different alloys is important.

- Quality Control and Inspection: Be ready to discuss techniques for inspecting soldered joints for quality and identifying potential defects.

- Industry Standards and Codes: Familiarity with relevant industry standards and codes of practice is a significant advantage.

Next Steps

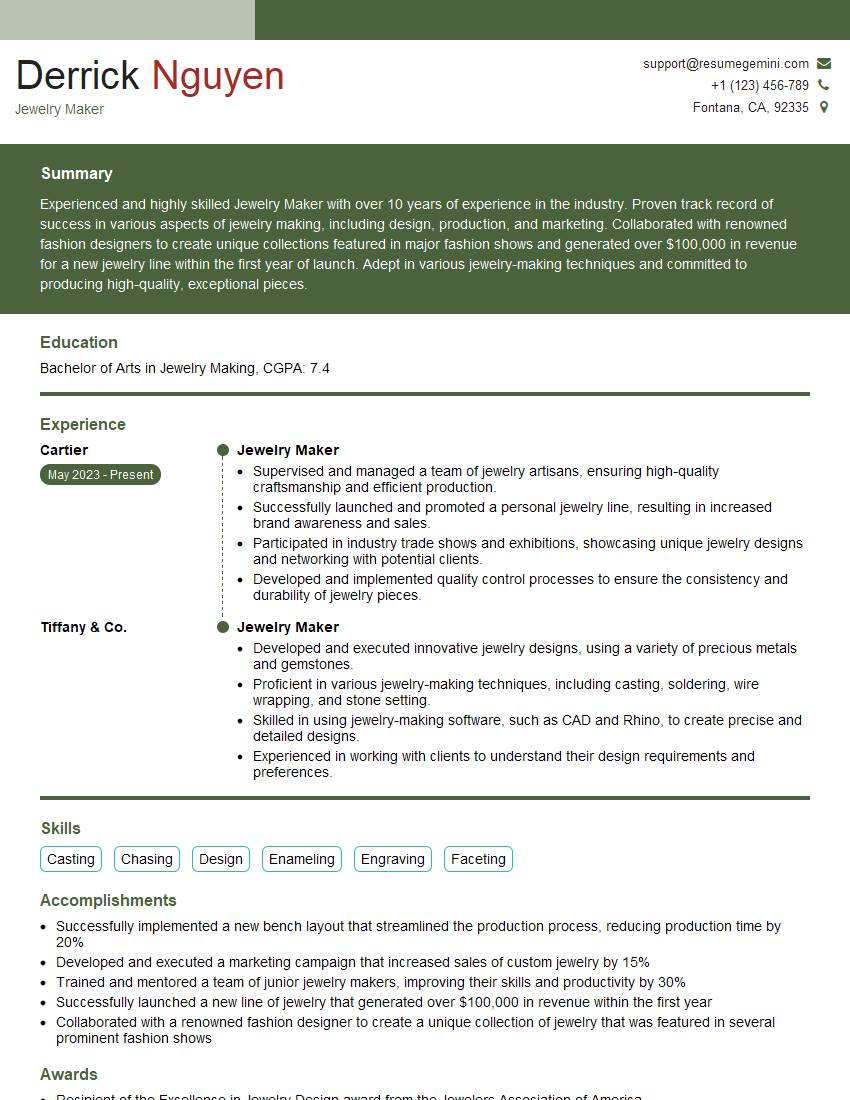

Mastering solder and copper work opens doors to exciting and rewarding careers in various industries, from electronics manufacturing to plumbing and HVAC. To maximize your job prospects, invest time in crafting a professional, ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a compelling resume tailored to the specifics of your experience. We provide examples of resumes tailored to the Solder and Copper Work field to help guide you. Take the next step towards your dream career – build a standout resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.