Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Additive and Subtractive Color Mixing interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Additive and Subtractive Color Mixing Interview

Q 1. Explain the difference between additive and subtractive color mixing.

Additive and subtractive color mixing are two fundamentally different approaches to creating colors. Additive mixing involves adding light sources together, while subtractive mixing involves removing light from a white light source. Think of it like this: additive is like building with LEGOs, adding pieces to create something bigger and brighter, while subtractive is like sculpting, taking away material to reveal a form.

In additive mixing, combining all primary colors produces white light, while in subtractive mixing, combining all primary colors results in a very dark color, close to black. This difference stems from how each process interacts with light.

Q 2. What are the primary colors in the additive color model?

The primary colors in the additive color model are Red (R), Green (G), and Blue (B), often referred to as RGB. These are the colors of light emitted by devices like computer monitors, TVs, and projectors. When combined in varying intensities, they can create a wide range of colors. Mixing red and green produces yellow, red and blue produces magenta, and green and blue produces cyan. Combining all three at full intensity results in white light.

Example: A pixel on a screen displaying yellow might be using a high intensity of red and green light, with blue at a low intensity.Q 3. What are the primary colors in the subtractive color model?

The primary colors in the subtractive color model are Cyan (C), Magenta (M), and Yellow (Y), often used with a fourth color, Black (K), hence the CMYK model. These are the colors of pigments that absorb certain wavelengths of light, reflecting others. These are the colors used in printing inks, paints, and dyes. Combining cyan, magenta and yellow aims for black, but often a key black (K) is added to achieve a true black and improve accuracy. Think about how a red apple looks red because it’s absorbing all colors except red, which it reflects back to our eyes. That’s subtractive mixing in action!

Q 4. How does CMYK work in printing?

CMYK, representing Cyan, Magenta, Yellow, and Key (black), is the subtractive color model used in printing. The process works by applying layers of these colored inks to a white substrate (like paper). Each ink subtracts wavelengths of light from the white light reflecting off the paper. Cyan absorbs red, magenta absorbs green, and yellow absorbs blue. The amount of each ink applied determines the final color. Black (Key) is added not just to deepen colors but to significantly improve the overall print quality and save ink compared to relying only on CMY for darker colors.

For instance, a deep blue would be produced by combining cyan and magenta with a small amount of yellow, and more black. This layering effect allows printers to produce a wide range of colors and precise detail, although it is not as color accurate as RGB.

Q 5. How does RGB work in digital displays?

RGB, representing Red, Green, and Blue, is the additive color model used in digital displays such as computer monitors and televisions. Each pixel on the screen is made up of tiny red, green, and blue subpixels. The intensity of each subpixel’s light determines the overall color of the pixel. By varying the intensity of each subpixel (from 0 to its maximum value), millions of different colors can be created. Black is produced when all three subpixels are off (0 intensity), and white is produced when all three subpixels are at full intensity.

Example: A pixel displaying pure green would have its green subpixel at full intensity (e.g., 255) and its red and blue subpixels at 0 intensity.Q 6. Explain the concept of color gamut.

Color gamut refers to the range of colors that a particular device or system can reproduce. Think of it as the color ‘vocabulary’ of a specific device. Each device has limitations in producing the full spectrum of visible colors. For instance, a printer’s color gamut might be smaller than a high-end monitor’s gamut. This means the printer can’t reproduce all the colors that the monitor can display. It’s important to consider color gamut when designing for print, because a color that looks vibrant on screen might appear dull or different when printed. A wider gamut typically means more vibrant and richer colours but more sophisticated and expensive technology is required.

Q 7. What is color space and why is it important?

A color space is a standardized system for representing colors numerically. It defines a range of colors and how they are described using specific values, like RGB or CMYK. Different color spaces are optimized for different purposes. For example, sRGB is a widely used color space for web and digital displays, while Adobe RGB offers a wider gamut for professional photography and printing. They ensure consistent color reproduction across different devices and workflows. Choosing the right color space is crucial; using the wrong one can lead to significant color inaccuracies when moving your work from screen to print, or between different software programs. For example, images designed in Adobe RGB with a larger gamut might lose color accuracy when viewed in sRGB

Q 8. Describe the relationship between light and color.

The relationship between light and color is fundamental. Color, as we perceive it, is essentially our interpretation of light’s wavelengths. Visible light, a small portion of the electromagnetic spectrum, consists of various wavelengths, each perceived as a different color. When all wavelengths of visible light are present, we see white light. The absence of light results in black. Objects appear colored because they absorb certain wavelengths and reflect others. A red apple, for example, absorbs most wavelengths of light except for red, which it reflects back to our eyes.

This is crucial to understanding both additive and subtractive color mixing because additive mixing deals with adding light sources (like on a screen), while subtractive deals with the reflection of light from pigments (like paints or inks).

Q 9. What is color temperature and how does it affect color perception?

Color temperature is a way of describing the color of light emitted from a source, measured in Kelvin (K). It’s not about the actual temperature of the object, but rather how the light appears to our eyes. Lower Kelvin temperatures (e.g., 2700K) represent warmer colors like reds and oranges, reminiscent of candlelight or incandescent bulbs. Higher Kelvin temperatures (e.g., 6500K) represent cooler colors like blues and whites, similar to daylight or fluorescent lighting.

Color temperature significantly impacts color perception because different light sources will make the same color appear differently. A fabric that looks vibrant red under incandescent lighting might appear duller and slightly purplish under cool daylight. This is why it’s essential to consider the color temperature of your light source when working with color in photography, design, and printing.

Q 10. Explain the concept of color profile.

A color profile is a standardized description of a color space. It’s a set of data that defines the color gamut (range of reproducible colors) and the relationship between the color values displayed on a screen or printed on a paper. It essentially tells a device how to interpret and represent colors correctly. Without a color profile, the same digital color value could be represented differently on different devices, leading to significant color discrepancies.

Imagine trying to paint a picture with paints from different manufacturers, each with its unique color formulations. A color profile acts like a recipe book, ensuring that the “red” you select from each manufacturer’s palette creates a similar final color in your painting.

Q 11. What are some common color profile standards (e.g., sRGB, Adobe RGB)?

Some common color profile standards include:

sRGB (Standard Red Green Blue): A widely used standard for the internet and many consumer devices. Its gamut is relatively small, making it suitable for broad compatibility but limiting the range of reproducible colors.Adobe RGB (1998): Offers a wider color gamut than sRGB, encompassing a larger range of colors, particularly in the greens and blues. It’s commonly used in professional photography and printing.CMYK (Cyan, Magenta, Yellow, Key/Black): The subtractive color model used in printing. Each color subtracts light from the white paper, resulting in the final color.

The choice of color profile depends greatly on the intended application. For web use, sRGB is usually the best choice. For professional image editing and printing, Adobe RGB is a common choice, but other profiles like ProPhoto RGB offer even wider gamuts.

Q 12. How do you convert colors between different color spaces?

Converting colors between different color spaces requires specialized software or algorithms. This involves translating color values from one color model (e.g., RGB) to another (e.g., CMYK) while attempting to maintain visual consistency. However, this is not always perfect since different color spaces have different gamuts. Colors outside the destination color space’s gamut will often be clipped (converted to the nearest representable color), leading to color shifts.

The process involves complex mathematical transformations. Software like Adobe Photoshop and image editing libraries (e.g., OpenCV) offer tools and functions to handle these conversions automatically, but understanding the underlying principles is crucial for troubleshooting potential issues.

For example, converting an image from Adobe RGB to sRGB might result in a slight desaturation of some colors because sRGB has a smaller color gamut.

Q 13. What are the challenges of matching colors across different mediums?

Matching colors across different mediums (e.g., screen to print, print to fabric) is notoriously challenging due to several factors:

- Different Color Gamuts: Screens use RGB, while printing uses CMYK. RGB typically has a wider gamut, meaning some colors achievable on screen may not be reproducible in print.

- Media Characteristics: Paper type, ink type, and fabric texture all influence how colors are perceived and rendered. The same CMYK values can produce different visual results on different materials.

- Viewing Conditions: Ambient lighting conditions impact color perception. A color that looks accurate under one light source might look different under another.

- Color Profile Mismatches: Inconsistent use of color profiles can introduce significant color errors.

Addressing these challenges often requires color management systems, careful calibration of printing devices, and rigorous color proofing.

Q 14. Describe a situation where you had to troubleshoot a color-related issue.

During a project involving the production of marketing brochures, we encountered a significant color mismatch between the client’s digital mock-up and the final printed brochures. The client’s design used Adobe RGB, while our printing press was calibrated for sRGB. This discrepancy led to a noticeably less vibrant final product.

To troubleshoot, we first reviewed the color profiles involved in each stage of the process: design, prepress, and printing. We then used a color management system (CMS) to convert the client’s design from Adobe RGB to sRGB before sending it to the printer. This involved meticulous soft-proofing to check how the colors would appear after conversion. Finally, we implemented a color-proof check, physically printing a test run of the brochures before mass production. This allowed us to compare the printed results with the soft-proof and make any necessary adjustments to ensure an accurate color reproduction.

Q 15. How do you handle color inconsistencies in a print job?

Color inconsistencies in print jobs stem from discrepancies between the digital representation of a color and its physical manifestation on paper. This can be due to variations in the printing press, the ink used, the paper stock, or even the calibration of the monitor used for design. Addressing this requires a multi-pronged approach.

- Profile Matching: Ensure the printer’s ICC (International Color Consortium) profile accurately reflects its capabilities. This profile translates digital color data to the printer’s specific color space. Mismatched or outdated profiles are a major culprit.

- Proofing: Soft proofing using a calibrated monitor and hard proofing with a similar print process are crucial for verifying color accuracy before a full print run. This helps catch inconsistencies early.

- Calibration and Maintenance: Regular calibration of the printer and color measurement tools (spectrophotometer) is paramount. Cleaning print heads and ensuring proper ink levels prevent inconsistencies caused by hardware malfunctions.

- Color Management System (CMS): Utilizing a robust CMS across all stages, from design to output, ensures color consistency by managing the transformation of color data between devices.

- Paper Consistency: Using the same type and batch of paper throughout the print run prevents variations caused by differing paper absorption and reflectance properties.

For instance, I once worked on a project where the client complained about color shifts between different batches of printed brochures. After investigating, we discovered a slight variation in the paper stock between batches, leading to the color inconsistency. Switching to a consistent paper source solved the problem.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of color management in a digital workflow.

Color management in a digital workflow is the process of controlling and predicting how colors will look across different devices and stages of production. It’s like having a universal translator for colors. Think of it as ensuring your vibrant design on your screen looks exactly the same on the printer and, ultimately, in the customer’s hands. This is achieved through the use of color profiles, which mathematically define a device’s color space.

The workflow typically involves:

- Device Calibration: Calibrating your monitor, scanner, and printer using a colorimeter or spectrophotometer to ensure accurate color representation.

- Profile Creation and Embedding: Creating ICC profiles for each device and embedding them into digital files ensures consistent color transformations. For example, a JPEG might include a profile for the sRGB color space.

- Color Space Conversion: A Color Management System (CMS) handles the transformation between different color spaces (e.g., sRGB to CMYK) while maintaining color fidelity as much as possible. This is crucial for screen-to-print workflows.

- Proofing: Soft proofing (on-screen) and hard proofing (physical print) help check for color accuracy before committing to a large print run.

Q 17. What software or tools do you use for color management?

I utilize a range of software and tools for color management, depending on the specific task and workflow. This typically includes:

- Color Management Software: Adobe Color, X-Rite ColorMunki software, or other dedicated color management applications.

- Image Editing Software: Adobe Photoshop, Illustrator, and InDesign are essential, as they offer robust color management features, allowing for profile selection and conversion.

- RIP Software (Raster Image Processor): When working with large format printing, a RIP software is crucial for color management and controlling the output to the printer. It uses the device profile to interpret color data and translates it into instructions for the printing hardware.

- Color Measurement Devices: I use spectrophotometers, such as the X-Rite i1iSis, or colorimeters for accurate color measurement and profiling.

For example, when preparing files for a high-end print job, I use Photoshop’s color management features to convert the image to the required CMYK color space, embedding the appropriate ICC profile to maintain consistency.

Q 18. What are some common color problems in printing (e.g., banding, moiré)?

Common color problems in printing include:

- Banding: The appearance of distinct color bands or stripes across a gradient or smooth color transition. This is often due to insufficient color resolution or limitations in the printer’s capabilities.

- Moiré Patterns: Unwanted interference patterns that appear when two patterns (e.g., a halftone screen and an image with fine details) are overlaid. This is often caused by a mismatch between the screen frequency and the image details.

- Color Casts: An overall shift in hue away from the intended color, often caused by inaccurate color profiles, ink inconsistencies, or lighting conditions during proofing.

- Metamerism: A color that appears the same under one light source but different under another. It’s critical to consider the lighting conditions in the final viewing environment.

Imagine a smooth sunset gradient appearing banded and striped instead of smoothly blended; that’s banding. Moiré is like a shimmering effect, often seen as an undesirable interference pattern in fabrics, textiles, and sometimes even in digital print.

Q 19. How would you address banding in a print?

Addressing banding involves several strategies:

- Increasing Bit Depth: Using higher bit-depth images (e.g., 16-bit instead of 8-bit) provides a smoother gradient, reducing the chance of banding.

- Using a Different Halftone Screen: Experimenting with different halftone screen angles and frequencies can sometimes alleviate banding. This is particularly relevant for high-resolution images.

- Smoothing Techniques: Applying gentle smoothing or diffusion filters in image editing software can blend colors more smoothly, thus reducing banding effects. This should be done judiciously to avoid losing detail.

- Adjusting Printer Settings: Some printers offer settings to control color gradients and dithering. Optimizing these settings can improve the smoothness of gradients.

- Converting to a different color mode: If using a bitmap image, sometimes switching to a vector graphic format can help

For example, I’ve successfully reduced banding in a photo print by increasing the image’s bit depth and applying a subtle Gaussian blur, carefully monitoring the effect to avoid excessive softening of details.

Q 20. How would you address moiré patterns in a print or image?

Addressing moiré patterns often requires preventative measures during the design phase:

- Adjusting Screen Frequency: The most common solution involves adjusting the halftone screen frequency (lines per inch or lpi) in the RIP software. A different screen angle or frequency can significantly reduce or eliminate the moiré.

- Image Resampling: Resampling the image to a different resolution can sometimes help minimize the interference. However, this needs to be done carefully to avoid losing crucial image detail.

- Using a Different Screening Method: Switching to a different halftone screening method (e.g., frequency-modulated screening) can produce smoother results and reduce moiré.

- Design Considerations: In some cases, redesigning elements with potentially conflicting patterns can eliminate the problem at its source.

I remember a project where moiré patterns were appearing in a logo printed on a textile. By adjusting the halftone screen angle and frequency during the print job setup, the issue was resolved without compromising the logo design.

Q 21. Explain the difference between spot colors and process colors.

Spot colors and process colors are two fundamentally different approaches to color reproduction in printing.

- Spot Colors: Spot colors are premixed inks with specific formulations and unique color names (e.g., Pantone colors). Each spot color is printed as a solid, unseparated ink. Think of them as custom-mixed paint colors, each having a precise formula. They are ideal for situations where consistent color matching across various materials and printing methods is crucial.

- Process Colors (CMYK): Process colors are a subtractive color model using Cyan, Magenta, Yellow, and Key (black) inks to create a wide range of colors. Different percentages of each ink are layered to approximate the desired color. This is the most common printing method, offering a vast spectrum of colors but with some variations depending on ink, paper, and printing conditions.

Imagine designing a logo with a specific corporate blue. Using a spot color (like Pantone 294 C) guarantees that the blue will be exactly the same across various applications, from business cards to banners. Process colors, on the other hand, are more versatile but may not achieve the exact same shade in all scenarios.

Q 22. What is overprinting and how does it affect color?

Overprinting is a printing technique where one color of ink is printed over a previously printed, partially or fully dried, color. This differs from standard printing where colors are printed sequentially without overlapping. The effect on color is significant because it involves subtractive color mixing. Instead of combining colors additively (like on a screen), we’re layering inks, and each layer absorbs some light.

For example, if you overprint cyan over yellow, you don’t get a bright, additive green. Instead, you get a muddy, darker green because the cyan ink absorbs some of the yellow light, and the yellow absorbs some of the cyan. This is because the cyan ink is partially transparent, allowing some yellow light to show through. The result is a less vibrant and often duller color than expected. Accurate color prediction during overprinting requires careful consideration of ink opacity and color profiles. It’s a crucial aspect of print design that requires specialized knowledge and software.

In practice, overprinting can be used creatively to achieve certain effects. However, getting the desired color is challenging and needs careful planning and often specialized software that can simulate the results.

Q 23. How do you ensure color accuracy in web design?

Ensuring color accuracy in web design is crucial for a consistent user experience. This process relies heavily on understanding color models and managing the display’s capabilities. The most important thing is to design using a color space suitable for the web such as sRGB. This is a widely adopted standard and most screens can accurately display it.

We need to work in a managed color workflow; utilizing color management tools and software. This involves using color profiles (ICC profiles, discussed later) to define how colors are interpreted on different devices.

Testing on multiple devices and browsers is also critical, as color representation can vary. Online tools and color simulators can help predict how a color will appear on different screens and devices. Finally, utilizing a professional color calibration tool to accurately adjust your monitor also plays an important role in consistency.

Q 24. Explain the concept of color calibration.

Color calibration is the process of adjusting the color output of a display device (monitor, printer, projector) to match a known standard. This is essential to ensure that colors appear accurately and consistently across devices. Think of it like tuning a musical instrument – you’re adjusting it to play the correct notes.

Calibration involves using a colorimeter or spectrophotometer to measure the color output of your device and then using software to create a profile that corrects any discrepancies. This profile tells the operating system how to adjust the device’s settings to produce colors more accurately. Without calibration, colors may appear too bright, too dark, or completely different across devices, which makes any color-critical work unreliable.

Professional color calibration tools are crucial in ensuring consistent and accurate color across different displays and output devices. These tools provide very fine-tuned control and sophisticated testing and measurement.

Q 25. Describe your experience with Pantone matching system.

The Pantone Matching System (PMS) is a standardized color reproduction system. It uses a library of pre-mixed inks with specific color formulas. This is highly valuable because it guarantees consistency across different print jobs and printers. It’s like having a recipe for every color.

My experience with PMS involves its usage in print design, especially when exact color matching is crucial. I’ve used Pantone color books to select specific colors for projects, ensuring consistent color reproduction across multiple print runs. I’ve also worked with prepress professionals who use specialized software to create accurate color separations based on PMS specifications. The advantage is that it eliminates the uncertainty associated with trying to get exact color reproduction by mixing inks manually.

Accurate Pantone color reproduction relies on factors such as the quality of the inks used and the calibration of the printing press, but the PMS system vastly minimizes this risk.

Q 26. How does metamerism affect color matching?

Metamerism is a phenomenon where two colors appear identical under one light source but different under another. This is because our perception of color depends on the spectral distribution of light reflecting off the object. Two objects may have different spectral curves, but still look the same under a specific light source. Think of it like two musical chords that sound similar in a certain context but different in another.

In color matching, metamerism presents a significant challenge. Two samples might match perfectly under the lighting conditions of a design studio, but appear drastically different under sunlight or fluorescent lights. This means that a color match achieved in one environment may not hold true in another, especially when light sources drastically vary.

To mitigate the effects of metamerism, it’s essential to specify and carefully control the light source under which the color matching is done. In critical applications, multiple light sources must be considered.

Q 27. How familiar are you with ICC profiles?

ICC profiles (International Color Consortium) are digital files that describe the color characteristics of a specific device or a color space. They act as translators, telling the computer how to convert colors from one color space to another accurately. These are essential for color management in digital workflows.

My familiarity with ICC profiles is extensive. I regularly use them to manage color across different devices and software. For instance, when working with images from a digital camera, I incorporate the camera’s ICC profile to ensure accurate color representation on my monitor, during edits, and in the final output. Similarly, I use printer profiles to ensure that the printed colors accurately reflect the colors on screen.

ICC profiles are fundamentally important for consistency; without them, color discrepancies are practically inevitable across various stages of the production chain.

Q 28. What are your strategies for troubleshooting color issues in different media?

Troubleshooting color issues involves a systematic approach, varying slightly depending on the media (print or digital). First, I’d identify the problem – is it a color shift, inconsistency across devices, or unexpected color reproduction? Then I’d identify the stage where the error occurs. The problem could be the source image, the monitor, the printer, or even the paper used.

For digital media, I’d check the color space (sRGB or Adobe RGB), the ICC profile used, the monitor calibration, and the browser or software settings. For print, I’d examine the proofing methods, the ink specifications, the printer calibration, and the paper stock.

Step-by-step troubleshooting might involve: checking color profiles, recalibrating my monitor, testing on multiple devices, re-evaluating the source files, reviewing the printing settings, and if necessary, consulting with a color specialist or prepress professional for complex issues. The key is systematic observation and investigation.

Key Topics to Learn for Additive and Subtractive Color Mixing Interviews

- Additive Color Mixing: Understanding the principles of additive color mixing (red, green, blue – RGB) in digital displays and lighting. Explore how different combinations create various colors and the concept of white light.

- Subtractive Color Mixing: Mastering the principles of subtractive color mixing (cyan, magenta, yellow, and black – CMYK) in printing and painting. Understand how inks and pigments absorb certain wavelengths of light to create color.

- Color Models: Familiarize yourself with different color models (RGB, CMYK, HSV, LAB) and their applications in various industries (e.g., graphic design, photography, printing).

- Color Gamuts: Learn about the limitations of color reproduction in different color spaces and how this impacts color accuracy across various mediums.

- Practical Applications: Explore real-world applications of both additive and subtractive color mixing in fields such as graphic design, web development, photography, printing, and manufacturing.

- Color Management: Understand the importance of color management systems and profiles in ensuring consistent color reproduction across different devices and workflows.

- Troubleshooting Color Issues: Develop problem-solving skills related to color discrepancies, mismatches, and inconsistencies in different color reproduction processes.

- Color Theory Fundamentals: Review fundamental concepts of color theory, such as hue, saturation, value (HSV), and their impact on color perception and mixing.

Next Steps

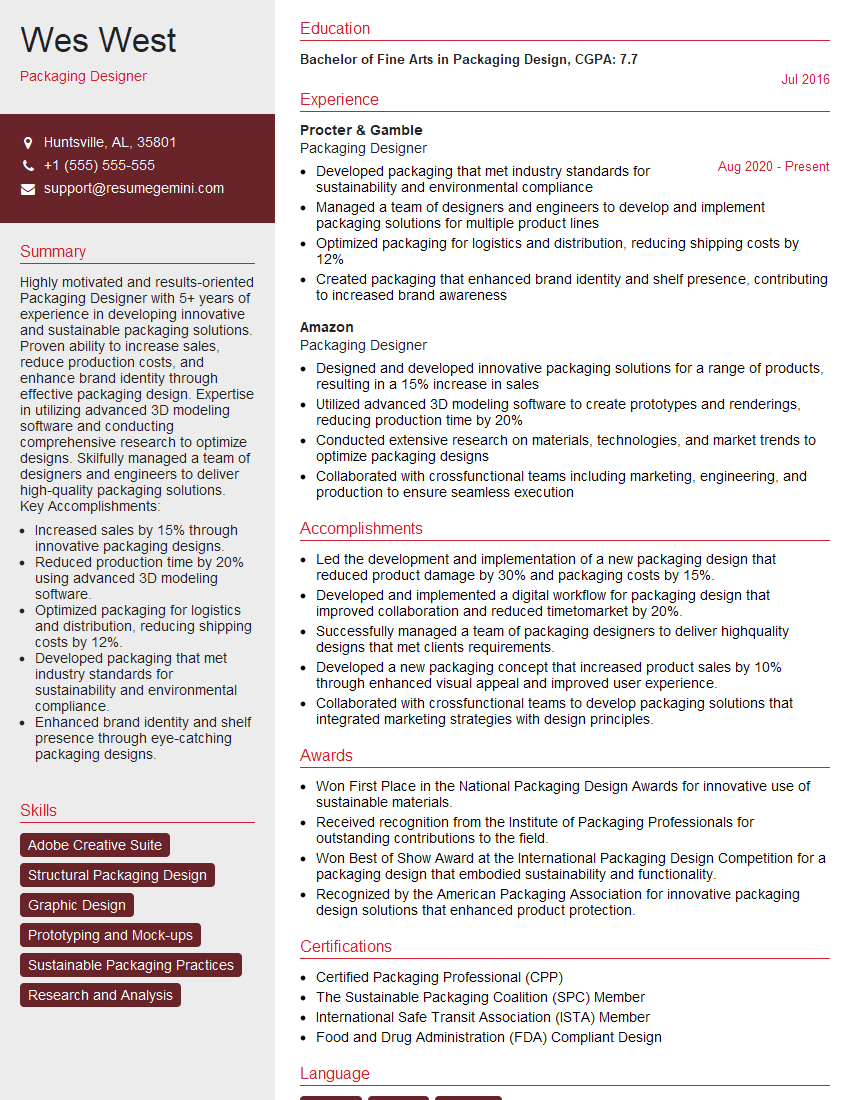

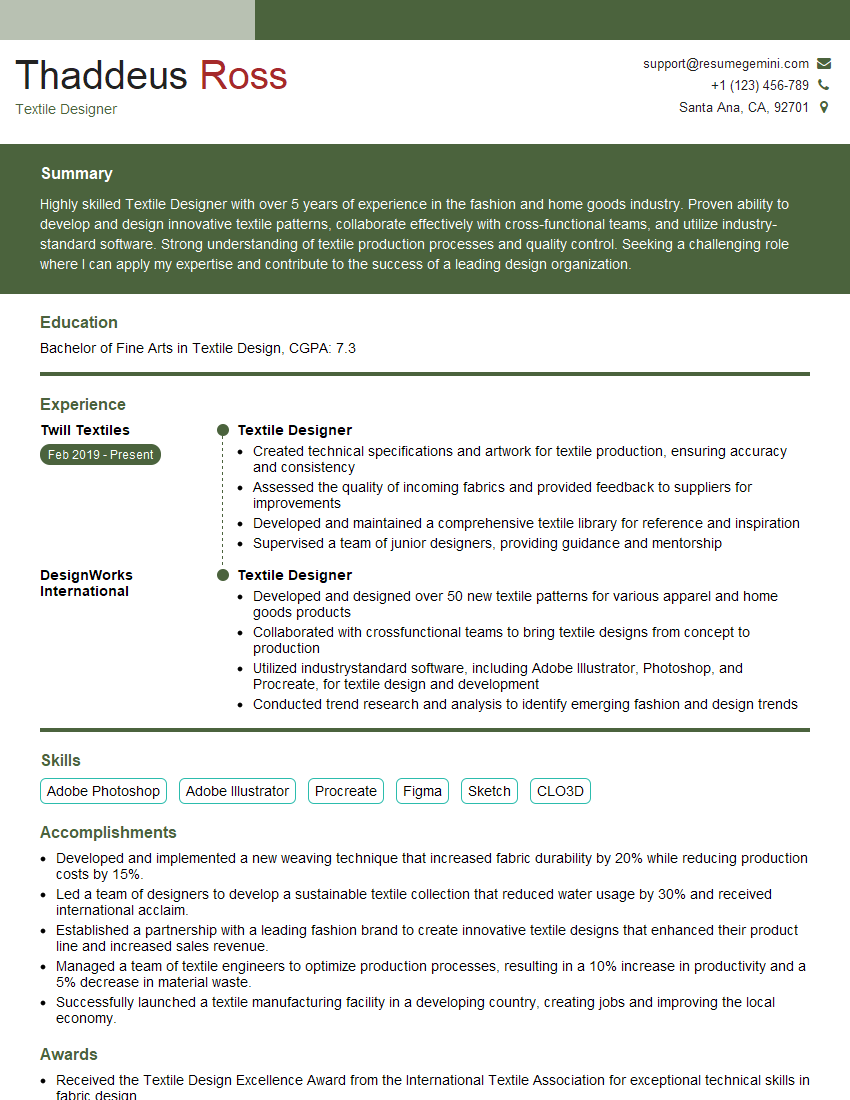

Mastering additive and subtractive color mixing is crucial for success in many creative and technical fields. A strong understanding of these concepts demonstrates a solid foundation and problem-solving abilities highly valued by employers. To significantly boost your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to Additive and Subtractive Color Mixing are available to guide you. Invest time in crafting a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.