Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Saponification Value Determination interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Saponification Value Determination Interview

Q 1. Define saponification value and its significance.

The saponification value is a crucial measure in chemistry, specifically in the analysis of fats and oils. It quantifies the amount of potassium hydroxide (KOH) in milligrams required to saponify one gram of fat or oil under specific conditions. In simpler terms, it tells us how many grams of KOH are needed to completely convert all the fatty acids in one gram of fat or oil into their corresponding potassium salts (soaps). Its significance lies in its ability to provide insights into the average molecular weight of the fatty acids present and to assess the quality and purity of fats and oils. A high saponification value generally indicates the presence of shorter-chain fatty acids, while a lower value suggests longer-chain fatty acids. This is crucial in quality control for various industries like cosmetics, food, and pharmaceuticals, ensuring consistent product quality.

Q 2. Explain the principle behind saponification value determination.

Saponification is essentially a base-catalyzed hydrolysis reaction. When fats or oils (which are triglycerides – esters of glycerol and fatty acids) are reacted with a strong base like KOH, they undergo hydrolysis, breaking down into glycerol and their constituent fatty acids. These fatty acids then react with the KOH to form potassium salts, commonly known as soaps. The principle behind the saponification value determination lies in precisely measuring the amount of KOH consumed in this reaction. By knowing the amount of KOH consumed, we can indirectly determine the amount of fatty acids present and consequently, the saponification value.

Q 3. Describe the procedure for determining the saponification value of an oil or fat.

Determining the saponification value involves a precise titration procedure. First, a weighed sample of the oil or fat is refluxed with an excess of alcoholic potassium hydroxide solution for a specified time (usually around one hour) to ensure complete saponification. This refluxing ensures that the reaction proceeds to completion. After the reflux, the excess KOH is titrated against a standard acid solution (usually hydrochloric acid) using phenolphthalein as an indicator. The difference between the initial amount of KOH added and the amount remaining (determined by titration) represents the amount of KOH consumed in the saponification reaction. This value is then used to calculate the saponification value.

Q 4. What are the necessary reagents and equipment for a saponification value determination?

The necessary reagents and equipment include:

- Analytical balance: For precise weighing of the oil or fat sample and KOH solution.

- Round-bottom flask: To carry out the reflux reaction.

- Reflux condenser: To prevent loss of volatile components during reflux.

- Burette: For accurate titration of the excess KOH.

- Pipettes: For precise measurement of the KOH and acid solutions.

- Erlenmeyer flask: To perform the titration.

- Alcoholic potassium hydroxide solution (standard solution): The base for saponification.

- Standard hydrochloric acid solution: For titrating the excess KOH.

- Phenolphthalein indicator: To indicate the endpoint of the titration.

- Heating mantle or hot plate: For refluxing.

Q 5. Calculate the saponification value given the mass of oil, KOH concentration, and volume of KOH used.

The saponification value (SV) is calculated using the following formula:

SV = [(Vblank - Vsample) x N x 56.1] / W

Where:

Vblank= Volume of HCl used for the blank titration (mL)Vsample= Volume of HCl used for the sample titration (mL)N= Normality of the HCl solutionW= Weight of the oil or fat sample (g)56.1= Molecular weight of KOH

Example: Let’s say 2g of oil was refluxed with 25ml of 0.5N KOH. After reflux, 10ml of 0.5N HCl was used to titrate the excess KOH. The blank titration used 20ml of 0.5N HCl. Then:

SV = [(20 - 10) x 0.5 x 56.1] / 2 = 280.5 mg KOH/g of oil

Q 6. What are the common units for expressing saponification value?

The saponification value is typically expressed in milligrams of potassium hydroxide (KOH) required to saponify one gram of fat or oil. Therefore, the common unit is mg KOH/g. Sometimes, it’s also represented as KOH/g. It’s crucial to maintain consistent units throughout the calculations to avoid errors.

Q 7. Explain the effect of impurities on the saponification value.

Impurities in the oil or fat sample can significantly affect the saponification value. Free fatty acids, for instance, will react with the KOH, leading to an artificially high saponification value. Conversely, the presence of unsaponifiable matter (substances that don’t react with KOH, such as waxes or hydrocarbons) will result in a lower saponification value because less KOH is consumed. Accurate results depend on using a pure sample and adhering strictly to the standard procedure. Careful sample preparation is critical to minimize the impact of impurities and obtain reliable results for quality control and product analysis.

Q 8. How does the saponification value relate to the average molecular weight of fatty acids in a sample?

The saponification value (SV) is inversely related to the average molecular weight of fatty acids in a sample. A higher SV indicates a lower average molecular weight, and vice versa. This is because the saponification reaction involves the hydrolysis of ester bonds in triglycerides, forming fatty acid salts (soaps). Shorter chain fatty acids require less alkali to complete saponification, resulting in a higher SV. Imagine it like this: smaller molecules (lower molecular weight fatty acids) need less cleaning solution (alkali) to be fully cleaned (saponified), while larger molecules need more. Conversely, triglycerides with longer-chain fatty acids have a lower SV because they need more alkali for complete saponification. Quantitatively, the SV is defined as the milligrams of potassium hydroxide (KOH) required to saponify one gram of fat or oil.

Q 9. What are the potential sources of error in the saponification value determination?

Several factors can introduce errors in saponification value determination. These include:

- Incomplete saponification: If the reaction time is insufficient or the temperature is too low, the saponification may not go to completion, leading to a lower than expected SV.

- Presence of unsaponifiable matter: Substances like sterols and hydrocarbons in the sample won’t react with the alkali, leading to an overestimation of the amount of alkali needed for the saponifiable matter, hence a falsely high SV.

- Water content in the sample: Excess water in the sample can interfere with the reaction and lead to inaccurate results. Water can react with the potassium hydroxide and lower the effective concentration of alkali.

- Indicator error: Incorrect use or selection of the indicator (e.g., phenolphthalein) can lead to imprecise endpoint determination in the titration, impacting the accuracy of the SV value.

- Impurities in the reagents: Impurities in the potassium hydroxide solution or the ethanol can affect the titration and lead to inaccurate results.

Q 10. How can these errors be minimized?

Minimizing errors in saponification value determination involves careful attention to detail and proper technique:

- Ensure complete saponification: Use an appropriate reflux time and temperature, usually around an hour at gentle reflux. The use of a solvent like ethanol ensures a homogeneous mixture and facilitates the reaction.

- Use accurate measurements: Precisely weigh the sample and use calibrated volumetric glassware for all measurements.

- Use high-purity reagents: Employ high-quality, analytical-grade reagents to minimize the impact of impurities.

- Proper titration technique: Practice careful titration to obtain a sharp endpoint. The addition of alkali should be slow near the endpoint.

- Carry out a blank titration: This corrects for any alkalinity in the reagents themselves, which would otherwise lead to an overestimation of the SV.

- Control for water content: Dry the sample if high water content is suspected.

Q 11. Describe the blank titration in the saponification value determination.

The blank titration is a crucial step in the saponification value determination. It involves carrying out the entire procedure (heating, refluxing, cooling) without the addition of the oil or fat sample. This titration determines the amount of alkali consumed by the reagents themselves (ethanol and potassium hydroxide) and any impurities present. By subtracting the volume of alkali used in the blank titration from the volume used in the sample titration, we correct for the alkali consumed by the reagents. This ensures that the calculated saponification value reflects only the alkali consumed by the saponification reaction.

For example, if 25ml of KOH was consumed in the sample titration and 1 ml in the blank, the actual KOH consumed by the fat would be 24 ml.

Q 12. What is the purpose of refluxing during the saponification reaction?

Refluxing during the saponification reaction is essential to ensure complete saponification. Refluxing involves heating the reaction mixture to boiling point and then condensing the vapors to return them to the flask. This maintains a constant temperature and prevents the loss of volatile components (like ethanol), which is crucial for the reaction. The higher temperature and constant boiling conditions accelerate the reaction rate and help achieve complete saponification of the fats and oils. Without refluxing, the reaction would be incomplete, leading to a lower saponification value.

Q 13. How does the saponification value vary across different types of oils and fats?

The saponification value varies considerably across different types of oils and fats. This variation is primarily due to the differences in the average molecular weight of the fatty acids present. Oils and fats rich in short-chain fatty acids (e.g., butyric acid in butter) will have higher saponification values compared to those rich in long-chain fatty acids (e.g., oleic acid in olive oil). For instance, coconut oil, which is rich in short-chain fatty acids, has a very high saponification value, while oils like castor oil and olive oil which have longer fatty acids have lower SV values. This is because shorter chain fatty acids have a higher number of molecules per gram, thus requiring more KOH for saponification.

Q 14. Explain the difference between saponification value and acid value.

Saponification value and acid value are both important parameters used to characterize fats and oils but measure different aspects of their chemical composition. The saponification value (SV) represents the total amount of alkali required to saponify all the esters (triglycerides) in one gram of fat or oil, indicating the average molecular weight of the fatty acids present. The acid value (AV), on the other hand, measures the amount of free fatty acids present in one gram of fat or oil. It is determined by titrating the free fatty acids with a standard alkali solution. A high AV indicates the presence of significant free fatty acids due to hydrolysis or oxidation, often leading to rancidity. In essence, SV measures the total ester content while AV measures the free fatty acid content. While both are crucial for quality assessment, the SV reflects the overall composition, while AV focuses on the degree of hydrolysis or degradation.

Q 15. What is the significance of knowing the saponification value in the quality control of oils and fats?

The saponification value (SV) is a crucial indicator of the average molecular weight of fatty acids in oils and fats. In quality control, it helps assess the purity and consistency of a batch. A lower SV suggests the presence of higher molecular weight fatty acids, while a higher SV indicates the presence of lower molecular weight fatty acids. This is significant because it directly impacts the properties of the oil or fat, affecting its suitability for various applications. For example, an oil intended for soap making requires a specific SV range to ensure proper soap formation. Deviations from the expected SV can signal adulteration, rancidity, or other quality issues, leading to rejection of the batch.

Imagine baking a cake: you wouldn’t use just any flour; you’d use a specific type that ensures the right texture and taste. Similarly, in oil and fat processing, the SV acts as a measure to guarantee the right ‘ingredients’ for desired product quality.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How is the saponification value used in the formulation of soaps and detergents?

The saponification value is paramount in soap and detergent formulation because it dictates the amount of alkali (typically sodium hydroxide or potassium hydroxide) needed for complete saponification. Saponification is the chemical reaction where fats or oils react with a strong alkali to produce soap (fatty acid salts) and glycerol. Knowing the SV allows formulators to precisely calculate the alkali-to-oil ratio, ensuring complete conversion of fats/oils into soap. Insufficient alkali results in unsaponified fats, leading to a poor-quality, greasy soap. Excess alkali leaves residual alkalinity, making the soap harsh and potentially damaging to skin. Therefore, precise SV determination is crucial for producing a high-quality, safe product.

For instance, coconut oil, having a high SV, requires a larger quantity of alkali compared to olive oil, which possesses a lower SV. This precise calculation ensures the optimal soap formation process.

Q 17. What are the limitations of the saponification value as a quality parameter?

While the saponification value is a valuable parameter, it does have limitations. It provides an average molecular weight, neglecting the distribution of fatty acid chain lengths. This means two oils can have the same SV but differ significantly in their fatty acid composition. Furthermore, the SV doesn’t account for the presence of unsaponifiable matter, such as waxes, sterols, or hydrocarbons that are present in some oils and fats. These components don’t participate in saponification and can lead to inaccurate interpretations of the SV. Finally, the presence of free fatty acids, which can occur during rancidification or hydrolysis, can elevate the SV, potentially masking other quality issues.

Think of it like measuring the average height of a basketball team: it tells you something, but doesn’t reveal the individual heights of each player. Similarly, the SV provides an average, but not the detailed picture of the fat or oil composition.

Q 18. What are the alternative methods for determining the average molecular weight of fatty acids?

Several alternative methods exist to determine the average molecular weight of fatty acids. Gas chromatography (GC) and high-performance liquid chromatography (HPLC) are commonly employed to separate and quantify individual fatty acids in a sample. Knowing the concentration of each fatty acid allows for calculation of the average molecular weight with more precision than the SV method. Other methods include mass spectrometry (MS), which provides detailed structural information, and titration techniques, which can determine the concentration of free fatty acids.

These techniques provide a much more comprehensive analysis of fatty acid composition, offering greater accuracy and insight compared to the overall average provided by the saponification value.

Q 19. How does temperature affect the saponification value determination?

Temperature significantly influences the saponification value determination. The reaction rate increases with temperature, leading to faster saponification. However, excessive heat can cause volatilization of some components, leading to inaccurate results. The standard procedure typically specifies a specific temperature range (often around reflux temperature) to ensure consistent and reliable results. Deviations from this range can affect the reaction kinetics and consequently the calculated SV. Therefore, maintaining the prescribed temperature throughout the procedure is critical for accurate results.

A controlled environment is essential to ensure consistency and reproducibility of the results. Think of cooking: a recipe specifies a temperature range to guarantee consistent outcome. Similar principles apply to SV determination.

Q 20. Discuss the importance of accurate weighing in the procedure.

Accurate weighing is paramount in the saponification value determination because it directly affects the stoichiometry of the reaction. The SV is calculated based on the precise masses of the oil or fat sample and the alkali used. Any error in weighing will propagate through the calculations, leading to an inaccurate SV. This inaccuracy can have serious repercussions in applications where precise alkali-to-oil ratios are needed, such as soap making. Using high-precision analytical balances and following meticulous weighing procedures are necessary to minimize errors and ensure accurate results.

Imagine building a house: if your measurements are inaccurate, the entire structure will be compromised. Similarly, accurate weighing is the foundation for a precise saponification value determination.

Q 21. Interpret a saponification value result and draw appropriate conclusions.

Interpreting a saponification value result involves comparing it to known values for different oils and fats. For instance, a high SV (e.g., above 240 mg KOH/g) could indicate a predominance of short-chain fatty acids, such as those found in coconut or palm kernel oils. A lower SV (e.g., below 200 mg KOH/g) might suggest higher proportions of long-chain fatty acids, as found in olive or castor oils. However, interpreting the SV alone is insufficient. It must be considered alongside other quality parameters, such as iodine value, acid value, and refractive index, to provide a comprehensive assessment of the oil or fat quality. Significant deviations from expected values could signal adulteration, rancidity, or other quality issues.

For example, if an olive oil sample displays a much higher SV than expected, it may suggest adulteration with a higher-SV oil like coconut oil. Further investigations would be needed to confirm such suspicions.

Q 22. Explain the role of the indicator in the titration process.

The indicator in saponification value determination plays a crucial role in signaling the endpoint of the titration. We use phenolphthalein, a pH indicator that changes color from colorless in acidic or neutral solutions to pink in alkaline solutions. During the titration, we’re adding a standardized acid (like KOH or NaOH) to neutralize the excess base remaining after the saponification reaction. The endpoint is reached when the last of the excess base is neutralized, causing a sharp color change from pink to colorless. This precise color change indicates that the reaction is complete, allowing for accurate calculation of the saponification value.

Think of it like baking a cake – the indicator is like a timer that tells you when the cake is perfectly baked. If you remove the cake too early or too late, the result will be incorrect. Similarly, precise detection of the endpoint using the indicator is key to getting an accurate saponification value.

Q 23. What are the safety precautions that should be taken during the saponification value determination?

Safety is paramount when conducting saponification value determination. We’re dealing with corrosive alkali solutions (like potassium hydroxide or sodium hydroxide) and organic solvents, both posing potential hazards. Key precautions include:

- Eye protection: Always wear safety goggles to protect against splashes of caustic solutions.

- Gloves: Use chemical-resistant gloves to prevent skin contact with the alkali and solvents.

- Lab coat: A lab coat provides an additional layer of protection for your clothing.

- Proper ventilation: Work in a well-ventilated area or under a fume hood to minimize exposure to any volatile organic compounds.

- Careful handling of glassware: Handle glassware carefully to prevent breakage and potential injuries.

- Waste disposal: Dispose of chemical waste according to established safety protocols and local regulations. Never pour caustic solutions down the drain without neutralization.

Remember, prevention is key. Following these simple safety measures minimizes risks and ensures a safe working environment.

Q 24. How would you handle a sample that has a very high saponification value?

A sample with a very high saponification value indicates a high concentration of fatty acids with low molecular weights, or a significant amount of short-chain triglycerides. To handle such a sample accurately, we must modify the procedure. Simply using the standard amount of alkali might result in an incomplete reaction, leading to an inaccurate result. We need to adjust the initial alkali concentration.

The solution is to use a smaller sample weight or increase the concentration of the standardized alkali solution used for saponification. It might also be beneficial to perform a preliminary test with a small amount of sample to establish a suitable working range. Precisely titrating the excess alkali after saponification remains crucial for accurate results. Through these adjustments, we can still obtain accurate measurements even for samples with extreme saponification values.

Q 25. How would you troubleshoot a saponification value determination that yields an unexpectedly low result?

An unexpectedly low saponification value points to several potential issues in the procedure. Let’s troubleshoot systematically:

- Incomplete saponification: This is the most common cause. Ensure the sample was thoroughly saponified by refluxing for a sufficient time (usually around one hour) and at a sufficiently high temperature. Insufficient heating or shorter reflux times can lead to incomplete saponification.

- Errors in titration: A missed endpoint during titration, especially if a slow color change occurs, will lead to a lower than expected value. Using more accurate titration methods, ensuring proper mixing, or using a more sensitive indicator can resolve this issue.

- Sample contamination: Impurities in the sample, such as water, may react with the alkali, leading to lower results. Ensure your sample is dry and free of contaminants.

- Incorrect standardization of alkali solution: An inaccurately standardized alkali solution will inevitably lead to incorrect results. Ensure the alkali solution concentration is accurately determined before conducting the analysis.

Careful review of each step of the procedure, combined with systematic testing, will often pinpoint the source of the low result. Repeating the test with increased attention to detail usually provides a more accurate saponification value.

Q 26. Explain the relationship between saponification value and the degree of unsaturation of fats and oils.

The relationship between saponification value and the degree of unsaturation is inverse. The saponification value reflects the average molecular weight of the fatty acids in the fat or oil. Fats and oils with a high proportion of unsaturated fatty acids (containing double bonds) generally have lower saponification values because unsaturated fatty acids tend to have higher molecular weights than saturated fatty acids. Conversely, fats and oils rich in saturated fatty acids will show higher saponification values because the shorter chain saturated fatty acids result in lower molecular weights and hence a higher saponification value for the same mass.

Imagine two oils, one primarily composed of short-chain saturated fatty acids and another predominantly containing long-chain unsaturated fatty acids. The first oil will require more alkali for complete saponification because there are more fatty acid molecules to neutralize. This leads to a higher saponification value. Conversely, the second oil, having fewer, larger fatty acid molecules, will require less alkali for complete neutralization, resulting in a lower saponification value.

Q 27. Compare and contrast different saponification methods.

Several methods exist for determining the saponification value, but they all share the fundamental principle of saponifying the fat or oil with an alkali and then titrating the excess alkali. The differences lie mainly in the method of saponification and the type of alkali used.

- Traditional Hot Saponification: This is the most common method involving heating a weighed sample of fat or oil with an excess of alcoholic potassium hydroxide (KOH) solution under reflux for a defined time. This ensures complete saponification. The excess KOH is then titrated with a standardized acid.

- Cold Saponification: This method employs the same principles but bypasses the reflux step. This accelerates analysis but requires more time for complete saponification and may result in incomplete reactions and lower accuracy. It is typically used for samples that are difficult to saponify under reflux.

- Automated Saponification: Some instruments automate the entire process, from sample preparation to titration, allowing for increased precision and reproducibility in addition to faster analysis.

The choice of method depends on factors such as the nature of the sample, the desired accuracy, and the availability of equipment. The hot saponification method is generally preferred for its accuracy and reliability.

Q 28. Discuss the environmental considerations related to saponification value determination.

Environmental considerations in saponification value determination primarily focus on the safe disposal of chemical waste. The alkali solutions (KOH or NaOH) used are corrosive and require careful neutralization before disposal. Excess alkali can be neutralized with an acid, usually hydrochloric acid (HCl), to form a salt and water. The resulting solution, after neutralization, should be disposed of according to local regulations. Furthermore, any organic solvents used during sample preparation or cleanup should also be handled and disposed of responsibly to minimize environmental impact. The use of greener solvents is an area of ongoing research to minimize the environmental impact of this important analytical technique.

In addition to waste disposal, minimizing the consumption of chemicals is environmentally beneficial. Optimizing the saponification procedure to use minimal quantities of reagents while maintaining accurate results is a significant way to contribute to environmentally friendly laboratory practices.

Key Topics to Learn for Saponification Value Determination Interview

- Definition and Significance: Understand the fundamental definition of saponification value and its importance in characterizing fats and oils. Explore its significance in various industries.

- Theoretical Principles: Grasp the underlying chemical reactions involved in saponification, including the role of esters, alkali hydroxides, and the formation of soap. Be prepared to discuss reaction mechanisms and stoichiometry.

- Procedure and Methodology: Detail the step-by-step procedure for determining saponification value, including sample preparation, titration techniques (e.g., using phenolphthalein indicator), and accurate data recording.

- Calculations and Data Analysis: Master the calculations required to determine the saponification value from titration data. Understand how to interpret results and identify potential sources of error.

- Practical Applications: Discuss the real-world applications of saponification value determination in various fields, such as quality control in the food industry, cosmetics manufacturing, and biodiesel production.

- Advanced Concepts: Familiarize yourself with variations in saponification methods, the influence of different factors on the saponification value (e.g., temperature, time), and advanced analytical techniques related to fat and oil analysis.

- Troubleshooting and Problem Solving: Be prepared to discuss common challenges encountered during saponification value determination and how to troubleshoot them effectively. This includes understanding the impact of impurities and variations in experimental conditions.

Next Steps

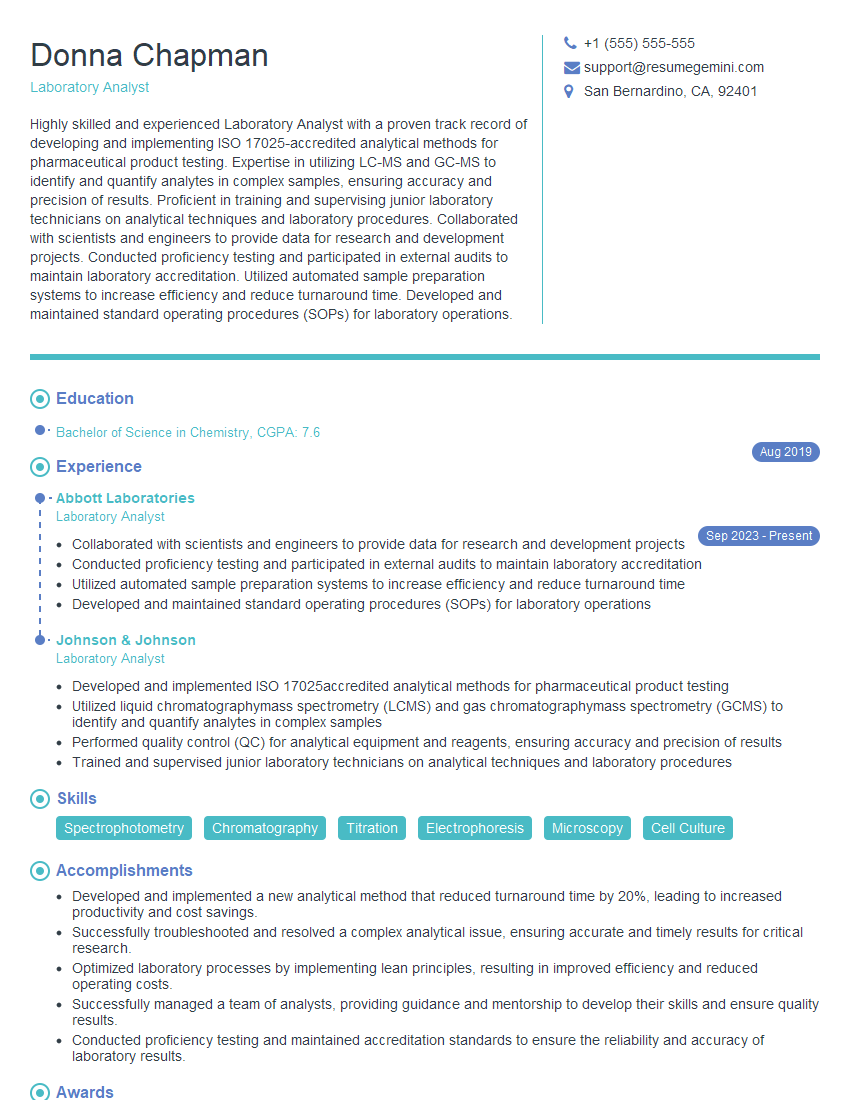

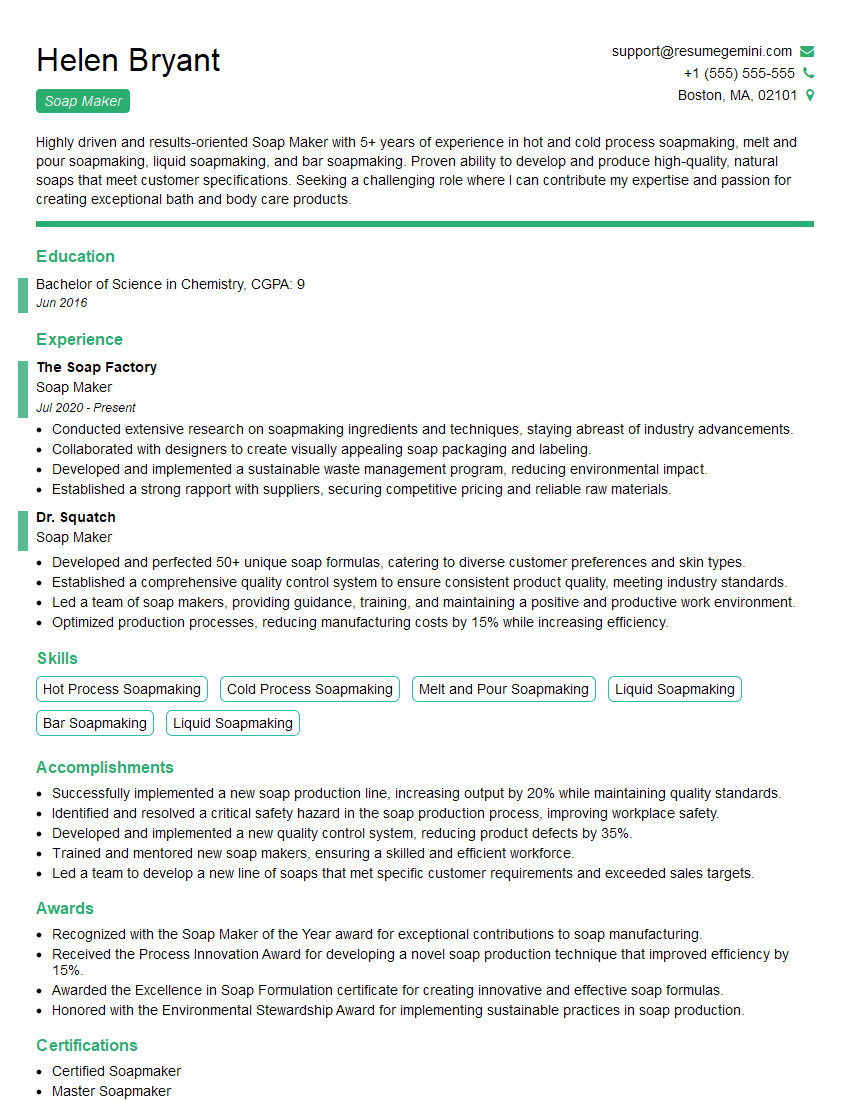

Mastering Saponification Value Determination demonstrates a strong foundation in chemistry and analytical techniques, highly valuable for careers in quality control, research and development, and manufacturing within various industries. This expertise significantly enhances your job prospects. To maximize your chances of landing your dream role, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is key to getting noticed by recruiters. We strongly encourage you to leverage ResumeGemini, a trusted resource, to build a professional and impactful resume that showcases your expertise in Saponification Value Determination. ResumeGemini provides examples of resumes tailored to this specific area of expertise, helping you create a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.