Unlock your full potential by mastering the most common Ability to troubleshoot and resolve equipment issues interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Ability to troubleshoot and resolve equipment issues Interview

Q 1. Describe your experience troubleshooting malfunctioning equipment.

Troubleshooting malfunctioning equipment is a core skill for me, honed over years of experience. It’s essentially a systematic process of identifying the root cause of a problem and implementing the appropriate solution. This involves a blend of technical expertise, problem-solving skills, and a methodical approach. I’ve tackled everything from minor software glitches to complex hardware failures, always focusing on minimizing downtime and ensuring the equipment’s continued optimal performance.

For example, in my previous role, I frequently dealt with network connectivity issues. I’d systematically check cables, routers, and server configurations to pinpoint the source of the disruption, often resolving issues by simply replacing a faulty cable or adjusting network settings. In other instances, deeper diagnostic procedures were required.

Q 2. Explain your process for diagnosing equipment problems.

My diagnostic process follows a structured approach. Think of it like a detective investigating a crime scene. First, I gather information: What are the symptoms? When did the problem start? What was happening just before the failure? Then, I visually inspect the equipment – are there any obvious signs of damage? This is followed by a series of tests, depending on the equipment and the nature of the malfunction. I might run diagnostics, check logs, or use specialized tools (discussed in the next answer). I carefully analyze the results, forming hypotheses about the root cause and testing them systematically until I’ve identified the problem. Once the cause is found, I implement the solution and thoroughly test to ensure the problem is resolved.

Q 3. What tools and techniques do you use for equipment troubleshooting?

My toolkit is quite extensive and adapts to the situation. For basic troubleshooting, I rely on multimeters to check voltage and current, network testers to diagnose connectivity problems, and specialized diagnostic software provided by the equipment manufacturers. For more complex scenarios, I might employ oscilloscopes to examine electronic signals, logic analyzers to trace digital signals, or even thermal cameras to identify overheating components. Beyond tools, my techniques include consulting technical documentation, searching online forums and databases for known issues and solutions, and collaborating with colleagues or vendors for expert assistance when needed. Knowing when to escalate a problem is also a crucial skill.

Q 4. How do you prioritize multiple equipment issues?

Prioritizing multiple equipment issues requires a structured approach. I use a combination of factors to determine urgency: impact on operations (critical systems get priority), potential for escalation (a small problem that could lead to a major outage gets prioritized), and ease of resolution (quick fixes are tackled first to free up time for more complex problems). I often use a ticketing system to track and manage issues, assigning priorities and deadlines to ensure efficiency. It’s like managing a to-do list, but with the added pressure of keeping critical systems running smoothly.

Q 5. Describe a time you had to troubleshoot a complex equipment failure.

One particularly challenging case involved a server cluster experiencing intermittent data corruption. Initial diagnostics pointed to multiple potential causes: hardware failure, software bugs, or even network instability. I started by systematically eliminating simpler possibilities – network issues were ruled out through extensive testing. I then used specialized memory diagnostic tools to find a faulty RAM module in one of the servers. Replacing this seemingly minor component solved the issue. The complexity arose from the fact that the failure was intermittent, requiring careful monitoring and data analysis to pinpoint the root cause. This experience reinforced the importance of thorough investigation and not jumping to conclusions before exhausting all possibilities.

Q 6. How do you document your troubleshooting process?

Documentation is paramount. I meticulously document every step of the troubleshooting process. This includes initial observations, test results, hypotheses, actions taken, and the final solution. I typically use a combination of written reports, diagrams, and screenshots. For example, if a software bug is the cause, I’d include relevant error logs and code snippets. This detailed documentation not only assists in future troubleshooting but also serves as a valuable learning tool and helps in sharing knowledge with others. A well-documented process improves efficiency and reduces future downtime.

Q 7. How do you handle situations where you cannot immediately resolve an equipment issue?

When I encounter an issue I can’t immediately resolve, I follow a clear escalation plan. This involves leveraging available resources: consulting technical documentation, searching online forums and knowledge bases, and reaching out to vendors or support teams. I also communicate the problem clearly to relevant stakeholders, providing regular updates on progress and estimated time to resolution. Transparency and effective communication are key in managing expectations during such situations. It’s important to remember that even experienced professionals encounter challenges – the key lies in effective problem-solving and communication.

Q 8. What safety precautions do you follow when troubleshooting equipment?

Safety is paramount when troubleshooting equipment. My approach is always based on a risk assessment, starting with identifying potential hazards. This might include electrical shock, burns, moving parts, exposure to hazardous materials, or even falling objects. I always follow the established safety procedures of the worksite or company, which typically includes:

- Lockout/Tagout (LOTO): Before working on any electrically powered equipment, I always use LOTO procedures to isolate power sources and prevent accidental energization. This is non-negotiable.

- Personal Protective Equipment (PPE): I always wear appropriate PPE, which might include safety glasses, gloves, hearing protection, steel-toe boots, and sometimes even respirators, depending on the task and potential hazards. This is tailored to the specific equipment and environment.

- Proper Grounding: Ensuring proper grounding of the equipment to prevent electrical shocks is crucial. This is especially important when dealing with high-voltage equipment.

- Awareness of Surroundings: I maintain awareness of my surroundings, paying attention to potential tripping hazards, and ensuring a safe working area free from obstructions. I’m careful not to work alone on risky tasks.

- Following Manufacturer’s Guidelines: I always consult the equipment’s documentation for specific safety precautions before beginning any troubleshooting.

For instance, once I was troubleshooting a malfunctioning industrial oven. Before even touching it, I ensured the oven was completely powered down and locked out, then checked the temperature to make sure it was safe to approach. I also wore heat-resistant gloves to protect myself from residual heat.

Q 9. How do you stay up-to-date with the latest troubleshooting techniques?

Staying current with troubleshooting techniques requires a multi-pronged approach. I leverage several resources to stay ahead of the curve:

- Manufacturer Websites and Documentation: I regularly check the websites of equipment manufacturers for updates, service bulletins, and troubleshooting guides. Many manufacturers provide detailed documentation and videos.

- Industry Publications and Journals: Staying informed through technical publications and journals keeps me abreast of advancements in troubleshooting methods and new technologies.

- Professional Organizations and Conferences: Participating in professional organizations and attending industry conferences provides invaluable networking opportunities and access to the latest information and best practices. These events allow me to learn from experts in the field.

- Online Courses and Webinars: Online learning platforms offer various courses and webinars on equipment maintenance and troubleshooting. This allows for continuous professional development at my own pace.

- Mentorship and Collaboration: I actively seek mentorship from experienced technicians and collaborate with colleagues to share knowledge and learn from each other’s experiences.

For example, I recently attended a webinar on the latest diagnostic techniques for PLC controllers, which significantly enhanced my troubleshooting capabilities for automated systems.

Q 10. Describe your experience with diagnostic software and tools.

I have extensive experience using a variety of diagnostic software and tools. My proficiency spans both hardware and software diagnostic tools. This includes:

- Multimeters: I’m adept at using multimeters to measure voltage, current, resistance, and continuity to pinpoint electrical faults in circuits. I can identify shorts, open circuits, and other electrical issues.

- Oscilloscope: I utilize oscilloscopes to analyze waveforms and identify signal integrity problems, timing issues, and other complex electrical phenomena.

- Logic Analyzers: For digital systems, logic analyzers help me capture and analyze digital signals, allowing for the diagnosis of problems in digital circuits.

- Specialized Software: I have experience with diagnostic software provided by equipment manufacturers. This software often includes advanced troubleshooting capabilities and error codes.

- Diagnostic Interfaces: I am familiar with using various communication protocols (e.g., RS-232, RS-485, Ethernet/IP, Profibus) and interfaces to connect to equipment and retrieve diagnostic information.

For example, during a recent project, I used a combination of a multimeter, an oscilloscope, and specialized software to diagnose an intermittent fault in a complex industrial control system. The software helped pinpoint the faulty component, while the oscilloscope allowed for the analysis of the signal’s integrity, leading to efficient repair.

Q 11. How do you handle equipment with limited or no documentation?

When dealing with equipment lacking documentation, a systematic and methodical approach is crucial. My strategy involves:

- Visual Inspection: I begin with a thorough visual inspection of the equipment, looking for any obvious signs of damage, wear, or loose connections. This often reveals a lot of information.

- Component Testing: I test individual components using multimeters, oscilloscopes, or other appropriate tools. This helps to isolate the faulty component.

- Tracing Signals: I trace the signals and power pathways through the equipment to understand how different components interact and identify potential points of failure. This involves carefully examining wiring and connections.

- Reverse Engineering: In some cases, it may be necessary to reverse engineer the equipment to understand its functionality. This is done by carefully studying the circuit diagrams, if any exist, and observing how the components work together.

- Seeking External Resources: I leverage online forums, technical communities, and potentially contact the manufacturer (even if it’s a discontinued model) or other experts to seek information.

Once, I was faced with an old, undocumented milling machine. By carefully studying its wiring and mechanism, combined with online research on similar machines, I managed to trace a faulty relay causing intermittent operation.

Q 12. How familiar are you with preventative maintenance procedures?

I’m very familiar with preventative maintenance procedures and understand their importance in extending equipment lifespan and minimizing downtime. My knowledge includes:

- Scheduled Inspections: Regularly scheduled inspections help to detect potential problems early on, before they escalate into major failures. This might involve visual checks, lubrication, and functional testing.

- Lubrication: Proper lubrication is essential for the smooth operation of many types of equipment, reducing friction and wear. I’m skilled in using appropriate lubricants and greases according to manufacturer recommendations.

- Cleaning: Keeping equipment clean removes debris and contaminants that can lead to malfunctions. This might involve using compressed air, specialized cleaning solvents, or even ultrasonic cleaning for delicate components.

- Calibration: For instruments and equipment requiring calibration, I follow strict procedures and use appropriate calibration equipment to ensure accuracy.

- Replacing Worn Parts: Regularly replacing worn parts proactively prevents unexpected failures. This often involves consulting maintenance logs and manufacturer recommendations.

For instance, in a previous role, I implemented a preventative maintenance program for a fleet of robotic arms, which resulted in a significant reduction in downtime and repair costs.

Q 13. How do you determine the root cause of an equipment malfunction?

Determining the root cause of equipment malfunction involves a structured approach. I typically follow these steps:

- Gather Information: I start by gathering information about the malfunction, including the symptoms, when it started, any preceding events, and the operational context. I interview operators to understand the problem thoroughly.

- Visual Inspection: A thorough visual inspection is always the first step. This often reveals loose connections, damage, or other obvious issues.

- Testing and Measurements: I perform relevant tests and measurements using appropriate diagnostic tools (multimeters, oscilloscopes, etc.) to gather data related to the problem.

- Analyzing Data: I carefully analyze the gathered data, looking for patterns, anomalies, and correlations that might point to the root cause.

- Eliminating Possibilities: Using a systematic process of elimination, I rule out potential causes until the most likely root cause is identified.

- Verification: Once a root cause is identified, I need to verify it by implementing a corrective action and observing the result. This confirms that the root cause has indeed been addressed.

For example, a conveyor belt stopped functioning. By meticulously checking the motor, power supply, and drive belt, and systematically testing each component, I discovered a burnt-out motor capacitor as the root cause.

Q 14. Describe your experience working with different types of equipment.

My experience working with different types of equipment is extensive and encompasses a wide range of technologies. This includes:

- Industrial Machinery: I have experience troubleshooting various types of industrial machinery, including conveyor systems, robotic arms, CNC machines, and packaging equipment.

- HVAC Systems: I am proficient in diagnosing and repairing HVAC systems, including chillers, air handlers, and refrigeration units.

- Electrical Systems: My skills cover troubleshooting low-voltage and high-voltage electrical systems, including power distribution, motor controls, and lighting.

- Instrumentation and Control Systems: I have experience with programmable logic controllers (PLCs), sensors, actuators, and other components of industrial control systems.

- Computer Networks: In certain roles, I’ve had to troubleshoot networking issues related to industrial equipment communication.

This broad experience allows me to adapt quickly to new equipment and situations, effectively applying my troubleshooting expertise to a wide variety of challenges.

Q 15. How do you effectively communicate technical information to non-technical individuals?

Communicating technical information to non-technical individuals requires a shift in perspective. Instead of using jargon and technical terms, I focus on using plain language, analogies, and visual aids. I imagine I’m explaining the issue to a friend who doesn’t have a technical background.

For instance, if explaining a network problem, instead of saying “The TCP/IP stack is experiencing packet loss,” I’d say something like, “Imagine your internet connection as a highway; right now, there’s traffic congestion, and some of the packages delivering your information are getting lost or delayed, causing slowdowns.”

- Plain Language: Replace technical terms with everyday words.

- Analogies and Metaphors: Use relatable examples to illustrate complex concepts.

- Visual Aids: Diagrams, charts, or even simple drawings can clarify complex technical issues.

- Active Listening: Check for understanding and adjust my explanation accordingly.

This approach ensures that the information is not only understood but also retained.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with remote troubleshooting?

I have extensive experience with remote troubleshooting, primarily utilizing remote desktop software, screen sharing tools, and collaborative platforms. My approach begins with gathering as much information as possible from the user – error messages, symptoms, recent changes to the system, etc. This allows me to build a hypothesis before initiating remote access. Once connected, I systematically test various aspects of the equipment, using remote commands and diagnostic tools. For example, I might use command-line tools to check network connectivity, log files to identify error patterns, or remote monitoring software to view system performance metrics.

I’ve successfully resolved issues ranging from network connectivity problems to software glitches and hardware malfunctions using this methodology. One memorable case involved troubleshooting a server outage for a client halfway across the country. By using remote access tools and systematically checking logs, I was able to pinpoint a faulty hard drive, preventing significant downtime. Effective communication is key during remote troubleshooting – using clear, concise language, screen sharing, and walking the user through the steps are all crucial for success.

Q 17. How do you manage your time effectively when troubleshooting multiple equipment issues?

Managing time effectively when troubleshooting multiple equipment issues requires a systematic and prioritized approach. I employ a combination of techniques:

- Prioritization: I categorize issues based on urgency and impact. Critical issues that affect multiple users or core services are tackled first.

- Time Blocking: Allocating specific time blocks for each issue prevents multitasking and enhances focus. This also helps track progress.

- Task Management Tools: Using ticketing systems or task management software allows for efficient tracking of all open issues, their status, and assigned resources.

- Documentation: Maintaining detailed notes about each issue, including the steps taken, findings, and solutions, saves time in the future and aids in knowledge sharing.

I often utilize the Pareto Principle (80/20 rule), focusing on the 20% of issues that cause 80% of the problems. This allows me to quickly address the most significant problems and then work on the smaller issues at a more relaxed pace. Regular breaks are also essential to prevent burnout and maintain effectiveness.

Q 18. What are some common causes of equipment failure in your field of expertise?

Common causes of equipment failure vary depending on the specific field, but some general culprits include:

- Power Surges and Brownouts: Unstable power supply can damage sensitive electronic components.

- Overheating: Inadequate ventilation or excessive workload can lead to overheating and component failure.

- Hardware Degradation: Components wear out over time, leading to malfunctions. This is particularly true for mechanical parts like hard drives and fans.

- Software Errors/Glitches: Bugs in software can cause system instability and crashes.

- Physical Damage: Accidental drops, impacts, or liquid spills can cause immediate or gradual hardware failure.

- Environmental Factors: Extreme temperatures, humidity, or dust can negatively affect equipment performance.

For example, in networking, faulty cabling or network switches are frequently seen causes of connectivity issues. In server environments, hard drive failures are a major cause of data loss and system downtime.

Q 19. Describe your experience with electrical safety procedures.

Electrical safety is paramount in my work. I am thoroughly familiar with and strictly adhere to all relevant safety regulations and procedures. This includes:

- Lockout/Tagout (LOTO) Procedures: Before working on any electrical equipment, I always follow proper LOTO procedures to prevent accidental energization.

- Personal Protective Equipment (PPE): I consistently use appropriate PPE, such as safety glasses, insulated gloves, and non-conductive footwear.

- Grounding and Bonding: I ensure proper grounding and bonding techniques are used to prevent electrical shocks.

- Voltage Testing: Before touching any electrical equipment, I always verify that the power is off using a reliable voltage tester.

- Awareness of Potential Hazards: I am constantly aware of potential electrical hazards and take all necessary precautions to avoid them. This includes being careful around live wires and high-voltage equipment.

My training emphasizes the importance of preventing accidents, and I take my responsibilities in this area very seriously. Safety is not just a procedure, but a mindset.

Q 20. How do you ensure the accuracy of your troubleshooting analysis?

Ensuring the accuracy of my troubleshooting analysis relies on a methodical approach and a commitment to verification. My process involves:

- Systematic Investigation: I follow a structured process of elimination, testing hypotheses one by one to isolate the root cause.

- Data Validation: I utilize multiple data points and sources to confirm my findings. This may involve checking logs, monitoring system metrics, or using diagnostic tools.

- Peer Review (When Applicable): If the problem is complex or I am unsure of my diagnosis, I consult with colleagues for a second opinion.

- Documentation: I thoroughly document all steps taken, findings, and solutions. This serves as a record of the troubleshooting process and helps ensure future reproducibility.

- Testing and Verification: After implementing a solution, I rigorously test to ensure that the problem is completely resolved and doesn’t reappear.

For example, if I suspect a network connectivity issue, I would verify the problem by pinging different devices, checking network cables, and testing the network switch. I wouldn’t rely on a single test result but would use multiple methods to ensure the accuracy of my diagnosis.

Q 21. How do you handle situations where you need to escalate a problem to a senior technician?

Escalating a problem to a senior technician is a crucial part of effective troubleshooting. My approach involves:

- Clear and Concise Communication: I prepare a comprehensive summary of the issue, including all relevant information gathered, steps taken, and the current status. This ensures the senior technician has all the necessary context.

- Prioritization: I prioritize the escalation based on the urgency and complexity of the issue. Critical issues requiring immediate attention are escalated promptly.

- Transparency: I’m open about my limitations and clearly articulate what I’ve already attempted and what I’m still unsure of.

- Collaboration: I actively participate in the troubleshooting process with the senior technician, providing assistance and sharing knowledge.

- Documentation: After the resolution, I document the entire process, including the senior technician’s contribution and the final solution. This contributes to team learning and knowledge sharing.

Escalating doesn’t mean failure; it’s a collaborative effort towards resolving challenging issues, fostering team growth and learning.

Q 22. Describe your experience with calibration and testing equipment.

Calibration and testing equipment are crucial for ensuring the accuracy and reliability of other instruments. My experience encompasses a wide range of equipment, from simple multimeters and oscilloscopes to sophisticated automated test systems. I’m proficient in calibrating various types of equipment, including pressure transducers, temperature sensors, and flow meters, following established procedures and using certified reference standards. For example, when calibrating a pressure transducer, I would use a deadweight tester as a reference, comparing the transducer’s readings against known pressures. Any deviations would be documented and adjustments made as needed. Furthermore, I’m experienced in performing functional tests on equipment, verifying that it operates within its specified parameters. This involves understanding the equipment’s specifications and utilizing appropriate test methods and procedures to identify any malfunctions or anomalies. My experience also includes maintaining detailed calibration records, ensuring traceability and compliance with industry standards.

Q 23. How do you utilize schematics and diagrams in troubleshooting?

Schematics and diagrams are essential tools in troubleshooting. Think of them as a roadmap for the equipment. I use them to understand the signal flow, identify components, and trace connections. For instance, if a circuit isn’t working, I’ll consult the schematic to trace the signal path from input to output, checking for voltage drops, signal discontinuities, or component failures at each stage. Diagrams, like block diagrams, provide a higher-level view of the system architecture, allowing me to focus on particular sections when troubleshooting. If a system has multiple subsystems, a block diagram helps isolate the faulty section quickly. For example, if a printer isn’t working, I’d start by checking the power supply (using the diagram), then the data connection, and finally the print mechanism, isolating the problem systematically. I’m also adept at interpreting different types of diagrams, including wiring diagrams, PCB layouts, and piping and instrumentation diagrams (P&IDs), adapting my approach to the specific type of equipment.

Q 24. How do you determine when to replace versus repair a piece of equipment?

The decision to repair or replace equipment is based on several factors: the cost of repair versus replacement, the equipment’s age and remaining useful life, the availability of parts, the complexity of the repair, and the criticality of the equipment to overall operations. For example, a minor repair on a relatively new, critical piece of equipment is usually more cost-effective and efficient than replacement. On the other hand, if a piece of equipment is old, requires numerous costly repairs, and has limited availability of spare parts, replacement might be the more prudent choice. I always perform a cost-benefit analysis, considering the total cost of ownership (TCO) for both repair and replacement scenarios. I’d also factor in downtime; if the repair process is excessively lengthy, impacting production significantly, replacement could be prioritized. The decision is always made in the context of minimizing overall downtime and operational costs.

Q 25. What is your experience with preventative maintenance schedules?

Preventative maintenance schedules are fundamental to equipment reliability and longevity. My experience includes developing and implementing these schedules, tailoring them to the specific needs of different types of equipment. These schedules typically involve regular inspections, lubrication, cleaning, and functional testing. For example, I’ve created schedules for industrial machinery that included weekly lubrication checks, monthly functional tests, and annual overhauls. For more complex equipment, the schedule is more detailed and might include specific diagnostic tests. I’m also experienced in using Computerized Maintenance Management Systems (CMMS) to track maintenance activities, generate work orders, and manage spare parts inventory. A well-maintained preventative maintenance schedule leads to fewer breakdowns, extended equipment lifespan, and ultimately, cost savings.

Q 26. How do you maintain accurate records of repairs and maintenance?

Maintaining accurate records is crucial for tracking equipment history and facilitating future maintenance and repairs. I use a combination of physical and digital methods to maintain these records. For example, I use CMMS software to log all maintenance and repair activities, including dates, descriptions of work performed, parts used, and labor hours. This system generates reports that show the history of each piece of equipment, making it easy to identify trends and potential issues. I also maintain physical records such as calibration certificates and inspection reports, which are stored securely and organized according to established procedures. This approach ensures that all records are easily accessible and auditable, vital for regulatory compliance and ensuring the quality of the maintenance process. The accuracy of these records is paramount for efficient troubleshooting and planning future maintenance.

Q 27. Explain your understanding of various troubleshooting methodologies (e.g., binary search, divide and conquer).

Troubleshooting methodologies are critical for efficient problem solving. The binary search method, for example, is particularly useful when dealing with systems that can be divided into smaller, independent parts. Imagine troubleshooting a faulty circuit board: by successively dividing the board into smaller sections and testing each, you can quickly locate the faulty component. The ‘divide and conquer’ strategy is similar, breaking down a complex problem into smaller, more manageable sub-problems that are solved individually. For example, when diagnosing a complex system failure, I would first try to identify the subsystem where the problem originates, using system diagnostics. Then I would apply the binary search or other appropriate techniques within that subsystem. Other techniques involve using logical deduction based on observed symptoms, utilizing test equipment to measure signals and parameters, and consulting technical documentation. My approach adapts to the specific situation; sometimes a combination of methods is required for effective troubleshooting.

Key Topics to Learn for Ability to Troubleshoot and Resolve Equipment Issues Interview

- Understanding the Problem: Learn to effectively gather information about equipment malfunctions. This includes identifying symptoms, gathering relevant data (error codes, logs), and accurately describing the issue.

- Systematic Troubleshooting: Practice using a structured approach to troubleshooting, such as the “5 Whys” method or a decision tree, to efficiently isolate the root cause of the problem. This demonstrates a logical and methodical approach to problem-solving.

- Diagnostic Tools and Techniques: Familiarize yourself with common diagnostic tools and techniques relevant to the specific equipment you work with. This might include using multimeters, specialized software, or online resources.

- Safety Procedures: Highlight your understanding of and adherence to safety protocols when working with potentially hazardous equipment. This demonstrates responsibility and professionalism.

- Documentation and Reporting: Practice clear and concise documentation of troubleshooting steps, solutions implemented, and outcomes. This shows attention to detail and the ability to communicate technical information effectively.

- Preventive Maintenance: Discuss your understanding of preventive maintenance procedures and their role in reducing equipment failures. This shows proactive problem-solving skills.

- Resourcefulness and Problem-Solving: Be prepared to discuss situations where you had to creatively solve equipment issues with limited resources or information. Focus on your critical thinking and adaptability.

Next Steps

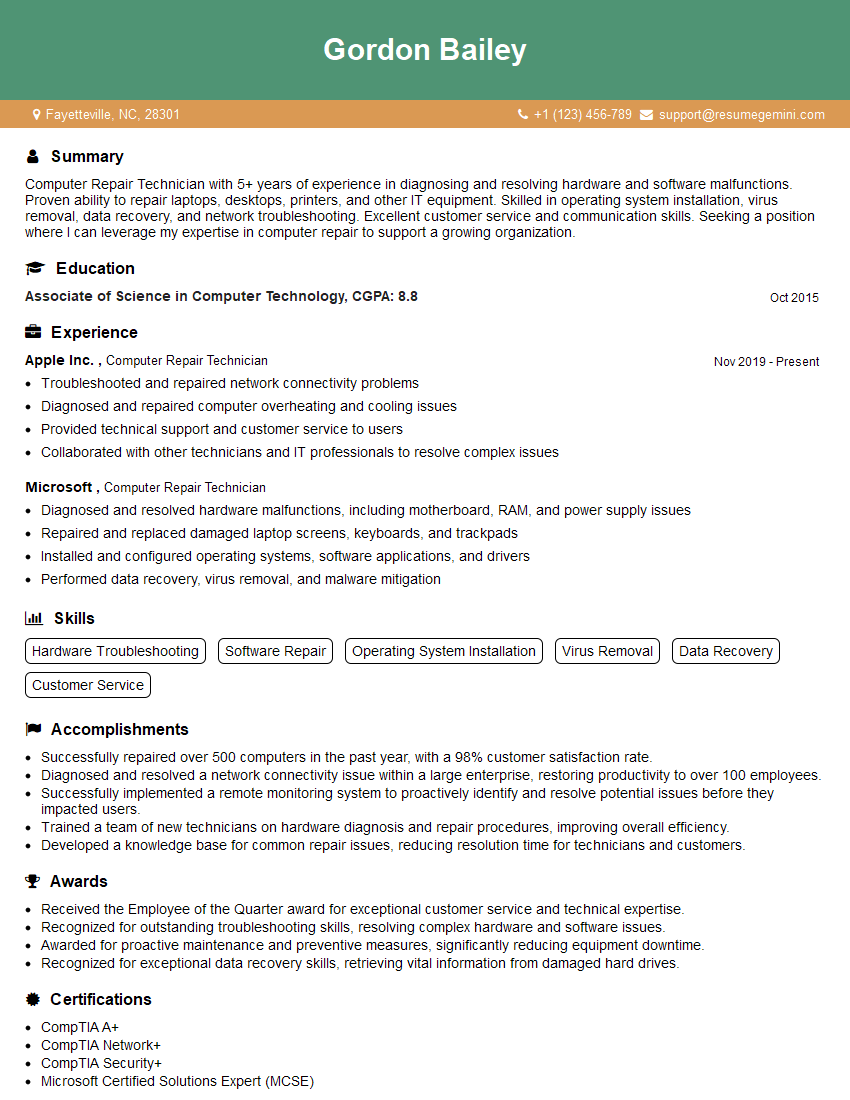

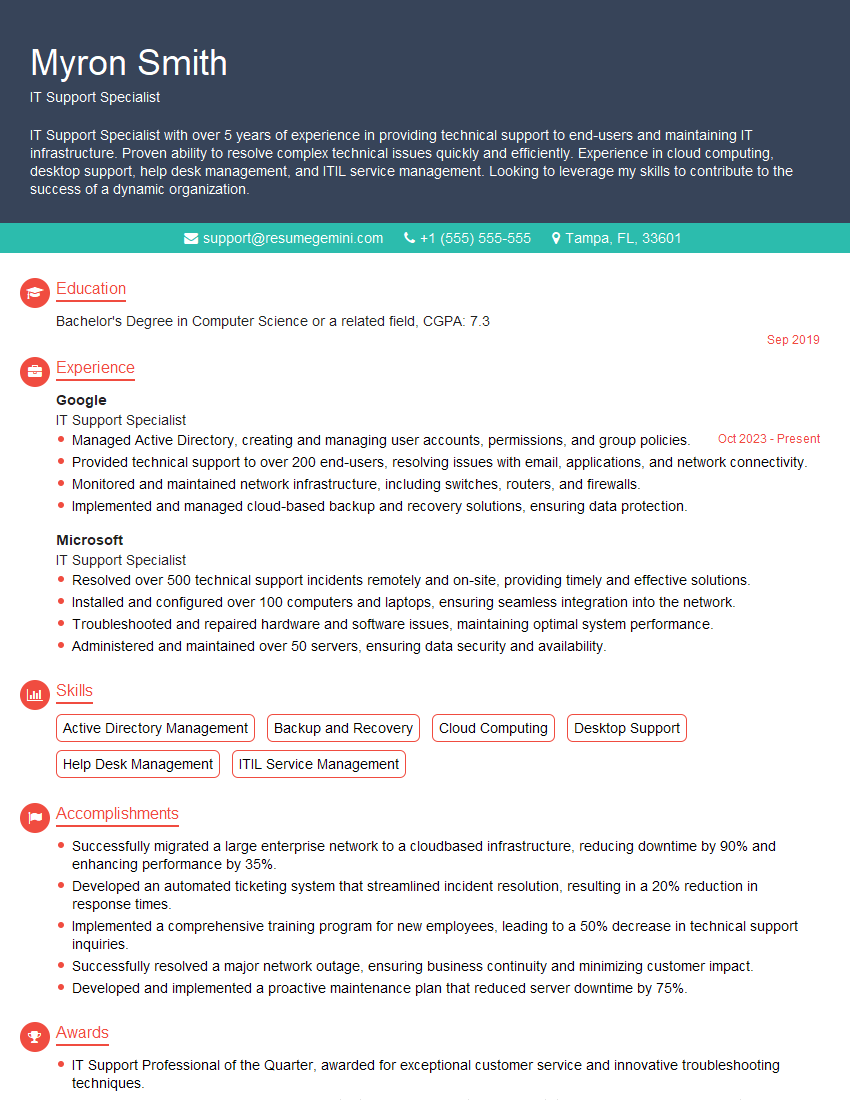

Mastering the ability to troubleshoot and resolve equipment issues is crucial for career advancement in almost any technical field. It showcases your problem-solving skills, technical expertise, and ability to handle pressure – all highly sought-after qualities by employers. To increase your chances of landing your dream job, it’s vital to create an ATS-friendly resume that effectively highlights these skills. ResumeGemini is a trusted resource that can help you build a professional resume tailored to your experience. We provide examples of resumes specifically tailored to showcase expertise in troubleshooting and resolving equipment issues, helping you present your skills in the most compelling way possible.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.