Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Concrete Structural Assessment and Evaluation interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Concrete Structural Assessment and Evaluation Interview

Q 1. Explain the different types of concrete deterioration and their causes.

Concrete deterioration is a complex process encompassing various mechanisms that degrade its properties over time. Understanding these mechanisms is crucial for effective assessment and repair. Let’s explore some common types:

- Alkaline-Aggregate Reaction (AAR): A chemical reaction between certain aggregates and the high-pH cement pore solution, causing expansion and cracking. This is particularly problematic in structures built with reactive aggregates like certain types of siliceous rocks.

- Corrosion of Embedded Steel: Steel reinforcement within concrete is vulnerable to corrosion when chloride ions penetrate the concrete cover, lowering the pH and initiating rusting. This expansion can lead to cracking and spalling of the concrete.

- Carbonation: Atmospheric carbon dioxide reacts with calcium hydroxide in the concrete, lowering its pH. This weakens the concrete and can compromise the passive protection of the embedded steel, leading to corrosion.

- Freeze-Thaw Damage: Water within concrete pores expands upon freezing, creating internal stresses that can cause cracking and deterioration, especially in porous concrete exposed to repeated freeze-thaw cycles.

- Sulfate Attack: Sulfates in groundwater or soil react with the cement phases, causing expansion and deterioration. This is commonly observed in structures exposed to aggressive environments such as marine or industrial settings.

- Abrasion and Erosion: Physical wear from traffic, water flow, or other mechanical actions can erode the concrete surface, reducing its thickness and structural capacity.

The causes of these deterioration mechanisms are diverse, including material selection, environmental exposure (e.g., de-icing salts, aggressive groundwater), inadequate design or construction practices, and insufficient maintenance.

Q 2. Describe the methods used to assess the strength of existing concrete.

Assessing the strength of existing concrete requires a multifaceted approach, combining non-destructive and destructive testing methods. The choice of method depends on factors such as accessibility, the required accuracy, and the condition of the concrete.

- Non-destructive Testing (NDT): These methods don’t damage the concrete and include:

- Rebound Hammer Test: Measures the hardness of the concrete surface, providing an indirect indication of compressive strength. It’s simple, quick, and portable, but accuracy is affected by factors like surface condition and moisture content.

- Ultrasonic Pulse Velocity (UPV) Test: Measures the speed of sound waves traveling through the concrete. It provides information about the homogeneity and overall quality of the concrete, offering insights into potential internal defects.

- Covermeter Test: Determines the thickness of concrete cover over the reinforcing steel, essential for assessing corrosion risk.

- Destructive Testing (DT): These methods involve extracting cores from the concrete and testing them in a laboratory. While more invasive, they provide the most accurate assessment of strength.

- Compressive Strength Test: Cores are tested to failure under compressive load, giving a direct measure of concrete’s compressive strength. This is the most commonly used method for assessing strength.

Often, a combination of NDT and DT is employed to provide a comprehensive assessment. For instance, NDT methods can be used for initial screening and to guide the location of core samples for DT, optimizing both cost and information gathering.

Q 3. How do you determine the need for concrete repair or strengthening?

The decision to repair or strengthen concrete hinges on comparing its existing condition and capacity with the required performance level. This involves a thorough assessment of several factors:

- Structural Capacity Evaluation: This involves assessing the load-carrying capacity of the existing concrete structure using analytical methods, such as finite element analysis, and/or testing methods as described previously.

- Deterioration Assessment: A detailed investigation of the extent and severity of deterioration, including visual inspection, mapping of cracks and spalls, and material testing. The rate of deterioration is also considered to predict future performance.

- Service Life Evaluation: Predicting the remaining service life of the structure based on the observed deterioration rates and environmental conditions.

- Performance Requirements: Defining the desired performance level of the structure based on current code requirements, safety considerations, and functional needs. The performance requirements often depend on the intended use of the structure.

If the structural capacity falls short of the performance requirements, or if the predicted service life is insufficient, repair or strengthening is necessary. The choice between repair and strengthening depends on the extent of the damage and the desired level of enhancement. Repair might be sufficient for minor damage, while strengthening is needed for significant deterioration or increased load demands. For example, simple crack repair may suffice for surface cracks without significant structural implications, whereas substantial strengthening might be needed to address severe corrosion damage to reinforcing steel or significant loss of concrete section.

Q 4. What are the common methods used for concrete repair?

Concrete repair methods vary depending on the type and extent of damage. Common techniques include:

- Crack Repair: Small cracks can be repaired using epoxy injection, which fills the crack and restores structural integrity. Larger cracks may require more substantial repairs, such as stitching or widening and filling with a suitable repair mortar.

- Surface Repairs: Deteriorated surfaces can be repaired using patching mortars or overlays, restoring the protective concrete cover and improving aesthetics. The choice of repair material depends on the nature and severity of the damage and the required performance.

- Spalling Repair: Spalling (chipping or flaking of concrete) is usually repaired by removing the damaged concrete and replacing it with a compatible repair material. Ensuring good adhesion between the old and new concrete is crucial for the success of the repair.

- Corrosion Repair: This involves removing corroded steel reinforcement, cleaning the surface, and providing additional cover with either new concrete or specialized corrosion-resistant materials.

- Section Repair: Severe damage, like loss of a large section of concrete, may require full section replacement. This often involves demolishing and rebuilding the affected part using reinforced concrete.

In each case, careful selection of repair materials, proper surface preparation, and adherence to established guidelines are crucial for ensuring the long-term effectiveness of the repair.

Q 5. Explain the principles of crack evaluation and repair in concrete structures.

Crack evaluation and repair in concrete structures require a systematic approach to ensure the structural integrity and safety of the structure. The principles include:

- Crack Identification and Mapping: Systematic mapping of cracks, including their location, width, length, orientation, and pattern, is the first step. This provides valuable information about the cause and extent of the damage.

- Crack Width Measurement: Crack width is a critical parameter influencing the repair strategy. Small cracks may require simple surface treatments, while wider cracks may indicate more severe damage needing more extensive repair such as epoxy injection or stitching.

- Crack Classification: Cracks are often classified based on their width, depth, and pattern to determine their significance and appropriate repair methods.

- Cause Determination: Determining the cause of cracking is crucial for effective repair. This involves analyzing factors like structural overloading, shrinkage, temperature changes, corrosion, and foundation settlement.

- Repair Strategies: Repair methods are selected based on the crack width, depth, cause, and location. Methods include surface sealing, epoxy injection, stitching, crack widening and filling, and more extensive repairs such as section replacement.

- Monitoring and Inspection: Post-repair monitoring and inspection are crucial to assess the effectiveness of the repair and to detect any recurrence of cracking.

A common analogy is a human body: a small cut (crack) might heal naturally (simple surface treatment), while a deep wound (wide crack) requires stitches (stitching) or even surgery (section replacement) depending on the severity. Accurate diagnosis of the ‘injury’ (crack) is paramount to selecting the appropriate ‘treatment’ (repair).

Q 6. What are the different types of concrete testing and their applications?

Concrete testing encompasses a broad range of methods used to determine its various properties. These tests are essential for quality control, structural assessment, and material characterization.

- Compressive Strength Test: The most common test, measuring the concrete’s resistance to crushing forces. It’s crucial for determining the structural capacity of concrete elements.

- Flexural Strength Test: Evaluates the concrete’s resistance to bending stresses, often used for assessing the durability and fracture toughness.

- Splitting Tensile Strength Test: Determines the concrete’s tensile strength indirectly using a splitting load applied to a cylindrical specimen. This indirectly gives tensile strength information.

- Elastic Modulus Test: Measures the concrete’s stiffness, relating stress and strain under elastic loading. Important for structural analysis.

- Water Absorption Test: Determines the concrete’s porosity and permeability. It is indicative of durability and resistance to freeze-thaw damage and chemical attack.

- Chloride Content Test: Measures the concentration of chloride ions within the concrete, an indicator of corrosion risk to embedded steel.

- Air Content Test: Determines the amount of air entrained in the concrete. Air entrainment improves the concrete’s resistance to freeze-thaw damage.

The specific tests employed depend on the purpose of the investigation. For instance, a routine quality control test on freshly mixed concrete might include compressive strength and air content tests. Conversely, evaluating a deteriorated structure might require compressive strength, chloride content, and possibly UPV tests.

Q 7. How do you interpret concrete test results to assess structural integrity?

Interpreting concrete test results requires a thorough understanding of the context and limitations of each test. It involves comparing the obtained values with relevant standards, design codes, and expected performance criteria. Here’s a breakdown:

- Compressive Strength: A low compressive strength indicates potential weakness and compromised structural capacity. This needs comparison with the design strength and the allowable stress levels defined in building codes. Significant deviations require further investigation.

- Chloride Content: High chloride content signifies a high risk of corrosion in reinforcing steel. This warrants careful analysis of the concrete cover and additional measures such as cathodic protection or repair.

- Ultrasonic Pulse Velocity (UPV): A low UPV value suggests potential internal defects, cracking, or deterioration. This could indicate areas requiring further investigation using other tests or visual inspection.

- Water Absorption: High water absorption indicates high porosity and susceptibility to freeze-thaw damage and ingress of aggressive chemicals. This informs decisions on appropriate surface treatments or repairs.

It’s important to consider all test results holistically and in the context of the structure’s overall condition, environmental exposure, and intended use. For instance, a slightly low compressive strength may be acceptable in a non-critical structural element, whereas the same strength reduction would be unacceptable in a primary load-bearing column. Expert judgment is crucial in interpreting these results and making informed decisions regarding structural integrity and appropriate remedial actions.

Q 8. Describe your experience with non-destructive testing (NDT) methods for concrete.

Non-destructive testing (NDT) is crucial for assessing concrete structures without causing damage. My experience encompasses a range of techniques, each providing unique insights into the concrete’s condition. For example, rebound hammer testing provides a quick assessment of the concrete’s compressive strength by measuring the rebound of a hammer. This is excellent for initial surveys and identifying potentially weak areas. Ultrasonic pulse velocity testing measures the time it takes for sound waves to travel through the concrete, indicating the presence of internal voids or cracks which affect its integrity. I’ve extensively used this method to assess the homogeneity of concrete slabs and walls. Another important technique is ground-penetrating radar (GPR), which uses electromagnetic waves to detect subsurface features like rebar location, voids, and delaminations, invaluable for planning repairs and avoiding unexpected damage during renovations. Finally, cover meter testing helps determine the concrete cover over reinforcing steel, which is vital for evaluating corrosion risk. In practice, I often combine several NDT methods for a comprehensive assessment, tailoring the approach to the specific structure and objectives.

Q 9. How do you determine the load-carrying capacity of a damaged concrete member?

Determining the load-carrying capacity of a damaged concrete member requires a systematic approach. It starts with a thorough visual inspection to identify the type and extent of damage – cracks, spalling, delamination etc. Then, I’d utilize NDT methods (as described above) to quantify the damage further. This data informs the selection of appropriate analytical methods. For minor damage, simple calculations based on reduced effective section properties might suffice. For more significant damage, I typically employ finite element analysis (FEA), which is extremely versatile in modelling complex geometries and material non-linearities. FEA allows simulating the behavior of the damaged member under different load scenarios, providing accurate estimates of its residual load-carrying capacity. In certain cases, when the damage is extensive, destructive testing on core samples might be necessary to establish the material properties more accurately. The final load-carrying capacity is determined by comparing the FEA results or simplified calculations against relevant codes and standards. For example, I once assessed a damaged column in a multi-story building; FEA, combined with material testing data, revealed it could still support a significant portion of its original design load after necessary repairs were factored in.

Q 10. Explain the use of finite element analysis (FEA) in concrete structural assessment.

Finite Element Analysis (FEA) is an indispensable tool in concrete structural assessment. It allows for detailed modeling of the structure, incorporating complex geometries, material properties (including non-linear behavior of concrete under stress), and various loading conditions. This enables accurate prediction of stress, strain, and displacement distributions within the structure. In assessing damaged concrete, FEA can simulate the effect of cracks, voids, or corrosion on the structural behavior. For example, I can model a cracked beam to determine its weakened flexural capacity. I also use FEA for evaluating the effectiveness of repair strategies. By simulating the repair, I can compare the strengthened member’s performance with the original undamaged state and predict the member’s overall lifespan after the implemented repair method. This approach ensures repairs are optimal and cost-effective. Furthermore, FEA can facilitate the investigation of complex failure mechanisms that are difficult to understand through traditional methods.

Q 11. Describe your experience with software used for structural analysis and design (e.g., SAP2000, ETABS).

My experience with structural analysis software includes extensive use of SAP2000 and ETABS. These programs are powerful tools for modeling, analyzing, and designing concrete structures. In SAP2000, I’m proficient in creating complex 3D models, defining material properties, applying loads, performing linear and nonlinear analyses, and interpreting the results to assess structural performance. Similarly, with ETABS, I routinely handle dynamic analysis (for seismic considerations), time-history analysis, and pushover analysis (for assessing structural vulnerability under extreme events). I utilize these software packages to model various scenarios, such as assessing the structural integrity of existing buildings, designing new structures, and evaluating the effectiveness of strengthening schemes. The results from these analyses are crucial in preparing detailed reports for clients, outlining findings, and recommending appropriate remediation strategies. I also have experience with other structural software packages, adapting my approach to the client’s needs and project requirements.

Q 12. How do you evaluate the corrosion of reinforcing steel in concrete structures?

Evaluating corrosion of reinforcing steel is critical for assessing the long-term durability of concrete structures. Several methods are employed. Visual inspection is the first step, looking for signs like staining, spalling, or rust deposits. More quantitative methods include half-cell potential measurements, which measure the electrochemical potential of the steel relative to a reference electrode, revealing areas prone to corrosion. Linear polarization resistance measures the corrosion rate directly. Cover meter testing, as mentioned previously, is essential to determine the thickness of the concrete cover. Thin concrete cover increases the risk of corrosion. Finally, destructive testing involving extraction of core samples allows for direct examination of the rebar’s condition and the extent of corrosion. I often use a combination of these techniques to obtain a comprehensive understanding of the corrosion’s severity and its impact on the structure’s integrity. The choice of methods is tailored to the specific situation and its unique challenges, always striving to minimize disruption and project costs while maintaining accuracy.

Q 13. What are the common methods for mitigating corrosion in concrete?

Mitigating corrosion in concrete involves preventing the ingress of chlorides and moisture, and managing the environment to prevent electrochemical reactions. Common methods include:

- Applying protective coatings to the concrete surface to prevent chloride penetration.

- Using corrosion inhibitors which are added to the concrete mix to slow down the corrosion process.

- Cathodic protection, an electrochemical technique that protects the steel by making it the cathode, preventing corrosion.

- Repairing damaged concrete to restore the protective cover over the reinforcing steel. This can involve patching, replacing damaged sections, or applying epoxy-based repair materials.

- Improving drainage around the structure to reduce moisture accumulation and subsequent chloride ingress.

Q 14. Explain the principles of concrete durability and its factors.

Concrete durability refers to its ability to resist deterioration under the service conditions it’s subjected to. It’s influenced by several factors:

- Material properties: The quality of the cement, aggregates, and admixtures significantly influences the concrete’s long-term performance. Using high-quality materials and proper mix design are fundamental.

- Environmental factors: Exposure to aggressive environments (e.g., de-icing salts, seawater, freeze-thaw cycles) significantly accelerates deterioration. Understanding the local climate and exposure conditions is essential.

- Construction practices: Poor construction practices can lead to defects (e.g., honeycombing, cracks) that compromise durability. Careful quality control is necessary during construction.

- Design considerations: Proper design to minimize cracking and ensure adequate cover over reinforcement is vital for durability.

Q 15. How do you assess the seismic performance of concrete structures?

Assessing the seismic performance of concrete structures involves a multi-faceted approach combining analysis, testing, and observation. We start by understanding the structure’s design, materials used, and its overall condition. This includes reviewing original construction documents, if available, and conducting a thorough visual inspection to identify any signs of distress like cracks, spalling, or corrosion.

Next, we’ll employ analytical methods, often using sophisticated software, to simulate the structure’s response to seismic loading. This might involve nonlinear static procedures (pushover analysis) or nonlinear dynamic analysis, depending on the complexity of the structure and the desired level of accuracy. These analyses predict the structure’s behavior under different earthquake intensities, estimating potential damage and collapse mechanisms.

In-situ testing may also be needed to confirm the strength and stiffness of the concrete and reinforcement. This could include core sampling to assess concrete compressive strength, or conducting non-destructive testing methods like ultrasonic pulse velocity or rebound hammer tests. The results from both analytical and experimental evaluations are then integrated to determine the seismic performance level, often expressed as a performance point on a capacity curve. This informs decisions on whether strengthening or retrofitting is necessary.

For example, I recently worked on a project involving a mid-rise building constructed in the 1970s. The initial assessment, which combined visual inspection and pushover analysis, revealed a potential deficiency in the shear capacity of the columns during a significant earthquake event. Further testing validated this finding, leading to recommendations for strengthening the columns with fiber-reinforced polymer (FRP) jackets.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common methods used for strengthening existing concrete structures?

Strengthening existing concrete structures employs various techniques depending on the type of deficiency and the desired level of improvement. Common methods include:

- External Strengthening: This involves adding materials to the exterior of the existing structural members. Common techniques include adding concrete jackets, steel plates or fiber-reinforced polymer (FRP) sheets. FRP, in particular, is gaining popularity due to its high strength-to-weight ratio and corrosion resistance. Imagine wrapping a weak column with carbon fiber sheets to significantly increase its load-carrying capacity.

- Internal Strengthening: This involves adding reinforcement within the existing concrete member, often through techniques like grout injection (to fill cracks and improve concrete’s integrity) or installing new steel bars within carefully-drilled holes.

- Shotcreting: This method involves spraying concrete onto the surface of a member to increase its thickness and strength. It’s particularly useful for repairing damaged or deteriorated sections.

- Base Isolation: For entire buildings, base isolation is a highly effective method to protect the structure from seismic forces. This involves placing a flexible layer (usually elastomeric bearings or lead-rubber bearings) between the building’s foundation and the ground, allowing the building to move independently from the ground during an earthquake.

The selection of the most appropriate strengthening technique depends on several factors including the type and extent of damage, the available space, and budgetary constraints. A comprehensive assessment is crucial to determine the best course of action.

Q 17. Describe your experience with the design and detailing of concrete repairs.

My experience in concrete repair design and detailing is extensive, encompassing various types of damage mechanisms and repair strategies. I’ve worked on projects ranging from simple crack repairs to complex repairs involving significant structural damage due to fire, corrosion, or seismic events.

Designing repairs goes beyond simply filling cracks; it requires understanding the root cause of the damage. For example, a simple crack might be due to shrinkage, but a network of cracks might indicate a more serious structural deficiency. The design process involves analyzing the stresses and strains on the damaged element and selecting appropriate materials and techniques to restore the member’s load-carrying capacity and durability. Detailed drawings are essential, specifying the type and quantity of materials, the repair sequence, and all quality control requirements.

One project involved repairing a large section of a bridge deck damaged by freeze-thaw cycles. The design included a detailed plan for removing deteriorated concrete, cleaning the surface, repairing reinforcement, and then installing a new reinforced concrete overlay. I meticulously created detailed drawings, including reinforcement details, dimensions, and material specifications, ensuring seamless integration of the repair with the existing structure.

Q 18. How do you ensure the quality control of concrete repair work?

Quality control in concrete repair is paramount to ensure the long-term success of the repair and the safety of the structure. My approach involves a multi-layered strategy:

- Material Testing: Rigorous testing of all materials used, including concrete, steel, and admixtures, is essential to ensure they meet the specified requirements.

- In-process Inspection: Regular inspection throughout the repair process ensures that the work is being carried out according to the design specifications. This includes monitoring the cleaning of surfaces, the placement of reinforcement, and the proper mixing and placement of concrete.

- Documentation: Meticulous documentation of all aspects of the repair process, including photographs, test results, and inspection reports, creates a permanent record for future reference.

- Non-destructive Testing: After the repair is completed, non-destructive testing methods such as ultrasonic pulse velocity testing are employed to verify the quality of the repaired concrete.

- Independent Verification: In many cases, it’s beneficial to have an independent third-party inspection to provide an unbiased assessment of the quality of the repair work.

Ignoring quality control can lead to premature failure of the repair, potentially resulting in costly rework or even structural collapse. Therefore, implementing a thorough quality control plan is a crucial part of every project I undertake.

Q 19. Explain your understanding of building codes and standards related to concrete structures.

My understanding of building codes and standards related to concrete structures is comprehensive. I’m familiar with international codes like ACI 318 (American Concrete Institute) and Eurocode 2, as well as national and regional codes. I also stay updated on the latest revisions and amendments to ensure my designs and assessments always comply with current best practices.

These codes provide requirements for design, materials, construction, and inspection of concrete structures. They incorporate provisions for safety, serviceability, and durability. For instance, ACI 318 provides detailed guidelines on the design of reinforced concrete members, specifying minimum reinforcement requirements, detailing rules, and provisions for various loading conditions including seismic events. Understanding these codes and standards is critical for ensuring the safety and longevity of concrete structures. Ignoring or misinterpreting these codes can lead to serious structural deficiencies and failures.

In my work, I always ensure that my designs and assessments adhere to the relevant building codes, incorporating all necessary safety factors and provisions for specific environmental conditions. I regularly consult with building code officials to ensure projects comply with local regulations.

Q 20. How do you manage projects related to concrete structural assessment and evaluation?

Managing projects related to concrete structural assessment and evaluation requires a systematic approach. My typical process involves:

- Project Planning: This stage includes defining the project scope, objectives, timelines, and budget. We collaborate closely with the client to understand their needs and establish realistic expectations.

- Team Coordination: Assembling a skilled team with expertise in various aspects of structural assessment and evaluation is crucial. This often includes engineers, technicians, and contractors.

- Data Acquisition: Collecting necessary data involves reviewing design documents, conducting field inspections, and performing laboratory testing. Effective data management is vital to ensure efficient analysis.

- Analysis & Reporting: Analyzing the collected data through appropriate engineering methods and providing clear, comprehensive reports that detail findings, conclusions, and recommendations. Our reports clearly outline the condition of the structure, highlight any deficiencies, and suggest appropriate remedial measures.

- Project Monitoring: Closely monitoring the progress of the project throughout its lifecycle is essential to ensure the work is proceeding as planned and within budget.

For larger projects, I utilize project management software to track progress, manage resources, and facilitate communication among team members. Transparent communication with the client at every stage is crucial to ensure their satisfaction and to address any arising issues promptly.

Q 21. How do you communicate technical information effectively to both technical and non-technical audiences?

Effective communication is a cornerstone of my professional practice. I tailor my communication approach to suit the audience:

- Technical Audiences: When communicating with fellow engineers or other technical professionals, I use precise technical language, diagrams, and detailed calculations to ensure accurate and complete information exchange. My reports and presentations are thorough, providing detailed justifications for my conclusions.

- Non-technical Audiences: When communicating with clients or non-technical stakeholders, I focus on conveying the essential information in a clear, concise, and easily understood manner. I avoid jargon, using simple language and visual aids like photographs and illustrative diagrams to facilitate comprehension. I focus on explaining the implications of the assessment findings in a way that is relevant to their needs and concerns.

For example, when presenting a complex assessment report to a client, I might begin with a high-level summary of the key findings, followed by a more detailed explanation for those interested in the technical aspects. Using analogies and real-world examples helps bridge the technical gap and ensures the client fully understands the recommendations and their implications.

Q 22. Describe your experience with preparing technical reports for concrete structural assessments.

Preparing comprehensive technical reports is a crucial part of my work. I meticulously document every stage of a concrete structural assessment, ensuring clarity and accuracy for stakeholders. This includes a detailed description of the project scope, methodology employed, findings, and recommendations. My reports typically follow a standardized format to ensure consistency and easy understanding.

- Executive Summary: A concise overview of the assessment’s key findings and recommendations.

- Methodology: A detailed explanation of the techniques and equipment used, such as non-destructive testing (NDT) methods like ultrasonic pulse velocity testing (UPV) or cover meter measurements, and destructive testing if needed.

- Findings: A thorough presentation of the data collected, including photographic evidence, diagrams, and tables. I always clearly identify areas of concern and potential structural deficiencies.

- Analysis: An interpretation of the collected data, supported by relevant codes and standards (e.g., ACI 318). This section often involves calculations and engineering judgments.

- Recommendations: Specific and actionable suggestions for repairs, strengthening, or further investigation, including cost estimates where appropriate.

- Appendices: Supporting documentation such as test results, calculations, and relevant standards.

For example, in a recent assessment of a multi-story building, my report included detailed UPV results showing significant degradation in several columns. This was supplemented with high-resolution images of the affected areas, allowing for clear visualization of the problem and facilitating informed decision-making by the client.

Q 23. How do you handle unexpected issues or challenges during a concrete assessment project?

Unexpected issues are inevitable in concrete assessment. My approach focuses on proactive planning and a systematic problem-solving methodology. This involves:

- Thorough Initial Assessment: Conducting a comprehensive initial inspection to identify potential risks and challenges upfront. This minimizes surprises later in the project.

- Contingency Planning: Developing a plan for dealing with potential unforeseen circumstances, such as encountering unexpected subsurface conditions or discovering hidden damage.

- Adaptability and Flexibility: Adjusting the assessment plan as needed based on new information gathered during the project. This might involve incorporating additional testing or analysis.

- Open Communication: Maintaining clear and consistent communication with the client and other stakeholders to keep them informed of any issues and proposed solutions. This is vital for maintaining trust and ensuring project success.

- Expert Consultation: If confronted with highly specialized issues outside my expertise, I don’t hesitate to consult with specialists in geotechnical engineering, materials science, or other relevant fields.

For instance, during the assessment of an older bridge, we unexpectedly discovered significant corrosion in the reinforcing steel. We adapted by incorporating additional corrosion mapping and detailed metallurgical analysis to accurately assess the extent of the damage and propose effective repair strategies.

Q 24. Explain your experience with different types of concrete mix designs and their properties.

My experience encompasses a wide range of concrete mix designs, from conventional to high-performance concrete (HPC). Understanding these designs is crucial for accurately assessing structural integrity.

- Conventional Concrete: This is the most common type, with varying water-cement ratios affecting strength and durability. Factors like aggregate type and size also influence properties.

- High-Performance Concrete (HPC): HPC often uses supplementary cementitious materials (SCMs) like fly ash or silica fume to improve strength, durability, and workability. These mixes are used in demanding applications where high strength and resistance to aggressive environments are crucial.

- Fiber-Reinforced Concrete (FRC): The inclusion of fibers, such as steel or synthetic fibers, enhances tensile strength and improves crack control, increasing the concrete’s resistance to impact and fatigue.

- Self-Consolidating Concrete (SCC): This type of concrete flows readily into complex formwork without segregation, minimizing labor costs and improving the structural quality in intricate structures.

In my work, I regularly analyze concrete mix designs provided by engineers and contractors, evaluating their suitability for the intended application. I also utilize laboratory testing data (compressive strength, slump, air content) to verify the actual properties and compare them to the design specifications. For example, identifying a mismatch between the specified and actual concrete strength in a building’s columns necessitates a thorough assessment of its load-carrying capacity.

Q 25. Describe your experience working with different types of concrete structures (e.g., buildings, bridges, pavements).

My experience extends across a diverse range of concrete structures. Each type presents unique challenges and requires specialized knowledge:

- Buildings: Assessments often focus on columns, beams, slabs, and foundations, evaluating issues such as cracking, corrosion, and deterioration due to exposure to various environmental factors.

- Bridges: Bridge assessments demand a thorough understanding of structural mechanics, considering live load effects, environmental exposure, and potential deterioration of the deck, piers, and abutments. Specialized techniques such as dynamic testing may be necessary.

- Pavements: Pavement assessments often involve evaluating cracking, rutting, and surface deterioration. Techniques like Falling Weight Deflectometer (FWD) testing can help assess pavement structural capacity.

A recent project involved the assessment of a historic bridge, which required integrating historical information, material testing, and advanced analysis techniques. Another project involved evaluating the structural integrity of a high-rise building’s foundation after experiencing minor seismic activity.

Q 26. How do you prioritize tasks and manage time effectively during a concrete assessment project?

Effective time and task management is essential for successful concrete assessment projects. My approach involves:

- Detailed Project Planning: Creating a comprehensive project schedule that outlines all tasks and their timelines, taking into account potential delays.

- Prioritization: Identifying critical tasks that must be completed first based on their impact on the overall assessment. This might involve focusing on areas of highest risk or those that require more extensive analysis.

- Resource Allocation: Efficiently allocating resources (personnel, equipment, testing) to minimize delays and optimize productivity.

- Regular Monitoring and Evaluation: Tracking progress against the schedule and making necessary adjustments to ensure timely completion. This often involves regular meetings with the project team to discuss progress, challenges, and solutions.

- Utilizing Technology: Employing project management software to help track progress, manage tasks, and communicate effectively with stakeholders.

In one project, we used a critical path method (CPM) to schedule the assessment of a large industrial facility. This allowed us to identify potential bottlenecks and implement strategies to minimize delays. By meticulously planning and monitoring, we successfully completed the assessment within the allotted time and budget.

Q 27. Explain your understanding of the principles of sustainable concrete construction.

Sustainable concrete construction is crucial for reducing the environmental impact of the construction industry. My understanding encompasses several key principles:

- Reducing Carbon Footprint: Using SCMs like fly ash, slag, and silica fume to reduce the amount of Portland cement needed. Portland cement production is a significant source of CO2 emissions. Exploring the use of alternative binders like geopolymers is also important.

- Resource Efficiency: Utilizing recycled aggregates and industrial byproducts in concrete mixes, reducing reliance on virgin materials. This conserves natural resources and reduces waste.

- Durability and Longevity: Designing durable concrete structures that minimize the need for future repairs and replacements, extending the lifespan of the structure and reducing material consumption over time.

- Lifecycle Assessment: Evaluating the environmental impact of concrete throughout its entire lifecycle, from material production to demolition and disposal. This helps identify areas for improvement in sustainability.

- Waste Management: Implementing efficient waste management strategies during construction and demolition to minimize environmental impact.

For example, I advise clients on incorporating sustainable practices like using low-carbon cement mixes and recycled aggregates to achieve LEED certification for their projects. This involves specifying the necessary concrete mix design and working closely with contractors to ensure proper implementation.

Q 28. Describe your experience with the use of advanced materials and techniques in concrete repair and strengthening.

Advanced materials and techniques play a significant role in modern concrete repair and strengthening. My experience includes:

- Fiber-Reinforced Polymers (FRP): Utilizing FRP materials like carbon fiber or glass fiber reinforced polymers for strengthening existing concrete structures. This involves bonding FRP sheets or wraps to the concrete surface to increase its tensile strength and flexural capacity.

- Injection Grouting: Employing injection grouting techniques to repair cracks, voids, or deteriorated sections within concrete elements. This involves injecting specialized epoxy resins or cement-based grouts to restore structural integrity.

- Shotcrete: Using shotcrete (pneumatically applied concrete) for repair and rehabilitation. This is an effective technique for repairing damaged sections of concrete structures, particularly in vertical or overhead locations.

- Self-Healing Concrete: Working with innovative self-healing concrete mixes that incorporate capsules containing healing agents that are released when cracks occur, automatically repairing small cracks.

- Nano-materials: Exploring the use of nano-materials such as nano-silica or nano-clay to enhance the strength, durability, and resistance to chemicals of concrete.

For instance, I successfully employed FRP strengthening to rehabilitate a cracked concrete beam in a building, restoring its load-carrying capacity and extending its service life. The choice of materials and techniques is highly dependent on the specific circumstances and requires detailed assessment and careful planning.

Key Topics to Learn for Concrete Structural Assessment and Evaluation Interview

- Visual Inspection Techniques: Understanding crack patterns, spalling, corrosion indicators, and other visual signs of distress in concrete structures. Practical application: Developing a systematic inspection protocol for a bridge deck.

- Non-Destructive Testing (NDT): Familiarity with methods like rebound hammer testing, ultrasonic pulse velocity testing, and ground-penetrating radar. Practical application: Selecting appropriate NDT methods based on the specific structural element and suspected damage.

- Material Properties and Behavior: Understanding the mechanical properties of concrete, including compressive strength, tensile strength, modulus of elasticity, and creep. Practical application: Using material property data to assess the remaining service life of a concrete structure.

- Structural Analysis Techniques: Applying principles of structural mechanics to analyze stresses, strains, and deflections in concrete structures. Practical application: Evaluating the load-carrying capacity of a damaged column using finite element analysis (FEA) or simplified methods.

- Repair and Rehabilitation Methods: Knowledge of various repair techniques, including patching, strengthening, and jacketing. Practical application: Recommending suitable repair strategies for a deteriorated beam based on cost-effectiveness and structural integrity.

- Code Compliance and Standards: Familiarity with relevant building codes and standards (e.g., ACI, Eurocodes) related to concrete structures. Practical application: Ensuring a proposed repair meets all applicable codes and regulations.

- Life Cycle Assessment and Service Life Prediction: Understanding methods for predicting the remaining service life of concrete structures. Practical application: Developing a maintenance plan to extend the life of a parking garage.

- Report Writing and Communication: Clearly communicating assessment findings and recommendations to clients and stakeholders. Practical application: Preparing a concise and comprehensive report summarizing the inspection, analysis, and recommended actions.

Next Steps

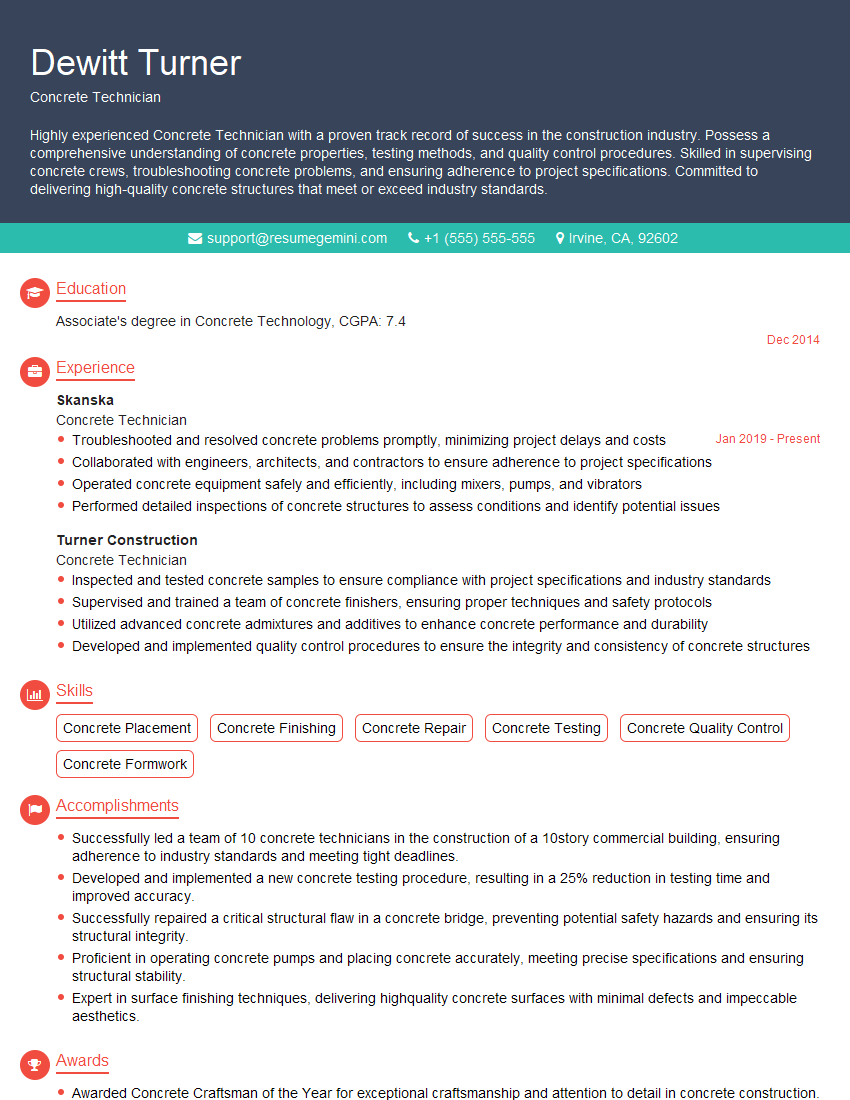

Mastering Concrete Structural Assessment and Evaluation opens doors to exciting career advancements, offering opportunities for specialization and leadership roles within the construction and engineering industries. To significantly boost your job prospects, crafting a compelling and ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume tailored to highlight your skills and experience in this field. Examples of resumes specifically designed for Concrete Structural Assessment and Evaluation roles are available to help you create a standout application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.