Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Operating Forklifts and Scissor Lifts interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Operating Forklifts and Scissor Lifts Interview

Q 1. What are the different types of forklifts and their applications?

Forklifts come in various types, each designed for specific tasks. The choice depends heavily on the load capacity, environment, and the type of material being handled. Here are some key examples:

- Counterbalance Forklifts: These are the most common type, using counterweights for stability. They’re versatile and used for various applications, from moving pallets in warehouses to transporting materials on construction sites. Think of them as the workhorses of the forklift world.

- Reach Trucks: These are excellent for narrow aisles, as the forks extend out horizontally. They’re frequently found in warehouses prioritizing space optimization.

- Sit-Down Rider Forklifts: These offer better control and comfort for extended use, especially in larger warehouses or outdoor areas. The operator sits while operating the machine.

- Stand-Up Rider Forklifts: Compact and maneuverable, these are ideal for smaller spaces or quick tasks. The operator stands while operating the machine.

- Order Pickers: Designed for high-level picking in warehouses, these allow operators to reach high shelves with their loads safely.

- Side Loaders: These handle long, bulky loads which may be difficult or impossible to handle with a traditional forklift. Often seen handling lumber or pipes.

The application ultimately dictates the best forklift type. For example, a reach truck would be ideal in a narrow-aisle warehouse, while a counterbalance forklift is better suited for outdoor loading docks.

Q 2. Explain the pre-operational checks you perform on a forklift.

Pre-operational checks are crucial for safety and to prevent equipment damage. Before even starting the engine, I always follow this checklist:

- Visual Inspection: Check for any visible damage to the forklift – including tires, forks, lights, mast, and body. Look for leaks and any signs of wear and tear.

- Fluid Levels: Inspect engine oil, transmission fluid, hydraulic fluid, and coolant levels. Ensure they are within the recommended ranges.

- Tires: Check tire pressure and look for any cuts, punctures, or excessive wear. Proper inflation is vital for stability and safe operation.

- Lights and Signals: Verify that all lights (headlights, brake lights, turn signals, and backup lights) are functioning correctly.

- Horn: Test the horn to ensure it’s working properly – a crucial safety feature.

- Brakes: Test the brakes for responsiveness and effectiveness. The brakes are the most important safety feature of the machine.

- Steering: Check for smooth and responsive steering. Any binding or unusual noises should be addressed before operation.

- Forks: Ensure the forks are straight, undamaged, and securely attached. Check for any excessive play or looseness.

- Safety Features: Verify that safety features such as the seat belt, parking brake, and emergency stop are in good working order.

By diligently completing these checks, I significantly reduce the risk of accidents and ensure the forklift is operating efficiently and safely.

Q 3. Describe the proper procedures for loading and unloading cargo.

Loading and unloading cargo requires a systematic approach to prioritize safety and efficiency. Here’s the procedure I follow:

- Assessment: Before starting, assess the load’s weight, dimensions, and center of gravity. Ensure it’s within the forklift’s capacity.

- Positioning: Position the forklift close to the cargo, ensuring a stable and level surface. Avoid unstable ground or inclines.

- Fork Placement: Carefully position the forks under the load, ensuring even weight distribution. Avoid damaging the load by inserting forks too deeply or unevenly.

- Lifting: Slowly lift the load, ensuring it’s balanced and secure. Maintain slow and controlled movements to avoid tipping or dropping the load.

- Transportation: Drive carefully and slowly, maintaining a safe distance from pedestrians and other equipment. Avoid sudden stops or turns.

- Unloading: Carefully lower the load to the designated area, again ensuring stability and even weight distribution.

- Post-Operation: Once complete, carefully return the forks to the lowered position and ensure the surrounding area is clear before shutting down.

For example, when loading pallets, I always make sure the forks are fully inserted and evenly centered under the pallet to prevent tilting or damage.

Q 4. How do you ensure the safety of pedestrians and other equipment while operating a forklift?

Ensuring the safety of pedestrians and other equipment is paramount. I employ several strategies:

- Visual Signals: Always use horn and lights to signal my intentions – especially when approaching intersections or tight corners.

- Speed Control: Maintain a slow, controlled speed, especially in areas with high pedestrian traffic.

- Awareness: Constantly scan my surroundings for pedestrians, other equipment, and obstacles. Avoid blind spots as much as possible.

- Designated Routes: Follow designated routes to minimize conflicts with pedestrian traffic and other equipment.

- Communication: Communicate effectively with pedestrians and other equipment operators to coordinate movements.

- Backup Signals: Use a backup alarm and spotter when operating in reverse, particularly in areas with limited visibility.

- Safety Training: Regular safety training reinforces safe operating practices for everyone in the workplace.

A clear example of this is using a spotter when operating in an area with poor visibility. They can help avoid collisions and alert me to potential hazards I might miss.

Q 5. What are the load capacity limits and how do you determine them?

Load capacity limits are crucial for safety and are clearly specified on the forklift’s data plate. This plate usually provides the maximum load weight the forklift can safely lift at various mast heights. I never exceed these limits.

To determine the load capacity, I always refer to the data plate located on the forklift itself. This plate clearly shows the maximum weight the forklift can handle at different mast heights. It’s crucial to understand that the capacity decreases as the load is lifted higher. Factors such as the load’s center of gravity and the type of load also influence the actual safe lifting capacity.

For example, a forklift might have a capacity of 5,000 lbs at ground level but only 3,000 lbs at its maximum lift height. Ignoring these limits could result in severe accidents. I always double-check before attempting to lift any load.

Q 6. What are the common causes of forklift accidents and how can they be prevented?

Forklift accidents often stem from preventable causes. Some of the most common include:

- Speeding and Reckless Operation: Operating at unsafe speeds, making sharp turns, or failing to maintain control are major factors.

- Improper Load Handling: Overloading the forklift, improper load securing, or uneven weight distribution significantly increases the risk of accidents.

- Lack of Training: Inadequate training on safe operation techniques and forklift maintenance greatly increases the risk of accidents.

- Poor Maintenance: Failing to maintain the forklift regularly, leading to mechanical failures, is a major safety risk.

- Poor Visibility: Operating in areas with poor visibility increases the chances of collisions.

- Ignoring Safety Rules: Neglecting safety procedures and ignoring warning signs is a significant factor in forklift accidents.

Preventing accidents requires a multifaceted approach, including comprehensive training, regular maintenance, adherence to safety regulations, and promotion of a strong safety culture within the workplace. Regular inspections, clear communication, and a commitment to safety from all employees are paramount.

Q 7. Explain the different types of scissor lifts and their uses.

Scissor lifts, unlike forklifts, are primarily designed for vertical lifting of personnel and materials. Several types exist:

- Electric Scissor Lifts: These are powered by electricity and are commonly used indoors due to their clean and quiet operation. Ideal for warehouses and indoor construction.

- Hydraulic Scissor Lifts: These utilize hydraulic systems for lifting and are often used both indoors and outdoors, offering greater lifting capacities than electric scissor lifts. These can be used for outdoor maintenance and construction work.

- Rough Terrain Scissor Lifts: Designed for uneven surfaces, these have larger tires and improved stability, suitable for construction sites or outdoor maintenance.

- Push-Around Scissor Lifts: These smaller, manually operated lifts are ideal for lighter tasks and confined spaces.

The choice depends on the work environment and the required lift height and capacity. For instance, an electric scissor lift would be suitable for indoor warehouse maintenance, while a rough terrain scissor lift would be better suited for outdoor construction projects.

Q 8. What safety precautions do you take when operating a scissor lift at height?

Operating a scissor lift at height demands meticulous adherence to safety protocols. Before even ascending, I always ensure the lift is properly positioned on a stable, level surface, away from any obstacles or power lines. I thoroughly inspect the platform and all safety mechanisms – including the emergency stop button, guardrails, and outrigger deployment (if applicable) – confirming they are in perfect working order. Once in the lift, I wear a safety harness attached to a secure anchor point and remain aware of my center of gravity at all times, avoiding sudden movements. I never exceed the lift’s weight capacity and always remain within the platform’s boundaries. During operation, maintaining three points of contact on the platform is crucial. Before descending, I ensure all tools and materials are secured, and the platform is clear. Regularly checking the surroundings for hazards and maintaining clear communication with ground personnel completes my height-specific safety routine. For example, on a recent project, I noticed a loose railing before ascent, reporting it immediately and halting work until it was repaired. This proactive approach prevents accidents.

Q 9. How do you handle uneven terrain or slopes while operating a forklift?

Navigating uneven terrain or slopes with a forklift requires a cautious and methodical approach. The primary safety precaution is assessing the terrain before moving. I check for significant inclines, potholes, debris, and soft spots that could compromise stability. I adjust my speed accordingly— slower speeds are essential on uneven surfaces. I avoid sharp turns, abrupt braking, and sudden movements that could cause the forklift to tip. I always ensure the load is appropriately secured and centered to maintain the forklift’s balance. If the incline exceeds the forklift’s safe operating angle (typically specified in the operator’s manual), I will not proceed with the lift. Thinking of it like driving a car on a snowy road; I would slow down and be extra careful. One time, I encountered a small incline that was manageable, but I proceeded at a significantly slower speed than normal and carefully positioned the load to keep the center of gravity low. This careful execution prevented any instability.

Q 10. What is your experience with different types of forklift attachments?

My experience with forklift attachments is extensive. I’m proficient with various attachments, including side-shifters, clamps, forks, rotators, and special purpose attachments like carton clamps or bale clamps. Each attachment requires different operating procedures and safety considerations. For instance, using a side-shifter requires precise control to avoid damaging the load or the surrounding environment. Clamp attachments require specific knowledge on load securing and weight distribution. Understanding the capabilities and limitations of each attachment is crucial to avoid accidents and ensure efficient operation. I always double-check the securement of any attachment before operation, and consult the operator’s manual for specific instructions for each. In one job, we used a rotating clamp to efficiently position large rolls of material onto racks, significantly speeding up the process while ensuring load stability.

Q 11. Describe your experience with maintaining forklift operational logs and records.

Maintaining accurate operational logs and records is a crucial part of responsible forklift operation. I meticulously record each operation, including the date, time, operator’s name, machine identification number, type of work performed, loads handled, and any incidents or near misses. I also document any maintenance or repairs undertaken on the forklift. These records are essential for tracking performance, identifying potential mechanical issues early on, and meeting regulatory compliance requirements. For example, I use a digital logbook app to ensure accurate and readily available data. This is vital for preventative maintenance scheduling and demonstrating operational safety. The detailed record keeping prevents potential safety issues and makes tracking forklift usage and identifying any patterns or problems easier for future operations.

Q 12. How do you respond to mechanical problems or malfunctions?

Responding to mechanical problems or malfunctions requires a methodical approach. I would first assess the situation to ensure safety – turning off the machine if necessary and removing myself from any hazardous positions. Next, I identify the problem, if possible, without attempting any unauthorized repairs. If the malfunction is minor and I have the necessary training, I may be able to safely address it. However, for significant problems, I immediately report the issue to the designated maintenance personnel and follow the company’s established procedures for reporting equipment malfunctions. I never attempt to operate a forklift with a known mechanical problem. Once, I experienced a sudden loss of hydraulic pressure. I immediately stopped the forklift, followed company protocol, reported the issue, and awaited trained technicians. This ensured that no damage was done to the machinery or caused an accident.

Q 13. What is your experience with using load stabilizers or other safety devices?

My experience with load stabilizers and other safety devices is extensive. I’m familiar with various types of stabilizers, including forks with load backrest extensions, load stabilizers for specific materials, and load securing straps and chains. I always utilize the appropriate safety devices based on the type of load and the operating environment. For example, when lifting unstable loads, I would employ load backrest extensions or stabilizing chains, to prevent the load from tipping over. The proper use of load stabilizers is crucial for safe and efficient operation, minimizing risks of accidents or damage. I’ve seen firsthand the importance of using these – during one instance, using load stabilizers prevented a pallet of heavy materials from shifting during transport, avoiding a potential accident.

Q 14. How do you handle emergency situations while operating a forklift or scissor lift?

Responding to emergency situations while operating a forklift or scissor lift involves prioritizing safety. My immediate action would be to stop the machine safely. Next, I’d assess the nature of the emergency – is it a mechanical malfunction, a collision, a fire, or something else? Based on the situation, I would take appropriate action such as activating the emergency stop, contacting emergency services (if necessary), evacuating the area, and securing the machine. If someone is injured, I would provide first aid as trained and alert emergency responders. Having a clear understanding of emergency procedures, knowing the location of emergency shut-off switches and exits, and maintaining open communication are all essential for a safe response to any situation. In training, we practiced various emergency scenarios, helping me develop a quick and efficient response plan. Preparedness is key to handling any unforeseen emergency effectively.

Q 15. What is your understanding of OSHA regulations related to forklift and scissor lift operation?

OSHA regulations concerning forklift and scissor lift operation are paramount for workplace safety. They cover a wide range of aspects, from operator training and certification to equipment maintenance and safe operating procedures. For example, OSHA mandates that operators must be properly trained and certified before operating any powered industrial truck. This training covers pre-operation inspections, safe load handling techniques, and awareness of potential hazards. Further regulations address the safe use of seatbelts, the importance of load stability, and restrictions on operating forklifts in certain conditions, such as near drop-offs or on uneven surfaces. Regular inspections of the equipment are also mandatory, focusing on areas like brakes, steering, and load capacity indicators. Failure to comply with these regulations can lead to severe penalties, including fines and even workplace shutdowns.

In my experience, a thorough understanding of OSHA regulations isn’t just about avoiding penalties; it’s about fostering a culture of safety. I’ve seen firsthand how a well-trained and conscientious operator can prevent accidents, protecting both themselves and their colleagues.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the stability of loads during transportation?

Ensuring load stability is crucial to prevent accidents. It involves several key steps: first, I always assess the load’s weight and dimensions. Knowing the load’s center of gravity is paramount, as this significantly influences stability. This is followed by carefully selecting the appropriate forklift for the job—the load’s weight must be well within the forklift’s rated capacity.

Before lifting, I make sure the forks are evenly positioned beneath the load, ensuring it’s balanced. During transportation, I maintain a slow, controlled speed, avoiding sudden stops or turns. I also avoid driving over uneven terrain or inclines as much as possible. Finally, I always check the load’s stability before setting it down. If the load feels unstable, I readjust its placement, ensuring that it rests securely. For example, I once had to transport a long, oddly shaped piece of machinery. To ensure stability, I used chains to secure it properly and only moved at a walking pace.

Q 17. Describe your experience with working in a warehouse environment.

I have extensive experience working in various warehouse environments, from small distribution centers to large fulfillment facilities. My roles have included operating both forklifts and scissor lifts, loading and unloading trucks, and maintaining inventory accuracy. I’m familiar with different warehouse management systems, including RF scanning and inventory control software. I’ve worked with diverse teams and have adapted quickly to various warehouse layouts and operational procedures. The experience has provided me with a comprehensive understanding of warehouse efficiency and safety protocols. I am particularly adept at navigating tight spaces and optimizing workflow to maximize productivity while maintaining a safe working environment.

One memorable experience involved optimizing the layout of a small warehouse. By analyzing traffic flow and storage patterns, we were able to increase efficiency by 15%. This illustrates my ability to observe inefficiencies and create solutions that improve productivity while adhering to safety regulations.

Q 18. What are the different types of forklift fuel sources and their maintenance?

Forklifts utilize several fuel sources, each with unique maintenance needs. Common types include gasoline, propane (LPG), diesel, and electric. Gasoline forklifts are powerful but require regular oil changes, air filter cleaning, and spark plug replacements. Propane forklifts offer cleaner emissions and require tank inspections and valve maintenance. Diesel forklifts are powerful and fuel-efficient but need more frequent oil changes and filter replacements. Electric forklifts are the cleanest and quietest, requiring battery charging and regular fluid level checks. However, the batteries have a limited lifespan and require periodic replacement.

In my experience, preventive maintenance is crucial. Ignoring minor issues can quickly lead to major breakdowns. A regular maintenance schedule—tailored to the specific type of forklift and its usage—ensures optimal performance and extends the equipment’s lifespan. This also includes regular inspections of all safety features, such as lights, horns, and brakes.

Q 19. How do you calculate the center of gravity for a load?

Calculating the center of gravity (CG) for a load is crucial for safe handling. The CG is the point where the weight of the load is evenly distributed in all directions. For simple rectangular loads, the CG is simply the geometric center. However, for irregularly shaped loads, it’s more complex. One method involves suspending the load from different points and observing where the load balances. The point of balance represents the CG. Alternatively, you can use a precise weighing scale, weighing the load at different points to calculate the CG using physics formulas.

In practice, understanding the CG helps me to determine the best method to handle and transport loads safely and efficiently. Loads with high CGs are more prone to tipping, requiring additional care and potentially specialized equipment.

Q 20. Explain the importance of regular maintenance for forklifts and scissor lifts.

Regular maintenance for forklifts and scissor lifts is not just a good practice; it’s essential for safety and efficiency. It minimizes the risk of equipment failure, preventing accidents and downtime. Scheduled maintenance includes checking fluid levels (hydraulic fluid, engine oil, coolant), inspecting tires and brakes, ensuring the proper operation of safety devices (horn, lights, seatbelts), and verifying the condition of the forks or platform. The frequency of maintenance depends on the type of equipment and its usage intensity. For example, a forklift operating in a demanding environment might require more frequent inspections than one used in a less strenuous setting.

Neglecting maintenance can lead to costly repairs, potential injuries, and damage to goods. A well-maintained machine is reliable, more fuel-efficient (for combustion engines), and works better, directly contributing to productivity.

Q 21. How familiar are you with different types of warehouse layouts and traffic patterns?

I’m very familiar with various warehouse layouts and traffic patterns. I’ve worked in facilities with narrow aisles, wide-open spaces, and complex racking systems. I understand the importance of following designated traffic routes, maintaining a safe speed, and yielding to pedestrians and other equipment. I’m also aware of how different layouts can impact efficiency, and I’m adept at adapting to various arrangements. For example, in a facility with narrow aisles, I’m careful to maintain a safe distance from racking units and avoid sudden turns. In a facility with high traffic, I’m particularly vigilant and cautious.

Understanding warehouse layouts is crucial for efficient and safe operation. It allows me to anticipate potential hazards and avoid collisions, optimizing productivity without compromising safety.

Q 22. What is your experience working with warehouse management systems (WMS)?

My experience with Warehouse Management Systems (WMS) is extensive. I’ve worked with several different systems, including Oracle WMS and Blue Yonder. My role often involves using the WMS to receive and locate inventory, track shipments, manage stock levels, and generate picking lists. For example, I’ll receive a picking list from the WMS detailing the specific items, quantities, and locations needed for an order. I then use this information to efficiently locate the items using my forklift, ensuring accuracy and minimizing picking time. Understanding the WMS is crucial for optimizing workflow and productivity within the warehouse. I’m proficient in using the system’s reporting features to identify areas for improvement in processes and to troubleshoot any discrepancies.

Q 23. Describe your experience with using hand signals or communication devices during operation.

Effective communication is paramount in warehouse environments. I’m highly proficient in using both hand signals and communication devices. Standard hand signals, such as those for backing up, stopping, and indicating direction, are second nature to me. This is particularly critical in areas where radio communication might be difficult or where immediate visual cues are needed for safety. In addition to hand signals, I’m experienced in utilizing two-way radios to communicate with warehouse personnel, supervisors, and other equipment operators. This helps to coordinate movements, avoid collisions, and ensure efficient workflow. For example, I’ll use the radio to inform others when I’m approaching an intersection or navigating a narrow aisle. Clear and concise communication prevents accidents and streamlines operations.

Q 24. How do you handle situations where you encounter a malfunctioning lift?

If I encounter a malfunctioning lift, my immediate priority is safety. I’ll immediately shut down the machine and secure it to prevent further incidents or accidents. Then, depending on the nature of the malfunction, my actions will vary. If it’s a minor issue, such as a low-fuel warning, I’ll follow established procedures to refuel or address the problem. For more significant malfunctions, like hydraulic leaks or unusual noises, I’ll immediately report the problem to my supervisor, following company protocol. I will not attempt any repairs myself unless specifically trained and authorized to do so. Documentation of the malfunction and the subsequent steps taken is crucial for maintenance and safety records. For instance, I once experienced a sudden loss of power on a forklift mid-lift. Following protocol, I immediately engaged the emergency brake, assessed the situation, and notified my supervisor before leaving the machine and reporting the incident.

Q 25. What are the limitations of scissor lifts?

Scissor lifts, while versatile for reaching heights, have certain limitations. Their primary limitation is their relatively small platform size, which restricts the amount of weight and the number of people that can be lifted simultaneously. Their reach is also limited by their height and the stability of the base. Uneven terrain significantly impacts stability and can prevent safe operation. Furthermore, scissor lifts are typically not suited for heavy loads or outdoor work in harsh weather conditions. They also have limitations in maneuverability, requiring more space to turn and operate compared to forklifts. For instance, a scissor lift wouldn’t be appropriate for moving heavy pallets in a narrow warehouse aisle. Instead, a forklift is the best choice for that purpose.

Q 26. Explain your experience with different types of pallet configurations.

I’m familiar with various pallet configurations, including standard, double-deep, and block stacking. Understanding these configurations is critical for efficient storage and retrieval. Standard pallets are easy to handle, while double-deep requires more precise forklift maneuvering to avoid damage. Block stacking maximizes space utilization but demands careful planning and execution to prevent collapse. For example, when dealing with double-deep pallets, I use a slower, more cautious approach to ensure both pallets are moved safely and accurately. Improper handling of these diverse configurations can lead to pallet damage, product damage, and even injuries. Proficiency in handling various pallet types is vital for optimizing warehouse space and productivity.

Q 27. How do you ensure visibility while operating a forklift in a busy warehouse?

Maintaining visibility in a busy warehouse is crucial for safety. Before beginning any operation, I conduct a thorough visual check of my surroundings, including checking blind spots. I use my mirrors frequently, especially when backing up or making turns. I also slow down in congested areas and use my horn or two-way radio to announce my presence and intended movements. Additionally, I am trained and always prioritize maintaining a safe operating distance from other workers and equipment. For example, I will always yield to pedestrian traffic and actively look out for individuals working in areas where I’m moving equipment. Keeping a clear understanding of my surroundings is the primary method to prevent accidents.

Q 28. How do you adapt to different working conditions, such as temperature or lighting?

Adapting to different working conditions is part of my everyday routine. Extreme temperatures, both hot and cold, can affect equipment performance and operator comfort. In hot conditions, I stay hydrated and take regular breaks to avoid heat exhaustion. In cold conditions, I wear appropriate layers of clothing to stay warm and avoid hypothermia. Varying lighting conditions also demand attention. I adjust my speed and operating techniques to ensure visibility and safety, using additional lighting on the lift when needed, especially during low-light hours or in poorly lit areas of the warehouse. Staying aware of these factors and proactively taking measures to compensate helps maintain safety and productivity.

Key Topics to Learn for Operating Forklifts and Scissor Lifts Interview

- Safe Operation Procedures: Understanding and applying all safety regulations, pre-operation checks, and emergency procedures for both forklifts and scissor lifts. This includes recognizing and avoiding potential hazards.

- Equipment Functionality: Detailed knowledge of the controls, mechanisms, and operational capabilities of different forklift and scissor lift models. This includes understanding load capacity limitations and safe operating speeds.

- Load Handling and Stability: Mastering techniques for safely loading, transporting, and unloading various materials using both forklifts and scissor lifts, considering weight distribution and balance to prevent accidents.

- Maintenance and Inspection: Familiarity with routine maintenance checks, identifying potential mechanical issues, and reporting any necessary repairs. Understanding the importance of preventative maintenance.

- Workplace Safety Regulations: Thorough understanding of OSHA (or relevant regional) regulations pertaining to the operation of forklifts and scissor lifts, including personal protective equipment (PPE) requirements.

- Practical Application: Be prepared to discuss real-world scenarios involving load handling, maneuvering in confined spaces, and responding to unexpected situations (e.g., equipment malfunction, obstructed pathways).

- Problem-Solving: Demonstrate your ability to think critically and solve problems related to equipment operation, load stability, and safety concerns. Be ready to explain your decision-making process.

Next Steps

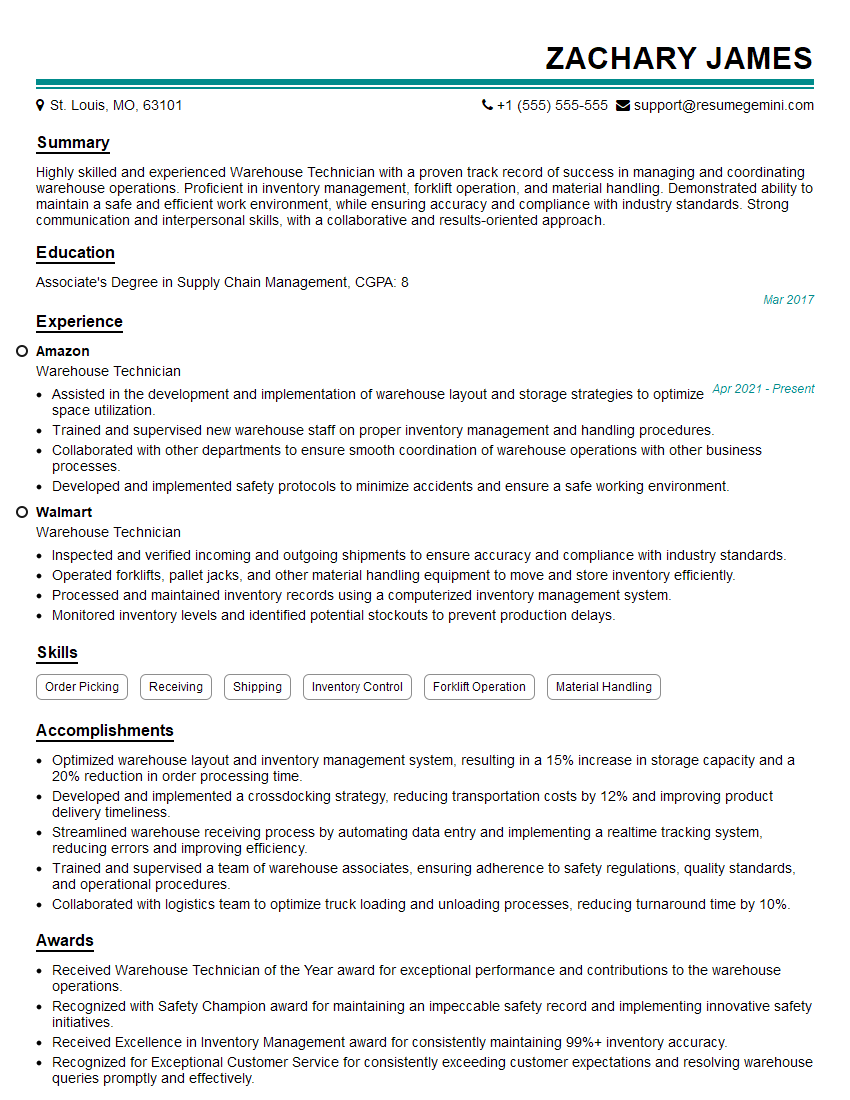

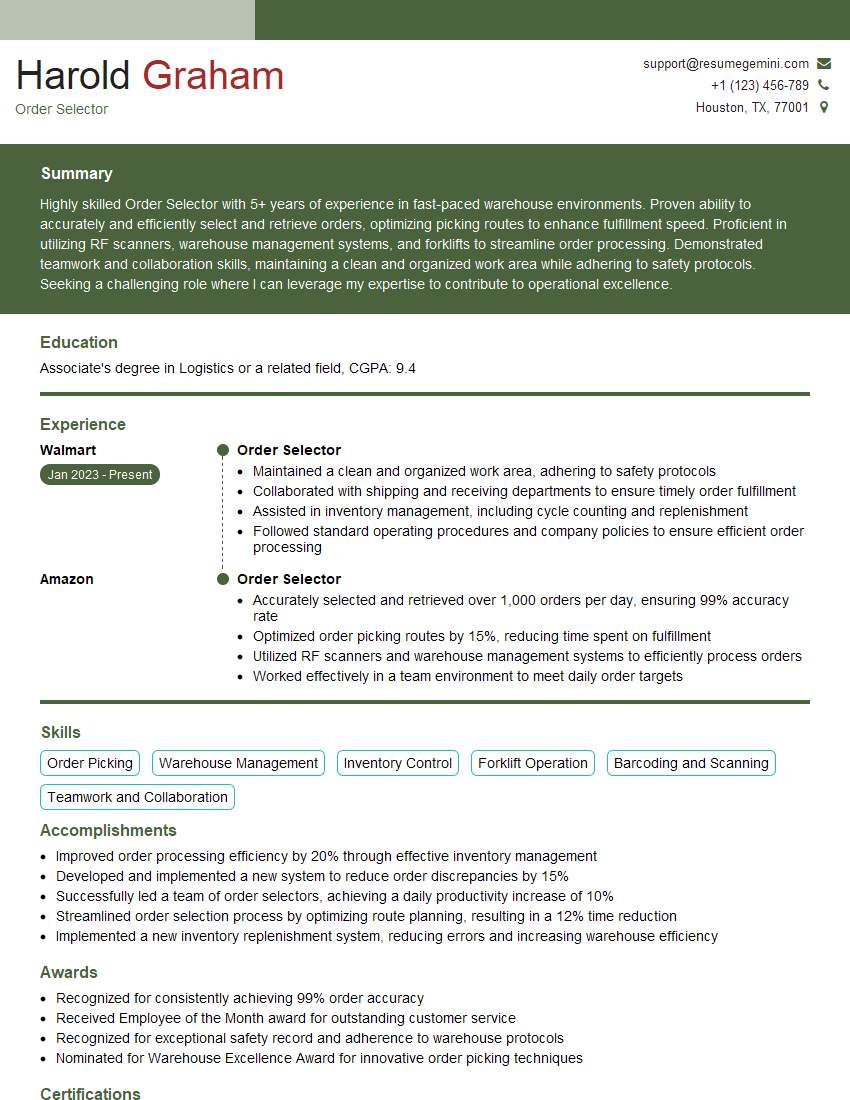

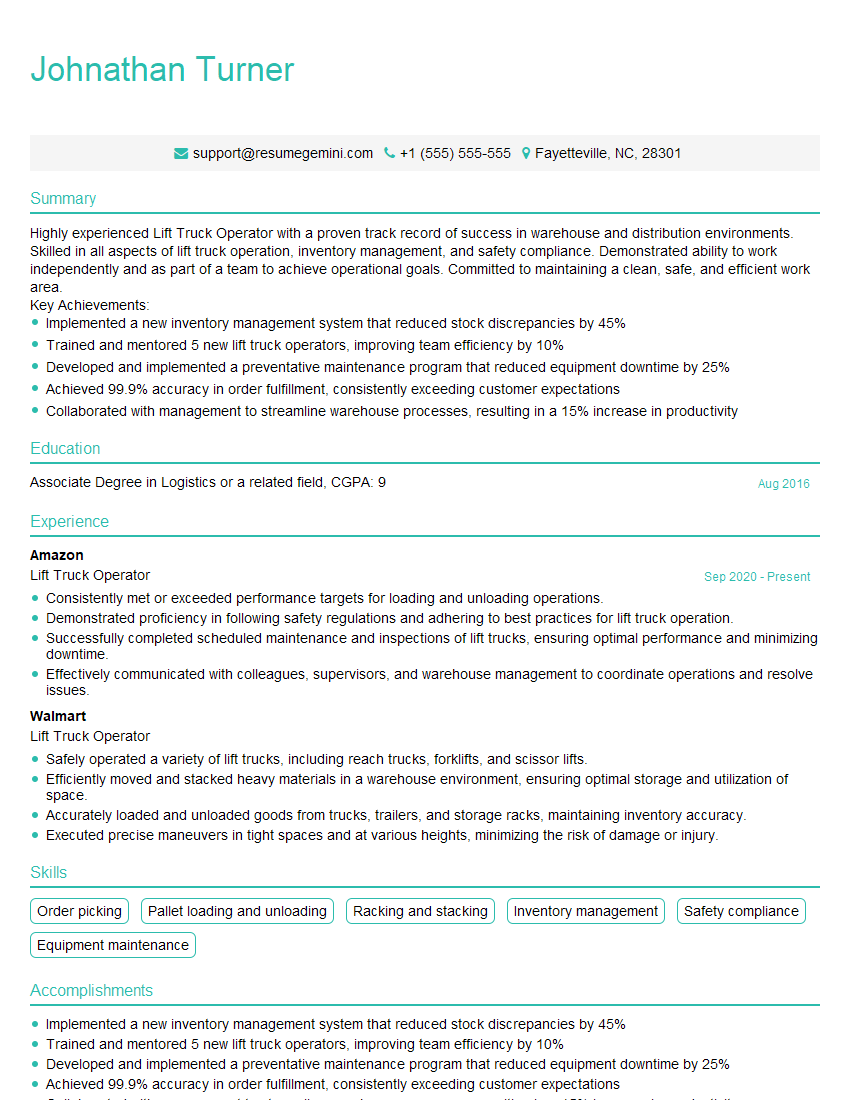

Mastering the operation of forklifts and scissor lifts opens doors to numerous career opportunities in logistics, warehousing, and construction, offering growth potential and competitive salaries. To maximize your job prospects, it’s crucial to present your skills effectively. Crafting an ATS-friendly resume is key to getting your application noticed. ResumeGemini can help you build a professional and impactful resume that highlights your expertise. We provide examples of resumes tailored specifically to Operating Forklifts and Scissor Lifts operators to guide you through the process. Let ResumeGemini help you land your dream job!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.