Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Ability to work in a clean environment interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Ability to work in a clean environment Interview

Q 1. Describe your experience maintaining a clean and organized workspace.

Maintaining a clean and organized workspace is paramount to my efficiency and productivity. It’s not just about aesthetics; it’s about creating a safe and effective environment. In my previous role at a pharmaceutical lab, for instance, meticulous organization was crucial to prevent cross-contamination and ensure accurate results. My approach involves a multi-pronged strategy: daily tidying to address immediate clutter, weekly deep cleaning of specific areas, and monthly comprehensive organization checks. This ensures a consistently clean and efficient space. I utilize color-coded containers for different types of materials and label everything clearly, allowing for quick location and retrieval of items.

For example, I’d dedicate the start of each day to clearing my desk, arranging materials in logical order, and disposing of unnecessary documents. At the end of each week, I’d conduct a more thorough cleaning, including wiping down surfaces and vacuuming the floor. Monthly, I’d reorganize cabinets and shelves to optimize storage and ensure proper airflow.

Q 2. How do you prioritize tasks to ensure a clean and efficient workflow?

Prioritizing tasks for a clean and efficient workflow requires a methodical approach. I employ a combination of techniques, including time management methodologies like the Eisenhower Matrix (urgent/important), and a visual task management system (Kanban boards or checklists). I begin by identifying high-impact cleaning tasks – those that significantly affect safety or workflow – and prioritize them. Then, I break larger tasks down into smaller, manageable steps. This approach helps avoid feeling overwhelmed and ensures consistency.

For example, if a spill occurs, cleaning it immediately takes priority over other tasks. However, if we have a routine weekly deep clean, I’d schedule specific times for each zone, ensuring no one area gets neglected. I find this combination prevents procrastination and allows for better resource allocation.

Q 3. What are your preferred methods for cleaning different types of surfaces?

My cleaning methods vary depending on the surface. For delicate surfaces like glass or polished wood, I use a soft, lint-free cloth and a gentle, pH-neutral cleaner. For more robust surfaces like stainless steel or countertops, I can use stronger disinfectants. I always pre-test any cleaning solution on an inconspicuous area to avoid damage. For electronic equipment, I use compressed air and anti-static wipes. For fabric surfaces, I vacuum or spot-clean with appropriate solutions. I always follow the manufacturer’s instructions for cleaning agents and avoid mixing different products.

For instance, cleaning a microscope requires a specialized approach, using lens cleaning solution and appropriate brushes to prevent scratching the lenses. Conversely, cleaning a laboratory bench might involve a more robust disinfectant to maintain sterility.

Q 4. What safety precautions do you take when handling cleaning supplies?

Safety is paramount when handling cleaning supplies. I always wear appropriate personal protective equipment (PPE), including gloves and eye protection, to minimize exposure to chemicals. I read and follow all safety data sheets (SDS) before using any cleaning agent and store chemicals properly, away from food and out of reach of unauthorized personnel. I properly label all containers and dispose of cleaning supplies according to regulations. I ensure adequate ventilation when working with strong chemicals. I also take measures to prevent accidental spills or exposure, such as using spill trays and securing containers during transportation.

In my previous role, we had regular safety training sessions covering the proper handling of hazardous materials. This training emphasized the importance of meticulous attention to SDS information, proper PPE, and safe disposal procedures.

Q 5. How do you handle spills or unexpected messes in a clean environment?

Handling spills or unexpected messes requires immediate action. My first step is to assess the situation and determine the type of spill and potential hazards. I then proceed to contain the spill using absorbent materials and prevent further spread. I clean the area thoroughly using appropriate cleaning agents, paying attention to any residue or lingering contamination. Depending on the nature of the spill (e.g., biohazard, chemical spill), additional protocols may be necessary. I always document the incident, including the time, location, type of spill, and the remediation steps taken.

For example, a chemical spill would require a different approach than a food spill. A chemical spill might necessitate evacuation of the area, specific neutralizing agents, and a more thorough cleanup according to established emergency procedures.

Q 6. Explain your understanding of proper sanitation techniques.

Proper sanitation techniques involve eliminating or reducing harmful microorganisms (bacteria, viruses, fungi) to a safe level. This includes cleaning (removal of visible dirt and debris), disinfection (killing or inactivating microorganisms), and sterilization (complete elimination of all microorganisms). The specific technique depends on the area and the level of contamination. For example, regular handwashing is a basic sanitation technique, while sterilization is required for surgical instruments. The selection of disinfectants varies depending on the microorganisms being targeted.

Understanding the difference between cleaning and disinfecting is crucial. Cleaning removes visible dirt, but disinfection reduces the number of pathogens. Sterilization goes further, eliminating all microorganisms.

Q 7. How familiar are you with cleanroom protocols and procedures?

I have a good understanding of cleanroom protocols and procedures, having worked in environments requiring controlled contamination. My familiarity includes understanding the importance of gowning procedures, maintaining appropriate airflow, minimizing particle generation, and following strict cleaning and disinfection schedules. I understand the different ISO classifications for cleanrooms and the associated requirements. My knowledge extends to the use of specialized cleaning agents and equipment commonly employed in cleanroom environments, including HEPA-filtered vacuum cleaners and validated cleaning methods. I am also familiar with environmental monitoring techniques and documentation procedures required to maintain cleanroom certification.

For example, I understand the importance of following a specific gowning sequence, including the correct order of donning and removing garments, to minimize the risk of particle shedding within the cleanroom. I am familiar with various cleaning validation techniques and the importance of documentation for regulatory compliance.

Q 8. Describe your experience with personal protective equipment (PPE) in a clean environment.

My experience with personal protective equipment (PPE) in clean environments is extensive. I understand that the type of PPE required depends heavily on the specific environment and the potential hazards. In a cleanroom setting, for instance, I’m very familiar with using cleanroom suits, including coveralls, gloves, booties, and masks. These are crucial to preventing contamination from my own person. In other clean environments, such as those involving handling chemicals, I’ve utilized safety glasses, lab coats, and specialized gloves designed for chemical resistance. My approach is always proactive; I meticulously inspect all PPE before use and ensure it is properly donned and doffed to maintain the integrity of the clean environment. I’ve also participated in regular training on PPE use and disposal, emphasizing proper procedures to prevent cross-contamination.

For example, during my time at [Previous Company Name], I worked in a pharmaceutical cleanroom where the use of appropriate PPE was strictly enforced and monitored. Any breaches in procedure resulted in immediate corrective action, training reiteration and increased vigilance. This rigorous adherence to protocol ensured product sterility and workplace safety.

Q 9. How do you maintain a clean and organized workspace while working under pressure?

Maintaining a clean and organized workspace under pressure requires discipline and a proactive approach. I utilize a system of 5S – Sort, Set in Order, Shine, Standardize, and Sustain. This lean methodology helps me prioritize tasks and manage my workspace effectively, even during peak workload. The key is to anticipate clutter and address it immediately. For example, I often clean and organize my immediate work area at the end of each task, rather than letting things pile up. This prevents build-up of potentially contaminating materials. I also maintain a dedicated space for each tool and material to minimize searching and maximize efficiency.

Think of it like a well-organized kitchen – when everything has its place, you can work quickly and efficiently, even when under pressure to prepare a meal. In my experience, a clean and organized workspace significantly reduces the risk of errors and promotes faster, more accurate work, regardless of pressure.

Q 10. How do you address issues with cleanliness or sanitation standards?

Addressing cleanliness or sanitation issues requires a systematic approach. My first step is always to identify the root cause of the problem. Is it a procedural issue? Equipment malfunction? Lack of training? Once the cause is understood, I implement corrective actions, starting with immediate remediation. This might involve deep cleaning the affected area, replacing contaminated materials, or reporting a malfunctioning piece of equipment. Following remediation, I focus on preventative measures to prevent recurrence, which often involves refining protocols, providing additional training, or implementing improved quality control checks. I firmly believe in documenting all issues, corrective actions, and preventative measures to ensure continuous improvement in our cleanroom practices.

For instance, if I notice a spill, I wouldn’t just clean it up, I would also investigate the cause (e.g., leaky container, improper handling) and implement solutions to prevent future occurrences, possibly including improved container sealing or additional training on handling procedures.

Q 11. What are your strategies for preventing contamination in a clean environment?

Preventing contamination in a clean environment requires a multi-faceted approach. This starts with understanding the specific contamination risks within the given environment. We then implement control measures, including strict adherence to gowning protocols (detailed above), proper cleaning and disinfection procedures, regular air quality monitoring, and controlled access to the area. Airflow management, including laminar flow hoods and HEPA filters is also vital in certain settings. Furthermore, regular training and awareness programs are crucial to ensure that all personnel understand and follow established protocols. Maintaining a positive pressure environment is also critical, preventing outside contaminants from entering.

A simple analogy would be a hospital operating room – the stringent protocols for cleanliness and sterilization are paramount to preventing infections. Similarly, in clean environments, proactive contamination prevention is crucial.

Q 12. How do you adapt your cleaning methods to different types of environments?

Adapting cleaning methods to different environments requires understanding the specific needs of each space. A cleanroom requires different procedures than a laboratory or a manufacturing facility. Factors to consider include the materials present, the level of cleanliness required, and the types of potential contaminants. For example, a cleanroom might necessitate the use of isopropyl alcohol and specialized wipes, while a laboratory could require different cleaning agents depending on the chemicals used. I always prioritize safety and efficacy when selecting cleaning agents and adapt procedures based on the specific environment and regulatory requirements. I’m always keen to familiarize myself with the unique cleaning requirements of the environment prior to beginning any work. This includes reviewing protocols and standard operating procedures (SOPs).

Q 13. What are your preferred cleaning agents and why?

My preferred cleaning agents depend on the specific application. However, I commonly utilize isopropyl alcohol (IPA) for its effectiveness against a broad spectrum of microorganisms and its relatively low toxicity. For certain applications, hydrogen peroxide is another effective option, particularly useful when sterilization is needed. I always prioritize cleaning agents that are compatible with the materials being cleaned and that are approved for use in the specific environment. When selecting cleaning agents, factors such as environmental impact and the potential for residue are also taken into account. The choice of cleaning agent is always carefully considered and documented to ensure traceability and compliance.

Q 14. How do you ensure the proper disposal of hazardous waste?

Ensuring the proper disposal of hazardous waste is critical in maintaining a safe and compliant clean environment. I strictly adhere to all relevant regulations and protocols. This includes segregating hazardous waste according to its type (e.g., chemical waste, biological waste, sharps) and using properly labeled containers. All waste is then handled by a licensed waste disposal company, ensuring compliance with all environmental regulations. Documentation of waste disposal processes is meticulous and regularly reviewed to confirm adherence to protocol and to identify potential improvements in waste management. Safety is my paramount concern during this process; I always prioritize personal protection and proper handling to prevent accidental exposure or contamination.

Q 15. Describe your experience with maintaining inventory of cleaning supplies.

Maintaining inventory of cleaning supplies requires a systematic approach. It’s not just about having enough; it’s about having the right supplies, in the right quantities, at the right time. This ensures efficient cleaning operations and minimizes downtime. My experience involves using a combination of methods. First, I conduct regular stock checks, noting levels of each item against a predetermined par stock level. This ‘par stock’ represents the ideal quantity to have on hand to meet typical cleaning needs. Second, I meticulously record usage patterns to anticipate future demands. For example, if hand sanitizer usage spikes during flu season, I adjust the par stock accordingly. Third, I leverage inventory management software or spreadsheets to track items, automate reordering, and generate reports on consumption trends, allowing for proactive management and minimizing waste. This system helps me spot potential shortages early, prevent unexpected disruptions in cleaning routines, and optimize purchasing decisions.

For example, in my previous role, I implemented a color-coded system for cleaning supplies, using different colors for different areas (e.g., blue for restrooms, green for kitchen). This made identifying and locating specific supplies quick and easy, improving efficiency.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you identify and address potential hazards related to cleanliness?

Identifying and addressing potential hazards related to cleanliness involves a proactive, multi-step process. It starts with regular inspections of the cleaning environment, looking for potential sources of contamination and slips, trips, and falls. This includes checking for spills, damaged flooring, clutter, inadequate lighting, and malfunctioning equipment. I use checklists to ensure thoroughness and consistency. Once a hazard is identified, I follow a specific protocol. This might involve immediately cleaning up a spill, cordoning off a hazardous area, or reporting a faulty piece of equipment to the appropriate personnel for repair. The key is prompt action to minimize risks. In addition, I focus on promoting safe work practices among the cleaning staff, ensuring they utilize appropriate personal protective equipment (PPE), such as gloves and eye protection, and follow proper lifting techniques to prevent injuries. Hazard communication is crucial; I make sure all staff is aware of potential hazards and appropriate safety measures.

For example, I once discovered a loose floor tile that posed a tripping hazard. I immediately reported it to facilities management, and the area was temporarily cordoned off until the repair was completed. This proactive approach prevented potential accidents.

Q 17. What is your understanding of infection control practices?

Infection control practices are critical in maintaining a clean and safe environment. My understanding encompasses several key elements. Firstly, it’s about understanding the transmission routes of pathogens – airborne, contact, and droplet. Based on this understanding, we employ appropriate control measures. This includes proper hand hygiene, using appropriate disinfectants (choosing those effective against specific pathogens based on the environment), and adhering to strict cleaning protocols, especially in high-risk areas like restrooms or medical facilities. Proper waste disposal is also paramount – separating potentially infectious waste from regular waste to prevent further contamination. Regular staff training on infection control protocols is vital to ensure consistent practice and a clean environment.

For instance, after a confirmed case of influenza in a facility, we implemented enhanced cleaning protocols, focusing on high-touch surfaces like doorknobs, light switches, and handrails, using hospital-grade disinfectants effective against influenza viruses. This helped prevent further spread.

Q 18. How do you stay updated on current cleaning and sanitation best practices?

Staying updated on cleaning and sanitation best practices requires a multifaceted approach. I regularly read industry publications, journals, and online resources dedicated to cleaning and sanitation. Attending workshops and conferences provides opportunities for networking and learning about new techniques and technologies. I also actively participate in professional organizations related to cleaning and sanitation, which offers access to continuing education materials and expert insights. Furthermore, I pay close attention to regulatory updates and changes in guidelines from relevant government agencies (e.g., the FDA, EPA). This ensures that our cleaning practices consistently meet and exceed the highest standards and reflect current scientific understanding.

For example, I recently completed a certification course on sustainable cleaning practices, integrating eco-friendly products and methods into our cleaning routines.

Q 19. Explain your understanding of different sterilization techniques.

Sterilization techniques are crucial for eliminating all forms of microbial life, including bacteria, viruses, fungi, and spores. There are several methods, each with its own application and effectiveness. Physical methods include heat sterilization (e.g., autoclaving using high pressure steam), which is highly effective for many materials. Dry heat sterilization is also used, typically at higher temperatures for longer durations. Radiation sterilization, employing gamma rays or electron beams, is suitable for heat-sensitive materials but requires specialized equipment. Chemical methods involve using liquid disinfectants or gases (e.g., ethylene oxide) to kill microbes. The choice of method depends on factors like the type of material being sterilized, the level of contamination, and the desired sterility assurance level. It’s critical to follow the manufacturer’s instructions precisely for each technique to ensure effectiveness and safety.

For example, in a medical setting, autoclaving is commonly used to sterilize surgical instruments. Ethylene oxide gas sterilization is used for heat-sensitive medical equipment like plastic disposables.

Q 20. How do you ensure compliance with all relevant safety and hygiene regulations?

Ensuring compliance with safety and hygiene regulations is a cornerstone of my approach. This begins with a thorough understanding of all applicable local, state, and federal regulations related to cleaning and sanitation. I use regulatory compliance checklists and actively seek updates to any changes in legislation. Proper documentation is crucial; we maintain meticulous records of cleaning activities, chemical usage, equipment maintenance, and employee training. Regular audits are conducted to assess our compliance with regulations and identify any areas needing improvement. I also ensure all cleaning staff receive regular training on these regulations and relevant safety procedures. By actively monitoring compliance and promptly addressing any discrepancies, we minimize risks and maintain a safe and legally compliant environment.

For example, we maintain detailed records of all chemical usage, including Safety Data Sheets (SDS), ensuring we adhere to proper handling and disposal procedures to comply with OSHA regulations.

Q 21. Describe a time you had to resolve a cleanliness-related issue.

In one instance, we experienced a persistent odor issue in a restroom despite regular cleaning. Initial cleaning protocols seemed ineffective. To resolve the problem, I first conducted a thorough investigation, checking for any blocked drains or leaks that might be contributing to the odor. After identifying a malfunctioning plumbing vent, I immediately reported the issue to maintenance. In the meantime, I implemented temporary measures to mitigate the odor, such as deploying odor neutralizers and increasing the frequency of cleaning with stronger disinfectants specifically targeting biological odors. Once the plumbing issue was resolved, the odor problem dissipated completely. This situation reinforced the importance of addressing underlying issues and using a systematic approach when tackling cleaning challenges.

Q 22. How would you handle a situation where a coworker was not following cleanliness protocols?

Addressing a coworker’s lapse in cleanliness protocols requires a tactful and collaborative approach. My first step would be to observe the situation carefully to understand the root cause. Is it a lack of training, a misunderstanding of the procedures, or perhaps a genuine oversight?

If it’s a minor issue, I’d approach my coworker privately and politely address the concern, perhaps suggesting a different technique or reminding them of the specific protocol. For instance, if they are leaving equipment unclean, I might casually mention, “Hey, I noticed the centrifuge wasn’t wiped down after use. Remember, we need to follow Step 4 of the cleaning procedure to prevent cross-contamination.”

However, if the issue is persistent or involves a significant breach of protocol—such as improper disposal of hazardous waste—I would escalate the concern to my supervisor. It’s vital to maintain a safe and clean working environment for everyone, and reporting such issues ensures adherence to safety standards. The goal is constructive collaboration, not confrontation; the focus should always be on improving the situation rather than assigning blame.

Q 23. What are some common challenges in maintaining a clean environment and how do you overcome them?

Maintaining a pristine work environment presents several common challenges. One major hurdle is the human element: inconsistent practices due to oversight, time constraints, or simply a lack of awareness. Another challenge is the sheer volume of items requiring cleaning and disinfection in a busy workplace, ranging from equipment to surfaces. Limited resources— insufficient cleaning supplies, equipment malfunctions, or an inadequate cleaning schedule—also play a role.

To overcome these challenges, a structured approach is crucial. We need a clearly defined and easily accessible cleaning schedule, specifying the cleaning tasks, frequency, and responsible personnel. Providing adequate training on proper techniques and the importance of each step is essential. Regular monitoring and feedback are critical to ensure compliance and promptly address any deviations from the protocols. Additionally, proactive measures such as pre-cleaning and regular maintenance of equipment reduce the workload and prevent build-up of contaminants. Finally, a culture of cleanliness, where everyone feels responsible and takes ownership, makes a substantial difference.

Q 24. How do you ensure equipment is properly cleaned and maintained?

Ensuring proper cleaning and maintenance of equipment is paramount for maintaining both cleanliness and equipment longevity. My approach involves a multi-step process. First, every piece of equipment has a designated cleaning procedure, tailored to its specific needs and materials. These procedures, often detailed in the equipment’s user manual, are readily available to all personnel. Second, we utilize appropriate cleaning agents and tools, ensuring they are stored properly and regularly replenished. Third, regular inspections are conducted to identify any potential issues, such as wear and tear or damage, that may affect the cleaning process or equipment functionality. Fourth, all cleaning and maintenance activities are meticulously documented, including the date, time, personnel involved, cleaning agents used, and any observations made.

For example, after using a high-speed centrifuge, I’d follow the specific protocol: power down the machine, wait for it to fully stop, then carefully wipe the rotor, interior chamber, and exterior surfaces with an approved disinfectant solution. Any spills are immediately cleaned and the area is disinfected. This meticulous approach minimizes the risk of contamination and prolongs the life of the equipment.

Q 25. Describe your experience with documenting cleaning procedures.

I have extensive experience documenting cleaning procedures, which is an integral part of maintaining a clean and safe work environment. My approach emphasizes clarity, completeness, and ease of understanding. The documentation typically includes the following components:

- Equipment Name and ID: Precisely identifies the equipment to which the procedure applies.

- Purpose of the Procedure: Briefly states the objective of the cleaning.

- Step-by-Step Instructions: A clear, sequential listing of the actions required, including the use of specific cleaning agents and tools.

- Frequency of Cleaning: Defines how often the procedure should be performed.

- Safety Precautions: Highlights any potential hazards associated with the procedure, such as handling hazardous materials, and specifies the necessary safety measures.

- Record-Keeping Section: Provides space for documenting the date, time, personnel responsible, and any significant observations.

Using a standardized format, typically a template that ensures consistency, makes the procedures easy to understand and implement for all personnel. The documents are stored in a readily accessible location, often digitally and physically, allowing easy retrieval when needed.

Q 26. How familiar are you with different types of cleaning equipment?

My familiarity with various types of cleaning equipment is comprehensive, encompassing both manual and automated systems. I’m proficient with autoclaves, ultrasonic cleaners, various types of cleaning brushes and sponges, vacuum cleaners (wet/dry), and specialized equipment specific to various applications, such as those used in biological laboratories, or for cleaning delicate instrumentation. Understanding the strengths and limitations of different equipment is crucial for choosing the most appropriate tool for each cleaning task. For instance, an ultrasonic cleaner is excellent for delicate instruments, while an autoclave is vital for sterilizing laboratory equipment.

Beyond the equipment itself, I am also familiar with the various cleaning agents, disinfectants, and detergents suitable for different materials and applications, and I always follow safety protocols when using them. Knowing how to properly maintain and troubleshoot common equipment issues is also an important aspect of my expertise.

Q 27. What is your approach to teamwork when maintaining a clean work environment?

Teamwork is indispensable in maintaining a clean and efficient workplace. My approach emphasizes open communication, collaboration, and mutual respect. I believe in fostering a team environment where everyone shares responsibility and understands the importance of their contributions to maintaining a clean space. This requires establishing clear roles and responsibilities, ensuring that each team member understands their tasks and how they contribute to the overall objective.

For example, during a large-scale cleaning project, we might divide tasks according to individual strengths and preferences, assigning specific areas or equipment to different team members. Regular check-ins and briefings help coordinate efforts and address any issues that might arise. Celebrating successes and acknowledging individual contributions reinforces team morale and encourages continued collaboration. Constructive feedback and positive reinforcement are vital to maintain a healthy and productive work environment.

Q 28. How would you train new employees on cleanliness and sanitation protocols?

Training new employees on cleanliness and sanitation protocols is a crucial aspect of maintaining a clean and safe work environment. My training approach incorporates several key elements. First, I provide a comprehensive overview of the importance of cleanliness and its impact on safety, health, and productivity. This is followed by a step-by-step walkthrough of the cleaning procedures, emphasizing proper techniques, safety precautions, and the use of appropriate equipment and cleaning agents. Hands-on training, where new employees practice the procedures under supervision, is essential. Visual aids, such as diagrams, checklists, and videos, are beneficial to enhance understanding. Regular quizzes and feedback sessions ensure comprehension and allow for addressing any questions or concerns. Finally, ongoing mentoring and support are provided to reinforce learned skills and address any challenges that may arise.

The training also includes detailed instructions on how to use and maintain different types of cleaning equipment, including safety procedures for operating and storing the equipment. The goal is to create a culture of cleanliness where all employees understand the protocols, can perform the tasks efficiently and safely, and take pride in maintaining a clean and organized workplace.

Key Topics to Learn for Ability to Work in a Clean Environment Interview

- Understanding Cleanliness Standards: Familiarize yourself with different levels of cleanliness required in various industries (e.g., pharmaceutical, food service, manufacturing). Consider the specific standards relevant to the job you’re applying for.

- Hygiene Practices: Demonstrate your knowledge of proper handwashing, sanitation techniques, and the use of personal protective equipment (PPE) like gloves and masks where applicable. Be prepared to discuss situations where you’ve maintained hygiene standards.

- Maintaining a Clean Workspace: Explain how you organize your workspace for efficiency and cleanliness. Discuss strategies for preventing contamination and promptly addressing spills or messes.

- Following Safety Protocols: Understand and explain how cleanliness relates to safety regulations and procedures. Be able to discuss your experience following specific safety guidelines related to cleanliness in a work environment.

- Waste Management and Disposal: Describe your understanding of proper waste disposal procedures, including the segregation and handling of different waste types (e.g., hazardous waste, recyclable materials).

- Equipment Cleaning and Maintenance: If relevant to the job, be prepared to discuss your experience cleaning and maintaining equipment, tools, or machinery. Highlight your ability to follow specific cleaning instructions.

- Problem-Solving and Adaptability: Prepare examples showcasing your ability to adapt to changing cleanliness requirements or troubleshoot unexpected cleanliness issues.

Next Steps

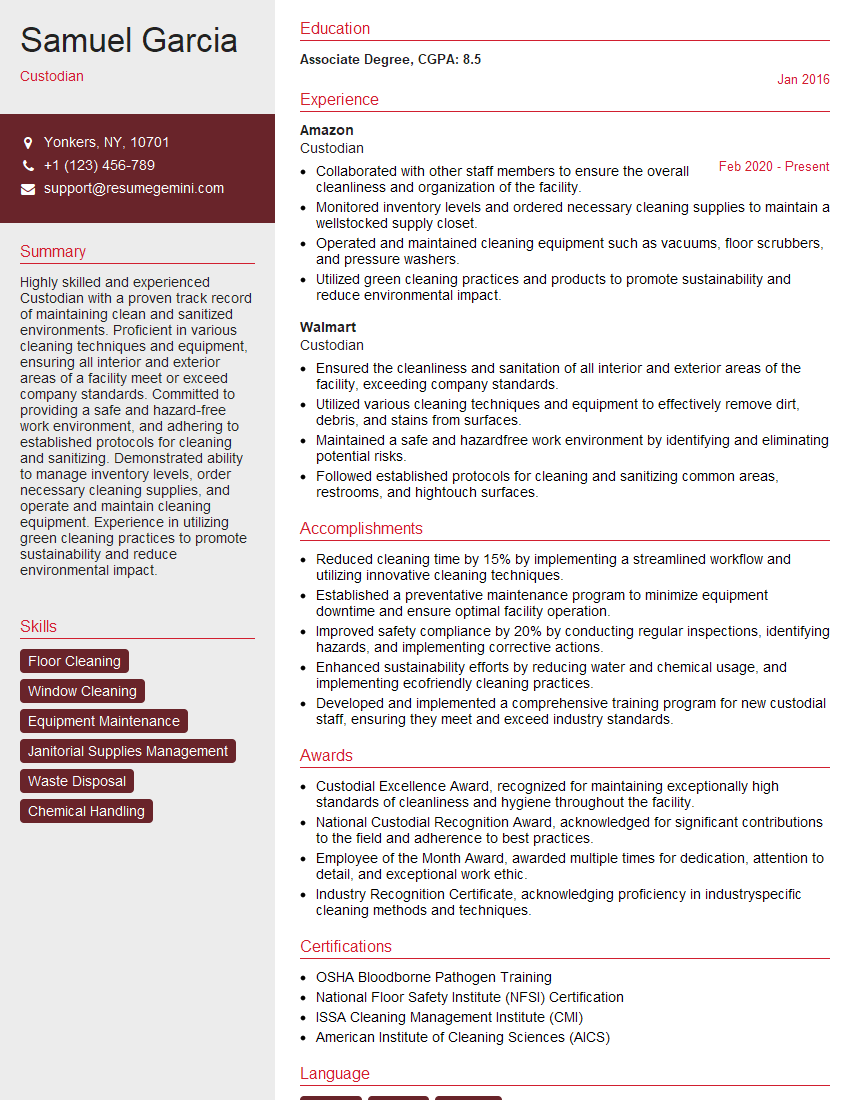

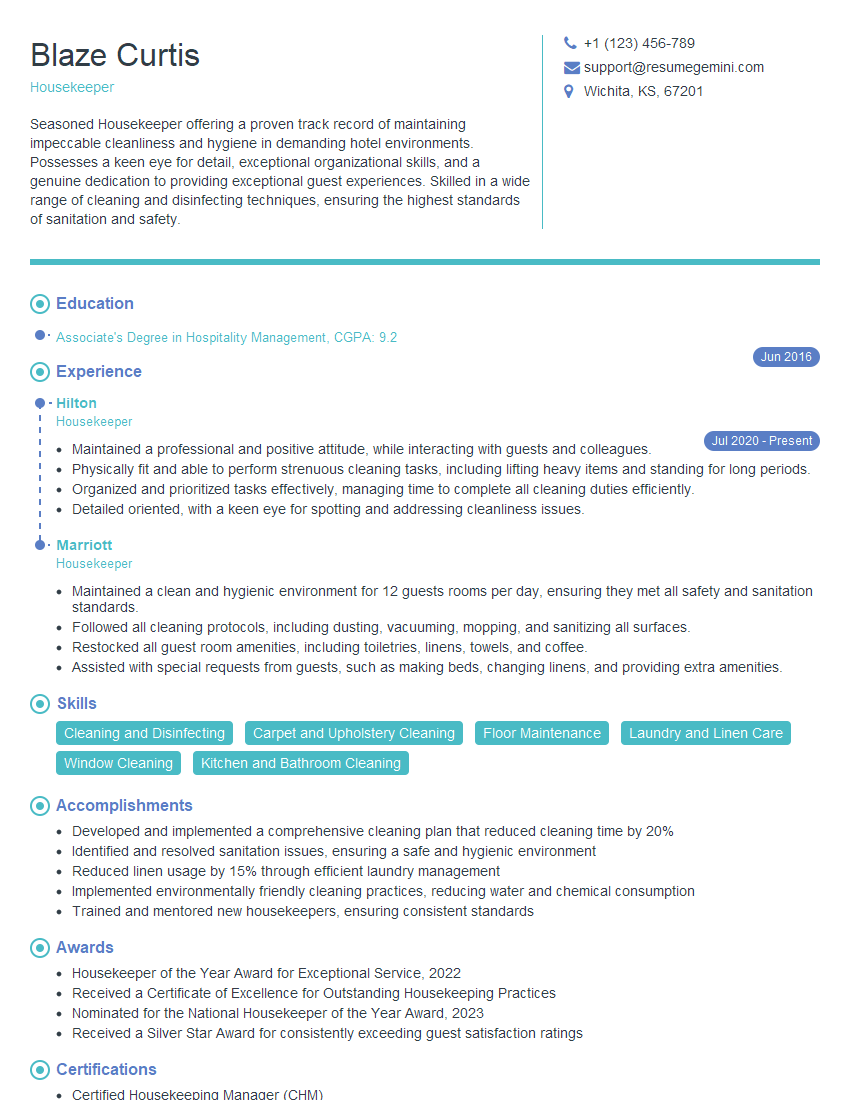

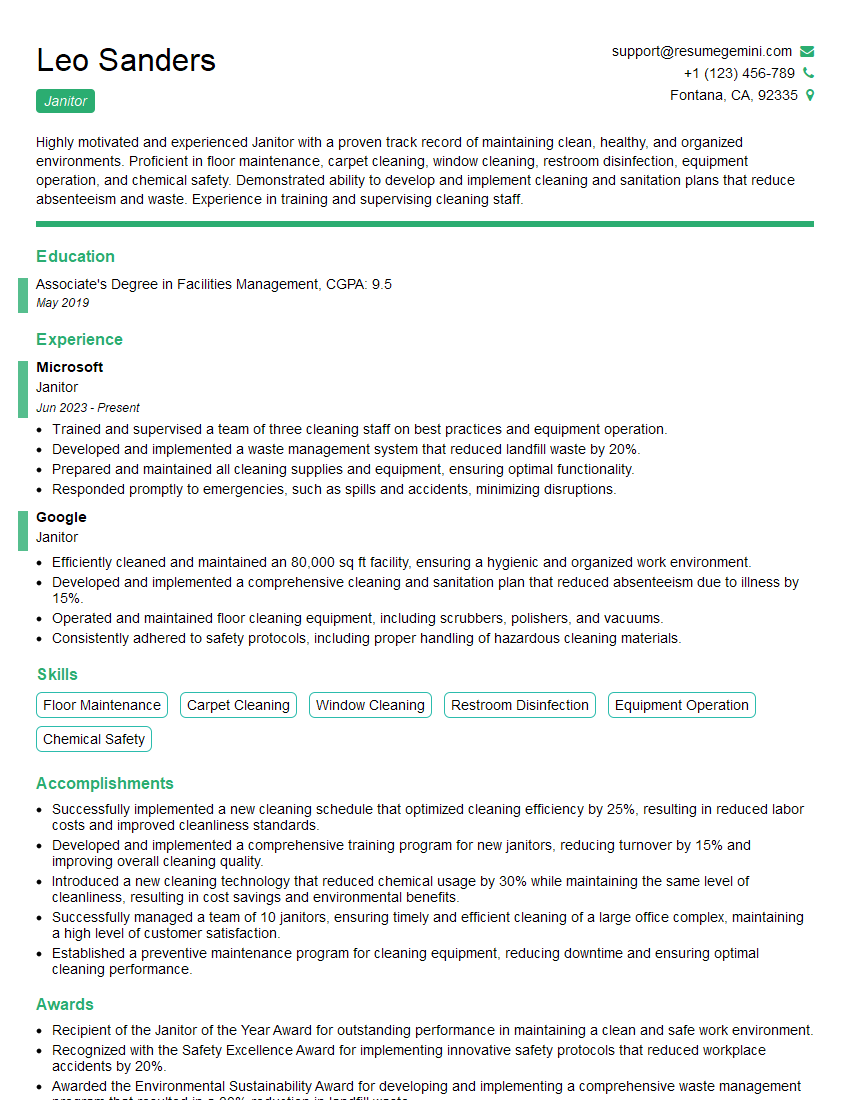

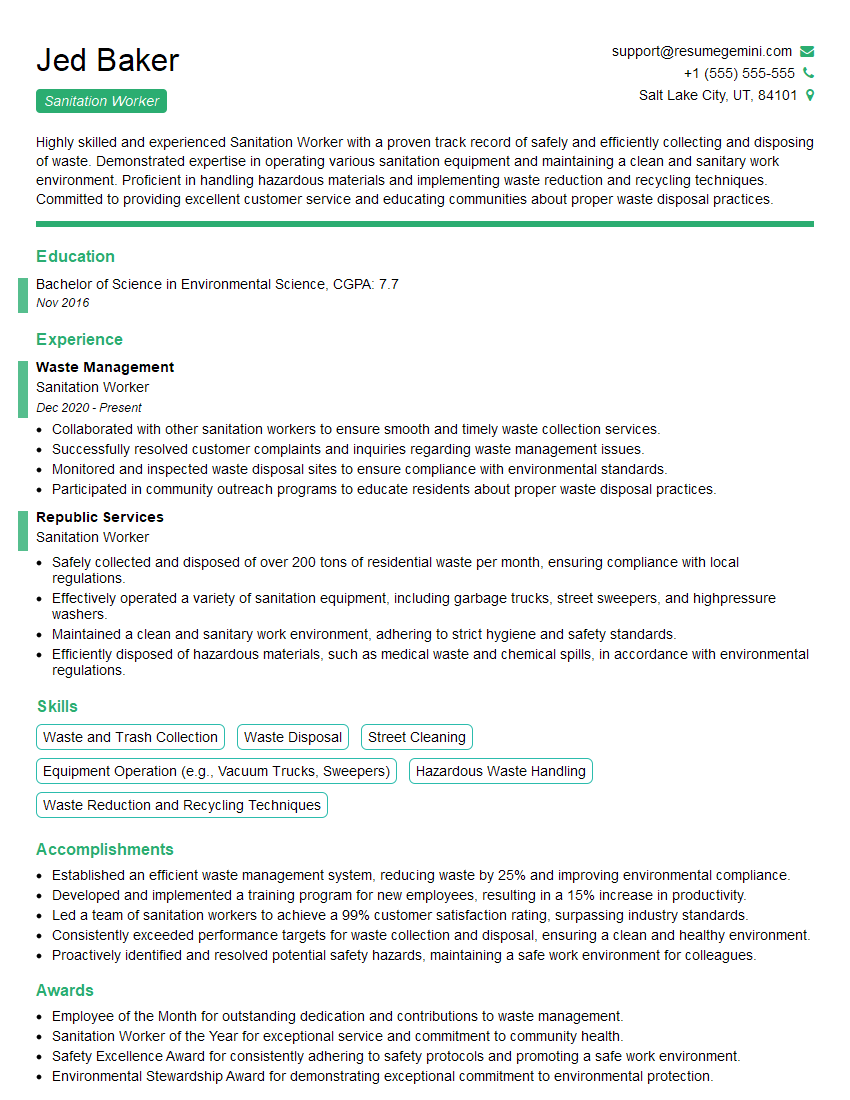

Mastering the ability to work in a clean environment is crucial for success in many industries, demonstrating responsibility, attention to detail, and commitment to safety. A strong resume is vital to showcasing these skills to potential employers. To increase your chances of getting noticed by Applicant Tracking Systems (ATS), ensure your resume is ATS-friendly. ResumeGemini is a trusted resource to help you build a professional and effective resume that highlights your capabilities. Examples of resumes tailored to emphasize your ability to work in a clean environment are available within ResumeGemini to help guide your creation.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.