The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Flat and Stepped Roof Installation interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Flat and Stepped Roof Installation Interview

Q 1. Explain the differences between single-ply and built-up roofing systems.

The key difference between single-ply and built-up roofing systems lies in their construction. Single-ply membranes are large, continuous sheets of synthetic material like TPO, EPDM, or PVC, installed in one layer. Think of it like wrapping a giant present – one continuous sheet. Built-up roofing (BUR), on the other hand, is a multi-layered system comprised of layers of bitumen (tar) and reinforcing felts. It’s like building a roofing sandwich, layer by layer. Single-ply systems are generally faster to install and require less labor, while BUR systems, historically prevalent, offer good durability but can be more time-consuming and labor-intensive.

- Single-Ply Advantages: Faster installation, lower labor costs, lighter weight, seamless membranes.

- Single-Ply Disadvantages: Can be susceptible to punctures, may require specialized equipment for installation.

- Built-Up Roofing Advantages: High durability, good resistance to punctures, can handle higher temperatures.

- Built-Up Roofing Disadvantages: Slower installation, more labor-intensive, heavier, prone to cracking with age and movement.

Q 2. Describe the process of installing a TPO membrane on a flat roof.

Installing a TPO membrane on a flat roof is a meticulous process requiring precision and attention to detail. Here’s a simplified overview:

- Substrate Preparation: The existing roof deck needs to be clean, dry, and free of debris. Any damaged areas must be repaired.

- Primer Application: A specialized primer is applied to ensure proper adhesion between the TPO membrane and the substrate. This is crucial for preventing future issues.

- Membrane Installation: Large sheets of TPO are rolled out, carefully overlapped according to manufacturer’s specifications, and adhered using heat welding. This creates a seamless, waterproof barrier.

- Seaming: The seams are heat-welded using specialized equipment, forming a strong and durable bond. Proper seam sealing is vital for preventing leaks.

- Flashing Installation: Flashing around penetrations (pipes, vents, etc.) is installed to protect vulnerable areas. This is often a crucial step often overlooked which can cause future problems.

- Inspection: A thorough inspection is performed to ensure that the membrane is properly installed and sealed, with no gaps or imperfections.

Proper training and use of the correct tools are essential for a successful TPO installation. A poorly executed installation can quickly lead to expensive repairs down the line.

Q 3. What are the common problems associated with flat roof leaks?

Flat roof leaks are frustrating and costly. They commonly stem from several sources:

- Improper Flashing: Failures around penetrations (pipes, vents, skylights) are frequent culprits. Water can easily infiltrate through poorly installed or damaged flashing.

- Seam Failures: Issues with the seams of single-ply membranes or the layers of BUR can lead to leakage. Poor welding, inadequate adhesion, or movement of the roofing material are major factors.

- Ponding Water: Poor drainage leading to pooling water puts significant stress on the roofing membrane. The weight of standing water can eventually lead to failure.

- Damaged Membrane: Punctures, tears, or deterioration of the roofing material itself allow water penetration. This can be caused by foot traffic, falling debris, or simply age.

- Improper Installation: Incorrect installation techniques, like inadequate substrate preparation or improper application of adhesives or sealants, lead to numerous points of vulnerability.

Identifying the exact source of a leak often requires a careful inspection involving visual examination, and sometimes even more advanced tools such as thermal imaging.

Q 4. How do you ensure proper drainage on a flat roof?

Proper drainage on a flat roof is essential to prevent ponding water and subsequent leaks. This is achieved through a combination of strategies:

- Slope Design: The roof should be designed with a slight slope (typically 1/4 inch to 1/2 inch per foot) towards drains or gutters to ensure proper water runoff. This often requires careful consideration during the design phase.

- Drainage System: Adequate drainage systems, including gutters, downspouts, and drains, must be properly sized and positioned to handle expected rainfall. Regular cleaning of these systems is critical to prevent clogs.

- Membrane Design: The roof membrane itself needs to be installed taut and without wrinkles to facilitate water run-off. Improper installation can lead to pooling water.

- Regular Maintenance: Cleaning debris and inspecting the drainage system regularly will significantly improve its effectiveness and overall lifespan.

Ignoring proper drainage design can lead to premature roof failure, costly repairs and even structural damage to the building.

Q 5. What are the different types of flashing used in stepped roof installation?

Stepped roofs, with their multiple planes and changes in slope, necessitate careful flashing to prevent leaks at these transitions. Common types include:

- Step Flashing: Used at the intersection of a vertical wall and a sloped roof. It consists of several individual pieces of metal carefully overlapped and installed to create a watertight seal. This type of flashing requires careful planning and installation to avoid potential leaks.

- Counter Flashing: Installed on top of step flashing, creating a second layer of protection and helping to secure the step flashing.

- Valley Flashing: Used at the intersection of two sloped roof surfaces, directing water flow. Its design and installation require a skilled roofing professional to ensure water is diverted away correctly.

- Ridge Flashing: Installed along the highest point of a roof to protect the intersection of two roof surfaces and prevent water infiltration at this key juncture. This often involves specialized caps or coverings.

- Chimney Flashing: A critical component to protect the area where a chimney penetrates the roof. It involves careful installation around the chimney base and often multiple layers to create a secure watertight seal.

Each type requires careful planning and precise installation to provide sufficient weather protection. The use of quality materials and proper installation techniques significantly impact the long-term durability and performance of the roof.

Q 6. Explain the importance of proper insulation in both flat and stepped roofs.

Proper insulation in both flat and stepped roofs is crucial for energy efficiency, comfort, and the longevity of the roofing system itself. In flat roofs, insulation helps prevent heat transfer, reducing cooling and heating costs. It also helps protect the roofing membrane from extreme temperature fluctuations which can lead to premature aging and cracking. For stepped roofs, insulation significantly improves indoor climate control in the winter and the summer. It helps reduce condensation and ice damming, common problems in colder climates. The benefits extends beyond energy savings to preventing moisture damage which can compromise the structural integrity of the building.

The type and thickness of insulation used depend on climate, building code, and energy efficiency requirements. Proper installation is also vital; gaps and air pockets can significantly reduce the effectiveness of the insulation. Different types of insulation – like rigid foam boards or spray foam – might be selected based on the specific needs of the project.

Q 7. Describe your experience with different types of roofing materials (e.g., EPDM, TPO, PVC, bitumen).

Throughout my career, I’ve worked extensively with various roofing materials, each with its own strengths and weaknesses:

- EPDM (Ethylene Propylene Diene Monomer): A durable, rubber-based membrane known for its flexibility and longevity. It’s relatively easy to install and repair, making it a popular choice for many flat roofs. I’ve successfully used EPDM on numerous commercial and residential projects, appreciating its resilience and ease of maintenance.

- TPO (Thermoplastic Polyolefin): A more modern single-ply membrane, offering excellent UV resistance, reflectivity, and durability. It’s often chosen for its high performance and resistance to punctures. I find TPO a great option for projects requiring a long-lasting and energy-efficient solution.

- PVC (Polyvinyl Chloride): Another single-ply option with high strength and durability. It’s known for its resistance to punctures and weathering, making it suitable for various applications. However, it’s usually more expensive than EPDM and requires specialized welding equipment.

- Bitumen (Asphalt): The traditional base for built-up roofing systems. While durable, it’s becoming less common due to its higher installation costs, higher maintenance needs, and potential for cracking over time. I’ve worked with bitumen extensively in the past and appreciate the traditional approach, however more modern materials offer clear advantages.

My experience allows me to select the most appropriate material for each project based on factors like budget, lifespan requirements, and client preference, ensuring optimal performance and longevity.

Q 8. How do you address issues with ponding water on a flat roof?

Ponding water on a flat roof is a serious issue that can lead to premature roof failure. It’s essentially a pool of water that sits on the roof surface, putting extra stress on the membrane and potentially causing leaks. Addressing it requires a multi-pronged approach.

- Identify the cause: This could be anything from a clogged drain to a low spot in the roof’s design, or even a problem with the membrane itself. We use specialized tools to measure the slope and locate the problem areas.

- Clean the drains: Clogged drains are a frequent culprit. Regular cleaning is crucial, and if necessary, we’ll repair or replace damaged drains.

- Repair or replace the membrane: If the ponding is due to a damaged membrane, we need to identify the damaged sections, and repair or replace them using appropriate materials. The goal is to create a seamless waterproof surface.

- Improve drainage: In cases of insufficient slope, we might install additional drains or re-slope the roof using techniques like tapered insulation boards. This ensures water flows efficiently to the drains.

For instance, I once worked on a building where ponding was caused by a poorly installed drain. After replacing the drain and re-sloping a small section of the roof, the problem was solved, preventing significant damage and costly repairs.

Q 9. What safety precautions do you take during roof installation?

Safety is paramount in roof installation. We follow strict protocols to mitigate risks. Think of it like climbing a mountain – you need the right equipment and preparation to avoid accidents.

- Fall protection: Harnesses, lifelines, and anchor points are mandatory. We always ensure secure anchorage and regularly inspect equipment. No shortcuts here.

- Proper footwear: We use safety boots with slip-resistant soles to maintain footing on the roof surface.

- Equipment inspection: All tools and equipment are inspected for damage or defects before each job. A faulty tool can be just as dangerous as a lack of fall protection.

- Weather conditions: Work stops immediately if conditions are unsafe, like high winds or heavy rain. Safety trumps scheduling every time.

- Training and communication: All team members are properly trained and we communicate clearly throughout the process, making sure everyone is aware of potential hazards and safety procedures.

On one occasion, a sudden thunderstorm forced us to halt work. We were able to secure our equipment and ourselves without incident. It reinforced the importance of continuous monitoring of weather conditions.

Q 10. Describe your experience with roof inspections and repairs.

My experience with roof inspections and repairs encompasses a wide range of scenarios, from minor leak repairs to extensive roof overhauls. The process begins with a thorough visual inspection, looking for signs of damage, deterioration, and potential issues. We employ specialized tools, such as thermal cameras, moisture meters and drones to get detailed analysis of the roof condition.

- Visual inspection: We check for cracks, blisters, punctures, and areas of ponding water.

- Moisture detection: Moisture meters help locate hidden leaks and water damage.

- Thermal imaging: Thermal cameras detect temperature differences that can indicate hidden moisture problems.

- Repair strategies: Depending on the findings, repairs range from simple patching to complete roof replacements. We select appropriate materials and techniques for optimal long-term performance.

For example, during a recent inspection, a thermal image revealed hidden water damage behind a seemingly minor crack. This allowed us to address the underlying problem, preventing more extensive and costly future damage.

Q 11. What are the signs of a failing flat roof?

A failing flat roof often shows several telltale signs. Early detection is critical to prevent more extensive and costly repairs. Think of it like a slow leak in a tire – you’ll notice it sooner rather than later if you pay attention.

- Leaks: Water stains on ceilings or walls are obvious indicators. These leaks could stem from cracks, damaged seams, or deteriorated flashings.

- Blisters or bubbles in the roofing membrane: These are signs of moisture buildup beneath the roofing membrane.

- Sagging or uneven areas: This might suggest structural problems or deterioration of the roofing system.

- Standing water or ponding: This puts significant strain on the roofing system and indicates drainage issues.

- Visible cracks or damage: Large or multiple cracks in the roofing membrane are serious issues that require immediate attention.

I once encountered a flat roof where the owner reported minor leaks. Our inspection revealed significant deterioration beneath the surface, leading to a full roof replacement. Early detection could have saved money and disruption.

Q 12. Explain the process of installing a stepped roof.

Installing a stepped roof, also known as a tiered roof, involves creating a series of sloping roof sections at varying heights. It’s more complex than a flat roof, but offers aesthetic appeal and better water runoff. Think of it as a series of smaller roofs connected together.

- Design and planning: Accurate measurements and design plans are crucial. This phase also considers local building codes and material selection.

- Framing: Creating the framework for each level of the stepped roof requires precise cuts and angles to ensure proper support and drainage.

- Sheathing: Installing sheathing provides a solid base for the roofing material, while also ensuring structural integrity.

- Underlayment: Waterproof underlayment is essential to prevent leaks and protect the roof structure.

- Roofing material installation: This involves carefully fitting and securing the chosen roofing material, paying attention to flashing and sealing around the edges and junctions between different levels.

Recently, I oversaw a stepped roof project where proper planning and teamwork were crucial for success. The precise cutting and installation of the framing ensured the perfect fit and aesthetic appeal of the final product.

Q 13. How do you account for different roof pitches in stepped roof installation?

Different roof pitches in stepped roof installation require careful attention to ensure proper water runoff and structural integrity. Each level needs to be designed to drain efficiently, preventing water from pooling on any section.

- Accurate measurements: Precise measurements are essential to achieve the desired slope on each level. We use laser levels and other precision instruments.

- Proper framing: The framing must be adjusted to create the specified slope for each step. The angles of the rafters and the support structure are critical.

- Flashing and sealing: Flashing is critical at the junctions between different roof levels to create a watertight seal. Proper sealing is essential to avoid leaks.

- Drainage calculations: The design must account for water drainage to prevent ponding or overflow. Gutters and downspouts should be appropriately sized for the roof area.

In one project, we encountered a complex stepped roof design. By meticulously calculating the angles and installing the proper flashing at each level, we created a beautiful and fully functional roof system.

Q 14. What tools and equipment are essential for flat and stepped roof installation?

The tools and equipment for flat and stepped roof installation vary depending on the specific project, but some essentials are common to both. Think of it like a surgeon’s toolkit – you need the right instruments for the job.

- Safety equipment: Harnesses, lifelines, safety boots, and gloves are crucial for worker safety.

- Measuring tools: Tape measures, laser levels, and squares are essential for accurate measurements.

- Cutting tools: Circular saws, utility knives, and shears are needed for cutting roofing materials.

- Fasteners: Nails, screws, and roofing staples are used to secure the roofing materials.

- Roofing materials: The specific materials will vary, but this includes membranes, insulation, underlayment, and flashing.

- Specialized equipment: For larger projects, equipment like a crane or lift may be needed.

For instance, on a recent large flat roof project, a crane was essential for safely and efficiently lifting the large rolls of membrane onto the roof. The right tools and equipment always make the job easier, safer, and more efficient.

Q 15. Describe your experience with different types of roof underlayment.

Roof underlayment is a crucial component, acting as a protective layer between the roof decking and the final roofing material. It safeguards against moisture damage, ensuring the longevity of the roof. My experience encompasses a variety of underlayments, each with its strengths and weaknesses.

- Felt Underlayment: This is a traditional, asphalt-saturated felt, relatively inexpensive but less durable and less resistant to tears compared to newer options.

- Synthetic Underlayment: These are generally made from polypropylene or polyethylene. They offer superior tear resistance, water shedding capabilities, and UV resistance, making them a more reliable choice, although more expensive initially.

- Rubberized Asphalt Underlayment: Combining the benefits of asphalt and a rubberized polymer, these offer improved flexibility, durability, and water resistance. They’re often chosen for steeper slopes.

For instance, on a recent flat roof project, we opted for a high-performance synthetic underlayment due to the potential for long periods of rain during the installation. Its superior water resistance minimized the risk of damage during construction.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage challenging weather conditions during roof installation?

Working in challenging weather conditions is an unavoidable aspect of roofing. Safety is paramount. We employ several strategies:

- Weather Monitoring: We constantly monitor forecasts and adjust schedules accordingly. High winds, heavy rain, or extreme temperatures can halt operations.

- Safety Protocols: Strict adherence to fall protection measures is crucial regardless of weather. This includes the use of harnesses, lifelines, and designated anchor points.

- Adaptive Techniques: We adapt our methods based on conditions. For instance, in strong winds, we may use extra securing measures for materials to prevent them from blowing away.

- Material Protection: Materials are carefully covered and stored to prevent water damage or deterioration due to extreme temperatures.

During a recent project with unexpected heavy snowfall, we temporarily ceased work until the snow had cleared to ensure worker safety and prevent material damage.

Q 17. What is your experience with working from heights and fall protection?

Working at heights is inherently risky, and fall protection is non-negotiable. My experience includes extensive training and certification in OSHA fall protection standards. We utilize a multi-layered approach:

- Proper Equipment: We use only ANSI-approved harnesses, lanyards, and anchor points regularly inspected for safety.

- Safe Work Practices: We follow strict procedures for accessing and working at heights, including using scaffolding, ladders, and proper tie-off points.

- Regular Inspections: Regular inspections are done to ensure equipment is in good working order and the work area is safe.

- Training and Supervision: All crew members receive thorough training and are supervised closely.

Imagine a scenario where a worker needs to access a steeply pitched roof. We would utilize a properly anchored harness and lifeline system, ensuring the worker is secured at all times. This safeguards against falls, potentially preventing serious injury or fatalities.

Q 18. Describe your experience with roof ventilation.

Adequate roof ventilation is critical for preventing moisture buildup, extending the roof’s lifespan, and improving energy efficiency. I have experience with various ventilation systems:

- Ridge Vents: These vents run along the ridge of the roof, allowing hot air to escape. They’re highly effective on steeper roofs.

- Soffit Vents: Located at the eaves, soffit vents allow cool outside air to enter the attic. Proper spacing is essential for effective airflow.

- Power Vents: These motorized vents offer increased ventilation power, beneficial for attics with poor natural airflow.

- Gable Vents: Often located in the gables of the roof, providing another pathway for air movement.

For example, on a recent project with a low-sloped roof, we incorporated a combination of ridge and soffit vents to ensure sufficient airflow. We calculated the correct vent area based on the attic’s size and climate to prevent condensation and ice damming.

Q 19. How do you calculate the amount of roofing materials needed for a project?

Accurate material calculation is essential for preventing waste and delays. The process typically involves:

- Detailed Measurements: Precise measurements of the roof’s area are obtained, taking into account the roof’s shape, pitch, and any valleys or hips.

- Waste Factor: A waste factor is added to the calculation (typically 5-10%, but more for complex roofs) to account for cuts, overlaps, and unavoidable material loss.

- Manufacturer’s Specifications: Manufacturer’s specifications for shingle coverage per bundle are followed meticulously.

- Software and Online Calculators: We utilize software and online calculators that allow us to input the measurements and get an accurate estimation.

For example, when calculating materials for a simple gable roof, we’d measure the area of each side, add them together, factor in the waste percentage, and then determine the number of bundles needed based on the manufacturer’s specifications.

Q 20. Explain the process of sealing seams and joints in a roofing system.

Proper sealing of seams and joints is crucial for a watertight roof. The process depends on the roofing material:

- Asphalt Shingles: Overlapping shingles create a natural barrier, but sealant is applied to vulnerable areas like valleys and around vents.

- Flat Roofing (e.g., EPDM, TPO): Seams are often welded or adhered using specialized tape or adhesive, creating a completely sealed surface.

- Sealants: Various sealants are used depending on the material; some are self-leveling, while others require precise application techniques.

For instance, in a flat roof installation using a TPO membrane, we’d clean the surfaces thoroughly before applying the adhesive tape to the seams, ensuring a strong and watertight bond. We then carefully press the seams to ensure proper adhesion. A final inspection is conducted to make certain that there are no gaps.

Q 21. Describe your experience with working with different types of roofing accessories (e.g., vents, skylights).

Working with roofing accessories requires precision and attention to detail. My experience includes installation of:

- Vents: Properly installing vents requires ensuring a weathertight seal to prevent leaks and optimize airflow. This involves using appropriate flashing and sealant.

- Skylights: Skylights require careful integration with the roofing system, ensuring proper flashing to prevent water intrusion. This also requires adherence to manufacturer’s instructions.

- Chimneys and Pipes: These require specialized flashing systems to create a watertight seal around the penetrations in the roof. This often requires specialized skills and knowledge.

For example, installing a skylight involves creating a precise opening in the roof deck, installing the skylight frame, and then applying flashing meticulously to prevent water damage around the edges. This requires precise measurement and careful application of sealant to ensure a watertight fit.

Q 22. What is your experience with thermal bridging in roof construction?

Thermal bridging in roof construction refers to the transfer of heat through conductive pathways in the building envelope. Think of it like a weak point in your roof’s insulation – heat escapes in winter and enters in summer, leading to energy inefficiency and discomfort. These pathways can be created by structural elements like purlins, rafters, or even gaps in insulation.

My experience includes identifying and mitigating thermal bridging in various projects. For example, on a recent flat roof installation, we utilized continuous insulation boards to minimize the contact between the exterior and interior environments, effectively breaking the thermal bridge. In another project involving a stepped roof, we carefully detailed the insulation around the roof valleys and edges to prevent heat loss in those vulnerable areas. We also specify the use of thermally broken fasteners whenever possible to further reduce heat transfer.

In assessing a design, I look for details like the type of insulation used (closed-cell spray foam is great at minimizing thermal bridging), the spacing and material of the structural members, and any potential air gaps. Using thermal modeling software helps to visualize and quantify the impact of thermal bridging, allowing for proactive solutions.

Q 23. How do you assess the structural integrity of a roof before installation?

Assessing the structural integrity of a roof before installation is paramount. Neglecting this crucial step can lead to disastrous consequences. My assessment process typically begins with a thorough visual inspection, checking for signs of rot, decay, sagging, or any damage caused by weather or pests.

This visual assessment is followed by a more in-depth investigation, which might include:

- Checking the existing roof structure for compliance with building codes and engineering standards.

- Using non-destructive testing methods, such as tapping to detect hollow sounds indicative of potential structural issues.

- Reviewing the building’s architectural and structural drawings to understand the roof design and load-bearing capacity.

- In cases of significant concern, I’ll recommend a structural engineer’s inspection for a detailed report and recommendations.

For instance, on one project, a visual inspection revealed significant deterioration in a section of the existing timber structure. This led to a structural engineer’s assessment, which confirmed the need for reinforcement before proceeding with the new roof installation. Ignoring this could have resulted in a collapse.

Q 24. What is your experience with green roofing systems?

I have significant experience working with green roofing systems, which offer numerous environmental and aesthetic benefits. These systems involve installing a layer of vegetation on top of a waterproof membrane, creating a living roof. The benefits include improved insulation, reduced stormwater runoff, increased biodiversity, and enhanced aesthetics.

My experience spans various types of green roofs, from extensive green roofs (low-maintenance, shallow soil depth) to intensive green roofs (deeper soil, supporting a wider variety of plants). I’m familiar with the design and installation process, including the selection of appropriate waterproofing membranes, drainage layers, root barriers, and growing media. The choice of plants is critical and depends on the climate, soil depth, and the intended purpose of the green roof. Proper drainage is also essential to prevent waterlogging and root penetration into the waterproof layer.

For example, I oversaw the installation of an extensive green roof on a commercial building. We used a sedum mat system for ease of installation and low maintenance. Careful consideration was given to the drainage layer to prevent water damage and to ensure the longevity of the system. Regular inspections and maintenance are essential for the long-term success of green roofs.

Q 25. How do you handle unexpected problems during a roof installation project?

Unexpected problems are inevitable in construction. My approach emphasizes proactive planning and problem-solving skills. A thorough pre-installation assessment helps reduce surprises, but unforeseen issues can still arise – like discovering hidden structural damage or encountering unexpected materials during demolition.

My problem-solving strategy involves:

- Immediate Assessment: Carefully evaluate the nature and extent of the problem. Photography and documentation are crucial.

- Risk Assessment: Determine the potential impact on the project timeline and budget.

- Communication: Inform the client and other stakeholders immediately. Transparency is key.

- Solution Development: Explore several solutions, weighing the pros and cons of each. This may involve consulting with specialists, engineers, or suppliers.

- Implementation & Monitoring: Implement the chosen solution, closely monitoring its effectiveness and making adjustments as needed.

For instance, during one flat roof installation, we unexpectedly uncovered asbestos. We immediately halted work, followed proper abatement procedures, and revised the project schedule to account for the delay. The extra cost was managed through transparent communication with the client and a revised budget.

Q 26. Explain your experience with different types of roof coatings.

My experience encompasses various roof coatings, each with its strengths and weaknesses. The choice of coating depends on factors like the roof type, climate, substrate material, and budget.

- Acrylic coatings: These are versatile, relatively inexpensive, and easy to apply. They offer good UV protection but are less durable than some other options.

- Silicone coatings: Highly elastic, offering excellent waterproofing and crack bridging capabilities. They’re suitable for challenging climates but can be more expensive.

- Elastomeric coatings: Known for their high elasticity and ability to withstand significant expansion and contraction. They provide excellent waterproofing and are suitable for various substrates.

- Polyurethane coatings: Durable and provide excellent waterproofing but require careful application to avoid pinholes.

I carefully consider the specific requirements of each project. For example, on a project in a high-UV climate, we chose a silicone coating for its superior UV resistance and durability. On another project with an older roof showing signs of cracking, an elastomeric coating was selected for its crack-bridging properties. Proper surface preparation before coating application is always critical for optimal performance.

Q 27. What are the best practices for maintaining a flat or stepped roof?

Maintaining a flat or stepped roof is crucial to extending its lifespan and preventing costly repairs. Regular inspections and proactive maintenance are key.

Best practices include:

- Regular Inspections: Conduct visual inspections at least twice a year, checking for signs of damage, leaks, ponding water, or debris buildup.

- Cleaning: Remove debris like leaves, dirt, and gravel regularly to prevent clogging drains and damage to the membrane.

- Drainage System Maintenance: Ensure proper drainage functionality by keeping gutters, downspouts, and drains clean and free of obstructions.

- Coating Maintenance: Depending on the type of coating, periodic recoating may be necessary to maintain waterproofing and UV protection. Inspect for wear and tear and address any areas of concern.

- Repair Promptly: Address any minor damage immediately to prevent it from escalating into major problems.

For instance, a yearly inspection might reveal a small crack in a flat roof’s membrane. Repairing this early is far less expensive and disruptive than waiting until a major leak develops. Regular maintenance is your best defense against costly and unexpected issues, keeping your roof in optimal condition for years to come.

Key Topics to Learn for Flat and Stepped Roof Installation Interview

- Flat Roof Systems: Understanding different types of flat roofs (built-up, single-ply, inverted), their components (membrane, insulation, flashing), and appropriate installation techniques for each.

- Stepped Roof Systems: Knowledge of various pitched roof structures, including gable, hip, and gambrel roofs, and their specific installation requirements and challenges.

- Roofing Materials: Familiarity with the properties and applications of common roofing materials like asphalt shingles, tiles, metal sheets, and single-ply membranes. Understanding material selection based on climate and building codes.

- Waterproofing and Drainage: Mastering techniques for effective waterproofing and ensuring proper drainage to prevent leaks and damage. This includes understanding flashing installation and gutter systems.

- Safety Procedures and Regulations: Demonstrating a thorough understanding of OSHA safety regulations and best practices for working at heights, using proper safety equipment, and adhering to site safety protocols.

- Problem-Solving and Troubleshooting: Ability to identify and resolve common roofing issues such as leaks, damage from weather, and improper installation techniques. Experience with diagnosing problems and implementing effective solutions.

- Estimating and Project Management: Understanding the process of estimating materials, labor, and project timelines. Experience with managing resources effectively and working within budget constraints.

- Tools and Equipment: Familiarity with the operation and maintenance of common roofing tools and equipment, and understanding safety procedures for their use.

Next Steps

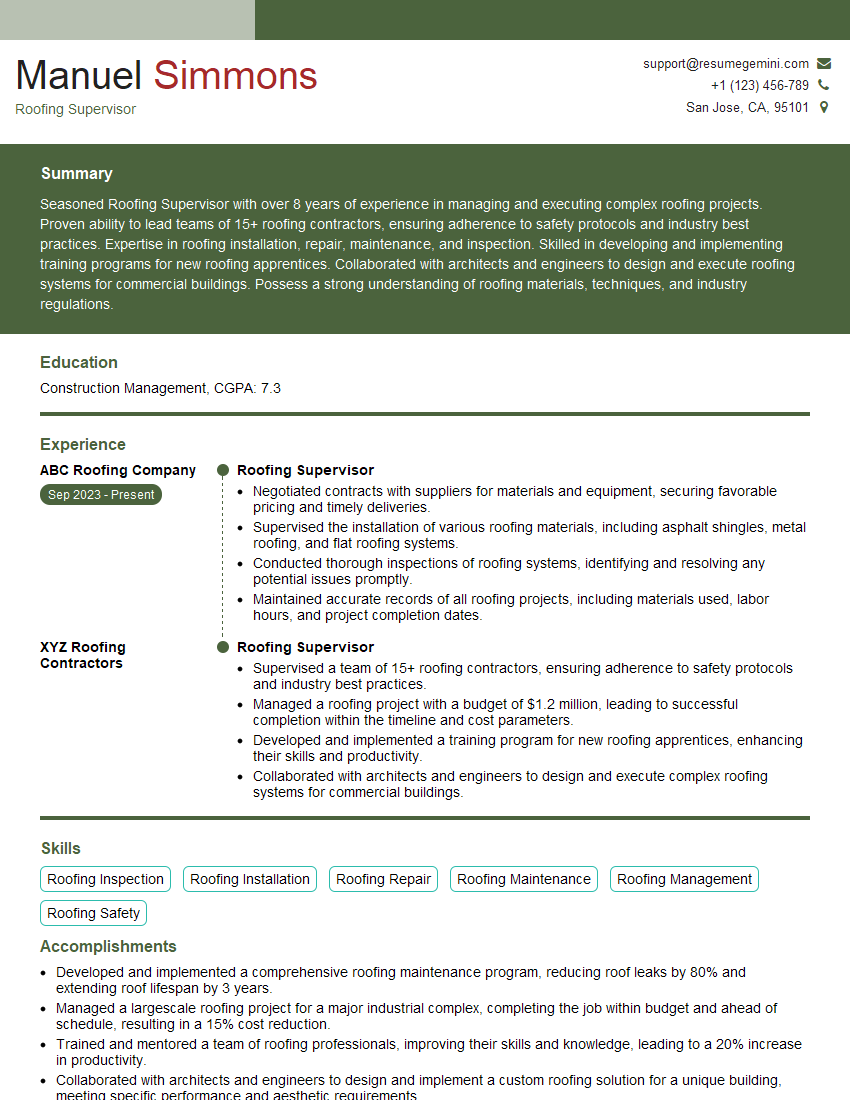

Mastering flat and stepped roof installation opens doors to rewarding and stable career growth within the construction industry. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume designed to get noticed by recruiters. Examples of resumes tailored specifically to Flat and Stepped Roof Installation professionals are available through ResumeGemini, providing you with valuable templates and guidance to showcase your skills and experience effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.