Are you ready to stand out in your next interview? Understanding and preparing for Predictive and Preventive Maintenance Techniques interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Predictive and Preventive Maintenance Techniques Interview

Q 1. Explain the difference between predictive and preventive maintenance.

Preventive maintenance (PM) and predictive maintenance (PdM) are both proactive approaches to equipment maintenance, but they differ significantly in their approach. Preventive maintenance follows a predetermined schedule, performing inspections and repairs at fixed intervals regardless of the asset’s actual condition. Think of it like changing your car’s oil every 3,000 miles, even if it seems to be running perfectly. Predictive maintenance, on the other hand, uses data and analytics to predict when maintenance is actually needed. It’s like having a mechanic monitor your car’s performance in real-time, identifying potential problems before they lead to a breakdown. This allows for targeted interventions only when necessary, minimizing downtime and maximizing efficiency.

In essence, PM is scheduled and time-based, while PdM is condition-based and driven by data.

Q 2. Describe the various predictive maintenance techniques you are familiar with.

I’m proficient in a range of predictive maintenance techniques. These include:

- Vibration Analysis: This involves monitoring the vibrations produced by machinery to identify imbalances, misalignments, or bearing wear. Abnormal vibration patterns often precede failures.

- Oil Analysis: Examining oil samples for contaminants, such as metal particles or degradation products, can indicate wear and tear within the machinery.

- Infrared Thermography: Using infrared cameras to detect heat signatures helps pinpoint overheating components, a common precursor to equipment failure.

- Ultrasonic Testing: Detecting high-frequency sound waves allows for early detection of leaks in pressurized systems, cracks in materials, and bearing wear.

- Acoustic Emission Monitoring: This technique listens for high-frequency acoustic emissions (tiny cracks, friction) that signal impending failure in structural components.

- Motor Current Signature Analysis (MCSA): Monitoring changes in motor current patterns can help detect problems such as winding faults or bearing damage.

- Data Analytics and Machine Learning: Leveraging historical data and machine learning algorithms to identify patterns and predict future failures. This often involves sensor data integration and sophisticated modelling.

The choice of technique depends on the specific asset, its criticality, and the available resources.

Q 3. How do you determine the optimal maintenance interval for a specific asset?

Determining the optimal maintenance interval requires a multi-faceted approach. It’s not a one-size-fits-all solution.

- Analyze historical data: Examine past maintenance records, including Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR) to establish baseline performance.

- Assess operating conditions: Consider factors such as the asset’s operating hours, environmental conditions (temperature, humidity), and the load it experiences. A machine operating under harsh conditions may require more frequent maintenance.

- Conduct Failure Mode and Effects Analysis (FMEA): Identify potential failure modes and their associated consequences. This helps prioritize critical components and determine appropriate maintenance frequencies.

- Implement predictive maintenance techniques: Utilize techniques like vibration analysis or oil analysis to monitor the asset’s condition. This provides real-time data on its health and allows for condition-based maintenance, optimizing the interval.

- Cost-benefit analysis: Evaluate the cost of maintenance against the cost of potential failures. This helps balance preventive measures with the risk of unplanned downtime.

- Risk assessment: Consider the safety and production implications of failure. High-risk assets might require more frequent maintenance.

The optimal interval is a balance between preventing failures, minimizing maintenance costs, and maximizing production uptime.

Q 4. What are the key performance indicators (KPIs) used to measure the effectiveness of a maintenance program?

Key Performance Indicators (KPIs) for a maintenance program track its effectiveness and efficiency. Examples include:

- Mean Time Between Failures (MTBF): The average time between failures of a system or component. A higher MTBF indicates better reliability.

- Mean Time To Repair (MTTR): The average time it takes to repair a failed system or component. A lower MTTR indicates faster response times and reduced downtime.

- Maintenance Cost per Unit of Production: Tracks the efficiency of maintenance spending relative to production output.

- Uptime Percentage: The percentage of time an asset is operational. Higher uptime indicates better maintenance practices.

- Downtime Cost: The financial impact of unplanned downtime. Minimizing downtime costs is a major goal.

- Preventable Maintenance Cost: The cost associated with planned and predictive maintenance actions.

- Inventory Turnover Rate for Maintenance Spares: Measures the efficiency of maintenance spare parts management.

By monitoring these KPIs, organizations can identify areas for improvement and optimize their maintenance strategies.

Q 5. Explain the concept of Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR).

Mean Time Between Failures (MTBF) is the average time a device or system operates before a failure occurs. It’s a measure of reliability. A higher MTBF indicates a more reliable system. For example, an MTBF of 10,000 hours for a pump means, on average, the pump operates for 10,000 hours before requiring repair.

Mean Time To Repair (MTTR) is the average time it takes to repair a failed device or system and restore it to operational status. A lower MTTR is desirable, as it minimizes downtime. For instance, an MTTR of 4 hours for a particular piece of equipment indicates the average repair time is four hours. Both MTBF and MTTR are crucial for assessing the effectiveness of a maintenance program.

Q 6. How do you use vibration analysis in predictive maintenance?

Vibration analysis is a cornerstone of predictive maintenance. We use specialized sensors (accelerometers) to measure the vibrations produced by rotating machinery. These vibrations are analyzed using Fast Fourier Transforms (FFTs) to identify specific frequencies and amplitudes. Different frequencies correspond to different problems: for instance, a high amplitude at a particular frequency might indicate an imbalance in a rotor, while other frequencies could signify bearing wear, gear meshing issues, or misalignment.

By trending these vibration signatures over time, we can detect gradual changes that indicate impending failure. Early detection allows for scheduled maintenance, preventing catastrophic failures and unplanned downtime. For example, a gradual increase in amplitude at a specific frequency associated with bearing wear would alert us to replace the bearing proactively before it fails completely.

Q 7. Describe your experience with different types of sensors used in predictive maintenance.

My experience encompasses a wide variety of sensors used in PdM. These include:

- Accelerometers: Measure vibration levels in various axes.

- Proximity sensors: Measure the distance between a sensor and a target (e.g., shaft position). Changes can indicate misalignment or other problems.

- Temperature sensors (thermocouples, RTDs): Monitor operating temperatures to identify overheating.

- Strain gauges: Measure stress and strain in structural components.

- Pressure sensors: Monitor pressure in hydraulic or pneumatic systems to detect leaks or pressure drops.

- Acoustic emission sensors: Detect high-frequency sounds related to material defects.

- Oil condition sensors: Monitor oil quality and degradation.

- Current sensors: Monitor motor current to detect anomalies.

The choice of sensor depends on the specific parameters being monitored and the type of asset. Data from multiple sensors are often integrated to provide a comprehensive picture of the asset’s health.

Q 8. How do you interpret data from vibration analysis, oil analysis, or thermal imaging?

Interpreting data from vibration analysis, oil analysis, and thermal imaging involves understanding the underlying principles and recognizing patterns indicative of machine health. It’s like being a detective, piecing together clues to identify potential problems before they escalate into major failures.

Vibration Analysis: We use sensors to measure vibrations in machinery. Excessive vibrations can indicate imbalances, misalignment, bearing wear, or looseness. Analyzing frequency spectrums helps pinpoint the source of the problem. For example, a high frequency spike might suggest bearing damage, while low-frequency vibrations could point to a foundation issue. We use software to analyze the data, comparing it to baseline readings to identify deviations.

Oil Analysis: Oil samples are analyzed for contaminants (metal particles, water, etc.) and changes in viscosity or chemical composition. High levels of iron particles might indicate wear in gear teeth or bearings. An increase in water content could signal a leak or seal failure. Again, trend analysis is critical here; we compare current readings to historical data to identify significant changes.

Thermal Imaging: Infrared cameras detect heat signatures. Overheating components indicate potential issues like electrical problems, friction, or blockages. For instance, a motor running significantly hotter than usual might suggest winding faults or bearing problems. Thermal images provide a visual representation of heat distribution, making it easy to pinpoint problem areas.

In all cases, data interpretation requires a deep understanding of the machinery, experience in analyzing data patterns, and a good grasp of the statistical methods used to identify anomalies and forecast potential failures.

Q 9. What is the role of a Computerized Maintenance Management System (CMMS) in predictive maintenance?

A Computerized Maintenance Management System (CMMS) is the backbone of an effective predictive maintenance program. Think of it as the central nervous system for your maintenance operations. It helps us organize, track, and analyze all aspects of maintenance, from work orders and inventory management to scheduling and reporting.

Work Order Management: CMMS facilitates the creation and tracking of work orders based on predictive maintenance data. For example, if vibration analysis reveals an impending bearing failure, a work order can be automatically generated and assigned.

Data Integration: CMMS integrates data from various sources like condition monitoring sensors, oil analysis reports, and thermal imaging scans, providing a holistic view of equipment health.

Scheduling & Optimization: CMMS allows for optimized scheduling of maintenance tasks based on predicted failures, minimizing downtime and maximizing equipment utilization.

Reporting & Analytics: The system generates reports and dashboards that provide insights into maintenance performance, equipment reliability, and overall maintenance costs.

Without a robust CMMS, managing a predictive maintenance program would be chaotic and inefficient. It’s the central hub that connects all the data streams and maintenance actions.

Q 10. How do you prioritize maintenance tasks based on risk and criticality?

Prioritizing maintenance tasks involves a risk-based approach, considering both the criticality of the equipment and the potential consequences of failure. We often use a risk matrix, which plots the likelihood of failure against the severity of the consequences.

For example:

High Criticality, High Likelihood: This represents equipment that is essential to operations and has a high probability of failure. Maintenance needs to be addressed immediately. Think of a critical pump in a chemical processing plant.

High Criticality, Low Likelihood: This could be equipment that is important but has a lower chance of failing soon. Maintenance can be scheduled proactively, but not as urgently. For instance, a backup generator.

Low Criticality, High Likelihood: This involves equipment that is less critical but may fail soon. Maintenance can be scheduled soon, but it doesn’t need to be a top priority. A conveyor belt in a less crucial area of a factory would fall here.

Low Criticality, Low Likelihood: This equipment can be maintained on a routine basis with lower urgency. This is good for less essential equipment with a low failure risk.

We often use a combination of quantitative data (failure rates, MTTR, etc.) and qualitative factors (safety risks, production impact) to refine the prioritization and efficiently allocate resources.

Q 11. Explain your experience with root cause analysis techniques.

Root cause analysis (RCA) is crucial for preventing recurring failures. It’s not just about fixing the immediate problem, but understanding *why* it happened in the first place. I’ve used several techniques, including the ‘5 Whys’ and Fishbone diagrams.

5 Whys: This iterative questioning technique involves repeatedly asking ‘why’ to delve deeper into the cause of a problem. For example: ‘Why did the pump fail? Because the bearings wore out. Why did the bearings wear out? Because of insufficient lubrication. Why was there insufficient lubrication? Because the lubrication system malfunctioned…and so on.’

Fishbone Diagrams (Ishikawa): This visual tool helps brainstorm potential causes, categorizing them into groups (materials, methods, manpower, machinery, environment, measurement). We systematically analyze each category to identify the root cause.

Regardless of the technique, effective RCA requires thorough investigation, data collection, and collaborative teamwork to identify all contributing factors and prevent future occurrences. I always ensure that corrective actions are clearly defined, documented, and verified after implementation.

Q 12. How do you develop and implement a predictive maintenance strategy?

Developing and implementing a predictive maintenance strategy is a multi-stage process that requires careful planning and execution. It’s like building a house: you need a solid foundation, proper materials, and skilled labor.

Assessment: Begin by assessing the criticality and failure modes of your assets. Identify equipment that’s most prone to failure and has the greatest impact on operations.

Data Acquisition: Determine the appropriate condition monitoring techniques (vibration analysis, oil analysis, thermal imaging, etc.) based on the equipment’s characteristics and potential failure modes. Install sensors and establish data collection procedures.

Data Analysis & Modeling: Use software and statistical methods to analyze the collected data, identify patterns and anomalies, and create predictive models for estimating remaining useful life (RUL) of components.

Maintenance Strategy Development: Establish maintenance procedures and workflows based on the RUL predictions. This could involve scheduling preventive maintenance tasks before failure is expected.

Implementation & Monitoring: Implement the strategy, track key performance indicators (KPIs), and continuously monitor and refine the approach to optimize performance and adapt to changing conditions. For example, we might adjust the thresholds for alerts based on real-world data.

Technology Integration: Integrate the predictive maintenance system with existing CMMS and other enterprise systems to streamline workflow and provide comprehensive data visibility.

Successful implementation relies on cross-functional collaboration, strong leadership, and a commitment to continuous improvement.

Q 13. Describe your experience with condition-based monitoring techniques.

Condition-based monitoring (CBM) is the cornerstone of predictive maintenance. It involves continuously monitoring the condition of equipment to detect early signs of degradation and predict potential failures. It’s like having a constant health check for your machinery.

My experience with CBM encompasses a wide range of techniques:

Vibration Monitoring: Using accelerometers and other sensors to detect changes in vibration patterns that indicate imbalances, misalignment, or bearing wear. We use both continuous monitoring and periodic inspections.

Oil Analysis: Regularly sampling and analyzing lubricating oil to detect contaminants, changes in viscosity, or degradation of additives that can indicate wear or other problems.

Thermal Imaging: Employing infrared cameras to detect overheating components that suggest electrical problems, friction, or other issues.

Acoustic Emission Monitoring: Using sensors to detect high-frequency sounds indicative of crack propagation, leaks, or other problems. This is particularly useful for detecting early signs of structural damage.

Effective CBM requires careful selection of appropriate sensors, reliable data acquisition systems, and sophisticated data analysis techniques to identify significant trends and anomalies. The choice of techniques depends heavily on the specific equipment and potential failure modes.

Q 14. What are the benefits and challenges of implementing predictive maintenance?

Predictive maintenance offers significant benefits but also faces challenges. Think of it as a powerful tool, but one that requires careful handling and understanding.

Benefits:

Reduced Downtime: By predicting failures, we can schedule maintenance proactively, minimizing unplanned downtime and maximizing production uptime.

Lower Maintenance Costs: Predictive maintenance avoids unnecessary preventative maintenance, reducing labor, parts, and overall maintenance expenses.

Improved Safety: Identifying potential failures before they occur helps prevent catastrophic events and enhance workplace safety.

Extended Equipment Life: Proactive maintenance extends the lifespan of equipment by addressing problems early and preventing major damage.

Better Resource Allocation: Predictive maintenance enables more efficient allocation of maintenance resources, focusing on critical equipment and high-risk failures.

Challenges:

High Initial Investment: Implementing predictive maintenance requires investment in sensors, software, and training.

Data Management & Analysis: Managing and analyzing large volumes of sensor data requires specialized expertise and robust data management systems.

Integration Complexity: Integrating predictive maintenance into existing maintenance systems and workflows can be complex.

Uncertainty in Predictions: Predictive models are not perfect; there’s always some degree of uncertainty in predictions, requiring careful interpretation and contingency planning.

Overcoming these challenges requires careful planning, a phased implementation approach, and a commitment to ongoing learning and improvement.

Q 15. How do you handle unexpected equipment failures?

Unexpected equipment failures are a reality in any industrial setting. My approach centers around a multi-pronged strategy that combines robust preventive maintenance with a swift and efficient response to unplanned downtime. First, we analyze the failure to understand the root cause. This involves meticulously documenting the circumstances surrounding the failure, examining the failed component, and reviewing historical maintenance data to identify patterns. Once the root cause is determined, we implement corrective actions to prevent recurrence. This might involve replacing faulty components, adjusting operational parameters, or improving our predictive maintenance models. Parallel to this, we have established protocols for rapid response. A dedicated team is trained to handle emergency situations, ensuring minimal disruption. We utilize a prioritized repair system, focusing on critical equipment first to minimize production losses. For instance, in a previous role involving a large-scale manufacturing plant, a critical compressor failed unexpectedly. Our rapid response team was able to get a replacement compressor installed within 8 hours, minimizing production loss to less than 1%.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the accuracy and reliability of predictive maintenance data?

Ensuring data accuracy and reliability is paramount for effective predictive maintenance. This starts with meticulous sensor selection and placement. Sensors must be appropriately chosen to capture the relevant parameters for the specific equipment, considering factors like temperature, vibration, pressure, and current. Regular calibration and validation of these sensors are essential to mitigate drift and ensure accurate readings. Data cleaning is another critical aspect, involving identifying and removing outliers, noise, and missing data. We employ various techniques such as moving averages, median filtering, and interpolation to handle these issues. Furthermore, data quality checks and validation procedures are integrated into our workflow to identify and correct anomalies early on. For example, if vibration data suddenly shows a significant increase beyond the expected range, we investigate immediately to determine if it’s a genuine issue or a sensor malfunction. Finally, we leverage statistical process control (SPC) charts to monitor data trends and identify potential problems before they escalate into failures.

Q 17. How do you communicate maintenance findings to stakeholders?

Effective communication of maintenance findings is key to stakeholder buy-in and successful implementation. My approach involves a multi-faceted strategy using various communication channels tailored to different audiences. For technical teams, detailed reports with data visualizations, graphs, and trend analysis are provided. These reports highlight key findings, recommended actions, and potential risks if action is delayed. For upper management, I present concise summaries focused on the financial implications of maintenance strategies, including cost savings, reduced downtime, and improved operational efficiency. Regular meetings with key stakeholders provide opportunities for discussions and collaborative decision-making. For example, when presenting a proposal for upgrading a critical piece of machinery, I use a cost-benefit analysis to demonstrate the long-term savings from reduced maintenance and increased uptime. We use dashboards to visualize key metrics in real time, allowing all stakeholders to monitor performance easily.

Q 18. Describe your experience working with different types of equipment.

My experience spans a wide range of equipment types, including rotating machinery (pumps, compressors, turbines), HVAC systems, industrial robots, and automated production lines. In my previous roles, I’ve worked with various manufacturers and technologies, from legacy equipment to the latest smart machinery equipped with advanced sensors and connectivity. I’m proficient in understanding the unique maintenance requirements of different equipment types, which involves grasping the operational principles, potential failure modes, and the most effective diagnostic and repair techniques. For instance, while working on a wind farm, I gained extensive experience in troubleshooting and maintaining large-scale wind turbines, including blade inspections, gearbox analysis, and generator diagnostics. This involved using specialized tools and techniques adapted to the unique challenges of a renewable energy environment.

Q 19. What software or tools are you proficient in for predictive maintenance?

I’m proficient in several software and tools used for predictive maintenance. This includes data acquisition systems such as Siemens SIMATIC and Rockwell Automation FactoryTalk for collecting data from various sources. I’m also adept at using data analysis software like MATLAB and Python (with libraries such as Pandas, NumPy, and Scikit-learn) for data preprocessing, analysis, and predictive modeling. Furthermore, I’m experienced with enterprise asset management (EAM) systems like SAP PM and IBM Maximo for managing work orders, inventory, and maintenance schedules. Finally, I’m familiar with cloud-based platforms like Azure IoT Hub and AWS IoT Core for managing and analyzing data from remotely located equipment. My experience extends to utilizing specialized software for specific equipment types, such as vibration analysis software (e.g., SpectraQuest) and thermal imaging software.

Q 20. How do you manage maintenance costs effectively?

Managing maintenance costs effectively involves balancing preventive and corrective maintenance actions to minimize total cost of ownership. This starts with a comprehensive risk assessment to identify critical equipment that requires more frequent and rigorous maintenance. By prioritizing preventive maintenance on high-risk equipment, we can avoid costly unplanned downtime and extensive repairs. We implement strategies like optimizing maintenance schedules using predictive analytics to perform maintenance only when necessary, reducing unnecessary interventions. We utilize condition-based monitoring, where maintenance is triggered by the actual condition of the equipment rather than a fixed schedule. Furthermore, we focus on improving maintenance efficiency by utilizing advanced techniques, streamlining processes, and optimizing inventory management. For instance, implementing a centralized lubrication system can significantly reduce lubrication costs and downtime. We also leverage data analytics to understand the underlying causes of equipment failures and implement targeted improvements to prevent future failures, minimizing the long-term cost of maintenance.

Q 21. What is your experience with developing and managing maintenance budgets?

My experience in developing and managing maintenance budgets involves a detailed process starting with forecasting future maintenance needs based on historical data, equipment age, and anticipated operational changes. This includes estimating the cost of labor, materials, and contract services. I then develop a budget that prioritizes critical maintenance activities while aligning with overall business objectives. Regular monitoring and tracking of actual maintenance expenses against the budget are performed to ensure that the budget remains on track. Variance analysis is used to identify any significant deviations and determine the root causes. This may involve renegotiating contracts, optimizing maintenance schedules, or identifying areas for cost savings. For instance, I successfully negotiated a long-term contract with a maintenance provider, leading to a 15% reduction in annual maintenance costs. Regular reporting to stakeholders on budget performance ensures transparency and allows for timely adjustments to the budget based on evolving needs and priorities.

Q 22. How do you ensure compliance with safety regulations during maintenance activities?

Ensuring safety during maintenance is paramount. My approach is multifaceted and begins with a thorough risk assessment, identifying potential hazards like energized equipment, hazardous materials, or confined spaces. This assessment informs the development of a comprehensive safety plan, which includes:

- Lockout/Tagout procedures: Strictly adhering to lockout/tagout protocols to de-energize equipment before maintenance, preventing accidental startup.

- Personal Protective Equipment (PPE): Mandatory use of appropriate PPE, such as safety glasses, gloves, hard hats, and hearing protection, tailored to the specific task.

- Permit-to-Work system: Employing a permit-to-work system for high-risk activities, ensuring authorization and verification before commencing work.

- Training and competency: Ensuring all maintenance personnel are adequately trained and competent in safe working practices relevant to their roles and the specific equipment.

- Regular safety inspections: Conducting regular inspections of the workplace and equipment to identify and mitigate potential hazards.

- Emergency response plan: Having a well-defined emergency response plan in place, including emergency contacts and procedures for dealing with accidents or incidents.

For instance, during a recent turbine maintenance project, we implemented a rigorous lockout/tagout procedure, involving multiple verifications before work commenced. This prevented any potential accidents due to unexpected power surges.

Q 23. Describe a time you had to troubleshoot a complex equipment failure.

I once faced a complex failure on a critical manufacturing process line. The equipment, a high-speed automated packaging machine, suddenly stopped, halting production. Initial diagnostics pointed to a motor failure, but replacing the motor didn’t resolve the issue. This led me to suspect a more complex problem.

My troubleshooting involved a systematic approach:

- Data analysis: I reviewed historical machine data, looking for patterns or anomalies preceding the failure. This revealed unusual vibration levels recorded just before the shutdown.

- Visual inspection: A thorough visual inspection uncovered misalignment in the machine’s components, likely caused by prolonged vibration.

- Component testing: Testing individual components, including bearings, belts, and the motor shaft, confirmed the misalignment as the root cause.

- Root cause analysis: By analyzing the misalignment, we determined that the foundation supporting the machine had settled unevenly over time.

- Corrective action: We implemented corrective actions, including leveling the machine’s foundation and aligning the components. We also initiated preventative measures such as regular foundation inspections and vibration monitoring.

This experience highlighted the importance of combining data-driven analysis with hands-on troubleshooting and meticulous attention to detail.

Q 24. How do you stay up-to-date with the latest advancements in predictive maintenance technology?

Staying current with predictive maintenance technology is crucial. My strategies include:

- Professional development: I actively participate in industry conferences, workshops, and webinars focused on predictive maintenance and related technologies (e.g., IoT, AI, machine learning).

- Industry publications: I regularly read industry journals, magazines, and online publications to stay informed about the latest advancements.

- Online courses and certifications: I pursue online courses and certifications to deepen my understanding of new technologies and techniques.

- Networking: I engage with other professionals in the field through online forums, professional organizations, and industry events to exchange knowledge and insights.

- Vendor interactions: I maintain contact with vendors of predictive maintenance technologies to learn about new product releases and updates.

For example, I recently completed a course on implementing AI-powered predictive models for equipment health monitoring, significantly enhancing my skillset.

Q 25. What are your strengths and weaknesses in predictive and preventive maintenance?

Strengths: My strengths lie in my analytical abilities, systematic troubleshooting approach, strong understanding of various predictive maintenance techniques (vibration analysis, oil analysis, thermography), and ability to translate complex technical information into actionable insights. I am also adept at implementing and managing predictive maintenance programs and collaborating effectively with cross-functional teams.

Weaknesses: While I am proficient in various predictive maintenance techniques, I am always striving to enhance my expertise in the emerging field of AI-driven predictive analytics. I am actively working to expand my knowledge in this area through continuous learning and practical application.

Q 26. Describe your experience with implementing a new maintenance strategy.

I was involved in implementing a new Reliability Centered Maintenance (RCM) strategy at a manufacturing plant. This involved transitioning from a primarily preventive maintenance approach to a more proactive, data-driven strategy.

The implementation included:

- Criticality analysis: We performed a thorough criticality analysis of all equipment to identify critical assets requiring the most attention.

- Data acquisition: We implemented a comprehensive data acquisition system to collect real-time equipment performance data.

- Predictive model development: We developed predictive models using machine learning techniques to forecast potential failures and optimize maintenance schedules.

- Maintenance task optimization: We optimized maintenance tasks based on the RCM analysis and predictive model outputs, focusing on preventing critical failures.

- Team training: We provided comprehensive training to the maintenance team on the new RCM strategy and the use of predictive maintenance tools.

The results were significant improvements in equipment reliability, reduced downtime, and optimized maintenance costs. This project demonstrated the value of a well-planned and executed transition to a more advanced maintenance strategy.

Q 27. How do you collaborate with other teams to ensure effective maintenance?

Effective maintenance requires strong collaboration. I foster collaboration by:

- Open communication: Maintaining open and transparent communication with all relevant teams (operations, engineering, procurement) through regular meetings, reports, and updates.

- Joint problem-solving: Actively involving other teams in problem-solving sessions, leveraging their expertise and perspectives to develop effective solutions.

- Shared goals and metrics: Establishing shared goals and key performance indicators (KPIs) to ensure everyone is working towards common objectives.

- Cross-functional training: Providing cross-functional training to enhance understanding and collaboration between teams.

- Regular feedback: Seeking and providing regular feedback to improve collaboration and address challenges proactively.

For example, during a recent project, I worked closely with the operations team to schedule maintenance activities during periods of low production, minimizing disruption to operations. This collaborative approach ensured the success of the maintenance program while maintaining operational efficiency.

Key Topics to Learn for Predictive and Preventive Maintenance Techniques Interview

- Fundamentals of Predictive Maintenance: Understanding the core principles, including condition monitoring techniques and data analysis methodologies. Explore the differences between predictive, preventive, and reactive maintenance strategies.

- Condition Monitoring Techniques: Deep dive into vibration analysis, oil analysis, thermal imaging, and ultrasonic testing. Learn how to interpret data from these methods and identify potential equipment failures.

- Data Analysis and Interpretation: Mastering data analysis techniques like statistical process control (SPC), root cause analysis (RCA), and trend analysis to extract actionable insights from condition monitoring data. Practice interpreting different types of graphs and charts.

- Preventive Maintenance Scheduling and Optimization: Learn how to develop and implement effective preventive maintenance schedules, considering factors such as equipment criticality, cost, and risk. Explore optimization techniques to maximize uptime and minimize maintenance costs.

- Reliability-Centered Maintenance (RCM): Understand the principles of RCM and how to apply it to optimize maintenance strategies based on equipment functionality and failure modes.

- Practical Applications and Case Studies: Review real-world examples of how predictive and preventive maintenance techniques have been successfully implemented across various industries. Consider studying case studies related to specific equipment or systems.

- Problem-Solving and Troubleshooting: Develop strong problem-solving skills to effectively diagnose equipment issues based on collected data and apply appropriate maintenance solutions.

- Software and Tools: Familiarize yourself with commonly used software and tools for predictive and preventive maintenance, such as CMMS (Computerized Maintenance Management Systems) and data analysis platforms.

Next Steps

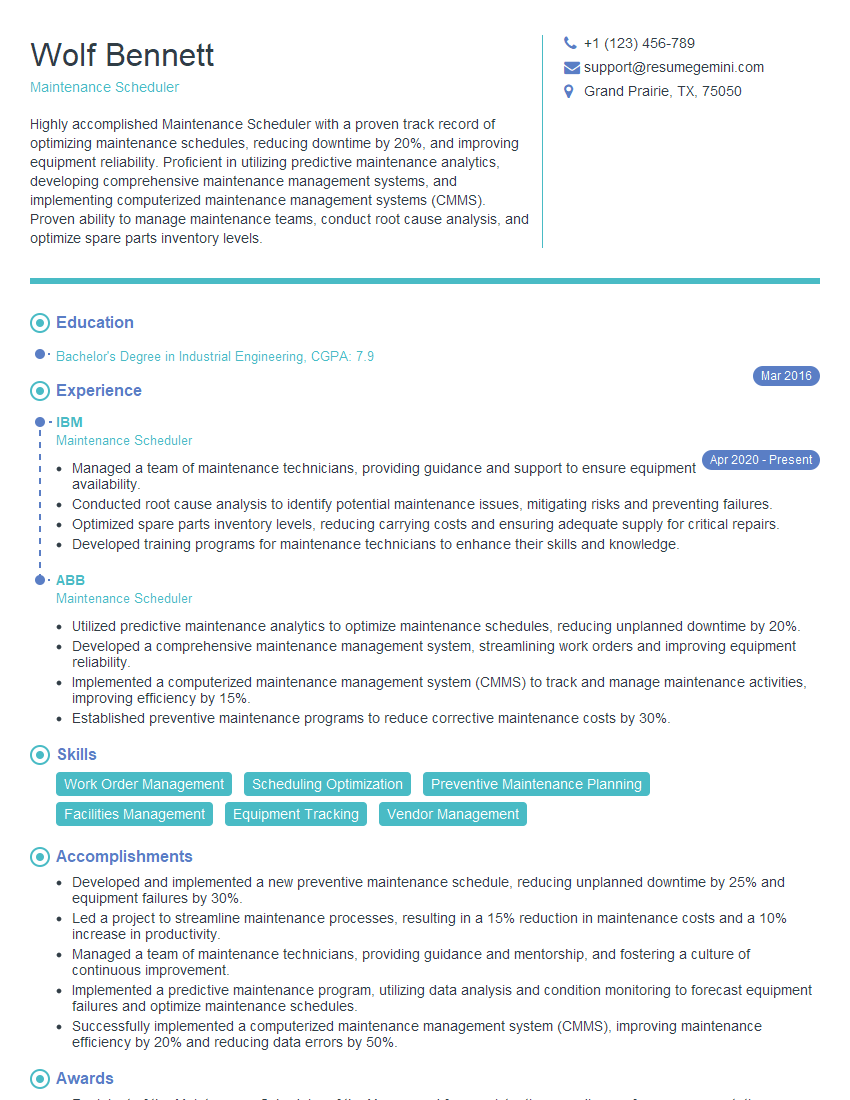

Mastering Predictive and Preventive Maintenance Techniques is crucial for career advancement in today’s increasingly data-driven industrial landscape. These skills are highly sought after, opening doors to exciting opportunities and higher earning potential. To stand out from the competition, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to showcase your expertise. Examples of resumes tailored to Predictive and Preventive Maintenance Techniques are available to guide you. Take the next step in your career journey – invest time in crafting a compelling resume that effectively communicates your skills and experience.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.