The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Continuous Improvement Tools (e.g., DMAIC) interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Continuous Improvement Tools (e.g., DMAIC) Interview

Q 1. Explain the DMAIC methodology.

DMAIC, which stands for Define, Measure, Analyze, Improve, and Control, is a structured five-phase methodology used for process improvement. It’s a data-driven approach, focusing on systematically reducing variation and defects in a process. Think of it as a roadmap for systematically solving problems and enhancing efficiency. Each phase builds upon the previous one, creating a continuous cycle of refinement.

- Define: Clearly define the problem, project goals, and customer requirements. This involves setting specific, measurable, achievable, relevant, and time-bound (SMART) goals.

- Measure: Collect data to understand the current process performance. This phase establishes baselines and identifies key metrics.

- Analyze: Analyze the collected data to identify the root causes of the problem. This often involves using statistical tools to pinpoint areas for improvement.

- Improve: Develop and implement solutions to address the root causes identified in the Analyze phase. This involves testing different solutions and selecting the most effective one.

- Control: Establish processes and controls to sustain the improvements made. This involves monitoring key metrics and making adjustments as needed to prevent regression.

For example, imagine a manufacturing process with a high defect rate. DMAIC would help define the specific defects, measure their frequency, analyze their root causes (e.g., faulty equipment, inadequate training), implement solutions (e.g., equipment maintenance, improved training), and finally, put controls in place (e.g., regular equipment checks, ongoing employee training) to prevent future defects.

Q 2. Describe your experience with Define phase activities.

In the Define phase, my experience involves working collaboratively with stakeholders to clearly articulate the problem and project scope. I facilitate brainstorming sessions using tools like SIPOC (Suppliers, Inputs, Process, Outputs, Customers) diagrams to map the process and identify key stakeholders. I then create a detailed Project Charter that includes the problem statement, project goals (expressed quantitatively whenever possible), project scope, timelines, team members, and key success metrics. For example, in a recent project focused on reducing customer order processing time, I led the team in defining the scope to include only online orders, specified a 20% reduction in processing time as the goal, and outlined specific metrics like average order processing time and customer order fulfillment rate.

A critical aspect of the Define phase is Voice of the Customer (VOC) analysis, where we gather customer requirements and expectations. This can involve surveys, focus groups, or analysis of customer feedback data. This ensures that our improvement efforts align directly with customer needs. In one project, VOC analysis revealed that customers valued quick and accurate order updates, guiding our focus towards improving the order tracking system.

Q 3. How do you measure process capability?

Process capability measures how well a process performs relative to its specifications. We typically use statistical tools like Cp and Cpk to assess capability. Cp indicates the inherent capability of the process, considering only the process variability and specification width. Cpk, however, considers both variability and the process centering relative to the specification limits, providing a more comprehensive measure. A Cpk value greater than 1.33 is generally considered acceptable, indicating that the process is capable of meeting specifications consistently.

To measure process capability, you need to collect a representative sample of data from the process. This data is then used to calculate the process mean and standard deviation. The specification limits (upper and lower control limits) for the process are also needed. These values are then plugged into the Cp and Cpk formulas. For example, if a process has a mean of 10, standard deviation of 1, and specification limits of 8 and 12, the Cp and Cpk values can be calculated and interpreted to determine the capability of the process.

It’s crucial to ensure the data collected is representative and free from assignable causes of variation before calculating Cp and Cpk, as these metrics can be misleading if the data doesn’t accurately reflect the process’s true performance.

Q 4. What are the key tools used in the Measure phase?

The Measure phase utilizes various tools to collect and analyze data, establishing a baseline for improvement. Key tools include:

- Histograms: To visualize the distribution of data and identify potential outliers.

- Control Charts: To monitor process stability and detect special cause variation. Examples include X-bar and R charts, p-charts, and c-charts.

- Check Sheets: For structured data collection, allowing for easy data tallying.

- Data Collection Plan: A detailed plan outlining what data will be collected, how it will be collected, and how frequently it will be collected.

- Measurement System Analysis (MSA): To ensure that the measurement system used is accurate and reliable. Gauge R&R studies are commonly used.

For instance, in a project to reduce customer complaints about late deliveries, we used a check sheet to categorize each complaint, control charts to monitor the daily number of complaints, and a histogram to visualize the distribution of delivery times.

Q 5. Explain your approach to root cause analysis.

My approach to root cause analysis is systematic and data-driven. I often employ a combination of techniques, including:

- 5 Whys: A simple yet effective technique to repeatedly ask “why” to uncover the underlying causes of a problem.

- Fishbone Diagram (Ishikawa Diagram): A visual tool that helps to brainstorm potential causes grouped by categories (e.g., manpower, machinery, materials, methods, measurement, environment).

- Pareto Chart: To prioritize causes based on their frequency or impact. This helps focus efforts on the most significant contributors to the problem.

- Failure Mode and Effects Analysis (FMEA): To systematically identify potential failure modes and their potential effects, allowing for proactive mitigation strategies.

I don’t rely on a single technique; instead, I select the most appropriate tool or combination of tools based on the specific problem and available data. For example, in a situation with a complex problem, I might start with a fishbone diagram to brainstorm potential causes, then use a Pareto chart to prioritize them and 5 Whys to delve deeper into the root cause of the most significant issue.

Q 6. How do you develop a control plan?

Developing a control plan is crucial for sustaining improvements. It’s a living document outlining the actions needed to maintain the improved process and prevent regression. I typically include the following elements:

- Key Process Variables (KPVs): The critical variables that need to be monitored to ensure the process remains stable.

- Measurement System: The methods and tools used to measure the KPVs.

- Control Limits: The upper and lower limits for the KPVs, indicating acceptable ranges.

- Response Plan: Actions to be taken if a KPV falls outside the control limits.

- Responsibility Matrix: Clearly defining who is responsible for monitoring each KPV and implementing the response plan.

- Review Schedule: A schedule for regularly reviewing the control plan and making updates as needed.

The control plan is not a static document; it should be reviewed and updated regularly to reflect changes in the process or environment. For instance, if a new technology is implemented, the control plan needs to be updated to reflect the new parameters and monitoring procedures. This ensures continuous monitoring and adaptation to sustain long-term improvements.

Q 7. What are the key metrics you track in a continuous improvement project?

The key metrics tracked in a continuous improvement project depend on the specific project goals, but generally include:

- Defect Rate: The number of defects per unit or per process cycle.

- Cycle Time: The time it takes to complete a process.

- Throughput: The rate at which the process produces outputs.

- Customer Satisfaction: Measured through surveys, feedback, or other methods.

- Cost Savings: The reduction in costs associated with the improved process.

- Process Capability Indices (Cp and Cpk): Quantify the process’s ability to meet specifications.

These metrics are tracked throughout the DMAIC process, from the baseline measurements in the Measure phase to the ongoing monitoring in the Control phase. Regular monitoring and reporting allow us to track progress, identify any deviations from the goals, and make necessary adjustments to ensure the project remains on track and delivers sustainable results. This data provides evidence of the impact of our improvements and justifies the continuation of the process improvement efforts.

Q 8. Explain the difference between a control chart and a histogram.

Control charts and histograms are both valuable tools in continuous improvement, but they serve distinct purposes. A histogram is a static representation of the distribution of data, showing the frequency of different values within a dataset. Think of it like a snapshot of your data at a specific point in time. It helps you understand the overall shape of your data – is it normally distributed, skewed, or bimodal? This information is crucial for identifying potential issues, such as excessive variability.

On the other hand, a control chart is a dynamic tool used to monitor a process over time. It plots data points sequentially, along with control limits (typically three standard deviations above and below the average). This allows you to visually identify if the process is stable (in control) or if there are assignable causes of variation leading to shifts or trends. Essentially, a control chart helps you detect changes in your process over time, while a histogram just provides a picture of the data at a given point.

Example: Imagine you’re monitoring the weight of cereal boxes coming off a production line. A histogram might show the distribution of weights from a single day’s production. A control chart would track the average weight of boxes over several weeks, flagging any significant deviations that indicate a problem with the filling machine or another aspect of the process.

Q 9. How do you handle stakeholder management in a continuous improvement project?

Stakeholder management is paramount to the success of any continuous improvement project. I approach it systematically, employing a proactive and communicative strategy. First, I identify all key stakeholders – from shop floor operators to senior management – and understand their interests and potential influence on the project. This often involves conducting interviews and reviewing organizational charts.

Next, I create a stakeholder register, documenting each stakeholder’s role, level of involvement, communication preferences, and potential concerns. This helps tailor my communication strategy. Regular communication is key. I provide updates through various channels—formal presentations, email updates, informal meetings—depending on the stakeholder’s preference and the information’s urgency.

Crucially, I actively seek feedback throughout the project lifecycle, addressing concerns promptly and transparently. This builds trust and ensures that the project aligns with overall organizational goals. Managing expectations realistically is also essential; I clearly articulate the project’s objectives, potential challenges, and timelines. Lastly, I celebrate successes and acknowledge contributions to foster a collaborative environment.

Q 10. Describe your experience using statistical software (e.g., Minitab).

I have extensive experience using Minitab, specifically for statistical process control (SPC) and data analysis within DMAIC projects. I’m proficient in creating various charts like control charts (X-bar and R charts, p-charts, c-charts, etc.), histograms, box plots, and capability analyses. I’ve utilized Minitab to perform hypothesis testing (t-tests, ANOVA), regression analysis, and design of experiments (DOE). For example, in a recent project focused on reducing defects in a manufacturing process, I used Minitab to analyze data from the process, identify significant factors affecting defect rates through ANOVA, and then used the results to support recommendations for process improvements. I am also comfortable with other statistical software like JMP and R but Minitab remains my preferred tool for its user-friendly interface and robust capabilities in SPC.

Q 11. What is your experience with SIPOC diagrams?

SIPOC diagrams (Suppliers, Inputs, Process, Outputs, Customers) are a valuable tool for visualizing the scope of a process. I’ve used them extensively to define the boundaries of projects before launching into detailed analysis. In essence, a SIPOC diagram provides a high-level overview of the entire process under consideration, identifying all key elements before delving into the specifics. This is particularly useful during the Define phase of a DMAIC project.

Example: In a project aimed at improving order fulfillment, a SIPOC diagram helped us clearly define the suppliers (raw material providers, packaging suppliers), inputs (raw materials, orders), the order fulfillment process itself, outputs (finished goods, shipping documents), and customers (retailers, end consumers). This provided a shared understanding of the scope and allowed us to focus our efforts effectively.

Q 12. How do you prioritize improvement projects?

Prioritizing improvement projects requires a balanced approach. I typically use a multi-criteria decision-making method, incorporating several key factors. The primary factors I consider include:

- Financial Impact: What is the potential cost savings or revenue increase associated with each project?

- Business Impact: How critical is the process to the overall business strategy? Does it affect customer satisfaction, operational efficiency, or regulatory compliance?

- Feasibility: How realistic is it to implement the proposed improvements? Are the necessary resources (time, personnel, budget) available?

- Urgency: How quickly does the problem need to be addressed? Are there immediate risks or consequences associated with the issue?

I usually present the prioritized list to stakeholders, ensuring transparency and buy-in. A simple matrix or scoring system is often used to facilitate this process, enabling a clear visual comparison of projects across different criteria.

Q 13. Explain the concept of value stream mapping.

Value stream mapping is a lean manufacturing technique used to visually represent the flow of materials and information in a process. It identifies value-added and non-value-added steps, helping to streamline processes and reduce waste. Essentially, it’s a detailed flowchart that goes beyond simple process steps to show the movement of materials, information, and the time spent at each stage.

The process typically involves walking through the process with team members, observing the actual workflow, and documenting each step’s duration, value add, and potential for improvement. The map then helps visualize bottlenecks, delays, and areas of waste (e.g., overproduction, inventory, motion). This visual representation fosters collaboration and identifies opportunities for improvement through process redesign and simplification. Future-state mapping helps visualize what the improved process might look like.

Q 14. Describe your experience with Kaizen events.

I have extensive experience facilitating Kaizen events, which are short, focused improvement workshops typically lasting a few days. My role usually involves leading a cross-functional team through a structured process to identify, analyze, and implement rapid improvements in a specific area. I’ve found that careful planning is crucial to the success of Kaizen events.

This includes clearly defining the scope, assembling a diverse and empowered team, and selecting an appropriate process to target. During the event, I facilitate brainstorming sessions, data collection, root cause analysis, and the development of countermeasures. The key is to ensure that the team members actively participate in the entire process, creating ownership and commitment to the implemented changes. Post-Kaizen event, I ensure that the improvements are standardized and monitored to prevent regression. I’ve seen significant improvements in efficiency, quality, and morale through well-executed Kaizen events, contributing positively to the overall continuous improvement journey.

Q 15. What is your understanding of 5S methodology?

5S is a workplace organization method that uses a list of five Japanese words: Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). It’s a foundational Lean methodology aimed at creating a more efficient and safe work environment.

- Seiri (Sort): Eliminate unnecessary items from the workspace. Think of it like decluttering your desk – only keep what you need for your daily tasks. This reduces waste and improves workflow.

- Seiton (Set in Order): Organize remaining items efficiently, placing frequently used tools within easy reach. This minimizes wasted time searching for items.

- Seiso (Shine): Clean and maintain the workspace regularly. A clean environment helps identify potential problems early and prevents accidents. Regular cleaning also improves morale and fosters a sense of pride.

- Seiketsu (Standardize): Establish consistent procedures for maintaining the first three S’s. This creates a sustainable system and ensures that improvements are maintained over time.

- Shitsuke (Sustain): Develop a habit of maintaining the first four S’s. This requires commitment, training, and regular audits to ensure that the improved practices become second nature.

For example, in a manufacturing setting, 5S might involve removing obsolete parts (Seiri), arranging tools logically in a designated area (Seiton), cleaning equipment daily (Seiso), creating a checklist for daily cleaning (Seiketsu), and implementing regular audits to ensure compliance (Shitsuke).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you identify and quantify the impact of a process improvement?

Identifying and quantifying the impact of a process improvement involves a structured approach. First, we need to establish baseline metrics before the improvement is implemented. These metrics should directly reflect the process’s performance. Then, after implementing the improvement, we collect data on the same metrics to see the change. The difference represents the impact.

For example, let’s say we are improving a customer service process. Our baseline metric could be average call resolution time. If the average was 10 minutes before the improvement and 7 minutes after, the impact is a 3-minute reduction.

Quantifying the impact goes beyond simply stating the change. We need to translate this improvement into tangible benefits like:

- Cost Savings: Reduced labor costs, lower material waste.

- Increased Efficiency: Shorter cycle times, higher throughput.

- Improved Quality: Fewer defects, higher customer satisfaction.

- Increased Revenue: Higher sales, improved customer retention.

To accurately quantify these benefits, we can use various techniques like cost-benefit analysis, return on investment (ROI) calculations, and statistical process control (SPC) charts to track the sustained impact.

Q 17. How do you handle resistance to change during a continuous improvement initiative?

Resistance to change is common during continuous improvement initiatives. Addressing it requires a proactive, empathetic approach. Here’s a strategy I use:

- Communication: Clearly explain the reasons for the change, the benefits, and how it will affect individuals. Open communication channels are key to addressing concerns.

- Involvement: Involve employees in the planning and implementation process. This helps them feel ownership and buy-in, rather than feeling like the change is being imposed upon them. Seek their feedback and address their concerns.

- Training and Support: Provide adequate training to help employees adapt to the new processes. Offer ongoing support to address any challenges they face.

- Addressing Concerns: Actively listen to and address concerns. Acknowledge any fears or anxieties and reassure employees that their input is valued.

- Pilot Testing: Implement the change in a small-scale pilot before full-scale deployment. This helps identify and address any potential problems early on and provides a chance to gather feedback and refine the process.

- Celebrate Successes: Recognize and celebrate successes along the way to build momentum and maintain morale. Positive reinforcement goes a long way.

For instance, when implementing a new software system, I might start with a pilot group to train and get feedback before rolling it out company-wide. This minimizes disruption and allows for adjustments based on early user experiences.

Q 18. What is your experience with FMEA (Failure Mode and Effects Analysis)?

FMEA (Failure Mode and Effects Analysis) is a systematic approach to identifying potential failure modes in a system or process and assessing their severity, occurrence, and detectability. The goal is to prioritize actions to mitigate the most critical risks.

My experience with FMEA involves leading workshops to identify potential failures, using a structured scoring system (severity, occurrence, detection), calculating the Risk Priority Number (RPN) for each failure mode, and developing mitigation strategies to reduce the RPN. I’ve used this in various contexts, including product development, manufacturing processes, and service delivery.

For instance, in a manufacturing process, we might use FMEA to identify potential failures in the assembly line, such as a faulty component, incorrect assembly, or operator error. We’d then assess the severity of each failure (e.g., customer injury, product recall), the likelihood of occurrence (e.g., frequency of component failure), and the probability of detecting the failure before it reaches the customer. This allows us to prioritize preventative actions, like improving component quality, enhancing worker training, or implementing better inspection procedures.

Q 19. How do you measure the success of a continuous improvement project?

Measuring the success of a continuous improvement project requires comparing pre- and post-implementation results against established goals and metrics. We need to evaluate whether the project achieved its intended outcomes and delivered the expected benefits.

Key metrics might include:

- Cost Reduction: Did the project deliver the expected cost savings?

- Efficiency Gains: Did cycle times improve as anticipated? Did throughput increase?

- Defect Reduction: Did the project lead to a decrease in defects or errors?

- Customer Satisfaction: Did customer satisfaction scores improve? Did customer complaints decrease?

- Return on Investment (ROI): Did the project generate a positive ROI?

Beyond numerical data, it’s also important to gather qualitative feedback through surveys, interviews, or focus groups to understand the impact on employees and customers. A successful project demonstrates not only quantitative improvements but also positive qualitative changes, sustainable improvements, and improved employee morale.

Q 20. Explain the difference between Lean and Six Sigma.

While both Lean and Six Sigma aim to improve efficiency and reduce waste, they approach it differently:

- Lean: Focuses on eliminating waste (muda) in all its forms – anything that doesn’t add value to the customer. It emphasizes continuous flow, pull systems (producing only what’s needed, when it’s needed), and reducing variability. Think of it as streamlining the process to move smoothly from start to finish. Tools include Value Stream Mapping, Kanban, and 5S.

- Six Sigma: Focuses on reducing variation and defects in processes to achieve near-perfection. It uses statistical methods to identify and eliminate root causes of variation. It’s more data-driven, using tools like DMAIC (Define, Measure, Analyze, Improve, Control) and Design of Experiments (DOE).

An analogy: Lean is like cleaning your house to make it easier to find things, while Six Sigma is like precisely measuring and adjusting your furniture to optimize the space. They can be complementary; a Six Sigma project might improve a specific step in a Lean process.

Q 21. Describe a time you identified and solved a process bottleneck.

In a previous role, we were experiencing significant delays in order fulfillment. Our investigation, using Value Stream Mapping, revealed a bottleneck in the packaging department. We were manually packaging items, and the process was slow and prone to errors. The team was working at maximum capacity, yet couldn’t keep up with demand.

To solve this, I followed these steps:

- Data Collection: We carefully measured the time taken for each step in the packaging process.

- Root Cause Analysis: We identified the causes of the slow process: manual packaging, inefficient layout, and lack of proper tools.

- Solution Development: We proposed three solutions: automating the packaging process using a semi-automated machine, reorganizing the packaging area for better workflow, and providing employees with ergonomic tools.

- Implementation: We implemented the semi-automated machine and reorganized the packaging area. The ergonomic tools were implemented in a phased approach.

- Monitoring and Control: We tracked order fulfillment times post-implementation and ensured that the improvements were maintained over time.

The result was a significant reduction in order fulfillment time, reducing it by 40% and decreasing backlogs. We also saw a reduction in packaging errors. This example illustrates how a targeted approach to identifying and eliminating a process bottleneck can have a significant positive impact on overall efficiency.

Q 22. How do you ensure the sustainability of process improvements?

Ensuring the sustainability of process improvements is crucial for realizing long-term benefits. It’s not enough to simply implement changes; we need to embed them into the organizational culture and processes. This involves several key strategies:

- Standard Work and Documentation: Clearly documenting the improved processes, including step-by-step instructions and visual aids, ensures consistency and prevents regression to old habits. Think of it like a well-written recipe – anyone can follow it and achieve the same results.

- Training and Empowerment: Thoroughly training all relevant personnel on the new processes is vital. Empowering employees to own the improvements and actively participate in their maintenance builds buy-in and sustains momentum.

- Performance Monitoring and Measurement: Regular monitoring using key performance indicators (KPIs) helps to track progress and identify any deviations early on. This proactive approach allows for prompt corrective actions, preventing small problems from escalating.

- Feedback Loops and Continuous Monitoring: Establishing feedback mechanisms enables continuous refinement and adaptation of the improved process. Regularly collecting data and analyzing results informs ongoing improvements.

- Leadership Commitment and Support: Sustainable improvement requires strong leadership support. Leaders must champion the initiative, allocate necessary resources, and actively participate in the process.

- Rewards and Recognition: Recognizing and rewarding individuals and teams for their contributions strengthens their commitment to sustaining improvements.

For example, in a previous project optimizing a manufacturing line, we not only improved the process but also created a visual management system (VMS) with clear KPIs displayed prominently on the shop floor. This ensured everyone was aware of the targets and their progress towards them. Regular team meetings allowed for feedback and problem-solving, sustaining the gains we made.

Q 23. What are your strengths and weaknesses in applying continuous improvement methodologies?

My strengths lie in my structured approach to problem-solving using methodologies like DMAIC. I’m adept at data analysis, statistical process control (SPC), and facilitating cross-functional teams. I excel at translating complex data into actionable insights and communicating them effectively to stakeholders at all levels. For example, in a past project involving reducing customer complaints, my ability to analyze the root cause through fishbone diagrams and Pareto charts led to a significant reduction in defect rates.

However, my weakness is occasionally getting too bogged down in the details. While meticulous data analysis is crucial, I’m working on improving my ability to prioritize tasks and efficiently move through the phases of a project without compromising the quality of the output. I’m actively addressing this by practicing time management techniques and delegating tasks where appropriate.

Q 24. What is your experience with different types of control charts (e.g., X-bar and R chart, p-chart, c-chart)?

I have extensive experience with various control charts. Control charts are powerful tools for monitoring process stability and identifying potential sources of variation. Here are a few examples:

- X-bar and R chart: Used to monitor the average (X-bar) and range (R) of a continuous variable. I’ve used this extensively to track manufacturing parameters like dimensions or weights.

- p-chart: Tracks the proportion of nonconforming units in a sample. This is particularly useful for monitoring defect rates in production processes. I applied this to improve the quality of a software development process by tracking the number of bugs found in each release.

- c-chart: Monitors the number of defects per unit. I used this in a project analyzing the number of scratches on painted car parts.

Choosing the right chart depends on the type of data being collected. For instance, if we’re tracking a continuous measurement like temperature, X-bar and R charts would be appropriate. If we’re tracking the proportion of defective items, a p-chart is the better choice. Misapplying a control chart can lead to incorrect conclusions, so selecting the right one is critical.

Q 25. Explain your understanding of Pareto charts and their application.

A Pareto chart is a combination bar and line graph that visually represents the ‘vital few’ factors contributing to a problem. It’s based on the Pareto principle (also known as the 80/20 rule), which suggests that 80% of effects come from 20% of causes. The bars represent the frequency of different causes, ordered from highest to lowest, while the line shows the cumulative percentage.

This helps prioritize improvement efforts by focusing on the most impactful causes first. For example, in a customer service context, a Pareto chart might reveal that 80% of complaints are due to three specific issues (e.g., slow response time, unhelpful staff, billing errors). By addressing these top three issues, we can achieve the most significant improvement in customer satisfaction.

Q 26. How do you use data to drive decisions in continuous improvement projects?

Data is the cornerstone of effective continuous improvement. I use data to drive decisions in several ways:

- Define the Problem: Data helps to quantify the problem and establish a baseline performance level. This might involve analyzing defect rates, customer complaints, cycle times, etc.

- Identify Root Causes: Tools like histograms, scatter plots, and control charts help identify patterns and correlations that reveal root causes of problems.

- Measure Improvement: Data tracks the effectiveness of implemented solutions and quantifies the achieved improvement.

- Control and Sustain: Ongoing data monitoring ensures that improvements are sustained over time and that any new issues are addressed promptly.

I always emphasize data integrity and accuracy, ensuring that data collection methods are robust and reliable. I also use statistical methods to analyze data and avoid drawing erroneous conclusions based on anecdotal evidence.

Q 27. Describe a challenging continuous improvement project and how you overcame the challenges.

One challenging project involved reducing cycle time in a highly automated manufacturing process. The initial assessment revealed numerous bottlenecks, complex interdependencies between machines, and resistance to change from some operators. We initially tried several quick fixes, but they had limited success.

To overcome these challenges, we employed a multi-pronged approach:

- Detailed Process Mapping: We created a detailed process map to visualize all steps in the process, highlighting bottlenecks and potential areas for improvement. This allowed the team to see the whole picture, not just isolated areas.

- Data-Driven Analysis: We collected detailed data on machine cycle times, downtime, and operator actions. This data-driven approach helped to identify the true bottlenecks and quantify the impact of various improvement initiatives.

- Kaizen Events: We organized several Kaizen events to involve operators directly in the improvement process. This increased their buy-in and led to valuable suggestions that we hadn’t considered.

- Cross-Functional Collaboration: We brought together engineers, operators, and management to address the interdependencies between machines and resolve operator concerns.

Through this collaborative and data-driven approach, we were able to significantly reduce cycle time, exceeding our initial targets. The success of the project was largely due to the combination of thorough analysis, effective teamwork, and active involvement of the shop floor personnel.

Key Topics to Learn for Continuous Improvement Tools (e.g., DMAIC) Interview

- DMAIC Methodology Overview: Understand the Define, Measure, Analyze, Improve, and Control phases, their sequential nature, and the iterative process.

- Define Phase: Mastering problem definition, using tools like SIPOC diagrams, and defining project scope and objectives. Practical application: Explain how to clearly articulate a problem statement and its impact on a business.

- Measure Phase: Proficiency in data collection methods, process mapping (e.g., value stream mapping), and key performance indicator (KPI) identification. Practical application: Describe how to select appropriate metrics and collect reliable data to assess process performance.

- Analyze Phase: Familiarity with statistical tools like hypothesis testing, regression analysis, and root cause analysis (e.g., 5 Whys, Fishbone diagrams). Practical application: Explain how to interpret data to identify the root causes of process variation.

- Improve Phase: Understanding process improvement techniques, such as design of experiments (DOE), Kaizen events, and Six Sigma methodologies. Practical application: Describe how to develop and implement solutions to address identified root causes.

- Control Phase: Knowledge of control charts, standard operating procedures (SOPs), and monitoring systems to sustain improvements. Practical application: Explain how to implement controls to prevent problems from recurring.

- Lean Principles Integration: Understanding the synergy between DMAIC and Lean principles (e.g., waste reduction, value stream mapping). Practical application: Discuss how Lean principles enhance the effectiveness of DMAIC.

- Software & Tools: Familiarity with relevant software and tools used in DMAIC projects (mention specific tools if applicable to your experience, e.g., Minitab, JMP).

Next Steps

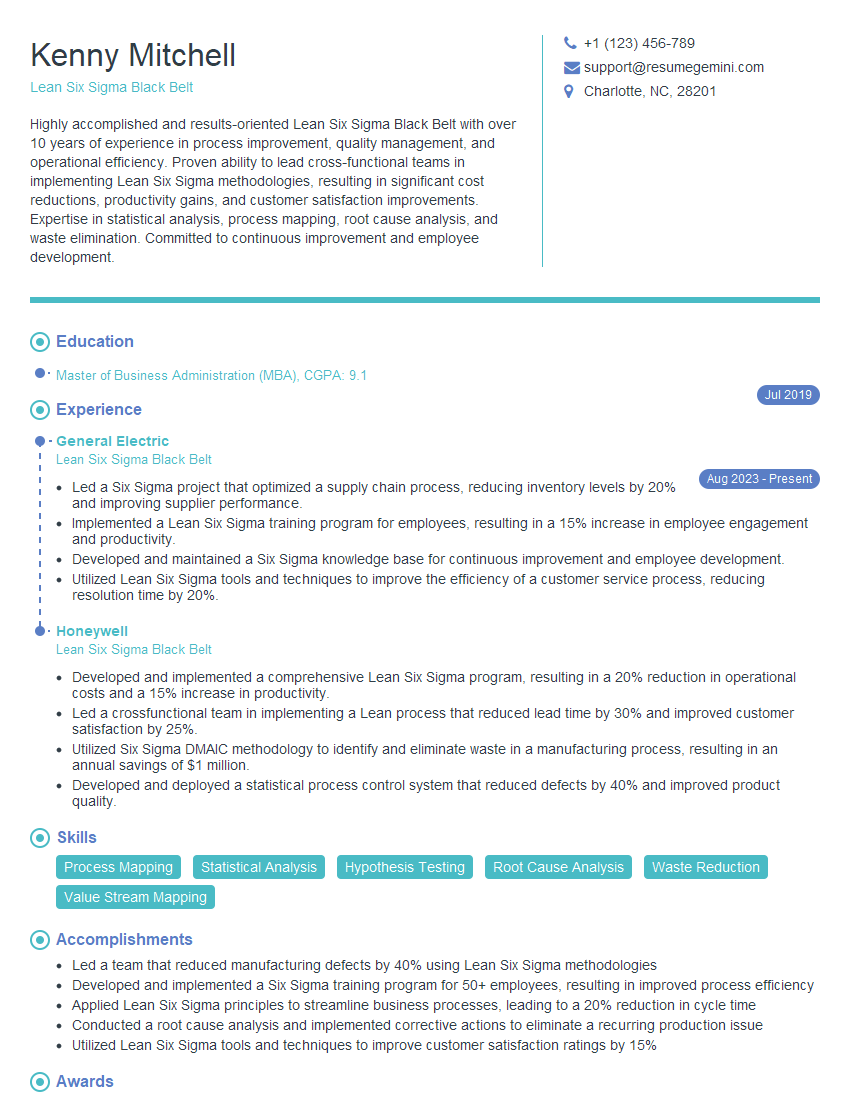

Mastering Continuous Improvement Tools like DMAIC is crucial for career advancement in many industries. It demonstrates your problem-solving skills, analytical abilities, and commitment to process optimization—highly valued attributes in today’s competitive job market. To significantly boost your job prospects, crafting an ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your DMAIC expertise. We provide examples of resumes tailored to Continuous Improvement Tools (e.g., DMAIC) to guide you in showcasing your skills effectively. Take the next step towards your dream career – build a winning resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.