The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Roof Inspections and Assessments interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Roof Inspections and Assessments Interview

Q 1. Describe your experience in identifying different types of roofing materials.

Identifying roofing materials is fundamental to a thorough roof inspection. My experience encompasses a wide range of materials, from common asphalt shingles to more specialized options like tile, slate, metal (standing seam, corrugated), and single-ply membranes (TPO, EPDM). I assess materials based on their visual characteristics, such as color, texture, and profile. For example, asphalt shingles are easily identified by their layered structure and granular surface, while clay tiles exhibit unique variations in color, size, and shape depending on the manufacturing process and region. Metal roofing is identifiable by its distinct metallic sheen and panels’ interlocking design. I also consider the age and condition of the material to understand its remaining lifespan and potential vulnerabilities. This involves examining for signs of wear and tear, such as cracking, curling, or missing pieces, which helps determine if materials are nearing the end of their service life.

- Asphalt Shingles: Easily identified by their granular surface and layered structure.

- Clay Tiles: Characterized by their unique color, shape and often visible porosity.

- Metal Roofing: Recognized by its metallic sheen and panel interlocking systems.

- Single-Ply Membranes: Identified by their smooth, seamless surface and typically large panel sizes.

Q 2. Explain the process of assessing roof damage caused by wind.

Assessing wind damage requires a systematic approach. I begin by examining the overall condition of the roof, looking for missing or damaged shingles, displaced flashing, or gaps in the roofing system. Wind damage often manifests as areas where shingles have been lifted, torn, or completely removed, particularly at the edges of the roof, ridges, and valleys – areas with higher wind exposure. I pay particular attention to areas where the wind may have lifted or peeled back shingles. I’ll also check for damage to vents, chimneys, and other roof penetrations. Furthermore, I’ll inspect the structural components of the roof for any signs of wind uplift, like damaged rafters or sheathing. Documenting wind damage includes taking detailed photos and noting the extent and location of the damage, including measurements if possible. I will also meticulously note any underlying issues that might have made the roof more vulnerable to wind damage, such as loose fasteners or deteriorated underlayment.

For example, I recently inspected a roof after a severe storm. The majority of the damage was concentrated along the south-facing slope which was most directly exposed to the prevailing winds. The inspection revealed numerous missing shingles, significant damage to the ridge cap, and a partially detached vent boot. This information was meticulously documented in my report with photos and detailed measurements of the affected areas.

Q 3. How do you identify and document water damage on a roof?

Identifying water damage involves a thorough examination of the entire roof system for signs of moisture intrusion. This includes looking for staining, discoloration, rot, mold, and mildew. On the roof surface itself, I look for dark streaks or discoloration on shingles, especially around valleys and flashing. Inside the attic, I examine the underside of the roof sheathing and insulation for evidence of water stains or dampness. I also assess the condition of the attic ventilation to ensure proper airflow. It’s crucial to identify the source of the leak as well, which often requires investigation beyond the visible damage. This may involve checking flashing around chimneys, skylights, vents, and penetrations. Documentation involves taking comprehensive photographs of all affected areas, including close-ups of damaged materials. Creating detailed sketches or diagrams illustrating the water paths can also be helpful, particularly for more complex leaks. I always record the location and extent of the damage for insurance purposes, using precise measurements and descriptions.

Q 4. What are the common signs of hail damage on asphalt shingles?

Hail damage on asphalt shingles often presents as small, circular bruises or indentations on the shingle surface. These are often referred to as ‘hail dimples’ or ‘hail marks’. The damage can range from barely noticeable to significant cracking or fracturing of the shingle granules. Severe hail can leave larger puncture marks, cracks, or even completely remove granules. The pattern of damage is usually inconsistent and scattered across the roof, though areas directly exposed to hail are likely to show more damage. It’s important to differentiate hail damage from other forms of shingle degradation, such as sun damage or wear and tear. Sun damage typically manifests as overall fading or cracking, whereas hail damage shows more localized impact points. I often use a magnifying glass to examine suspected hail damage closely, looking for granule loss, fracture patterns, or impact points that match the typical size and shape of hailstones based on reported storm data.

Q 5. Explain your experience using various inspection tools, such as drones or thermal imaging cameras.

My experience with various inspection tools significantly enhances the accuracy and efficiency of my roof assessments. I regularly utilize drones equipped with high-resolution cameras for capturing aerial imagery of the entire roof. This provides a comprehensive overview and allows for the detection of larger-scale issues, such as missing shingles or significant structural damage, that might be missed from ground-level inspections. Drones are particularly useful for accessing hard-to-reach areas. Furthermore, I frequently employ thermal imaging cameras to detect areas of moisture intrusion, temperature variations indicating potential insulation problems, or even subtle temperature differences pointing towards areas with structural defects. The thermal camera’s infrared technology allows me to identify problems not readily apparent during visual inspections. This technology is invaluable in identifying hidden moisture issues within walls and roofs, preventing potentially extensive and costly repairs down the line. I also employ moisture meters to quantify the moisture content in suspect areas, providing objective data to support my findings. All data obtained from these advanced tools is carefully documented and included in the final report.

Q 6. How do you determine the appropriate repair or replacement solutions for various roof defects?

Determining the appropriate repair or replacement solution depends on several factors, including the type of roofing material, the extent and nature of the damage, the age of the roof, and the client’s budget. For minor repairs, such as replacing a few damaged shingles, a simple patching solution may be sufficient. However, for more extensive damage, a more comprehensive repair or even a full roof replacement might be necessary. I consider the overall integrity of the roofing system. If significant areas of the roof are damaged or if the underlying structure is compromised, a full replacement may be the most cost-effective solution in the long run. I provide clients with several options, clearly outlining the advantages and disadvantages of each. This includes estimated costs, timelines, and potential long-term implications. My recommendations are always supported by the visual evidence captured during the inspection process and the data gathered from the inspection tools.

For instance, a client might have minor wind damage. I will discuss patching the affected areas as a cost-effective solution if the damage is limited. If, however, significant portions of the roof were affected by the wind, I would recommend a full roof replacement to prevent future issues and ensure the long-term integrity of the roof.

Q 7. Describe your experience in writing detailed roof inspection reports.

My roof inspection reports are comprehensive documents that clearly and concisely communicate the findings of my inspection. They are structured to provide a clear and logical flow of information, allowing for easy understanding. Each report begins with a summary of my findings and recommendations. This is followed by a detailed description of the inspection process, including the date, time, and location of the inspection. I then provide a section detailing the condition of various roofing components, such as the shingles, flashing, underlayment, and ventilation system. All observed defects, damages, or areas of concern are described in detail, using precise language and accompanied by high-quality photographic documentation and, where applicable, relevant thermal images or drone footage. I always quantify the extent of the damage using measurements and clear visual aids. Finally, I provide clear and concise recommendations, outlining necessary repairs or replacements, along with estimated costs and potential timelines. The reports are tailored to the specific needs of each client and the intended audience (e.g., homeowner, insurance adjuster).

Q 8. How do you prioritize repairs based on urgency and cost-effectiveness?

Prioritizing roof repairs involves a careful balancing act between urgency and cost-effectiveness. Think of it like a triage system in a hospital – you address the most critical issues first, then move to those that are important but less time-sensitive.

I use a two-pronged approach: First, I assess the safety risks. Anything that poses an immediate threat, like a significant leak causing interior water damage or a section of roof that’s about to collapse, takes top priority. These are emergency situations requiring immediate attention, regardless of cost. Second, I evaluate the extent of damage and its potential consequences. For example, a small crack in the flashing might be less urgent than widespread shingle damage, even if the flashing repair is slightly more expensive. I’ll create a prioritized list, presenting options to the homeowner, explaining the trade-offs between speed of repair, cost, and long-term impact on the roof’s lifespan.

- Safety First: Addressing structural issues or leaks that could cause damage to the home’s interior.

- Preventative Maintenance: Addressing smaller issues before they escalate into more expensive problems. This is where we look at cost-effectiveness – a small investment now might save a much larger one later.

- Long-Term Strategy: Considering the overall lifespan of the roof and planning repairs within a larger context of future maintenance.

Q 9. Explain your understanding of building codes and safety regulations related to roof inspections.

Building codes and safety regulations are crucial for ensuring a roof’s structural integrity and the safety of its occupants. My understanding covers aspects like minimum slope requirements, permitted materials, wind load resistance, and fire safety. These vary depending on location and the age of the structure. For example, in areas prone to high winds, the roof must meet specific wind resistance standards, and different materials might be required. I always consult the relevant local codes and standards for the specific area and project. I’m familiar with the International Building Code (IBC) and other regional codes, ensuring the roof meets the minimum safety standards. Furthermore, I’m well-versed in OSHA regulations related to fall protection and other safety measures necessary for working at heights during inspections and repairs. During inspections, I carefully look for compliance violations like improper flashing installation or inadequate ventilation, which can lead to significant issues and legal liabilities.

Q 10. How do you handle disagreements with homeowners or contractors about the findings of your inspection?

Disagreements can arise, and I approach them professionally and transparently. My approach is to calmly present my findings, supported by photos and detailed documentation. I explain my methodology and reasoning clearly, ensuring the homeowner and contractor understand the assessment. If there’s a discrepancy in interpretation, I’m willing to consider additional evidence or a second opinion from a qualified expert. Open communication is key – if a contractor disagrees with my findings, I try to understand their perspective and perhaps identify areas where we have differing opinions regarding acceptable standards or best practices. Ultimately, the goal is to arrive at a solution that prioritizes the roof’s structural integrity and the homeowner’s satisfaction. Sometimes, mediation from a neutral third party might be helpful.

Q 11. Describe your experience with different types of roof structures (e.g., gable, hip, flat).

My experience spans various roof structures, including gable, hip, flat, and more complex designs like mansard and gambrel. Each type presents unique challenges and necessitates a tailored inspection approach. Gable roofs, with their triangular ends, are common, but inspecting them involves checking the rafter tails and the potential for water damage in the valleys. Hip roofs, with sloped sides meeting at a ridge, require attention to the hip and ridge intersections, which are vulnerable to leaks. Flat roofs, often seen on commercial buildings, demand thorough assessment for ponding water, proper drainage, and membrane integrity. I’m adept at identifying potential weaknesses specific to each type, from checking for proper attic ventilation in gable roofs to ensuring adequate drainage on flat roofs. I’ve worked on numerous projects with different roof types and understand how to correctly assess their respective vulnerabilities.

Q 12. What are the common causes of roof leaks, and how do you locate them?

Roof leaks stem from various sources. Common culprits include damaged or missing shingles, cracked flashing, inadequate sealing around chimneys or vents, clogged gutters, and even ice dams in colder climates. Locating leaks requires a systematic approach. I start with a visual inspection, looking for obvious signs like stained ceilings or water marks. Then, I might use a moisture meter to detect hidden moisture within the roofing materials. In some cases, I’ll use a thermal imaging camera to identify temperature differences, indicating areas of heat loss that often coincide with leaks. A thorough examination of all flashings, chimneys, and vents is crucial. If the leak is hard to pinpoint, I might use a water test – carefully applying water to suspected areas to determine where the water is penetrating. The process often involves carefully examining each component of the roofing system to find the root cause.

Q 13. How do you assess the overall condition of a roof’s flashing and its importance?

Flashing is crucial for preventing leaks around penetrations in the roof, such as chimneys, vents, and skylights. It acts as a barrier, diverting water away from these vulnerable areas. Assessing flashing involves checking its condition for cracks, rust, or gaps. I look for proper installation and adequate overlap between flashing pieces. Missing or damaged flashing is a major contributor to roof leaks, so its integrity is paramount. During my inspection, I pay particular attention to the areas where flashing meets other components of the roof, as this is where issues frequently arise. Poorly installed or damaged flashing can lead to significant water damage if not addressed promptly. I’ll document any findings, clearly specifying the location and nature of damage, and recommend appropriate repair solutions.

Q 14. Explain the process of assessing the integrity of a roof’s underlayment.

Roof underlayment acts as a secondary water barrier, protecting the roof deck in case the shingles fail. Assessing its integrity usually involves accessing the attic space or carefully lifting shingles (in selected areas) to visually inspect the underlayment. I look for tears, punctures, or signs of deterioration. The underlayment’s condition is vital for preventing water damage to the structure. During inspections, I carefully note the type of underlayment used—synthetic or felt—as this influences its expected lifespan and vulnerability to damage. If significant damage is found, I’ll recommend its replacement to maintain a robust waterproofing system for the roof. For example, I might recommend replacing sections of damaged underlayment rather than the entire roof, offering a cost-effective solution while ensuring the roof’s protection.

Q 15. How do you determine the lifespan remaining for various roofing materials?

Estimating the remaining lifespan of roofing materials requires a multifaceted approach, combining visual inspection with knowledge of material properties and environmental factors. It’s not an exact science, but a well-informed estimation.

Asphalt Shingles: These typically last 15-30 years, depending on quality, climate, and installation. Factors like intense sun exposure, hail damage, and poor ventilation significantly reduce lifespan. I look for signs of granule loss, curling, cracking, and blistering to gauge their remaining life. For example, significant granule loss on more than 25% of the shingles suggests they are nearing the end of their life.

Tile Roofs (Clay or Concrete): These are known for their longevity, often lasting 50 years or more with proper maintenance. However, cracking, shifting, and damage from extreme weather events can shorten their lifespan. I’d check for cracks, broken tiles, and evidence of settling.

Metal Roofs (Steel, Aluminum, Copper): Metal roofs are exceptionally durable, potentially lasting 50-75 years or even longer. However, corrosion, particularly in coastal areas, can impact longevity. I examine for rust, dents, and signs of sealant failure at seams.

Built-Up Roofing (BUR): This type of roofing system used on flat roofs typically lasts 15-25 years but can be influenced by the quality of the materials, maintenance and exposure to the elements.

By carefully assessing these factors and combining visual inspection with knowledge of the specific material, I can provide a reasonably accurate estimate of the remaining lifespan, enabling homeowners to plan for future maintenance or replacement.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are some common signs of structural damage affecting the roof?

Structural damage to a roof can manifest in several ways, often indicating significant problems that need immediate attention. Early detection is key.

Sagging Rafters or Roofline: This often indicates weakened structural members due to age, rot, or excessive weight (snow, water accumulation). I would carefully examine the attic space for signs of deflection and assess the condition of rafters and trusses.

Cracked or Buckled Walls: Roof problems can transfer stress to the walls, leading to cracks. This is a serious sign that needs immediate investigation.

Roofline Separation: Gaps or separation between roof sections point to potential structural weakness or damage to the framing.

Chimney Issues: Cracks or leaning chimneys can indicate foundation issues that indirectly affect the roof’s structure. I’d inspect for any movement or damage.

Foundation Problems: A settling or uneven foundation can put immense stress on the roof structure. This may not be immediately obvious from the roof itself, requiring a close look at the foundation as well.

Identifying these signs requires a thorough inspection, which often includes accessing the attic and checking for signs of water damage or pest infestations that can weaken the structure.

Q 17. Describe your experience in using moisture meters for roof assessments.

Moisture meters are invaluable tools for detecting hidden moisture within roofing systems. I use both pin-type and non-contact meters, depending on the situation. The choice depends on the material and the access available.

Pin-type meters: These provide a more precise reading by penetrating the material. They are useful for checking wood framing, sheathing, and even some types of roofing materials. However, they can cause damage to certain surfaces.

Non-contact meters: These use infrared technology to detect moisture from a distance, ideal for initial scans and checking larger areas quickly. They’re less accurate than pin-type meters, but they cause no damage.

I use a systematic approach, creating a grid pattern to scan the roof. For example, when inspecting a suspected leak area, I’ll use a pin-type meter to check the wood sheathing around the leak area, carefully noting moisture readings at various points. The readings are then interpreted in conjunction with visual observations to determine the extent of water damage and inform repair decisions. It’s essential to understand that moisture readings need to be interpreted cautiously, as various factors such as ambient humidity can affect the readings. Therefore, I always compare the moisture readings with the surrounding environment and also use my visual assessment to check for other signs of moisture damage.

Q 18. How do you differentiate between necessary repairs and cosmetic issues?

Differentiating between necessary repairs and cosmetic issues is crucial for effective cost management and prioritizing work. A thorough inspection is vital for this distinction.

Necessary Repairs: These address issues that compromise the structural integrity, waterproofing, or energy efficiency of the roof. Examples include: leaking areas, damaged flashing around chimneys or vents, significant shingle damage, rotten structural members, and missing or damaged underlayment.

Cosmetic Issues: These affect the appearance of the roof without impacting its functionality or longevity. Examples include minor staining, slight discoloration, or minimal granule loss on asphalt shingles. Often, a simple cleaning or minor touch-ups may be sufficient.

I use a combination of visual inspection, detailed photography, and moisture testing to distinguish between these two. For instance, a small area of shingle discoloration might be cosmetic, but if it’s accompanied by elevated moisture readings beneath it, it becomes a sign of potential water ingress, necessitating repair. A thorough assessment ensures that I don’t recommend costly repairs for issues that pose minimal risk.

Q 19. How do you ensure accurate and comprehensive documentation of your findings?

Accurate and comprehensive documentation is paramount in roof inspections. It protects both the homeowner and the inspector. My documentation process involves:

Detailed Written Report: This includes a summary of findings, specific locations of identified problems, photographic evidence, and recommended solutions with estimated costs. The report clearly distinguishes between necessary repairs and cosmetic concerns.

High-Quality Photographs: I use a high-resolution camera to capture images of damaged areas, both close-up and wide shots, providing a visual record of the condition.

Sketch or Diagram: A simple sketch or diagram can help clarify the location of problems, especially in complex roofing systems.

Moisture Meter Readings: Numerical data from moisture meter readings are included, referencing specific locations.

Client Communication: I always thoroughly explain my findings to the client in person, answering all their questions before submitting the written report. Clear communication ensures they fully understand the situation.

This comprehensive approach ensures that the report provides a complete picture of the roof’s condition, serving as a valuable reference for future maintenance or repair decisions.

Q 20. Describe your proficiency in using specialized software for roof inspections (if applicable).

While I don’t rely solely on software, I utilize specialized software for report generation and image management. This improves efficiency and the professional presentation of my findings.

Specifically, I use software that allows me to:

Create professional-looking reports: The software helps me easily compile text, photos, diagrams, and moisture readings into a well-organized document.

Manage and organize images: Efficiently catalog and label all photos taken during the inspection.

Generate cost estimates: Some software programs have built-in features that help estimate repair costs based on the scope of work identified.

These tools streamline my workflow and enhance the overall quality of my reports, ensuring consistent and professional documentation.

Q 21. Explain your knowledge of different warranty types and their implications.

Understanding various warranty types is critical for both homeowners and inspectors. Different manufacturers offer different warranty structures, impacting the homeowner’s protection.

Manufacturer’s Warranty: This covers defects in materials and workmanship, typically for a specific period (e.g., 20-30 years for shingles). This warranty usually requires proof of purchase and proper installation.

Workmanship Warranty: This warranty, offered by the roofing contractor, covers their installation work. It typically covers issues arising from poor installation techniques.

Labor and Materials Warranty: Combines aspects of both manufacturer’s and workmanship warranties.

It’s important to note that warranties often have limitations and exclusions (e.g., damage caused by extreme weather events or neglect). As an inspector, I carefully review the warranty documents to understand the coverage and any potential limitations. I inform clients about the warranty terms and what aspects are covered, ensuring they understand their rights and responsibilities. Understanding the implications of warranty provisions is essential for managing expectations and ensuring that potential disputes are handled fairly.

Q 22. How do you communicate technical information effectively to non-technical clients?

Communicating complex roof inspection findings to non-technical clients requires a clear, concise, and relatable approach. I avoid jargon and instead use plain language, analogies, and visual aids. For example, instead of saying “compromised flashing,” I might say, “The seal around a part of your roof is damaged, allowing water to leak in, similar to a crack in a window.” I often use photos and diagrams from the inspection to illustrate my points, making the report easily understandable. I also prepare a summary report highlighting key findings and recommended actions, emphasizing the cost-benefit analysis of each repair option, putting the information into a context they readily understand. This ensures clients are informed and empowered to make the best decisions for their property.

Q 23. What are your methods for handling difficult or complex roof inspection scenarios?

Handling complex roof inspection scenarios involves a systematic approach. First, I thoroughly document all visible issues, taking detailed photos and notes. For example, if I find signs of significant water damage, I’ll meticulously record its location, extent, and potential source. Then, I might use specialized equipment, like a drone for hard-to-reach areas or a moisture meter to detect hidden problems. If the issue is beyond my expertise, I’ll consult with other specialists, such as structural engineers or restoration contractors, to get a second opinion and develop a comprehensive solution. Transparency and clear communication with the client are crucial throughout the process.

For example, one complex scenario involved a historical building with a slate roof. After initial inspection, I noticed subtle signs of shifting under the roof structure. I brought in a structural engineer to assess for potential foundation issues. This collaborative approach not only identified the root cause but also ensured the best solution for the preservation of the building and minimized cost for my client.

Q 24. How do you stay up-to-date on the latest roofing technologies and industry standards?

Staying current in the roofing industry is crucial for providing the best possible service. I regularly attend industry conferences and workshops, often sponsored by organizations like the NRCA (National Roofing Contractors Association). I subscribe to leading roofing journals and online resources, reading about new materials, techniques, and building codes. Additionally, I actively network with other roofing professionals to exchange knowledge and learn from their experiences. Manufacturer training programs for new products and technologies also play a vital role in keeping my skills sharp.

Q 25. Describe your experience with different types of roof ventilation systems.

I have extensive experience with various roof ventilation systems, including ridge vents, soffit vents, gable vents, and power ventilators. Understanding their individual strengths and weaknesses is vital for recommending the right system based on the specific roof design and climate. For instance, ridge vents are highly effective in creating even airflow across the roof, minimizing moisture buildup. However, they require proper soffit ventilation to function optimally, creating a balanced airflow system. Conversely, power ventilators are a good solution for difficult-to-ventilate roofs, but they require electricity and ongoing maintenance. I assess each roof’s needs considering its size, pitch, and material, as well as local climate conditions to ensure optimum performance and longevity.

Q 26. Explain your understanding of the impact of different climate conditions on roof longevity.

Climate conditions significantly impact roof longevity. Extreme temperatures, heavy snowfall, intense rainfall, and UV radiation all contribute to material degradation. For example, prolonged exposure to UV rays can cause asphalt shingles to become brittle and crack, reducing their lifespan. In regions with heavy snowfall, the weight of snow can place stress on the roof structure, potentially leading to damage. High winds can lift and damage roofing materials and systems. I account for these factors when evaluating a roof’s condition and predicting its remaining lifespan. My assessment includes considering the local climate history and anticipating potential future weather events relevant to the region.

Q 27. What safety precautions do you prioritize during roof inspections?

Safety is my top priority during every roof inspection. I always use appropriate fall protection equipment, including harnesses, ropes, and anchor points, especially when working on steep or high roofs. I regularly check the condition of my equipment. I wear appropriate safety footwear and clothing. I also inform the client of the inspection process and ensure the area is clear of obstructions before beginning the inspection. Before I even start any roof inspection, I conduct a visual assessment from the ground, looking for potential hazards. Weather conditions are always considered, and inspections are postponed if conditions are too dangerous.

Q 28. How do you handle emergency roof situations requiring immediate attention?

Emergency roof situations require immediate action. This could involve a significant leak during a storm, substantial structural damage from high winds, or any condition posing a safety risk. In such cases, I assess the severity of the problem, taking quick photos and notes of immediate damage. I then take steps to mitigate further damage: This could include temporarily covering a hole to prevent water ingress, securing loose materials to prevent them from falling, or evacuating the building if necessary. I immediately contact the client and appropriate emergency services if necessary, and advise them on immediate actions needed to protect the property. Following the immediate response, a complete inspection can then be carried out in the safety of appropriate conditions.

Key Topics to Learn for Roof Inspections and Assessments Interview

- Roofing Materials & Components: Understanding different roofing materials (asphalt shingles, tile, metal, etc.), their lifespan, common defects, and appropriate installation techniques. Practical application: Identifying signs of material degradation during an inspection.

- Structural Assessment: Evaluating the structural integrity of the roof system, including rafters, trusses, and sheathing. Practical application: Determining if a roof can safely support additional weight or requires repairs.

- Moisture Intrusion & Leak Detection: Identifying sources of water damage, such as leaks, missing flashing, and improper sealing. Practical application: Utilizing various techniques (moisture meters, visual inspection) to locate and diagnose leaks.

- Safety Procedures & Regulations: Adhering to safety protocols while conducting inspections, including fall protection and proper equipment use. Practical application: Demonstrating knowledge of OSHA regulations related to roof work.

- Report Writing & Documentation: Clearly documenting findings and recommendations in professional reports using appropriate terminology and photographic evidence. Practical application: Creating a comprehensive report summarizing the inspection, including photos and detailed descriptions of identified issues.

- Damage Assessment & Cost Estimation: Accurately assessing the extent of roof damage and providing cost estimates for repairs or replacements. Practical application: Using industry-standard pricing guides and experience to create realistic repair/replacement budgets.

- Insurance Claims & Codes: Understanding insurance claim processes and relevant building codes pertaining to roof inspections. Practical application: Preparing reports that are easily understood by insurance adjusters and meet regulatory requirements.

Next Steps

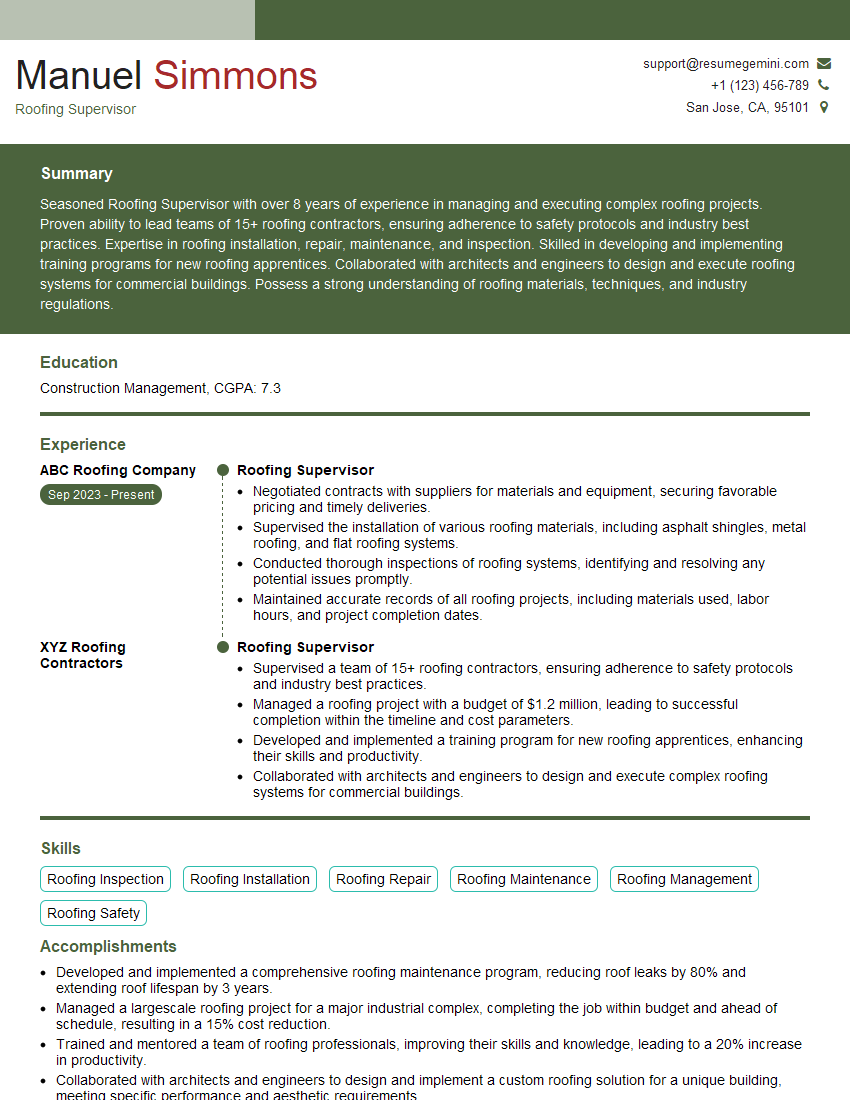

Mastering Roof Inspections and Assessments is crucial for career advancement in the construction and real estate industries, leading to higher earning potential and increased responsibility. To maximize your job prospects, it’s vital to create a professional, ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a compelling resume that stands out. Examples of resumes tailored to Roof Inspections and Assessments are available to guide you in showcasing your qualifications. Invest time in crafting a strong resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.