Are you ready to stand out in your next interview? Understanding and preparing for Warranty Management and Administration interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Warranty Management and Administration Interview

Q 1. Explain the different types of warranties (e.g., express, implied, extended).

Warranties are legally binding agreements that guarantee the quality of a product or service for a specific period. There are several key types:

- Express Warranties: These are explicitly stated by the seller, either orally or in writing. Think of the statement on a box: “One-year warranty against defects.” This clearly defines the terms and conditions. Examples include written warranties included with electronics or a verbal guarantee of a service’s quality.

- Implied Warranties: These are not explicitly stated but are implied by law. The most common are the implied warranty of merchantability (the product is fit for its ordinary purpose) and the implied warranty of fitness for a particular purpose (the product is fit for the specific purpose the buyer intends). For example, if you buy a toaster, it’s implied it will toast bread. If you buy a specialized high-altitude cooking pot, it’s implied that it will perform reliably at high altitudes.

- Extended Warranties: These are purchased separately from the manufacturer or retailer, extending coverage beyond the original warranty period. They typically offer protection against malfunctions, but their coverage details can vary widely. For example, a car dealer might offer an extended warranty for an additional 2 years beyond the factory warranty. These often cost extra but can offer peace of mind.

Q 2. Describe your experience with warranty claims processing and management.

In my previous role at Acme Corp, I managed the entire warranty claims process, from initial registration to final resolution. This involved developing and implementing a streamlined workflow. My responsibilities included:

- Receiving and logging claims: Using a CRM and warranty management system, I meticulously recorded each claim, ensuring all relevant information (product details, customer information, issue description, purchase date, etc.) was captured accurately.

- Claim assessment and verification: I reviewed each claim to ensure it fell within the warranty guidelines, comparing it to the terms and conditions, product specifications, and purchase documentation.

- Troubleshooting and diagnosis: Many cases required investigating the root cause of the problem, and we had multiple channels for this. Sometimes this involved liaising with customers to collect more information and guide them on basic troubleshooting steps. Other times, I collaborated with the engineering team for more complex issues.

- Repair or replacement authorization: Once a claim’s validity was confirmed, I authorized the repair or replacement of the defective product, ensuring the optimal solution based on efficiency and cost.

- Tracking and reporting: I maintained detailed records of each claim’s progress, generating reports to monitor key metrics such as claim resolution time, cost of repairs, and customer satisfaction.

I improved Acme Corp’s claim processing time by 15% by implementing a new automated system for initial claim validation.

Q 3. How do you track and analyze warranty data to identify trends and patterns?

Effective warranty data analysis is crucial for identifying patterns and making informed business decisions. My approach typically involves these steps:

- Data Collection: Gather data from various sources, including the warranty management system, CRM, and customer feedback surveys. The data is aggregated to provide a holistic view of warranty performance.

- Data Cleaning and Preparation: Data needs to be cleaned and formatted to remove any inconsistencies or errors. This might include standardizing data formats, handling missing values, and removing duplicates.

- Trend Analysis: Visualize the data through dashboards and charts to look for recurring patterns. I use tools like Excel, Tableau, and Power BI to understand trends. We can see things such as spikes in claims for certain products during specific periods, suggesting potential quality issues in certain batches or product lines.

- Root Cause Analysis: Once trends are identified, I dig deeper to understand the root causes. This often requires collaboration with engineering and manufacturing to identify defects or design flaws.

- Predictive Modeling: In some cases, I use statistical methods or machine learning algorithms to predict future warranty claims and estimate associated costs. For example, we might predict potential failure rates for a new product line based on similar products from the past.

Q 4. What metrics do you use to measure the effectiveness of a warranty program?

Measuring the effectiveness of a warranty program requires a multifaceted approach. Key metrics include:

- Warranty Claim Rate: The number of warranty claims filed relative to the number of units sold. A higher rate may indicate quality issues.

- Claim Resolution Time: The average time taken to resolve a warranty claim. Faster resolution times indicate efficiency and improve customer satisfaction.

- Warranty Cost per Unit: The total warranty cost divided by the number of units sold. This helps assess the overall cost-effectiveness of the program.

- Customer Satisfaction (CSAT) Score: Measures how satisfied customers are with the warranty service. This gives qualitative insight into the program’s effectiveness.

- First-Time Fix Rate (FTFR): The percentage of warranty claims resolved on the first attempt. A high FTFR indicates efficient diagnosis and repair processes.

- Return Rate: The percentage of products returned under warranty. This metric is closely related to the claim rate and helps identify issues.

Q 5. How do you handle disputes or disagreements regarding warranty claims?

Disputes over warranty claims are inevitable. My approach involves:

- Thorough Review of Evidence: Carefully review all documentation, including the warranty agreement, purchase receipt, and any supporting evidence from both the customer and our technicians.

- Open Communication: Maintain open and transparent communication with the customer to understand their perspective and address their concerns. This includes active listening and empathy.

- Escalation Process: If the issue cannot be resolved at the initial level, follow an established escalation procedure to involve higher management or specialized departments.

- Fair and Consistent Application of Policy: Ensure consistent application of warranty policy and procedures across all cases, treating all customers fairly.

- Alternative Dispute Resolution (ADR): In certain cases, it may be necessary to involve ADR methods such as mediation or arbitration to reach a mutually agreeable solution.

- Documentation: Meticulously document all interactions and decisions related to a dispute.

Q 6. Describe your experience with warranty software or systems.

I have extensive experience with various warranty management software and systems. At Acme Corp., we utilized a comprehensive system that integrated with our CRM and ERP. The system allowed for:

- Automated Claim Tracking: Automated routing of claims, reducing manual workload.

- Centralized Database: Centralized storage of warranty information, providing a single source of truth.

- Reporting and Analytics: Automated generation of reports and dashboards to track key metrics.

- Integration with other systems: Seamless integration with CRM, ERP, and inventory management systems to automate workflows.

- Customer Portal: Self-service portal for customers to submit claims and track their status.

We also used a dedicated inventory management system to track replacement parts. The software was crucial in increasing efficiency and accuracy.

Q 7. How do you ensure compliance with warranty regulations and legal requirements?

Ensuring compliance with warranty regulations and legal requirements is paramount. This involves:

- Staying Updated on Regulations: Continuously monitor and stay updated on all relevant laws and regulations, including consumer protection laws and industry-specific standards (e.g., Magnuson-Moss Warranty Act in the US).

- Clear and Concise Warranty Documents: Develop warranty documents that are clear, concise, and easy for customers to understand. Avoid ambiguous language or hidden clauses.

- Accurate Record Keeping: Maintain accurate records of all warranty-related activities, including claim submissions, approvals, and resolutions. This is essential for audits and compliance checks.

- Regular Audits and Compliance Reviews: Conduct regular internal audits to assess compliance with all applicable regulations and identify potential risks.

- Training and Education: Provide regular training to employees involved in warranty management to ensure everyone understands the legal obligations and best practices.

- Legal Counsel: Consult with legal counsel when necessary to ensure compliance with complex regulations and to obtain guidance on specific issues.

Q 8. Explain your experience with warranty reserve calculations and forecasting.

Warranty reserve calculations and forecasting are crucial for accurately estimating the financial liability associated with future warranty claims. It’s like setting aside money in a savings account to cover potential repairs or replacements down the line. My approach involves a multi-step process. First, I analyze historical warranty claim data, looking for patterns and trends. This includes factors like product type, age, failure mode, and claim frequency. Then, I utilize statistical models, such as Weibull or exponential distributions, to predict future claim rates. These models allow for forecasting claim volumes and costs based on expected sales and product life cycles. Furthermore, I incorporate external factors, like economic conditions and changes in product design, to refine the forecast. Finally, I regularly review and adjust the forecast as new data becomes available, ensuring its accuracy and relevance. For example, during a product recall, I would significantly adjust the forecast upwards to account for the increased number of claims anticipated.

In one project, I used a Weibull distribution model to forecast warranty reserves for a new line of high-tech consumer electronics. The model accounted for the product’s expected lifespan and historical data from similar product lines. This resulted in a 15% reduction in the initial reserve estimate, optimizing capital allocation while still adequately covering potential warranty costs.

Q 9. How do you identify and resolve root causes of warranty claims?

Identifying and resolving the root causes of warranty claims is a detective-like process requiring a blend of data analysis and engineering expertise. I start by systematically collecting data from various sources: warranty claim reports, field service reports, product testing data, and customer feedback. This data allows me to identify common failure modes and potential contributing factors. I then use various analytical techniques, such as Pareto analysis (the 80/20 rule) to pinpoint the most frequent and costly issues. Next, I collaborate with engineering and manufacturing teams to analyze the identified root causes – was it a design flaw, a manufacturing defect, or user misuse? Once the root cause is identified, corrective actions are implemented, which could range from design modifications and improved quality control procedures to enhanced customer training programs. Ultimately, the goal is not just to fix the current problem but to prevent similar issues from occurring in the future.

For instance, a high number of warranty claims related to a specific component of a refrigerator pointed towards a faulty supplier. By switching to a more reliable supplier, we significantly reduced subsequent warranty claims associated with that part.

Q 10. What is your experience with warranty cost analysis and control?

Warranty cost analysis and control is all about understanding and minimizing warranty expenses. It’s like managing a household budget, but for warranties. I begin by carefully tracking and categorizing all warranty costs, including repair costs, parts replacement, labor, freight, and administrative expenses. This detailed tracking allows me to identify trends and outliers. Then, I analyze the data to identify cost drivers – are certain product lines or failure modes disproportionately expensive? I develop cost reduction strategies based on the analysis. This could involve negotiating better prices with suppliers, improving repair processes, and enhancing product design to minimize failures. Regular reporting and dashboarding provide a clear view of warranty cost performance and help identify areas needing immediate attention.

In a previous role, I implemented a new repair process that reduced labor costs by 20% by streamlining the workflow and providing technicians with better training and tools. This resulted in significant savings on warranty expenses.

Q 11. Describe your experience with negotiating warranty terms and conditions.

Negotiating warranty terms and conditions requires a deep understanding of both the product’s reliability and the market landscape. My approach is to strive for a balance between protecting the company’s financial interests and offering a competitive warranty that attracts customers. This involves careful analysis of industry benchmarks and competitor offerings to ensure the warranty is both reasonable and attractive. The negotiation process begins with understanding the customer’s needs and expectations. I then present a range of options with varying coverage periods and repair options. Strong data supporting the reliability of the product is vital in justifying the terms. Clear and concise language is used in the warranty document to minimize potential misunderstandings. The ultimate goal is to arrive at a mutually acceptable agreement that fairly balances risk and reward for both parties.

For example, when negotiating a warranty for a new software product, I successfully negotiated a shorter warranty period in exchange for increased support and expedited bug fixes, resulting in a more cost-effective solution for both our company and the client.

Q 12. How do you manage and prioritize warranty claims based on urgency and impact?

Managing and prioritizing warranty claims requires a robust system for tracking and assessing the urgency and impact of each claim. I typically use a system that assigns each claim a priority level based on factors such as the severity of the problem, the potential safety risk, the customer’s satisfaction level, and the cost of repair. Claims involving safety hazards or critical failures are prioritized immediately. This system ensures that urgent claims receive prompt attention, while less urgent claims are addressed efficiently within a reasonable timeframe. Effective communication with customers keeps them informed of the claim’s status and expected resolution time. Furthermore, regularly reviewing the performance of the claim management system allows for continuous improvement and optimization.

We implemented a ticketing system that automatically prioritized claims based on predefined criteria, reducing response times and improving customer satisfaction.

Q 13. How do you communicate warranty information to internal and external stakeholders?

Communicating warranty information effectively is crucial for both internal and external stakeholders. For internal stakeholders (engineering, manufacturing, finance), I utilize clear and concise reports, dashboards, and presentations that highlight key metrics and trends. These reports help identify areas for improvement and provide a clear picture of warranty performance. For external stakeholders (customers, dealers, distributors), I ensure that warranty information is easily accessible and readily understandable. This is achieved through clear and concise warranty documents, user-friendly websites, and accessible customer service channels. Regular updates and proactive communication with dealers and distributors are vital to ensuring they are fully informed and able to address customer inquiries efficiently.

We created a customer portal that allowed customers to submit warranty claims, track their progress, and access warranty documents, improving transparency and satisfaction.

Q 14. Explain your approach to improving warranty processes and efficiency.

Improving warranty processes and efficiency is an ongoing effort requiring continuous monitoring and improvement. My approach is based on a data-driven methodology, beginning with identifying areas of weakness in the current processes. This involves analyzing key performance indicators (KPIs) such as claim processing time, customer satisfaction scores, and warranty costs. Next, I explore opportunities for automation, such as implementing automated claim processing systems and utilizing data analytics to predict and prevent potential problems. Streamlining communication channels between different departments and stakeholders improves collaboration and reduces bottlenecks. Regular process reviews and stakeholder feedback sessions are essential for identifying additional opportunities for improvement. The ultimate goal is to create a more efficient and customer-centric warranty process that minimizes costs and maximizes customer satisfaction.

In one instance, we implemented a robotic process automation (RPA) solution to automate claim processing, reducing processing time by 50% and freeing up staff for higher-value tasks.

Q 15. Describe your experience with warranty data reporting and analysis.

Warranty data reporting and analysis is crucial for understanding product reliability, identifying failure patterns, and ultimately reducing warranty costs. It involves collecting, cleaning, and analyzing data from various sources, including warranty claims, field service reports, and manufacturing data.

In my previous role, I was responsible for developing and maintaining a comprehensive warranty data reporting system. This involved creating dashboards that visualized key performance indicators (KPIs) such as warranty claim rates, average repair costs, and failure rates by product component. For instance, we discovered a significant increase in failures of a particular motor in a specific product line through this analysis. This led to a root cause analysis, resulting in a design improvement that drastically reduced warranty claims associated with that component. We used SQL queries and statistical analysis tools to analyze the data, identifying trends and outliers.

My analysis extends beyond simple descriptive statistics. I frequently conduct predictive modeling to forecast future warranty costs and resource allocation. This involves utilizing techniques like regression analysis and survival analysis to estimate the probability of failure over time and thus better predict the financial implications of warranty obligations. This proactive approach allows for more effective budgeting and proactive measures to mitigate potential risks.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you use technology to improve warranty management processes?

Technology plays a vital role in optimizing warranty management processes. I’ve leveraged various technologies to streamline operations and improve efficiency. This includes utilizing robust Warranty Management Systems (WMS), implementing data analytics tools, and integrating these systems with other enterprise resource planning (ERP) systems.

For example, I’ve implemented a WMS that automates claim processing, tracks parts inventory, and provides real-time visibility into warranty performance. This system significantly reduced manual data entry errors and processing time. We also integrated the WMS with our CRM system, enabling seamless data flow between customer service and warranty departments, leading to faster resolution of customer issues.

Furthermore, I’ve utilized business intelligence tools to create interactive dashboards and reports that provide insights into warranty costs, claim trends, and product reliability. This facilitates data-driven decision-making and allows for proactive identification of potential problems. Specific tools I have experience with include Tableau and Power BI for data visualization and SQL for data extraction and manipulation.

Q 17. How familiar are you with different warranty claim management systems?

I have extensive experience with various warranty claim management systems, both on-premise and cloud-based. My familiarity spans a range of functionalities, from simple claim tracking systems to sophisticated platforms integrating with ERP and CRM systems. I’ve worked with systems like Oracle Warranty Management, SAP Service Cloud, and several specialized third-party WMS solutions.

My experience encompasses the entire lifecycle of WMS implementation, including requirements gathering, system selection, configuration, training, and ongoing support. I understand the importance of selecting a system that aligns with the specific needs of the organization, considering factors such as scalability, integration capabilities, reporting features, and user-friendliness. For instance, I helped a previous employer evaluate different WMS solutions before successfully implementing a cloud-based system that significantly improved their operational efficiency and reduced their IT infrastructure costs. Key criteria we focused on during the selection process included ease of use for claim processors, accurate reporting capabilities, and robust integration with existing enterprise systems.

Q 18. What are your strategies for reducing warranty costs?

Reducing warranty costs requires a multi-faceted approach that focuses on improving product quality, enhancing customer service, and optimizing warranty processes. My strategies involve a combination of proactive and reactive measures.

- Proactive Measures: This includes improving product design through robust testing and analysis, implementing rigorous quality control procedures during manufacturing, and providing comprehensive training to customers on proper product usage.

- Reactive Measures: This involves analyzing warranty claim data to identify failure patterns and root causes. This data-driven approach enables targeted corrective actions, such as design improvements, process changes, or supplier remediation. For example, analyzing warranty data helped identify a supplier’s faulty component as the source of frequent failures. Switching to a higher-quality supplier drastically reduced warranty costs associated with that component.

- Process Optimization: Streamlining the warranty claim process reduces administrative costs. This involves automating tasks wherever possible, improving communication with customers, and implementing efficient parts management strategies.

A key aspect is focusing on preventative maintenance and early detection of potential problems. This proactive approach is significantly more cost-effective than reacting to failures after they occur. By combining these strategies, I have consistently achieved significant reductions in warranty costs in my previous roles.

Q 19. How do you handle warranty claims that are outside of the warranty period?

Handling warranty claims outside the warranty period requires a careful and consistent approach, balancing customer satisfaction with the company’s financial interests. The first step is to thoroughly investigate the claim, reviewing the documentation, the product’s history, and the nature of the failure.

If the claim is valid but outside the warranty period, several options are available. These may include offering a goodwill repair or replacement at a discounted price. Alternatively, we may offer extended warranty options to the customer. The decision depends on factors such as customer loyalty, the severity of the failure, and the potential impact on the company’s reputation. Clear internal guidelines and procedures are crucial for consistent handling of such situations. Documentation of each decision is vital to maintain transparency and avoid inconsistencies.

It’s equally important to clearly communicate the company’s position to the customer, providing a detailed explanation of why the claim is outside the warranty period while offering potential solutions or alternatives. This transparent and empathetic approach helps maintain a positive customer relationship, even in situations where the claim is not covered under the standard warranty.

Q 20. Explain your experience in developing and implementing warranty programs.

I have extensive experience in developing and implementing warranty programs, from initial concept design to full-scale deployment. My approach is highly collaborative, involving cross-functional teams from engineering, manufacturing, sales, and customer service. The process typically involves the following steps:

- Needs Assessment: Defining the scope of the warranty program, including the covered products, the duration of the warranty, and the types of failures covered.

- Program Design: Developing detailed program guidelines, including claim procedures, parts management, and cost allocation.

- System Implementation: Selecting and configuring a suitable warranty management system (WMS) to manage the program.

- Training and Communication: Educating relevant personnel on the new warranty program and communicating the changes to customers.

- Monitoring and Evaluation: Tracking key performance indicators (KPIs), such as claim rates and repair costs, to assess the program’s effectiveness and identify areas for improvement.

For instance, I led the development of a new warranty program for a medical device manufacturer, resulting in a 15% reduction in warranty costs within the first year. This involved a comprehensive review of existing warranty policies, improvements in product design and quality control processes, and implementation of a new, more efficient WMS.

Q 21. What is your understanding of warranty liability and risk management?

Warranty liability and risk management are critical aspects of a successful warranty program. Warranty liability refers to the potential financial obligations a company may incur due to warranty claims. Understanding and managing this liability is crucial for financial planning and risk mitigation.

Effective risk management involves several key steps:

- Risk Identification: Identifying potential warranty risks, such as product design flaws, manufacturing defects, or inadequate customer training.

- Risk Assessment: Evaluating the likelihood and potential impact of each identified risk.

- Risk Mitigation: Implementing strategies to reduce the likelihood or impact of identified risks. This may involve improving product design, implementing quality control measures, or enhancing customer training.

- Contingency Planning: Developing plans to address potential warranty issues that may arise despite risk mitigation efforts. This includes having reserves set aside to cover potential warranty costs and establishing procedures for handling unexpected spikes in claim volume.

- Regular Monitoring and Review: Continuously monitoring warranty performance, reviewing risk assessments, and adapting strategies as needed.

By proactively addressing warranty risks, companies can minimize financial exposure, protect their reputation, and maintain customer satisfaction. This requires a data-driven approach, utilizing warranty data to identify potential problems and inform risk mitigation strategies.

Q 22. How do you ensure data accuracy and integrity in warranty management?

Data accuracy and integrity are paramount in warranty management. Inaccurate data leads to incorrect financial projections, poor customer service, and flawed product analysis. We achieve this through a multi-pronged approach:

- Robust Data Entry Processes: Implementing standardized forms, clear instructions, and data validation rules at the point of entry minimizes errors. For example, we might use dropdown menus instead of free-text fields for product model numbers to prevent typos.

- Regular Data Audits: Scheduled audits, both manual and automated, identify inconsistencies and inaccuracies. This could involve comparing warranty claim data against sales figures or checking for duplicate entries.

- Data Reconciliation: Regularly reconciling warranty data with other systems (e.g., CRM, ERP) ensures data consistency across the organization. This helps to identify discrepancies between different sources of truth.

- Data Cleaning and Standardization: Regularly cleaning and standardizing data ensures consistent formats and reduces ambiguity. This may involve correcting inconsistencies in spelling, formats and addressing missing or incomplete information.

- Automated Data Validation: Utilizing software with built-in validation rules (e.g., checking for logical inconsistencies like repair costs exceeding product value) further enhances accuracy.

- Secure Data Storage: Employing secure data storage and access controls prevents unauthorized modifications and data breaches, maintaining the integrity of our records.

Think of it like building a house – a solid foundation of accurate data is crucial for a strong and stable warranty management system.

Q 23. Describe your experience in training staff on warranty procedures.

Training staff on warranty procedures is essential for efficient and consistent claim processing. My approach focuses on both theoretical understanding and practical application:

- Needs Assessment: I begin by identifying the specific knowledge gaps and skills needed within the team, tailoring the training accordingly.

- Modular Training: I break down the training into manageable modules focusing on specific areas like claim submission, eligibility criteria, and different warranty types. This allows for targeted learning and easier comprehension.

- Hands-on Workshops: Practical workshops with real-life scenarios and case studies allow staff to apply their knowledge and develop problem-solving skills. For example, we might simulate the processing of a complex claim involving multiple components.

- Role-Playing Exercises: Role-playing exercises help staff develop the communication skills necessary to effectively interact with customers regarding warranty claims.

- Ongoing Support and Refresher Training: I ensure continued support through readily available resources and periodic refresher training to account for changes in policies or processes. This could involve creating a comprehensive internal wiki or online training modules.

- Assessment and Feedback: I incorporate assessments and feedback mechanisms to evaluate training effectiveness and identify areas needing improvement.

For example, in a previous role, I developed an online training module that reduced claim processing time by 15% by improving staff understanding of the warranty process.

Q 24. How do you manage and resolve escalated warranty claims?

Escalated warranty claims require a systematic approach that prioritizes effective communication and thorough investigation.

- Detailed Review: I start with a thorough review of the claim, examining all supporting documentation and communication history. This often involves scrutinizing the original product registration, repair attempts, and customer correspondence.

- Contacting the Customer: Direct communication with the customer is crucial to gather further information and understand their perspective. This helps to build rapport and identify any potential misunderstandings.

- Technical Assessment: Depending on the complexity of the claim, I may involve the engineering or technical team for a thorough assessment of the reported defect. This might include product teardown and analysis to determine the root cause.

- Policy Review: A comprehensive review of the applicable warranty policy is essential to determine the appropriate course of action. This includes checking the warranty period, coverage exclusions, and any applicable terms and conditions.

- Resolution and Communication: Once a decision is reached, I ensure clear and timely communication with the customer, explaining the resolution in detail and addressing any concerns they may have. I focus on providing a fair and transparent solution, even if it involves a compromise.

- Documentation: Meticulous documentation throughout the entire process is key, ensuring a clear audit trail for future reference.

For instance, I once successfully resolved an escalated claim involving a complex manufacturing defect by collaborating with the engineering team, leading to a product recall and a satisfactory resolution for affected customers.

Q 25. What is your understanding of different warranty contract types (e.g., pro-rata, time & material)?

Different warranty contract types offer varying levels of coverage and protection. Understanding these differences is crucial for effective warranty management.

- Pro-rata Warranty: This type of warranty covers the product for a specified period, but the coverage decreases proportionally with time. For example, a product with a 2-year pro-rata warranty might offer full coverage in the first year, 50% coverage in the second year, and no coverage after that. The cost of repair is often shared between the manufacturer and the customer based on the remaining warranty period.

- Time and Material Warranty: This type of warranty covers repairs for a specified time period, but the customer is responsible for paying the cost of labor and materials. This is common for extended warranties or service contracts.

- Full Warranty: This provides complete coverage for defects in materials or workmanship for a specific period, usually without any cost to the customer.

- Limited Warranty: This type of warranty covers specific parts or aspects of the product for a defined period. It might exclude certain components or types of damages.

Understanding the nuances of each type is vital for accurate claim processing and financial forecasting. For example, a pro-rata warranty requires more complex calculations than a full warranty, necessitating appropriate software and well-trained staff.

Q 26. How would you handle a large influx of warranty claims?

Managing a large influx of warranty claims requires a structured and scalable approach.

- Surge Capacity Planning: Having a plan in place to handle unexpected increases in claim volume is crucial. This may involve cross-training staff, engaging temporary help, or leveraging automated processes.

- Prioritization: Prioritizing claims based on urgency and severity ensures that critical issues are addressed promptly. For example, claims related to safety hazards would take precedence.

- Automation: Automating routine tasks like claim acknowledgment, eligibility checks, and basic troubleshooting significantly improves efficiency and reduces processing time. For example, a CRM system can automate email responses to customers.

- Improved Communication: Proactive communication with customers regarding potential delays and expected processing times helps to manage expectations.

- Root Cause Analysis: A significant increase in claims might indicate a problem with the product itself. A thorough root cause analysis helps identify and address underlying issues, reducing future claims.

- Temporary Staffing: Hiring temporary staff for the duration of the surge provides additional support for claim processing and other tasks.

Imagine a sudden surge due to a product recall – a well-defined process, incorporating these strategies, is essential to minimizing disruption and maintaining customer satisfaction.

Q 27. How do you balance customer satisfaction with cost control in warranty management?

Balancing customer satisfaction and cost control is a delicate but crucial aspect of warranty management. It’s not a zero-sum game; a well-managed warranty program can enhance both.

- Proactive Customer Service: Excellent customer service reduces the number of escalated claims. Prompt and helpful responses to initial inquiries can prevent minor issues from escalating.

- Streamlined Processes: Efficient claim processing reduces administrative costs and improves turnaround times. Automation and standardized procedures are essential here.

- Data-Driven Decision Making: Analyzing warranty data to identify trends and common failure points helps to improve product design and reduce future warranty costs. This proactive approach is more cost-effective than simply reacting to individual claims.

- Fair and Transparent Policies: Clearly defined and easily understood warranty policies help manage customer expectations and reduce disputes. This reduces the need for costly negotiations and legal intervention.

- Preventative Maintenance Programs: Encouraging or offering preventative maintenance programs can reduce the number of warranty claims, thereby lowering costs in the long run. This is particularly useful for complex or high-value products.

For example, one strategy I employed was implementing a tiered warranty system, offering more extensive coverage for customers willing to pay a premium. This balanced customer choice with better cost control for the company.

Q 28. Describe your experience with using warranty data for product improvement.

Warranty data is a goldmine of information for product improvement. By analyzing warranty claims, we can identify recurring problems, design flaws, and areas for improvement.

- Failure Analysis: Analyzing patterns in warranty claims – such as frequency, component failure, and geographical distribution – reveals potential product weaknesses. This data is invaluable for identifying areas needing redesign or improved manufacturing processes.

- Product Design Improvements: Identifying recurring failures leads to improved designs, stronger materials, or enhanced manufacturing processes. This ultimately reduces warranty costs and enhances product reliability.

- Supply Chain Management: Warranty claims can pinpoint problems with components supplied by third-party vendors. Addressing these issues strengthens the supply chain and ensures higher quality components.

- Process Improvements: Analyzing the claim process itself – the time taken to process, the number of escalations, etc. – identifies areas for improvement in internal workflows and staff training.

- Data Visualization: Using data visualization techniques to represent warranty data effectively communicates insights to engineers and product managers, fostering collaboration and faster problem-solving.

In a previous role, we used warranty data to identify a weakness in a specific component, leading to a redesign that reduced warranty claims related to that component by over 70%. This resulted in significant cost savings and enhanced customer satisfaction.

Key Topics to Learn for Warranty Management and Administration Interview

- Warranty Claim Processing: Understanding the entire lifecycle of a warranty claim, from initial registration to final resolution. This includes analyzing claim validity, processing documentation, and managing communication with customers and vendors.

- Warranty Data Analysis: Using data to identify trends, predict potential issues, and improve warranty processes. This involves working with databases, generating reports, and drawing actionable insights.

- Contractual Obligations: Thorough knowledge of warranty contracts, including terms and conditions, exclusions, and limitations. Being able to interpret and apply these clauses in real-world scenarios.

- Warranty Reserve Management: Accurately estimating and managing the financial reserves allocated for warranty claims. This requires understanding accounting principles and forecasting techniques.

- System and Software Proficiency: Demonstrating familiarity with common warranty management software and databases. Highlighting skills in data entry, reporting, and system optimization.

- Problem-Solving and Decision-Making: Presenting experience in resolving complex warranty disputes, navigating ambiguous situations, and making effective, data-driven decisions.

- Communication and Customer Service: Showcasing excellent communication skills, especially in handling customer inquiries, complaints, and providing timely updates.

- Regulatory Compliance: Understanding relevant laws and regulations related to warranties and consumer protection, ensuring compliance within all procedures.

- Process Improvement: Demonstrating experience in identifying areas for improvement within warranty management processes and implementing effective solutions to enhance efficiency and reduce costs.

Next Steps

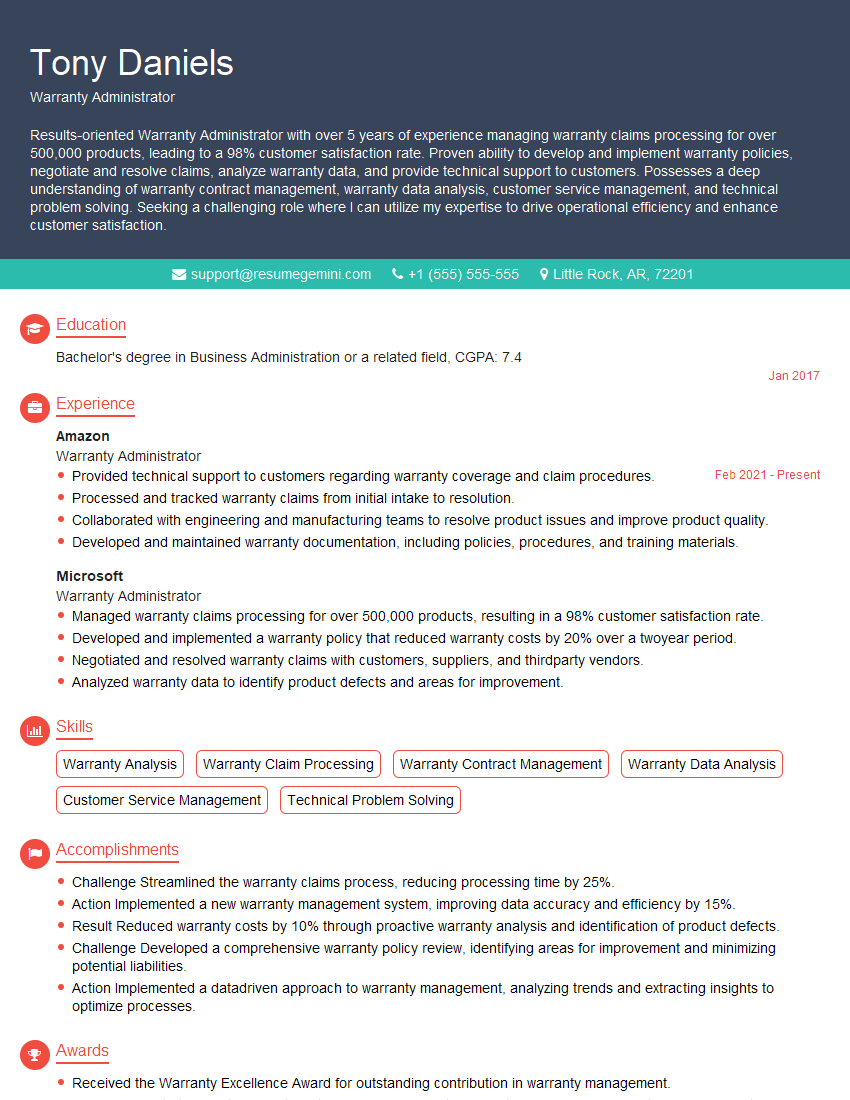

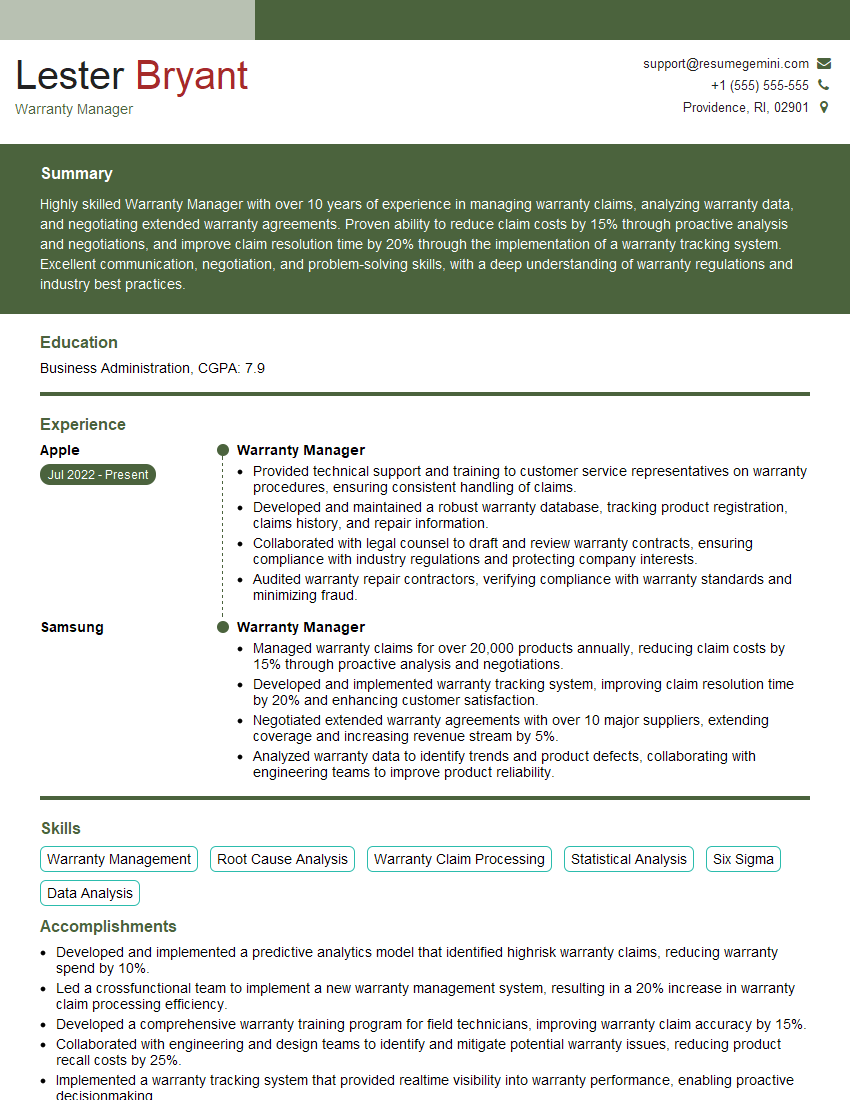

Mastering Warranty Management and Administration opens doors to rewarding career paths with increasing responsibility and higher earning potential. A strong understanding of these concepts is highly sought after in many industries. To maximize your job prospects, focus on creating a compelling, ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to Warranty Management and Administration are available to guide your efforts. Invest in crafting a strong resume—it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.