Are you ready to stand out in your next interview? Understanding and preparing for Yarn and Fabric Manufacturing interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Yarn and Fabric Manufacturing Interview

Q 1. Explain the difference between warp and weft yarns.

In weaving, warp and weft yarns are fundamentally different and determine the fabric’s structure. Imagine building a wall with bricks: the warp yarns are the lengthwise, vertical bricks, providing the foundation, while the weft yarns are the horizontal bricks that interlace with the warp, filling the gaps and creating the fabric’s surface.

- Warp yarns: These are the yarns that run lengthwise on the loom, providing the framework for the fabric. They are typically stronger and more tightly twisted than weft yarns to withstand the tension during weaving.

- Weft yarns: These are the yarns that run across the width of the fabric, interlacing with the warp yarns to create the fabric’s structure. They are often softer and less tightly twisted than warp yarns.

For example, in a simple plain weave, like your cotton shirt, the warp and weft yarns alternate over and under each other, creating a simple, strong, and versatile fabric. A more complex weave, like twill, would involve a more intricate pattern of interlacing.

Q 2. Describe the various types of weaving techniques.

Weaving techniques vary widely, influencing the fabric’s final appearance, texture, and properties. They’re categorized by the way the warp and weft interlace. Some common techniques include:

- Plain weave: The simplest weave, where the weft yarn goes over one warp yarn and under the next, creating a balanced, reversible fabric. Think of your basic cotton t-shirt.

- Twill weave: Creates diagonal lines on the fabric surface due to a pattern where the weft yarn floats over two or more warp yarns before going under one. Denim is a classic example of twill weave.

- Satin weave: Characterized by a smooth, lustrous surface due to long floats of the weft yarns. Satin sheets are a good illustration.

- Jacquard weave: A complex weave that allows for intricate patterns, often seen in tapestries or high-end upholstery fabrics. The design is woven directly into the fabric.

Choosing the right weaving technique is crucial for achieving the desired aesthetic and functional characteristics in the final fabric. The choice depends on factors such as the intended use, desired drape, durability needs, and cost considerations.

Q 3. What are the different types of knitting structures?

Knitting structures, unlike weaving, are created by interlocking loops of yarn. This process yields fabrics with different properties, such as stretch and drape.

- Knit fabrics: These are made by forming interlocking loops of yarn in a series of rows and columns. Examples are jersey (used in t-shirts), rib (used in cuffs and collars), and purl (creating textured surfaces).

- Weft knitting: This technique uses one yarn to create the fabric, feeding it across a bed of needles which form loops. It’s commonly used for producing seamless garments.

- Warp knitting: This process uses many yarns simultaneously. It’s quicker and better for producing fabrics with specific patterns or textures but requires more complex machinery. Lace is a prime example.

The type of knitting structure affects the fabric’s properties significantly. For instance, jersey knit is stretchy and drapes well, while rib knit is more stable and less prone to stretching. This diversity allows knit fabrics to find applications across various clothing and household textile areas.

Q 4. Explain the process of yarn spinning.

Yarn spinning transforms raw fibers into continuous strands of yarn. The process involves several crucial steps:

- Fiber opening and cleaning: Removes impurities and prepares the fibers for further processing.

- Carding: Aligns and disentangles the fibers, creating a continuous web.

- Combing (optional): Further refines the fibers, removing short fibers and improving the yarn’s evenness and smoothness.

- Drawing: Stretches and thins the fiber web, creating a more uniform strand.

- Spinning: Twists the fiber strands together, creating the yarn. Different spinning techniques (ring spinning, open-end spinning, air-jet spinning) provide varying yarn properties.

- Winding: The yarn is wound onto packages for further processing.

The choice of spinning technique and parameters significantly impacts the yarn’s properties. For example, ring spinning produces stronger, more even yarns but at a slower rate, while open-end spinning is faster but might result in slightly less uniform yarns. Therefore, yarn manufacturers carefully select processes and parameters to meet the desired quality and cost requirements.

Q 5. Describe different types of textile fibers and their properties.

Textile fibers are the basic building blocks of yarns and fabrics. They’re categorized into natural and synthetic fibers, each with unique properties:

- Natural fibers:

- Cotton: Soft, absorbent, comfortable, but prone to wrinkling.

- Wool: Warm, elastic, moisture-wicking, but can shrink or felt.

- Silk: Luxurious, smooth, lustrous, but delicate and expensive.

- Linen: Strong, absorbent, durable, but can wrinkle easily.

- Synthetic fibers:

- Polyester: Strong, wrinkle-resistant, durable, but less breathable.

- Nylon: Strong, elastic, wrinkle-resistant, but can be less absorbent.

- Acrylic: Soft, warm, affordable, but less durable than natural fibers.

- Rayon: Soft, smooth, drapes well, but can be weaker than other fibers.

Understanding these properties allows manufacturers to blend fibers, creating fabrics with optimized characteristics for specific applications. For example, a blend of cotton and polyester might create a durable and wrinkle-resistant shirt, while a blend of wool and silk could result in a luxurious, warm scarf.

Q 6. How do you ensure quality control in yarn manufacturing?

Quality control in yarn manufacturing is paramount for producing consistent and high-quality products. It’s a multi-stage process encompassing:

- Raw material inspection: Assessing fiber quality, cleanliness, and uniformity before spinning.

- In-process monitoring: Regularly checking the spinning process for consistency in yarn count, evenness, and strength.

- Testing: Employing various tests (tensile strength, elongation, yarn count, imperfections) at various stages of production.

- Statistical Process Control (SPC): Utilizing statistical methods to monitor and control the manufacturing process, minimizing variability.

- Visual inspection: Examining yarn for defects like knots, slubs, and neps.

Effective quality control involves employing automated systems, trained personnel, and robust quality management systems (like ISO 9001) to ensure that the yarn consistently meets pre-defined specifications. This ensures customer satisfaction and maintains brand reputation.

Q 7. What are the common fabric defects and their causes?

Fabric defects can significantly impact the quality and marketability of textile products. Some common defects and their causes include:

- Broken ends: Warp or weft yarns that break during weaving, often due to excessive tension or weak yarns.

- Holes: Gaps in the fabric, caused by missed warp or weft yarns during weaving.

- Slubs: Thick places in the yarn, caused by irregularities in the fiber distribution during spinning.

- Neps: Small entangled fiber clusters in the yarn, affecting the fabric’s surface appearance.

- Pilling: Formation of small balls of fiber on the fabric surface, caused by abrasion.

- Wrinkles: Creases or folds in the fabric, which can be caused by improper finishing or weaving.

Identifying the root cause of these defects is crucial for implementing corrective actions and preventing their recurrence. This involves meticulous inspection, careful analysis of the manufacturing process, and often adjustments to machine settings or raw materials.

Q 8. Explain the dyeing process for fabrics.

Fabric dyeing is the process of adding color to fibers, yarns, or fabrics. It’s a crucial step in textile manufacturing, transforming plain materials into vibrant and aesthetically pleasing products. The process involves immersing the fabric in a dye bath containing water, dye, and other chemicals to help the dye bind to the fibers. Different methods exist depending on the fiber type, desired color, and production scale.

Key methods include:

- Direct Dyeing: This method involves applying dye directly to the fabric. It’s simple and cost-effective but often produces less colorfast results.

- Reactive Dyeing: Reactive dyes form a chemical bond with the fiber, resulting in excellent colorfastness. This is common for cellulosic fibers like cotton.

- Vat Dyeing: Used for cellulosic fibers, this process involves insoluble dyes that are converted to soluble forms for dyeing and then made insoluble again to fix the color. This yields excellent washfastness.

- Disperse Dyeing: Suitable for synthetic fibers like polyester, disperse dyes are insoluble and are dispersed in the dye bath. They penetrate the fiber and are fixed by heat.

Factors influencing the dyeing process include: Dye concentration, temperature, pH level, time, and the presence of other chemicals like assistants that help with dye penetration and fixation. The choice of dyeing method depends on factors such as the fiber type, the desired colorfastness, and cost considerations. For example, a high-end garment might require reactive dyeing for its superior colorfastness, while a less expensive item might use direct dyeing.

Q 9. What are the different finishing treatments applied to fabrics?

Fabric finishing treatments enhance the fabric’s appearance, performance, and durability. These treatments are applied after dyeing and can significantly impact the final product’s quality and value. They can be broadly classified into:

- Mechanical Finishing: This involves processes like calendaring (pressing to create smooth surfaces), shearing (removing protruding fibers), and embossing (creating patterns).

- Chemical Finishing: This includes treatments such as:

- Mercerization: Treats cotton to increase luster, strength, and dye affinity.

- Water Repellency: Coating the fabric to make it resistant to water.

- Flame Retardancy: Treating the fabric to make it less flammable.

- Antimicrobial Finishing: Incorporating agents to inhibit the growth of bacteria and fungi.

- Softening: Improving the fabric’s hand feel (how it feels to the touch).

Choosing the right finishing treatments is crucial. For instance, a performance fabric for sportswear might require water repellency, breathability, and antimicrobial finishes, while a luxurious dress fabric may focus on softness and drape.

Q 10. How do you calculate fabric GSM (grams per square meter)?

GSM (Grams per Square Meter) is a measure of fabric weight. It indicates how many grams of fabric are present in one square meter. This value is crucial in determining fabric quality and cost. Calculating GSM involves weighing a known area of fabric.

Calculation:

- Cut a precise square of fabric (e.g., 1 meter x 1 meter or a smaller, known dimension).

- Weigh the fabric sample using a precise scale. Record the weight in grams.

- Calculate the GSM using the following formula:

GSM = (Weight of fabric sample in grams) / (Area of fabric sample in square meters)

Example: If a 0.5m x 0.5m sample weighs 25 grams, the GSM is:

GSM = 25 grams / (0.5m * 0.5m) = 100 GSM

Accurate measurement and a calibrated scale are essential for obtaining reliable GSM values. This value is vital for quality control, pricing, and selecting appropriate fabrics for different applications.

Q 11. Explain the concept of fabric shrinkage.

Fabric shrinkage refers to the reduction in fabric dimensions after washing or exposure to moisture and heat. This can occur due to the relaxation of fibers or the loss of certain finishes applied during manufacturing. Shrinkage can significantly affect the garment’s fit and appearance, causing issues like tightness or unevenness.

Types of Shrinkage:

- Relaxation Shrinkage: Occurs due to the fibers returning to their natural state after being stretched during manufacturing.

- Felting Shrinkage: Primarily affects wool fabrics and is caused by the entanglement of fibers during washing.

Preventing Shrinkage: Manufacturers employ various techniques to minimize shrinkage, including pre-shrinking the fabric, using specific yarn treatments, and careful selection of finishing processes. The type and extent of shrinkage can be determined through laboratory tests, allowing manufacturers to predict the final dimensions and address potential issues during the design process. For example, a manufacturer might use pre-shrunk cotton for a shirt to ensure it retains its shape after washing.

Q 12. What are the different types of textile machinery used in yarn and fabric manufacturing?

Textile machinery encompasses a wide range of equipment used in yarn and fabric production. These machines are sophisticated and precise, each playing a vital role in transforming raw materials into finished products. Key examples include:

- Spinning Machines: These machines convert fibers into yarn, with various types such as ring spinning, open-end spinning, and air-jet spinning machines, each producing yarn with different characteristics.

- Weaving Machines: These machines interlace yarns to create woven fabrics. They range from simple handlooms to highly automated shuttleless looms.

- Knitting Machines: Used for producing knitted fabrics by interlooping yarns. These can be weft knitting (creating fabrics like jersey) or warp knitting (creating fabrics with higher stability).

- Dyeing and Finishing Machines: These include jiggers, padding mangles, and stenters, used in the dyeing and finishing stages of fabric processing.

- Other machinery: This includes preparatory machinery (like carding and combing machines for fiber processing), winding and warping machines (preparing yarns for weaving or knitting), and inspection machines (checking for quality defects).

The choice of machinery depends on the type of fabric being produced, the desired quality, and production scale. A small-scale operation might use simpler machinery, while large-scale production requires highly automated and efficient systems.

Q 13. Describe the importance of maintaining textile machinery.

Maintaining textile machinery is paramount for ensuring consistent production, high-quality output, and minimizing downtime. Regular maintenance directly impacts productivity, efficiency, and the overall profitability of a textile operation. Neglecting maintenance can lead to costly breakdowns, reduced product quality, and increased waste.

Importance:

- Reduced Downtime: Preventative maintenance avoids unexpected breakdowns that can halt production.

- Improved Product Quality: Well-maintained machinery produces consistent and high-quality fabrics.

- Increased Efficiency: Smoothly running machines improve overall productivity.

- Extended Machine Lifespan: Regular maintenance prolongs the life of expensive machinery.

- Safety: Proper maintenance ensures the safe operation of machinery and protects workers.

A comprehensive maintenance program should include regular inspections, lubrication, cleaning, part replacement, and operator training. Implementing a computerized maintenance management system (CMMS) can help schedule and track maintenance activities effectively.

Q 14. How do you troubleshoot common problems in textile machinery?

Troubleshooting textile machinery requires a systematic approach. It involves identifying the problem, isolating the cause, and implementing the appropriate solution. The process often begins with observing the machine’s behavior and listening for unusual noises.

Steps in Troubleshooting:

- Identify the Problem: Determine what is malfunctioning (e.g., broken yarn, uneven fabric, machine stoppage).

- Gather Information: Collect information from machine operators, maintenance logs, and any available error messages.

- Isolate the Cause: Check for common causes such as faulty components, improper settings, or power issues. This often involves careful inspection of the machinery and its various parts.

- Implement the Solution: Once the cause is identified, take the necessary corrective actions (e.g., replace a broken part, adjust machine settings, or address a power problem).

- Document the Resolution: Keep detailed records of the problem, cause, and solution for future reference.

Example: If a weaving machine is producing fabric with broken ends, you might check the yarn quality, tension settings, or the condition of the heddles (parts that control the warp yarns). A systematic approach ensures that the problem is addressed effectively and efficiently, reducing downtime and improving productivity.

Q 15. Explain the role of a quality control inspector in textile manufacturing.

A quality control inspector in textile manufacturing plays a crucial role in ensuring that the final product meets the required standards of quality, consistency, and customer specifications. They act as the gatekeepers, preventing defective products from reaching the market. Their responsibilities span the entire production process, from raw materials to finished goods.

- Inspection of Raw Materials: Inspecting yarn for strength, evenness, and the absence of defects like knots or slubs. This ensures that the foundation of the fabric is sound.

- Monitoring the Manufacturing Process: Observing the weaving or knitting process to identify any inconsistencies or machine malfunctions that could affect the fabric’s quality. This might involve checking fabric tension, weft insertion, or needle operation.

- Fabric Testing: Performing various tests on the finished fabric, such as tensile strength, abrasion resistance, colorfastness, and shrinkage, using standardized methods and equipment.

- Defect Detection: Carefully examining the fabric for any defects like holes, broken yarns, mispicks, or uneven dyeing. This often involves visual inspection, aided by specialized equipment like magnifying glasses or automated defect detection systems.

- Documentation and Reporting: Maintaining detailed records of inspections, test results, and any detected defects. This documentation is essential for tracking quality trends and identifying areas for improvement.

For example, imagine a batch of fabric showing inconsistencies in dyeing. A QC inspector would identify the problem, investigate the root cause (perhaps a faulty dye bath), and prevent the entire batch from being shipped until the issue is resolved. Their work directly impacts customer satisfaction and brand reputation.

Career Expert Tips:

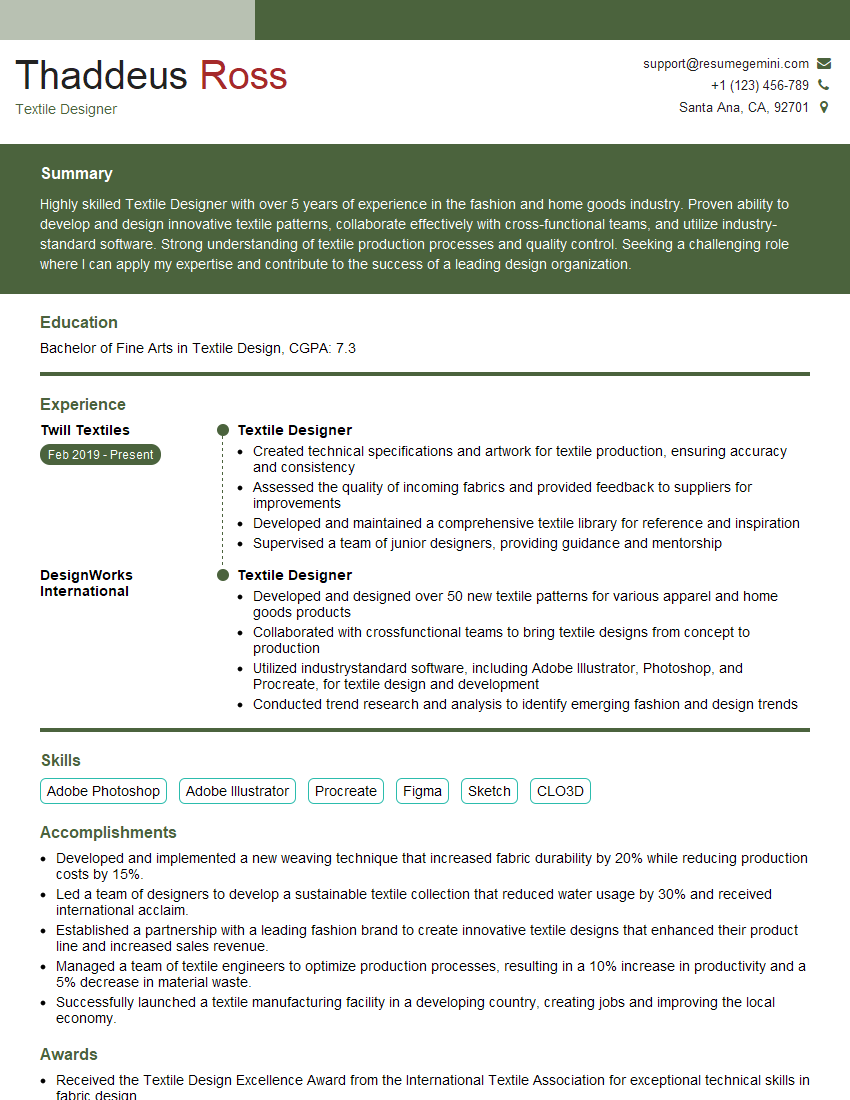

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you interpret fabric specifications?

Interpreting fabric specifications requires a thorough understanding of textile terminology and the properties of different fabrics. Specifications typically detail the fiber content, yarn count, fabric construction (weave, knit, etc.), weight, width, and various performance characteristics.

For example, a specification might read: “100% Cotton, 60 x 40 plain weave, 150 gsm, 58″ wide, colorfastness to washing 4/5.”

- Fiber Content: This indicates the type of fiber used (e.g., cotton, polyester, wool). It affects the fabric’s properties like drape, strength, and absorbency.

- Yarn Count: This refers to the fineness of the yarn and is expressed in different systems (explained in the next answer). It impacts the fabric’s density and hand feel.

- Fabric Construction: Describes how the yarns are interlaced (e.g., plain weave, twill weave, satin weave, knit structures). The weave influences the fabric’s durability, texture, and appearance.

- Weight (gsm): Gram per square meter, indicates the fabric’s weight per unit area. This affects drape, warmth, and durability.

- Width: The width of the fabric roll. This is crucial for efficient cutting and pattern making.

- Performance Characteristics: These cover aspects like colorfastness, shrinkage, abrasion resistance, and tensile strength. They describe how well the fabric holds up to different stresses and treatments.

Understanding these specifications allows for accurate material selection, production planning, and quality control throughout the manufacturing process.

Q 17. What are the different types of yarn counts?

Yarn count refers to the fineness or thickness of a yarn. Several systems exist to express yarn count, each with its own unique method of measurement:

- English System (Indirect): Expresses count as the number of hanks (840 yards) of yarn per pound. A higher number indicates finer yarn (e.g., 80s cotton is finer than 40s cotton).

- Metric System (Direct): Expresses count as the number of meters per gram (m/g) or the number of grams per 1000 meters (g/1000m). A higher number of meters per gram indicates finer yarn.

- Tex System (Direct): Expresses count as the weight in grams of 1000 meters of yarn. A lower Tex number indicates finer yarn.

- Ne System (Direct): Expresses count as the number of 1000 meter lengths per kilogram. A higher Ne number indicates finer yarn.

The choice of system depends on the region, type of yarn, and industry standards. It’s crucial to specify the system used when communicating yarn counts to avoid confusion. For example, a 20s cotton yarn in the English system will have a different thickness than a 20 Tex yarn.

Q 18. Describe the various methods used for testing fabric strength.

Fabric strength is crucial for determining a fabric’s durability and suitability for different applications. Several methods are used to test it:

- Tensile Strength Test: Measures the force required to break a fabric sample under tension. It provides information on the fabric’s resistance to stretching and tearing in the warp (lengthwise) and weft (widthwise) directions. A tensile strength tester applies a controlled force until the fabric breaks.

- Bursting Strength Test: Measures the pressure required to rupture a fabric sample when pressure is applied to both sides. This test is particularly important for fabrics intended for applications requiring high pressure resistance, such as airbags or medical textiles.

- Tear Strength Test: Measures the force required to initiate and propagate a tear in a fabric sample. Different methods exist, including the trapezoid method and the single rip method, yielding different tear strength values. This is useful for assessing a fabric’s resistance to snagging or tearing.

- Abrasion Resistance Test: Evaluates a fabric’s ability to withstand rubbing and wear. This involves rubbing the fabric against a standardized abrasive surface for a set number of cycles and measuring the loss in weight or strength.

These tests provide quantitative data about the fabric’s strength, enabling comparisons between different fabrics and ensuring the product meets the required performance standards. For example, a heavy-duty canvas needs significantly higher tensile and tear strength than a lightweight silk fabric.

Q 19. Explain the concept of fabric drape and hand feel.

Fabric drape and hand feel are crucial aspects of fabric quality that significantly impact its aesthetic appeal and the overall consumer experience. They are subjective properties, influenced by several factors:

- Drape: Refers to the way a fabric falls or hangs. It’s influenced by factors like fiber type, yarn count, fabric construction, and finishing treatments. A good drape is often described as flowing, graceful, or soft. For example, silk typically exhibits excellent drape due to its smooth, long fibers.

- Hand Feel: Refers to the tactile sensation when the fabric is touched. It encompasses various qualities like softness, roughness, smoothness, stiffness, resilience, and warmth. Hand feel is subjective, but can be analyzed based on factors such as fiber type, yarn structure, fabric finish, and density.

Drape and hand feel are often evaluated through sensory evaluation, where trained professionals assess the fabric’s properties based on touch and visual observation. These factors significantly impact the selection of fabrics for different garments and applications. For example, a soft, drapey fabric is ideal for clothing like dresses and scarves, whereas a stiffer, structured fabric might be preferred for workwear or outerwear.

Q 20. What are the environmental concerns in textile manufacturing?

Textile manufacturing poses several significant environmental concerns:

- Water Pollution: Dyeing and finishing processes consume large amounts of water and generate substantial wastewater containing toxic chemicals. These pollutants can contaminate water bodies, harming aquatic life and human health.

- Air Pollution: Emissions from energy consumption during manufacturing, and volatile organic compounds (VOCs) released from certain chemicals used in dyeing and finishing, contribute to air pollution.

- Waste Generation: Textile production generates significant amounts of solid waste, including fabric scraps, packaging materials, and sludge from wastewater treatment. Improper disposal can lead to land pollution.

- Greenhouse Gas Emissions: The production of synthetic fibers relies heavily on fossil fuels, contributing significantly to greenhouse gas emissions and climate change.

- Resource Depletion: The textile industry uses substantial quantities of raw materials, including cotton, which requires large amounts of land, water, and pesticides for cultivation.

Addressing these environmental challenges is essential for the long-term sustainability of the textile industry.

Q 21. How do you ensure sustainability in textile production?

Ensuring sustainability in textile production requires a multi-faceted approach, encompassing various strategies across the entire supply chain:

- Sustainable Raw Materials: Utilizing organic cotton, recycled fibers (e.g., recycled polyester), or innovative bio-based materials reduces environmental impact compared to conventional materials.

- Water Management: Implementing water-efficient dyeing and finishing techniques, such as closed-loop systems and zero-liquid discharge technologies, minimizes water consumption and pollution.

- Chemical Management: Using environmentally friendly dyes and chemicals that are less toxic and biodegradable reduces pollution and improves worker safety.

- Energy Efficiency: Investing in energy-efficient equipment and technologies reduces greenhouse gas emissions and operational costs.

- Waste Reduction and Recycling: Implementing strategies for reducing fabric waste through efficient cutting techniques, and establishing recycling programs for textile waste, minimizes landfill waste.

- Supply Chain Transparency and Traceability: Ensuring transparency and traceability throughout the supply chain helps identify and address environmental and social issues, promoting responsible sourcing and manufacturing practices.

- Eco-labeling and Certification: Using eco-labels (e.g., GOTS, OEKO-TEX) certifies that products meet certain environmental and social standards, providing assurance to consumers and promoting sustainable practices.

Adopting these strategies, along with a strong commitment to continuous improvement and innovation, is vital for building a more sustainable and responsible textile industry.

Q 22. Describe different fabric finishes and their effects on fabric properties.

Fabric finishes are treatments applied to textiles after weaving or knitting to enhance their properties like appearance, durability, and functionality. These finishes can significantly alter the final product’s feel, drape, and performance.

- Sizing: A coating applied to yarns before weaving to increase strength and reduce breakage. Think of it like giving the yarns a temporary protective layer. This is crucial for weaving high-quality fabrics.

- Mercerization: Treatment of cotton fabrics with a caustic soda solution to increase luster, strength, and dye affinity. Mercerized cotton is smoother and more absorbent, commonly used in high-quality shirts and towels.

- Calendering: Pressing fabrics under high pressure to improve smoothness, luster, and hand-feel. This is like ironing on an industrial scale, creating a more refined finish.

- Water Repellent Finishes: Applying chemicals that create a barrier on fabric surfaces, preventing water absorption. Examples include Teflon and similar treatments commonly found in outdoor apparel.

- Flame Retardant Finishes: Treating fabrics with chemicals to reduce flammability, crucial for safety in upholstery and children’s clothing. These treatments often hinder the spread of fire.

- Softening Finishes: These use chemicals like silicones or resins to give fabrics a softer, more luxurious feel. Think of the difference between a rough denim and a soft, washed denim.

The choice of finish depends heavily on the intended use of the fabric. For example, a wrinkle-resistant finish is essential for shirts, while water repellency is crucial for outerwear.

Q 23. Explain the difference between natural and synthetic fibers.

Natural fibers originate from plants or animals, while synthetic fibers are created from chemical processes. This fundamental difference leads to significant variations in their properties.

- Natural Fibers: Examples include cotton (plant), wool (animal), silk (animal), and linen (plant). They are generally biodegradable, breathable, and often have a unique texture and drape, but can be more expensive and less durable than synthetics.

- Synthetic Fibers: Examples include polyester, nylon, acrylic, and rayon. They are typically strong, durable, wrinkle-resistant, and easy to care for. However, they are not always as breathable or comfortable as natural fibers, and their environmental impact is a growing concern.

The choice between natural and synthetic fibers depends on the desired properties, cost, and sustainability considerations. A blend of both often provides the best of both worlds, combining strength with breathability.

Q 24. How does fiber length affect yarn quality?

Fiber length significantly impacts yarn quality. Longer fibers create stronger, smoother, and more even yarns, while shorter fibers result in weaker, fuzzier, and more uneven yarns.

- Longer Fibers: These produce yarns with superior strength and less breakage during processing. The inter-fiber bonds are stronger, leading to a higher quality fabric. Examples include long-staple cotton used in high-end apparel.

- Shorter Fibers: These can still be used to create yarn, but the resulting yarn is weaker and more prone to pilling (the formation of small balls of fiber on the fabric surface). These are often used in lower-grade fabrics or blends.

Imagine building a rope: Long strands make a strong, smooth rope; short strands make a weaker, more frayed rope. Similarly, long fibers in yarn produce a higher-quality fabric.

Q 25. What are the different methods for blending fibers?

Fiber blending involves combining different fibers to create yarns with enhanced properties. Several methods are employed:

- Pre-Blending: Fibers are mixed before spinning. This ensures a uniform distribution of fibers throughout the yarn. This is often preferred for evenness and consistent color.

- Post-Blending: Fibers are blended after spinning individual yarns. This is more common in creating novelty yarns or fabrics with visibly distinct fiber types, like a heather effect.

- Solution Blending: Fibers are dissolved and mixed together before being extruded to create synthetic fibers. This is usually done for synthetics, resulting in truly intimate blends.

- Mechanical Blending: Fibers are physically mixed using machines such as blending drums. This is widely used for natural fibers and fiber opening and cleaning.

The blending method chosen depends on the desired fiber distribution, cost, and the types of fibers being combined. Each approach leads to a unique final product in terms of appearance and performance.

Q 26. What are the common quality issues related to dyeing and finishing?

Common quality issues in dyeing and finishing include:

- Uneven Dyeing: Resulting in streaks or patches of different colors. This can be due to improper dye application or uneven fiber distribution.

- Crocking: Transfer of color from the fabric to other surfaces through rubbing. This is a major quality issue, especially in dark-colored fabrics.

- Bleeding: Color loss in the fabric due to water or washing. Proper dye fixation is crucial to prevent bleeding.

- Poor Wash Fastness: Deterioration of color or fabric strength after washing. Certain dyes may not be wash-fast without proper treatment.

- Wrinkling or Shrinkage: These can occur if improper finishing techniques are used. Proper pre-treatment and finishing are critical to control these.

- Pilling: The formation of small balls of fibers on the fabric surface, especially in fabrics with short fibers or loose structures.

These issues can be mitigated through careful control of dyeing and finishing processes, including selection of appropriate dyes and chemicals, precise process parameters, and rigorous quality control measures.

Q 27. Explain the importance of colorfastness in textile fabrics.

Colorfastness refers to the ability of a dyed fabric to retain its color under various conditions like washing, light exposure, rubbing, and perspiration. It’s crucial for maintaining the appearance and quality of textile fabrics over time and use.

Poor colorfastness can lead to significant problems:

- Loss of appeal: Faded or discolored fabrics lose their aesthetic value.

- Customer dissatisfaction: Customers expect fabrics to retain their color, and poor colorfastness can lead to returns and complaints.

- Damage to other garments: Bleeding or crocking can stain other fabrics during washing or wearing.

Testing for colorfastness is a vital part of quality control in the textile industry. Standards like AATCC tests define various colorfastness properties, enabling manufacturers to ensure their products meet required standards.

Q 28. Describe your experience with different types of textile testing equipment.

Throughout my career, I’ve extensively used various textile testing equipment, including:

- Universal Testing Machines (UTM): Used to measure tensile strength, elongation, and tear strength of fabrics. These machines are essential for evaluating fabric durability.

- Color Measurement Spectrophotometers: Used for precise color measurement and matching. These instruments ensure consistency in color across batches of fabric.

- Wash Fastness Testers: Used to evaluate the colorfastness of fabrics to washing and other treatments, simulating real-world conditions to assess color retention after laundering.

- Abrasion Testers: These evaluate the fabric’s resistance to wear and tear, important for understanding the durability of products like carpets or outdoor apparel.

- Pilling Testers: Measure the tendency of fabrics to form pills or fuzz balls. This is crucial for assessing the quality of materials intended for clothing or upholstery.

- Microscope: Used for fiber identification and analysis to help characterize fiber blends and assess their quality.

My experience with these instruments ensures that the fabrics and yarns meet the required standards for quality, durability, and color consistency. These tests are essential for ensuring customer satisfaction and the success of our products.

Key Topics to Learn for Yarn and Fabric Manufacturing Interview

- Fiber Properties and Selection: Understanding different fiber types (natural and synthetic), their characteristics (strength, elasticity, drape), and suitability for various fabric applications. Consider the impact of fiber selection on the final product’s performance and cost.

- Yarn Manufacturing Processes: Familiarize yourself with spinning systems (ring spinning, rotor spinning, air-jet spinning), their advantages and disadvantages, and the resulting yarn properties. Be prepared to discuss yarn quality control and testing methods.

- Fabric Construction: Master the different weaving and knitting techniques, including plain weave, twill weave, satin weave, and various knit structures. Understand how fabric structure affects drape, durability, and aesthetics. Be able to discuss the pros and cons of each method.

- Fabric Finishing Processes: Learn about various finishing techniques like bleaching, dyeing, printing, and coating. Understand their impact on fabric properties and the environmental considerations associated with each process. Be prepared to discuss sustainable finishing options.

- Quality Control and Testing: Understand the importance of quality control throughout the manufacturing process. Familiarize yourself with common testing methods used to assess yarn and fabric quality (e.g., tensile strength, abrasion resistance, colorfastness).

- Production Planning and Management: Gain a basic understanding of production planning, scheduling, and inventory management within a yarn and fabric manufacturing environment. Consider the challenges of optimizing production efficiency and minimizing waste.

- Textile Machinery and Equipment: Develop a foundational understanding of the types of machinery used in yarn and fabric manufacturing. This includes spinning machines, weaving looms, knitting machines, and finishing equipment. Knowing the basic functionalities and maintenance requirements is beneficial.

- Health and Safety Regulations: Understand the importance of adhering to health and safety regulations within a textile manufacturing facility. This includes knowledge of relevant safety procedures and personal protective equipment.

Next Steps

Mastering the principles of yarn and fabric manufacturing opens doors to exciting career opportunities in a dynamic industry. A strong understanding of these processes will significantly enhance your interview performance and overall career prospects. Creating an ATS-friendly resume is crucial for maximizing your job search success. We strongly recommend using ResumeGemini to build a compelling and effective resume that showcases your skills and experience. ResumeGemini provides examples of resumes tailored specifically to the Yarn and Fabric Manufacturing industry, helping you present yourself in the best possible light. Take the next step in your career journey – craft a standout resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.