The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Aircraft Inspection and Testing interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Aircraft Inspection and Testing Interview

Q 1. Explain the difference between preventative and corrective maintenance in aircraft inspection.

Preventative maintenance focuses on preventing aircraft malfunctions before they occur, while corrective maintenance addresses existing problems. Think of it like this: preventative maintenance is like regular checkups at the doctor’s office – catching potential issues early. Corrective maintenance is like going to the emergency room – dealing with an immediate problem after it’s already happened.

Preventative Maintenance involves scheduled inspections, lubrication, and part replacements based on manufacturer recommendations and flight hours. For example, changing engine oil and filters at specified intervals is preventative. This minimizes the risk of catastrophic failures.

Corrective Maintenance, on the other hand, is triggered by a detected malfunction or failure. Let’s say a hydraulic leak is discovered during a pre-flight inspection. Repairing that leak is corrective maintenance. It addresses an existing problem to restore functionality. The difference lies in the timing and nature of the intervention: proactive versus reactive.

Q 2. Describe your experience with Non-Destructive Testing (NDT) methods used in aircraft inspection.

My experience with Non-Destructive Testing (NDT) methods is extensive. I’m proficient in several techniques crucial for aircraft inspection, ensuring airworthiness without damaging the aircraft. These include:

- Visual Inspection (VI): The most basic but crucial method, involving a thorough visual examination for cracks, corrosion, dents, and other defects. This often involves using borescopes to access hard-to-reach areas.

- Liquid Penetrant Inspection (LPI): This technique identifies surface-breaking flaws by applying a dye that penetrates the crack and is then revealed by a developer. I’ve used this extensively to detect cracks in components like airframe structures.

- Magnetic Particle Inspection (MPI): Effective for ferromagnetic materials, MPI uses magnetic fields to detect surface and near-surface cracks. This is a valuable tool for inspecting engine components and landing gear.

- Ultrasonic Testing (UT): Employing ultrasonic waves to detect internal flaws. I have used this method to assess the integrity of welds, composite structures, and detect hidden corrosion.

- Eddy Current Testing (ECT): This electromagnetic method is used to detect surface and subsurface flaws in conductive materials, often utilized for inspecting wiring harnesses and aircraft skins.

I meticulously document all NDT procedures, results, and interpretations according to industry best practices and regulatory requirements, ensuring the accuracy and reliability of my findings. Each method’s application is carefully selected based on the material type and the potential types of defects to be found.

Q 3. What are the key regulatory requirements for aircraft inspection and maintenance?

Aircraft inspection and maintenance are governed by stringent regulatory requirements, primarily set by national aviation authorities (like the FAA in the US or EASA in Europe). These regulations ensure airworthiness and public safety. Key aspects include:

- Airworthiness Directives (ADs): Mandatory actions issued by regulatory bodies to address known safety issues or potential hazards. These ADs may require specific inspections or modifications to be carried out within a defined timeframe.

- Maintenance Manuals and Technical Publications: Aircraft manufacturers provide comprehensive manuals outlining maintenance schedules, procedures, and acceptable limits. Adherence to these is paramount.

- Continuing Airworthiness Management System (CAMS): Airlines and maintenance organizations must implement a structured system to manage the continuing airworthiness of their fleet. This involves detailed tracking of maintenance activities, inspections, and compliance with regulations.

- Certification and Licensing: Personnel involved in aircraft maintenance must hold appropriate certifications and licenses demonstrating their competency and qualifications. This ensures that work is performed by trained professionals.

Non-compliance with these regulations can result in serious penalties, including grounding of the aircraft and potential legal action. Strict adherence to these regulations is essential for maintaining safety and legal compliance.

Q 4. How do you identify and document discrepancies found during an aircraft inspection?

Discrepancies found during an aircraft inspection are meticulously documented using a standardized reporting system. This typically involves:

- Clear and Concise Description: A precise description of the discrepancy, including its location, severity, and visual characteristics. For example: “Corrosion detected on left wing spar, station 150, approximately 2cm in length.”

- Photographs or Sketches: Visual evidence is vital to support the written description. High-quality photographs are taken from various angles to capture the extent and nature of the damage.

- Reference to Applicable Documentation: The report should cross-reference relevant sections in the aircraft maintenance manual or other technical publications.

- Severity Assessment: The discrepancy’s severity is assessed using a standardized system (e.g., minor, major, critical), helping prioritize repair actions.

- Repair or Corrective Action Recommendation: A recommended course of action is suggested, based on applicable regulations and maintenance manuals.

- Disposition: The report needs to clearly state how the discrepancy will be addressed: repair, deferral (with justification), or other.

The completed report is reviewed by a supervisor, and a copy is placed in the aircraft’s maintenance logbook. This detailed documentation ensures proper tracking and accountability for all identified discrepancies.

Q 5. What is your experience with interpreting and applying maintenance manuals and technical publications?

Interpreting and applying maintenance manuals and technical publications is fundamental to my work. My experience involves working with various types of documentation, including:

- Aircraft Maintenance Manuals (AMM): These manuals provide comprehensive guidance on maintenance procedures, troubleshooting, and component replacement.

- Illustrated Parts Catalogs (IPC): These catalogs provide detailed diagrams and part numbers, crucial for ordering and identifying replacement parts.

- Service Bulletins (SBs): These documents highlight modifications, improvements, and corrective actions issued by the manufacturer after the aircraft’s initial delivery.

- Airworthiness Directives (ADs): As mentioned earlier, these are mandatory actions addressing safety concerns.

I understand the importance of cross-referencing information across multiple documents to ensure that all relevant procedures are followed accurately. For example, I recently used an AMM to diagnose a faulty sensor, then consulted an IPC to identify the replacement part number, and finally verified that the procedure was compliant with applicable SBs and ADs.

Q 6. Describe your experience with different types of aircraft inspections (e.g., pre-flight, routine, major).

My experience encompasses a range of aircraft inspections, each with its specific scope and purpose:

- Pre-flight Inspection: A brief visual inspection conducted before each flight, focusing on critical safety items like control surfaces, tires, and fluid levels. This is akin to a quick safety check before driving a car.

- Routine Inspections (e.g., A-checks, B-checks, C-checks): These are more comprehensive scheduled inspections performed at specific intervals (based on flight hours or calendar time). A-checks are generally shorter and more frequent, while C-checks are extensive and may involve significant disassembly and component checks.

- Major Inspections (e.g., D-checks, Heavy Maintenance): These are the most thorough inspections, typically conducted at longer intervals. They involve major component overhauls, structural inspections, and potentially significant modifications.

- Specialized Inspections: Some inspections target specific systems or components (e.g., engine inspections, landing gear inspections) and are often triggered by specific events or maintenance requirements.

The type and depth of each inspection are determined by regulatory requirements, maintenance schedules, and the aircraft’s operational history. My expertise spans all these categories, ensuring that I can effectively conduct and document inspections to meet airworthiness standards.

Q 7. How do you prioritize inspection tasks based on risk and urgency?

Prioritizing inspection tasks is crucial for efficient and effective maintenance. I use a risk-based approach, considering both the potential impact of a failure and the likelihood of that failure occurring. This typically involves:

- Risk Assessment: Assessing the probability and severity of potential failures for each component or system. A critical component with a high probability of failure would be prioritized over a less critical component with a lower probability of failure.

- Regulatory Requirements: Compliance with ADs, maintenance manuals, and other regulatory requirements is paramount. Tasks mandated by these regulations take precedence.

- Operational Urgency: In-service aircraft inspections often need to consider urgent or imminent safety concerns. Immediate action may be needed to rectify critical safety issues.

- Cost Considerations: While safety is paramount, economic factors can influence scheduling. Higher risk items needing timely attention are addressed first.

I often use a system such as a risk matrix, where potential failure consequences are plotted against probability. This helps visualize which items warrant immediate attention versus those that can be addressed at a later date. This approach ensures that the most critical aspects are addressed promptly, minimizing risks while maintaining operational efficiency.

Q 8. Explain your understanding of aircraft structural integrity and common failure modes.

Aircraft structural integrity refers to the ability of an aircraft’s structure to withstand the stresses and loads it experiences during flight, ground operations, and environmental exposure. Maintaining this integrity is paramount for safe operation. Common failure modes can be categorized into several key areas:

- Fatigue: Repeated stress cycles over time lead to microscopic cracks that eventually propagate, causing failure. Think of bending a paper clip back and forth – eventually it breaks. This is a significant concern in highly stressed areas like wings and fuselage.

- Corrosion: Chemical reactions degrade the structural material, reducing its strength and increasing the risk of cracking. This is particularly problematic in humid environments or near coastal areas.

- Impact Damage: Collisions with birds, hail, or foreign objects can cause significant damage, weakening the structure. This damage can be hidden and requires careful inspection.

- Manufacturing Defects: Flaws introduced during the manufacturing process can create areas of weakness, making the structure susceptible to failure. Stringent quality control is vital to prevent this.

- Overstress: Exceeding the design limits of the structure through overloading or unexpected maneuvers can lead to catastrophic failure.

Understanding these failure modes is crucial for developing effective inspection and maintenance procedures to ensure the continued airworthiness of an aircraft.

Q 9. Describe your experience with corrosion detection and prevention techniques.

My experience with corrosion detection and prevention encompasses a range of techniques. Initial detection often involves visual inspection, looking for surface pitting, rust, or discoloration. More advanced methods include:

- Dye penetrant inspection: A liquid dye is applied to the surface, revealing cracks by capillary action. It’s like using a highlighter to expose hidden flaws.

- Eddy current testing: Electromagnetic fields are used to detect subsurface flaws, like corrosion that’s hidden beneath the paint. This is particularly useful for inspecting metallic components.

- Ultrasonic testing: High-frequency sound waves are used to detect internal flaws and measure the thickness of materials. This allows for the assessment of corrosion that has progressed internally.

Prevention strategies are equally important and focus on minimizing exposure to corrosive elements. This includes:

- Protective coatings: Applying paints, sealants, or other coatings provides a barrier against moisture and chemicals.

- Corrosion inhibitors: Chemicals are applied to slow down the corrosion process.

- Proper cleaning and maintenance: Regular cleaning and removal of contaminants prevents the initiation of corrosion.

- Design features: Aircraft are designed with features to minimize moisture accumulation and promote drainage.

I’ve successfully used these methods in various aircraft inspections, identifying and addressing corrosion issues to maintain structural integrity and prevent potential failures.

Q 10. How do you handle discrepancies or disagreements with maintenance personnel during an inspection?

Discrepancies during inspections are common and require a professional, collaborative approach. My strategy focuses on:

- Open communication: I initiate a discussion, clearly outlining my observations and the basis for my findings. This avoids accusations and promotes a shared understanding.

- Data review: We carefully review the relevant maintenance records, inspection manuals, and any other supporting documentation. This is crucial for establishing the facts.

- Independent verification: If necessary, we involve a third party—a senior inspector or engineering representative—to provide an objective assessment. A fresh perspective can help resolve differences of opinion.

- Documentation: Regardless of the outcome, all discussions, findings, and decisions are thoroughly documented. This provides a clear record of the process and ensures accountability.

- Prioritization: We prioritize safety and airworthiness. If there’s a disagreement on a safety-critical issue, I would always err on the side of caution, recommending further investigation or corrective action.

My goal is always to reach a mutually agreeable solution while maintaining the highest safety standards. It’s about teamwork, not confrontation.

Q 11. What is your experience with composite material inspection?

My experience with composite material inspection includes both visual and non-destructive testing (NDT) methods. Visual inspection is the first step, looking for any signs of damage like delamination (separation of layers), impact damage, or cracks. NDT methods are crucial because damage in composites can be hidden beneath the surface.

- Ultrasonic testing (UT): Highly effective for detecting delaminations, voids, and other internal flaws. The sound waves reflect off imperfections, providing a clear picture of the internal structure.

- Thermography (infrared inspection): Detects variations in temperature, which can indicate delaminations or areas of moisture absorption. It’s like seeing hidden heat signatures.

- X-ray inspection: Uses X-rays to penetrate the material and identify internal flaws. Excellent for locating embedded objects or significant damage.

- Shearography: A non-contact method that measures surface deformation under stress to reveal subsurface damage. This is very sensitive to minor delaminations.

The choice of NDT method depends on the specific composite material, the type of damage suspected, and the accessibility of the inspection area. I’ve worked extensively with various composite structures, from aircraft wings and control surfaces to interior components, and have developed a strong understanding of the different challenges and solutions in this area.

Q 12. Explain your understanding of airworthiness directives (ADs) and their application.

Airworthiness directives (ADs) are mandatory instructions issued by aviation authorities, such as the FAA (Federal Aviation Administration) or EASA (European Union Aviation Safety Agency), to address safety concerns related to aircraft. They’re essentially safety alerts that mandate specific inspections, repairs, or modifications to prevent accidents or mitigate potential hazards.

An AD might be issued in response to a service difficulty report (SDR) documenting a failure or safety concern, or it might stem from ongoing research or design analysis revealing a potential weakness. These directives often contain specific instructions, including:

- Affected aircraft: Specifies the make, model, and serial numbers of the aircraft covered by the AD.

- Inspection procedures: Outlines the methods and frequency for inspecting the affected components.

- Corrective actions: Specifies the necessary repairs, modifications, or replacements to address the safety issue.

- Compliance times: Sets deadlines for completing the required actions.

Failure to comply with an AD can result in serious penalties, including grounding of the aircraft. My role includes staying updated on all relevant ADs, ensuring timely compliance for aircraft under my inspection purview, and meticulously documenting all actions taken.

Q 13. How do you ensure the accuracy and completeness of inspection records?

Accuracy and completeness of inspection records are critical for maintaining aircraft airworthiness and demonstrating compliance with regulations. My approach involves:

- Detailed documentation: All inspection findings, including both positive and negative results, are meticulously documented using standardized forms and clear, concise language. Ambiguity is avoided.

- Digital records management: I utilize digital record-keeping systems whenever possible, ensuring data integrity and ease of access. This also facilitates quick retrieval of information when needed.

- Verification and cross-checking: I regularly cross-check records against other available data, such as maintenance logs and previous inspection reports, to ensure consistency and detect any potential errors.

- Proper signatures and approvals: All records include appropriate signatures and approvals from authorized personnel, demonstrating accountability and traceability.

- Regular audits: Periodic internal audits of inspection procedures and records are conducted to identify areas for improvement and ensure ongoing accuracy.

Accurate records aren’t just about compliance; they’re essential for tracking the aircraft’s maintenance history and preventing potential recurrences of identified issues. This continuous feedback loop supports continuous improvement in maintenance practices.

Q 14. Describe a time you had to solve a complex inspection problem.

During an inspection of a regional jet, we discovered significant corrosion in a hard-to-reach area of the wing spar. The initial visual inspection revealed only minor surface corrosion, but further investigation using eddy current testing showed extensive damage hidden beneath the surface. The challenge was accessing the affected area for repair. The location was extremely tight and difficult to reach.

Our team initially considered several solutions, including partial wing disassembly, which would have been time-consuming and expensive. However, we developed a more creative solution, using a combination of robotic inspection tools and specialized repair techniques. This allowed us to precisely assess the damage and implement targeted repairs without complete disassembly. This minimized downtime and repair costs, while still ensuring the structural integrity of the wing spar. The successful application of this multidisciplinary approach demonstrated the importance of problem-solving and leveraging advanced technologies within the aviation maintenance domain. The case study was subsequently shared with other teams to enhance their problem-solving skills in similar circumstances.

Q 15. What safety measures do you prioritize during aircraft inspections?

Safety is paramount in aircraft inspections. My priority is always to ensure a controlled and hazard-free environment. This begins with a thorough pre-inspection planning phase, including a detailed risk assessment specific to the aircraft type, its condition, and the planned inspection tasks.

- Personal Protective Equipment (PPE): Mandatory use of appropriate PPE, including safety glasses, gloves, hearing protection, and specialized clothing, depending on the task (e.g., high-visibility vests in hangar environments).

- Lockout/Tagout Procedures: Strict adherence to lockout/tagout procedures to prevent accidental energization of systems during inspections. This is critical when working near hydraulic, pneumatic, or electrical systems.

- Controlled Access: Limiting access to the inspection area to authorized personnel only. This reduces the chance of accidental injury or damage to the aircraft.

- Ground Support Equipment (GSE): Ensuring GSE is properly inspected and maintained before use, including chocks, jacks, and ladders. Improper GSE can create serious hazards.

- Emergency Procedures: Having readily available emergency procedures and communication systems, including fire extinguishers and emergency contact information, is crucial.

- Fatigue Management: Recognizing that fatigue can lead to errors, inspections are planned to avoid extended periods of strenuous work. Breaks are scheduled to ensure alertness and prevent accidents.

For example, during a wing inspection, we might implement a ‘no-go zone’ under the wing to prevent personnel from being injured by falling debris. Each step is meticulously documented to maintain a complete safety record of the inspection.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of fatigue and its effect on aircraft structures.

Fatigue in aircraft structures is the progressive and localized weakening of a material due to repeated cyclic loading. Imagine bending a paperclip back and forth – eventually it will break, even though the applied force at each bending is relatively small. This is analogous to how aircraft structures experience fatigue. Over time, microscopic cracks initiate and propagate, reducing the structural integrity of the aircraft until failure occurs.

Factors influencing fatigue include the material properties (e.g., aluminum alloys are prone to fatigue cracking), the type of loading (e.g., repeated stress reversals are particularly damaging), the presence of stress concentrations (e.g., sharp corners or holes), and environmental factors (e.g., corrosion accelerates fatigue).

The effects of fatigue can be catastrophic, potentially leading to structural failure during flight. Therefore, fatigue crack detection is a critical part of aircraft maintenance. Techniques like visual inspection, dye penetrant testing, and ultrasonic testing are employed to detect cracks and assess their severity. Regular inspections, adherence to maintenance schedules, and diligent fatigue life monitoring are crucial for mitigating fatigue-related risks.

Q 17. Describe your experience with different types of NDT equipment (e.g., ultrasonic, eddy current, visual).

My experience encompasses a wide range of NDT methods. I’m proficient in visual inspection, ultrasonic testing (UT), eddy current testing (ECT), and dye penetrant testing.

- Visual Inspection: This is the foundation of any NDT program, involving a thorough visual examination of the aircraft’s structure for any surface anomalies like corrosion, cracks, dents, or damage. It is crucial for identifying issues readily visible to the naked eye, and often used in conjunction with other NDT techniques. I’ve used borescopes extensively for inspecting hard-to-reach areas like internal structures.

- Ultrasonic Testing (UT): I use UT extensively to detect internal flaws, such as cracks, delaminations, or inclusions, in materials. UT uses high-frequency sound waves to penetrate the material and detect discontinuities based on the reflection or scattering of these waves. I’m experienced with both manual and automated UT systems, and proficient in interpreting the resulting A-scans and B-scans. For example, I’ve used UT to inspect critical components such as landing gear struts.

- Eddy Current Testing (ECT): ECT is primarily used for detecting surface and near-surface flaws in conductive materials. It works by inducing eddy currents in the material using an electromagnetic field, and variations in the eddy current flow indicate the presence of flaws. I’ve employed ECT to check for corrosion or cracks in aircraft skin and tubing.

I regularly document all NDT findings with detailed sketches and photographic evidence, ensuring a complete record of the inspection process.

Q 18. What are the limitations of different NDT methods?

Each NDT method has limitations that must be carefully considered.

- Visual Inspection: Limited to surface defects; cannot detect internal flaws; effectiveness depends on lighting, surface condition, and inspector’s skill.

- Ultrasonic Testing (UT): Requires coupling medium (e.g., gel) between the transducer and the material; surface roughness can affect results; interpretation of results requires skill and experience; difficult to inspect complex geometries.

- Eddy Current Testing (ECT): Only suitable for conductive materials; depth of penetration is limited; surface coatings can interfere with results; difficult to detect deep or small flaws.

For instance, UT might not be effective for detecting very shallow cracks, while ECT cannot inspect non-conductive materials like composites. It’s important to choose the appropriate NDT technique considering the material, the type of defect expected, and the access available.

Q 19. How do you interpret NDT results and determine the significance of findings?

Interpreting NDT results involves a careful analysis of the indications obtained and comparing them against relevant standards and acceptance criteria.

For example, in UT, the amplitude and shape of the ultrasonic echoes provide information about the size, location, and orientation of the defects. I would consider factors like the signal-to-noise ratio and the characteristic echo patterns of known defects to aid my interpretation. For ECT, changes in the impedance and phase of the eddy current signals are indicative of flaws.

Determining the significance of findings involves considering the location, size, and type of defect in relation to the aircraft’s structural integrity. Damage tolerance principles are crucial in this evaluation, determining if the defect poses an immediate threat or can be safely monitored until the next scheduled maintenance.

I would then document all findings, including the NDT technique used, location of the defect, size measurement, and a clear assessment of its significance. This information is critical for determining the required repair actions.

Q 20. How do you ensure the traceability and calibration of inspection equipment?

Traceability and calibration of inspection equipment are essential for ensuring the accuracy and reliability of NDT results. We utilize a robust calibration and maintenance program.

- Calibration Schedule: All NDT equipment is calibrated according to a strict schedule, using traceable standards. Calibration certificates are meticulously maintained and readily available.

- Calibration Records: Detailed calibration records are kept, including the date of calibration, the equipment’s serial number, the calibration results, and the name of the technician who performed the calibration.

- Equipment Maintenance Logs: Comprehensive maintenance logs are maintained for each piece of equipment, including any repairs or adjustments made. This ensures the equipment is functioning correctly.

- Calibration Laboratory: We use accredited calibration laboratories to ensure the traceability of our calibration standards to national or international standards.

For instance, ultrasonic probes are regularly calibrated using standardized test blocks to verify their sensitivity and accuracy. Failure to maintain proper calibration can lead to inaccurate readings and potentially unsafe conclusions about the aircraft’s condition.

Q 21. Explain your understanding of aircraft maintenance records and their importance.

Aircraft maintenance records are a comprehensive history of all maintenance, repairs, and inspections performed on the aircraft throughout its operational life. These records are absolutely critical for ensuring the airworthiness and safety of the aircraft.

They include details like inspections conducted (type, date, results), repairs carried out (parts used, methods employed), modifications implemented, and any discrepancies or discrepancies found. The records serve as a crucial reference point for future inspections, maintenance scheduling, and troubleshooting.

The importance of these records cannot be overstated. They provide a clear and auditable trail of the aircraft’s history, enabling maintenance personnel to make informed decisions, predict potential problems, and ensure compliance with regulatory requirements. Inaccurate or incomplete records can lead to significant safety risks and operational challenges. I’m always meticulous in maintaining accurate and detailed maintenance records, ensuring compliance with all applicable regulations.

Q 22. How do you communicate inspection findings effectively to maintenance personnel and management?

Communicating inspection findings effectively is crucial for aircraft safety. My approach involves a multi-pronged strategy focusing on clarity, accuracy, and context.

- Clear and Concise Reporting: I utilize standardized reporting formats, ensuring all findings are documented meticulously, including location, severity (using a system like the FAA’s severity levels), and associated photographs or video evidence. For example, instead of saying ‘problem with the flap,’ I’d specify ‘Left flap track irregularity noted at station 125, exhibiting approximately 2mm of lateral play. See attached photos (Ref: IMG001, IMG002).

- Visual Aids: Pictures and diagrams significantly enhance understanding. I always include visual documentation to support written reports. This bypasses potential ambiguity. A detailed diagram showing the location of a crack, for instance, clarifies the issue better than just words.

- Prioritization: Findings are ranked by severity and urgency, using color-coding or similar systems to highlight critical issues that require immediate attention. A critical finding might be highlighted in red, while a less urgent one is in yellow.

- Direct Communication: I ensure direct and timely communication with maintenance personnel and management through briefings, verbal updates, and email confirmations of findings and recommended corrective actions. This ensures everyone is on the same page and facilitates a quick response.

- Formal Reporting System: I strictly adhere to the company’s formal reporting system, ensuring proper documentation and traceability of all inspection findings and subsequent maintenance actions. This is crucial for audits and future reference.

This method ensures everyone understands the findings, their significance, and the required actions, contributing to efficient maintenance and enhanced safety.

Q 23. What is your experience with using computerized maintenance management systems (CMMS)?

I have extensive experience using CMMS (Computerized Maintenance Management Systems), primarily with [mention specific CMMS software if comfortable, e.g., IBM Maximo, SAP PM]. My expertise spans data entry, report generation, and system troubleshooting. I’m proficient in using CMMS for:

- Scheduling and Tracking Inspections: I use the system to schedule routine and unscheduled inspections, track their completion, and generate reports on inspection compliance.

- Managing Parts Inventory: The CMMS helps me monitor parts availability and anticipate potential delays in maintenance due to part shortages. I can track part usage, create requisitions, and manage the entire lifecycle of a part within the system.

- Generating Reports: I generate customized reports on inspection findings, maintenance history, and overall aircraft performance, providing valuable insights for maintenance planning and decision-making.

- Integrating with other systems: I am familiar with integrating CMMS with other aviation systems, such as flight operations and safety management systems, for a holistic view of aircraft health.

In one instance, I identified a potential maintenance backlog using CMMS data analysis, prompting proactive planning and avoiding potential operational disruptions.

Q 24. Describe your experience with conducting engine inspections.

My experience encompasses a wide range of engine inspections, from routine visual inspections to more detailed borescope examinations and component tear-downs. My work includes:

- Visual Inspections: I meticulously inspect for leaks, corrosion, damage to external components, and signs of wear on engines during routine maintenance checks.

- Boroscope Inspections: I utilize borescopes to examine internal engine components such as combustion chambers, turbine blades, and other hard-to-reach areas for potential damage or degradation. This allows detection of flaws not visible externally.

- Component Inspections: I have experience inspecting individual engine components, including turbines, compressors, and fuel nozzles, following established procedures and checklists.

- Non-Destructive Testing (NDT): I am familiar with applying various NDT methods (e.g., dye penetrant inspection, magnetic particle inspection) to detect hidden flaws in engine components during detailed inspections.

For example, during a recent inspection, a borescope examination revealed a hairline crack in a turbine blade that was undetectable during a standard visual inspection. This early detection prevented a potential catastrophic engine failure. I always adhere to manufacturer’s maintenance manuals and regulatory requirements for each specific engine type.

Q 25. Explain your understanding of aircraft systems, such as hydraulics, pneumatics, and electrical systems.

I possess a strong understanding of aircraft systems, including hydraulics, pneumatics, and electrical systems. My knowledge extends to:

- Hydraulic Systems: I understand hydraulic system components like pumps, actuators, reservoirs, and valves. I can diagnose leaks, pressure issues, and malfunctions in these systems. I’m familiar with different types of hydraulic fluids and their properties. Troubleshooting hydraulic system problems requires understanding fluid dynamics, pressure regulation, and the role of various components.

- Pneumatic Systems: I’m knowledgeable about pneumatic system components like compressors, regulators, and actuators. I can troubleshoot issues related to air pressure, leaks, and system malfunctions. Understanding the pressure differentials and the flow of compressed air within the system is crucial for troubleshooting.

- Electrical Systems: I’m familiar with aircraft electrical power generation, distribution, and control. I can troubleshoot issues in wiring, circuit breakers, batteries, and other electrical components. Understanding voltage levels, current flows, and circuit diagrams is fundamental for this.

This understanding allows me to identify potential safety hazards and ensure the systems are functioning correctly and safely. Think of it like a car – a faulty electrical system can prevent the engine from starting, just as a leak in a hydraulic system can cause critical failures in an aircraft.

Q 26. How do you stay current with the latest advancements in aircraft inspection techniques and technologies?

Staying current in this rapidly evolving field is paramount. I employ several strategies to stay abreast of advancements:

- Industry Publications and Journals: I regularly read industry publications like Aviation Week & Space Technology and various technical journals to learn about new inspection techniques and technologies. This provides insights into the latest research and developments.

- Conferences and Workshops: Attending industry conferences and workshops allows me to network with other professionals and learn about the latest industry trends and technologies firsthand.

- Manufacturer’s Service Bulletins and Airworthiness Directives (ADs): I meticulously review all manufacturer’s service bulletins and Airworthiness Directives applicable to the aircraft types I inspect. These bulletins often contain critical information about new inspection techniques or solutions to previously unidentified problems.

- Online Resources and Training Courses: I utilize online resources and participate in continuing education programs to enhance my knowledge of new inspection technologies and techniques. This allows me to continually upgrade my skills and knowledge.

- Mentorship and Collaboration: I actively seek mentorship from experienced inspectors and collaborate with colleagues to share knowledge and learn from others’ experiences.

Continuous learning is not just about staying updated but about enhancing my problem-solving capabilities and ensuring safety remains my top priority.

Q 27. What are your strengths and weaknesses as an aircraft inspector?

My strengths lie in my meticulous attention to detail, my methodical approach to problem-solving, and my proactive safety mindset. I’m highly organized, able to prioritize tasks effectively, and I communicate clearly and concisely. I’m also a quick learner, always eager to adopt new technologies and techniques to enhance inspection efficiency and accuracy.

My weakness is occasionally being overly cautious, potentially leading to slightly longer inspection times. However, I actively mitigate this by continuously refining my efficiency, focusing on streamlining my processes and prioritizing critical inspections, without compromising safety.

Q 28. Why are you interested in this aircraft inspection position?

I am keenly interested in this aircraft inspection position because of [Company Name]’s reputation for safety and its commitment to continuous improvement. I am impressed by [mention specific company achievements, projects, or values]. I believe my skills and experience align perfectly with your requirements, and I am confident I can make a significant contribution to your team. This role offers an excellent opportunity for professional growth and to work on a variety of aircraft, expanding my expertise.

Key Topics to Learn for Aircraft Inspection and Testing Interview

- Aircraft Maintenance Manuals (AMM): Understanding the structure and application of AMMs, including interpreting maintenance schedules and troubleshooting procedures.

- Non-Destructive Testing (NDT) Methods: Practical knowledge of techniques like visual inspection, liquid penetrant inspection, magnetic particle inspection, ultrasonic testing, and eddy current testing. Be prepared to discuss their applications and limitations in aircraft inspection.

- Corrosion Control and Prevention: Understanding the causes of corrosion in aircraft structures, methods of detection, and effective prevention strategies.

- Aircraft Systems Knowledge: Demonstrate a solid understanding of major aircraft systems (e.g., hydraulics, pneumatics, electrical systems) and their inspection requirements.

- FAA Regulations and Airworthiness Directives (ADs): Familiarity with relevant FAA regulations and the interpretation and application of Airworthiness Directives.

- Risk Assessment and Safety Procedures: Demonstrate understanding of safety protocols and the ability to conduct risk assessments related to inspection and testing activities.

- Troubleshooting and Problem-Solving: Prepare examples illustrating your ability to identify, analyze, and resolve inspection-related issues using a systematic approach.

- Record Keeping and Documentation: Explain the importance of meticulous record-keeping and proper documentation procedures in aircraft maintenance.

- Specialized Inspection Techniques: Explore specific inspection techniques relevant to different aircraft components (e.g., engines, landing gear, flight controls).

- Quality Control and Assurance: Understand the importance of quality control in maintaining aircraft airworthiness and be prepared to discuss relevant quality assurance methodologies.

Next Steps

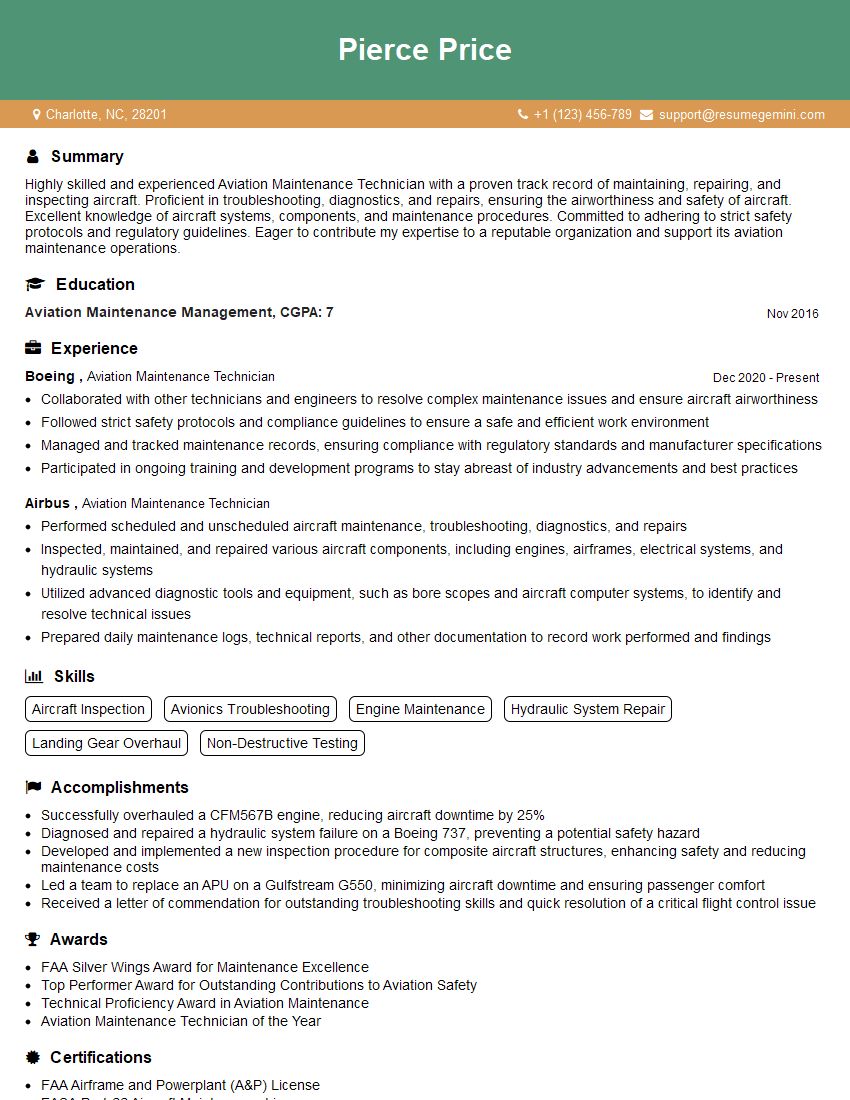

Mastering Aircraft Inspection and Testing is crucial for a rewarding and successful career in aviation. This specialized skillset is highly valued, opening doors to diverse opportunities and career advancement. To maximize your job prospects, it’s vital to create a compelling and ATS-friendly resume that effectively showcases your qualifications. ResumeGemini is a trusted resource that can significantly enhance your resume-building experience, helping you create a document that stands out. Examples of resumes tailored to Aircraft Inspection and Testing are available to guide you. Invest in crafting a professional resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.