Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Textile Sourcing and Procurement interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Textile Sourcing and Procurement Interview

Q 1. Explain the process of sourcing fabric from overseas suppliers.

Sourcing fabric from overseas suppliers is a multi-stage process requiring meticulous planning and execution. It begins with identifying potential suppliers, typically through online directories, trade shows, or industry referrals. Next, we meticulously review supplier capabilities, focusing on their production capacity, certifications (e.g., OEKO-TEX, GOTS), and past performance. A crucial step involves requesting fabric samples and conducting thorough quality checks, comparing them against our pre-defined specifications. Once a supplier is selected, detailed negotiations are undertaken, including price, payment terms, minimum order quantities (MOQs), and delivery timelines. The process concludes with placing the order, monitoring production, ensuring quality control throughout manufacturing, and managing logistics for shipment and customs clearance. For example, when sourcing organic cotton from India, I’ve personally managed the entire process from initial contact with multiple suppliers to final delivery, ensuring compliance with our sustainability standards and quality requirements.

- Supplier Identification & Qualification: Researching and vetting potential partners.

- Sample Evaluation & Quality Testing: Rigorous testing to meet standards.

- Negotiation & Order Placement: Finalizing terms and initiating production.

- Production Monitoring & Quality Control: Regular checks throughout the process.

- Logistics & Customs: Managing shipment and import/export compliance.

Q 2. What are the key factors to consider when negotiating fabric prices?

Negotiating fabric prices involves a delicate balance of securing favorable terms without jeopardizing the supplier relationship. Key factors include fabric type and quality (e.g., higher thread count generally commands a higher price), order quantity (larger orders often result in discounts), market conditions (fluctuations in raw material costs can impact prices), and payment terms (longer payment periods might lead to higher prices). Understanding the supplier’s cost structure – raw materials, labor, overhead – is vital. I always strive to build a strong, long-term relationship with my suppliers, fostering mutual trust and transparency. A successful negotiation usually involves compromise; for instance, I might negotiate a slightly higher price in exchange for guaranteed order volume over a longer period. It’s also important to be aware of hidden costs, such as freight and customs duties.

- Fabric Specifications: Quality, composition, and complexity directly affect cost.

- Order Volume: Larger quantities typically lead to lower unit prices (economies of scale).

- Market Conditions: Fluctuations in raw materials and currency exchange rates.

- Payment Terms: Longer payment periods may increase prices.

- Supplier Cost Structure: Understanding their operational expenses.

Q 3. How do you manage lead times effectively in textile sourcing?

Effective lead time management is crucial for on-time delivery and preventing production delays. This involves a proactive approach starting from the initial stages of sourcing. We collaboratively establish realistic lead times with our suppliers, factoring in production capacity, potential delays, and shipping times. Regular communication is essential, utilizing tools like project management software to track progress. Contingency plans should be in place to address unforeseen circumstances, such as raw material shortages or logistical hurdles. For example, I once encountered a significant port congestion that threatened to delay a large order. By proactively communicating with the supplier and exploring alternative shipping routes, I managed to minimize the disruption and ensure timely delivery.

- Realistic Lead Time Estimation: Collaboration with suppliers considering all factors.

- Regular Communication & Tracking: Using project management tools and maintaining open dialogue.

- Contingency Planning: Addressing potential delays with alternative solutions.

- Buffer Time: Building in extra time to account for unforeseen issues.

Q 4. Describe your experience with different fabric types and their sourcing challenges.

My experience encompasses a wide range of fabric types, each presenting unique sourcing challenges. For example, sourcing high-quality silk requires specialized knowledge and access to reputable silk farms and mills, often involving longer lead times and higher costs compared to cotton. Similarly, sourcing sustainable and ethically produced fabrics, like organic cotton or recycled materials, necessitates careful vetting of suppliers to ensure compliance with environmental and social standards. Technical fabrics, such as those used in performance apparel, often require specialized manufacturing processes and expertise, potentially limiting the pool of qualified suppliers. Each fabric type necessitates a tailored approach to sourcing, taking into consideration its specific production methods, quality control requirements, and potential supply chain complexities.

- Silk: Sourcing from reputable farms and mills, potentially longer lead times and higher costs.

- Organic Cotton: Ensuring compliance with sustainability certifications (e.g., GOTS).

- Recycled Materials: Verifying the authenticity and quality of recycled fibers.

- Technical Fabrics: Sourcing specialized manufacturers with expertise in performance fabrics.

Q 5. What are your strategies for mitigating supply chain risks in the textile industry?

Mitigating supply chain risks in the textile industry requires a multi-faceted approach. Diversifying supplier base is critical, reducing reliance on a single source and minimizing the impact of disruptions. Building strong relationships with key suppliers fosters transparency and collaboration, enabling early identification and mitigation of potential problems. Regularly reviewing and updating supplier performance metrics allows for proactive adjustments. Investing in robust risk management systems helps assess and prioritize potential threats, such as political instability, natural disasters, or geopolitical events. Furthermore, implementing robust quality control measures throughout the supply chain minimizes the risk of defective products. For example, we’ve established alternative sourcing options for key raw materials to mitigate the risk of disruptions caused by unforeseen events.

- Supplier Diversification: Reducing dependence on a single source.

- Strong Supplier Relationships: Fostering trust and transparency.

- Performance Monitoring: Regularly reviewing supplier metrics.

- Risk Management Systems: Identifying and addressing potential threats proactively.

- Quality Control: Implementing robust measures throughout the supply chain.

Q 6. How do you ensure the quality of sourced textiles?

Ensuring quality is paramount. This starts with establishing clear quality specifications and sharing them with suppliers upfront. It involves rigorous testing of fabric samples at various stages, from initial receipt to final inspection before shipment. Employing third-party quality control inspectors adds an extra layer of assurance, providing an independent assessment of conformity to specifications. Regular audits of supplier facilities help evaluate their processes and identify potential areas for improvement. Investing in quality management systems, such as ISO 9001, can help ensure consistency and traceability. For example, for a recent project requiring high-performance sportswear fabric, we employed both in-house and third-party testing to guarantee the fabric met the demanding specifications for durability, moisture-wicking, and UV protection.

- Clear Specifications: Defining quality parameters upfront.

- Sample Testing: Conducting rigorous tests at different stages.

- Third-Party Inspection: Utilizing independent quality assessment.

- Supplier Audits: Evaluating production processes and identifying areas for improvement.

- Quality Management Systems: Implementing ISO 9001 or similar standards.

Q 7. Explain your experience with different payment terms and their implications.

Payment terms significantly impact cash flow and supplier relationships. Common terms include Letter of Credit (LC), Documentary Collection (D/C), and Open Account. An LC offers the most security for the buyer, guaranteeing payment upon fulfillment of specific conditions. D/C provides moderate security, with payment released upon presentation of shipping documents. Open account, offering the least security, requires trust between buyer and supplier. The choice depends on factors like the supplier’s reliability, order value, and risk tolerance. Each term has implications; for example, an LC often requires more documentation and processing time, while open account can improve relationships but carries higher risk. My experience involves utilizing various payment methods based on specific circumstances and risk assessments, prioritizing mutual benefit and trust with our suppliers. Negotiating favorable terms is crucial for both cost optimization and maintaining strong supplier relationships.

- Letter of Credit (LC): High security, more documentation and processing time.

- Documentary Collection (D/C): Moderate security, payment released upon shipping documents.

- Open Account: Least security, higher risk, but can foster stronger relationships.

- Considerations: Supplier reliability, order value, risk tolerance, and cash flow.

Q 8. How do you handle supplier relationship management?

Supplier Relationship Management (SRM) is crucial for success in textile sourcing. It’s about building and maintaining strong, mutually beneficial relationships with suppliers. Think of it like cultivating a garden – you need consistent nurturing to reap a bountiful harvest.

- Regular Communication: I prioritize open and frequent communication, using a mix of emails, video calls, and even in-person visits when feasible. This keeps everyone informed and allows for proactive problem-solving.

- Performance Monitoring: I establish clear Key Performance Indicators (KPIs) for suppliers, such as on-time delivery, quality rates, and responsiveness. Regular performance reviews help identify areas for improvement and celebrate successes.

- Collaborative Problem-Solving: When issues arise (and they inevitably will!), I focus on collaboration. Rather than assigning blame, I work with suppliers to identify root causes and develop solutions together. This fosters trust and strengthens the relationship.

- Fair Pricing and Payment Terms: Maintaining fair and transparent pricing and payment terms is essential. This demonstrates respect for the supplier and encourages long-term commitment. I always negotiate contracts that are mutually beneficial.

- Relationship Building: Beyond the business aspect, I believe in building genuine relationships. Understanding a supplier’s culture, challenges, and goals helps build trust and fosters a collaborative spirit.

For example, I once worked with a supplier experiencing delays due to unexpected machinery failure. Instead of penalizing them, I helped them source replacement parts and offered flexible payment terms. This built trust and resulted in a stronger, more reliable partnership.

Q 9. Describe your experience with using sourcing platforms and technologies.

I have extensive experience utilizing various sourcing platforms and technologies to streamline the procurement process. This includes both traditional methods and sophisticated digital tools.

- Online Marketplaces: I’ve utilized platforms like Alibaba and Global Sources to identify and compare suppliers, request quotes, and manage orders. These platforms offer a wide selection of suppliers and facilitate efficient communication.

- Supplier Relationship Management (SRM) Software: I’ve used software such as SAP Ariba and Coupa to manage supplier information, track performance, and automate purchasing processes. This helps ensure consistency and reduces administrative overhead.

- Product Lifecycle Management (PLM) Systems: These systems aid in design collaboration, material tracking, and quality control throughout the entire product lifecycle. They provide a centralized platform for managing complex textile projects.

- Data Analytics: I leverage data analytics tools to analyze supplier performance, identify cost-saving opportunities, and predict potential risks. This data-driven approach helps make informed sourcing decisions.

For instance, using data analytics from a PLM system, I once identified a trend of late deliveries from a specific supplier linked to a specific type of fabric. By investigating the issue, we uncovered a bottleneck in their production process which we collaboratively resolved.

Q 10. How do you assess the sustainability and ethical sourcing practices of suppliers?

Assessing the sustainability and ethical sourcing practices of suppliers is paramount. It’s not just about meeting legal requirements but about ensuring responsible and transparent supply chains.

- Supplier Audits: I conduct regular audits, both on-site and remotely, to assess compliance with environmental and social standards. These audits cover areas like labor practices, waste management, and chemical usage.

- Certifications and Standards: I prioritize suppliers holding certifications such as GOTS (Global Organic Textile Standard), OEKO-TEX, and BSCI (Business Social Compliance Initiative). These certifications provide independent verification of their commitment to ethical and sustainable practices.

- Traceability: I work with suppliers who can provide transparent traceability of their materials and processes. This helps ensure the origin of raw materials and the working conditions throughout the supply chain.

- Social Responsibility Reporting: I review suppliers’ social responsibility reports to understand their commitment to fair labor practices, worker safety, and community engagement.

- Transparency and Communication: I value open communication with suppliers to identify and address potential challenges related to sustainability and ethical sourcing.

For example, I once identified a supplier who was using a potentially harmful dye. After thorough investigation and communication, we worked together to switch to a more sustainable alternative, improving both environmental impact and product quality.

Q 11. What is your experience with fabric testing and quality control procedures?

Fabric testing and quality control are crucial for ensuring the final product meets quality standards. My experience encompasses all stages, from raw material inspection to finished goods testing.

- Raw Material Testing: I ensure that fabrics meet the required specifications in terms of composition, strength, colorfastness, and other relevant properties. This typically involves laboratory testing by accredited facilities.

- In-Process Inspections: Regular inspections throughout the manufacturing process, including cutting, sewing, and finishing stages, are conducted to identify and address any defects early on.

- Finished Goods Testing: Comprehensive testing of the finished product ensures compliance with quality standards and customer specifications. This includes dimensional stability, shrinkage, and other relevant tests.

- Quality Control Documentation: Maintaining detailed records of all testing and inspection results is essential for traceability and accountability.

- Collaboration with Testing Labs: I work closely with accredited testing laboratories to ensure accurate and reliable results.

In one instance, inconsistencies in fabric color were detected during the finished goods inspection. Through rigorous testing, we pinpointed the issue to a batch of dye and were able to prevent the shipment of non-compliant products.

Q 12. How do you manage discrepancies between purchase orders and delivered goods?

Discrepancies between purchase orders and delivered goods are unfortunately common. Handling them efficiently requires a systematic approach.

- Detailed Documentation: Maintaining detailed and accurate purchase orders, including specifications, quantities, and delivery dates, is the first line of defense.

- Inspection Upon Delivery: Thorough inspection upon receipt of goods is critical to identify any discrepancies immediately.

- Communication with Supplier: Clear and prompt communication with the supplier is essential to resolve discrepancies. Providing photographic or video evidence of the discrepancies is highly beneficial.

- Negotiation and Resolution: Negotiating a resolution with the supplier, which may involve replacement of defective goods, price adjustments, or other compensations, is the next step.

- Documentation of Resolution: Documenting the entire process, including the discrepancy, the communication with the supplier, and the agreed-upon resolution, is crucial for future reference and dispute resolution.

For example, if a shipment arrives with a shortage of 10% of the ordered quantity, I would immediately contact the supplier, provide evidence, and negotiate a solution such as a replacement shipment or a price adjustment.

Q 13. What is your experience with customs regulations and import/export processes?

Navigating customs regulations and import/export processes is a complex but crucial aspect of textile sourcing. Understanding the rules and regulations of different countries is essential to avoid delays and penalties.

- Classification of Goods: Correctly classifying the textiles according to the Harmonized System (HS) codes is crucial for accurate customs duties and taxes calculation.

- Documentation: Preparing all necessary documentation, including commercial invoices, packing lists, certificates of origin, and other required permits, is essential.

- Customs Brokers: Utilizing the services of experienced customs brokers can streamline the process and reduce the risk of errors. They are well-versed in the intricacies of customs regulations.

- Compliance: Staying updated on changes in customs regulations and ensuring compliance with all applicable laws and regulations is essential.

- Risk Management: Identifying and mitigating potential risks associated with import/export, such as delays, penalties, and unforeseen charges, is critical.

For instance, a thorough understanding of HS codes helped me avoid a significant delay in a shipment by ensuring that the correct codes were used on the documentation. This prevented the shipment from being held up at customs.

Q 14. How do you analyze cost structures and optimize sourcing costs?

Analyzing cost structures and optimizing sourcing costs is a continuous process that requires a multi-faceted approach. It’s about finding the best balance between quality, cost, and lead time.

- Cost Breakdown: A detailed breakdown of the cost structure, including raw materials, labor, manufacturing, transportation, duties, and other associated costs, is crucial.

- Supplier Negotiation: Negotiating favorable pricing and payment terms with suppliers is essential. This may involve leveraging volume discounts or exploring alternative payment methods.

- Material Selection: Optimizing material selection can significantly impact costs. Choosing cost-effective fabrics without compromising quality is a key aspect.

- Manufacturing Efficiency: Working with suppliers to improve manufacturing efficiency can lead to cost savings. This might involve optimizing production processes or adopting new technologies.

- Transportation and Logistics: Optimizing transportation and logistics, such as selecting efficient shipping routes and consolidating shipments, can reduce costs.

- Data Analysis: Utilizing data analytics to identify trends and patterns in costs can help pinpoint areas for improvement.

For example, by analyzing transportation costs, I identified a significant saving by consolidating shipments from multiple suppliers. This resulted in a considerable reduction in overall sourcing costs without affecting delivery timelines.

Q 15. Explain your experience with capacity planning and forecasting demand.

Capacity planning and demand forecasting are crucial for efficient textile sourcing and procurement. It’s essentially predicting how much fabric and other materials we’ll need and ensuring our suppliers can meet those needs. This involves analyzing historical sales data, current market trends, and upcoming marketing campaigns. For example, if we’re launching a new line of winter coats in October, we need to forecast demand for wool, lining fabrics, and buttons well in advance. This forecasting informs our production schedules with suppliers, allowing us to secure the necessary resources on time and avoid shortages.

My approach involves using a combination of quantitative and qualitative methods. Quantitative methods include statistical forecasting models like exponential smoothing or ARIMA, which analyze historical sales data to predict future demand. Qualitative methods, such as sales team input and market research, provide valuable insights into potential disruptions or unexpected changes in consumer preferences. By integrating these two approaches, we create a more robust and accurate forecast, enabling better capacity planning and minimizing the risk of stockouts or overstocking.

For instance, in a previous role, we used a combination of time series analysis and market research to forecast demand for a new line of sustainable cotton shirts. The time series analysis indicated a steady increase in demand for sustainable apparel, while market research highlighted an emerging preference for specific colors and styles. By incorporating both types of data into our forecast, we were able to secure sufficient sustainable cotton fabric from our suppliers while minimizing waste and maximizing efficiency.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage inventory effectively to avoid stockouts or overstocking?

Effective inventory management is the backbone of successful textile sourcing. The goal is to maintain enough stock to meet customer demands without tying up excessive capital in storage or risking obsolescence. Think of it like balancing a tightrope – too little inventory and you lose sales, too much and you waste money.

My strategy involves implementing a robust inventory management system that tracks stock levels, monitors order fulfillment, and anticipates future demand. This system uses a combination of techniques, including:

- Just-in-Time (JIT) inventory: This minimizes storage costs by ordering materials only when needed. It’s especially effective for fast-moving items.

- Economic Order Quantity (EOQ): This model helps determine the optimal order size to minimize total inventory costs, considering ordering and holding costs.

- Safety Stock: A buffer stock maintained to account for unexpected demand spikes or supply chain disruptions. The level of safety stock is determined by the variability of demand and lead times.

- Regular Inventory Audits: Physical verification of inventory levels to ensure accuracy and identify discrepancies.

For example, we once faced a potential shortage of a key fabric due to an unforeseen delay at the supplier’s factory. Because we had a well-defined safety stock policy in place, we were able to meet our production deadlines without significant impact. Moreover, regular inventory audits ensure we avoid stock obsolescence by identifying slow-moving items and implementing strategies to liquidate them.

Q 17. Describe your experience with different types of textile production methods.

My experience encompasses a broad range of textile production methods, including weaving, knitting, dyeing, printing, and finishing. Each method has unique characteristics and implications for quality, cost, and lead times.

- Weaving: Creates fabrics by interlacing warp and weft yarns, resulting in strong and durable materials like denim or gabardine.

- Knitting: Produces fabrics by interlooping yarns, resulting in more flexible and stretchy materials like jersey or rib knit.

- Dyeing: Imparts color to fabrics using various techniques like vat dyeing, reactive dyeing, or pigment dyeing, each suitable for different fiber types and colors.

- Printing: Adds patterns and designs to fabrics using methods like screen printing, rotary printing, or digital printing, each offering different levels of detail and production scale.

- Finishing: Enhances fabric properties through processes like washing, calendaring, and mercerizing, impacting texture, drape, and durability.

Understanding these methods is essential for choosing the right fabric for a specific application, managing production timelines, and controlling costs. For instance, in a recent project, we opted for a knitted fabric instead of a woven fabric due to its superior drape and flexibility, even though the cost was slightly higher. This was deemed necessary to meet the design requirements for a specific garment style.

Q 18. What are your strategies for finding and onboarding new suppliers?

Finding and onboarding new suppliers requires a thorough and systematic approach. It’s not just about finding the cheapest option; it’s about finding reliable partners who can meet quality standards, deliver on time, and adhere to ethical practices.

My strategy includes:

- Online Directories and Trade Shows: Identifying potential suppliers through online databases and attending industry trade shows to network and assess capabilities in person.

- Supplier Audits and Assessments: Conducting rigorous audits to evaluate their production capabilities, quality control systems, and social compliance practices.

- Request for Information (RFI) and Request for Proposal (RFP): Sending out RFIs to gather information and RFPs to solicit bids from qualified suppliers. This allows for comparing offers based on cost, quality, and delivery times.

- Trial Orders and Pilot Runs: Placing small trial orders to evaluate supplier performance before committing to larger contracts.

- Onboarding Process: Developing a formal onboarding process that establishes clear communication channels, payment terms, and performance expectations.

For example, when searching for a new supplier of organic cotton, I used a combination of online directories specialized in sustainable materials and attending a relevant industry trade show. This allowed me to directly interact with suppliers, evaluate their certifications, and request samples before placing a trial order.

Q 19. How do you ensure compliance with relevant industry regulations and standards?

Compliance with industry regulations and standards is paramount in textile sourcing. This covers a wide range of areas, from environmental protection and worker safety to product labeling and ethical sourcing.

We ensure compliance through:

- Regular Audits: Conducting regular audits of our suppliers to ensure adherence to relevant laws and regulations, including those related to environmental sustainability, labor practices, and chemical usage.

- Certification Verification: Verifying that suppliers hold the necessary certifications, such as OEKO-TEX, GOTS (Global Organic Textile Standard), or BSCI (Business Social Compliance Initiative), demonstrating their commitment to ethical and sustainable practices.

- Traceability Systems: Implementing traceability systems to track the origin of materials and ensure transparency throughout the supply chain.

- Legal and Regulatory Monitoring: Staying abreast of changes in relevant laws and regulations to ensure ongoing compliance.

- Documentation and Reporting: Maintaining thorough documentation of compliance efforts and providing regular reports to relevant stakeholders.

For instance, a recent audit revealed a supplier’s non-compliance with water discharge regulations. We worked closely with them to implement corrective actions and ensure future compliance. This involved providing guidance and technical support to implement better wastewater treatment systems.

Q 20. How do you handle situations of unexpected delays or disruptions in the supply chain?

Unexpected delays or disruptions are an inherent risk in global supply chains. Having a proactive approach is key to mitigating their impact. This involves building resilience into the supply chain and having contingency plans in place.

My approach includes:

- Diversification of Suppliers: Reducing reliance on a single supplier to mitigate risks associated with potential disruptions at one facility.

- Strong Supplier Relationships: Maintaining open communication and building strong relationships with suppliers to enable early identification and resolution of potential problems.

- Contingency Planning: Developing contingency plans that identify alternative sourcing options or production methods in case of disruptions.

- Risk Assessment and Management: Regularly assessing potential risks and implementing mitigation strategies to minimize their impact.

- Communication and Transparency: Keeping all stakeholders informed about delays and working collaboratively to find solutions.

For example, during the COVID-19 pandemic, we experienced significant delays in shipments from a key supplier due to port closures and factory lockdowns. However, because we had diversified our supplier base and maintained strong relationships with our alternate suppliers, we were able to quickly shift orders and minimize the impact on our production schedule.

Q 21. Describe your approach to evaluating supplier performance.

Evaluating supplier performance is a continuous process, not a one-time event. This involves establishing clear Key Performance Indicators (KPIs) and regularly monitoring their performance against these metrics.

My approach includes:

- Establishing KPIs: Defining clear KPIs such as on-time delivery, quality of materials, compliance with standards, and responsiveness to communication.

- Regular Performance Reviews: Conducting regular performance reviews with suppliers to discuss their performance against established KPIs and identify areas for improvement.

- Data-Driven Analysis: Using data analytics to track key performance indicators and identify trends.

- Feedback Mechanisms: Establishing feedback mechanisms to gather information from various stakeholders, such as internal teams and customers, to gain a comprehensive view of supplier performance.

- Performance Improvement Plans: Developing performance improvement plans with underperforming suppliers to address deficiencies and improve future performance.

For example, we regularly track our suppliers’ on-time delivery rates and quality defect rates. If a supplier consistently fails to meet our expectations, we work with them to understand the root causes and develop a performance improvement plan. If improvements are not made, we may consider switching to an alternative supplier.

Q 22. What are your strategies for negotiating favorable contracts with suppliers?

Negotiating favorable contracts hinges on thorough preparation, strong relationships, and strategic leverage. It’s not just about price; it’s about securing a mutually beneficial partnership that ensures quality, timely delivery, and ethical practices.

- Pre-Negotiation Research: Before any meeting, I meticulously research the supplier’s financial stability, production capacity, and market reputation. Knowing their strengths and weaknesses gives me a significant advantage.

- Building Relationships: I foster long-term relationships with key suppliers, based on trust and mutual respect. This fosters open communication and collaborative problem-solving, leading to more favorable terms than simply transactional agreements.

- Strategic Leverage: This includes factors like order volume, contract length, and the ability to offer consistent business. For instance, promising a larger, multi-year contract can often secure a lower price per unit. I also leverage market knowledge: if I know similar fabrics are available at a lower price elsewhere, I use that information to negotiate.

- Detailed Contract Review: I carefully scrutinize every clause, focusing on payment terms, quality control provisions, and dispute resolution mechanisms. Any ambiguities are clarified before signing.

- Value-Based Negotiation: Instead of solely focusing on price, I emphasize the total value proposition, including quality, delivery reliability, and ethical sourcing practices. This allows for a more holistic negotiation, moving beyond just the lowest cost.

For example, in a recent negotiation with a denim supplier, I leveraged our consistent, high-volume orders to negotiate a 5% price reduction while simultaneously securing a faster turnaround time, benefiting both parties.

Q 23. Explain your experience with managing different currencies and exchange rate fluctuations.

Managing multiple currencies and exchange rate fluctuations requires a proactive and informed approach. Ignoring this aspect can significantly impact profitability.

- Hedging Strategies: I utilize various hedging techniques, such as forward contracts or currency options, to mitigate the risk of adverse exchange rate movements. This helps lock in exchange rates for future payments, protecting us from potential losses due to currency volatility.

- Currency Clause Inclusion: Contracts always include clauses specifying the currency of payment and how exchange rate fluctuations will be addressed. This clarity prevents disputes and ensures fairness.

- Real-time Monitoring: I closely monitor exchange rates and their potential impact on our costs and profits. This includes utilizing financial software and staying informed about market trends.

- Supplier Relationship Management: Open communication with suppliers about currency risks is crucial. We collaboratively explore strategies to minimize the impact on both parties.

- Diversification: While not always feasible, diversifying suppliers across different countries can help reduce the impact of fluctuations in a single currency.

In a recent project involving a supplier in Vietnam, we utilized a forward contract to secure a favorable exchange rate for our payments, shielding us from a significant devaluation of the Vietnamese Dong.

Q 24. How do you identify and mitigate potential risks associated with counterfeit textiles?

Counterfeit textiles pose a significant threat to brand reputation and consumer safety. Mitigating this risk requires a multi-faceted approach.

- Supplier Due Diligence: Rigorous due diligence on suppliers is paramount. This includes verifying their certifications, licenses, and production processes. On-site audits are crucial for assessing compliance and ethical practices.

- Third-Party Verification: Using independent third-party verification services to test fabrics and confirm their authenticity offers an extra layer of security.

- Chain-of-Custody Tracking: Implementing robust chain-of-custody tracking systems helps trace the origin of materials, making it harder to introduce counterfeits.

- Intellectual Property Protection: Protecting intellectual property rights through trademarks and patents is vital. This makes it more challenging for counterfeiters to reproduce designs and logos.

- Collaboration and Reporting: Working with industry associations and authorities to report counterfeit activity helps combat the issue collectively.

We once uncovered a significant counterfeiting operation through thorough supplier audits and subsequent testing by a third-party lab. This led to immediate termination of the contract and a strengthened due diligence process.

Q 25. What is your experience with technology in streamlining textile sourcing operations?

Technology plays a pivotal role in streamlining textile sourcing. It enhances efficiency, transparency, and data-driven decision-making.

- Sourcing Platforms: Utilizing online platforms that connect buyers and suppliers directly, offering access to a broader range of options and facilitating communication.

- Product Lifecycle Management (PLM) Software: PLM software manages the entire lifecycle of a product, from design to production, improving collaboration, tracking, and quality control.

- Supply Chain Management (SCM) Systems: SCM systems offer real-time visibility into the supply chain, improving transparency and responsiveness to disruptions.

- Data Analytics: Analyzing data to identify trends, predict demand, optimize inventory, and improve supplier selection.

- Automation: Automating tasks like purchase order processing and invoice management reduces manual work and increases efficiency.

Implementing a PLM system in my previous role dramatically reduced lead times and improved communication between our design team and suppliers, leading to more accurate production schedules and faster product launches.

Q 26. Explain your understanding of different fabric certifications (e.g., OEKO-TEX, GOTS).

Fabric certifications such as OEKO-TEX and GOTS provide assurance of safety, sustainability, and ethical production practices.

- OEKO-TEX Standard 100: This certification ensures that textiles are free from harmful substances, safeguarding both workers and consumers. It assesses chemicals used throughout the production process.

- Global Organic Textile Standard (GOTS): This certification defines requirements for organic fibers, ensuring environmentally and socially responsible manufacturing. It covers the entire supply chain, from farming to finished product.

- Other Certifications: There are many other certifications focusing on specific aspects, such as Fairtrade (ethical labor practices), Bluesign (reduced environmental impact), and recycled content certifications. Understanding which certifications are relevant to the brand’s values and target market is essential.

Understanding these certifications allows us to prioritize suppliers committed to sustainability and ethical practices, aligning with our brand values and meeting increasing consumer demand for transparency.

Q 27. How do you collaborate effectively with cross-functional teams in the sourcing process?

Effective cross-functional collaboration is crucial for successful sourcing. It requires clear communication, shared goals, and mutual respect.

- Regular Communication: Frequent meetings and updates keep everyone informed about progress and potential challenges. This ensures alignment and avoids misunderstandings.

- Shared Goals and Metrics: Setting clear, measurable goals for cost, quality, and delivery ensures everyone works towards the same objectives.

- Collaborative Tools: Utilizing project management tools and shared platforms for document sharing and communication promotes efficiency and transparency.

- Conflict Resolution Mechanisms: Establishing protocols for addressing disagreements and resolving conflicts prevents delays and maintains positive working relationships.

- Open and Transparent Communication: Encouraging open communication fosters trust and facilitates problem-solving.

In a recent project, I successfully facilitated collaboration between design, production, and logistics teams by implementing a shared project management platform. This improved communication, reduced errors, and ensured timely delivery.

Q 28. Describe your experience with using different sourcing techniques, such as auctions or direct sourcing.

Different sourcing techniques offer various advantages and disadvantages, depending on the specific needs and context.

- Direct Sourcing: This involves establishing direct relationships with suppliers, offering greater control over quality, pricing, and ethical practices. It’s suitable for larger orders and long-term partnerships.

- Auctions: Online auctions can be efficient for sourcing certain materials, especially for shorter-term needs or smaller quantities. However, due diligence is crucial to ensure supplier reliability.

- Agent Sourcing: Using sourcing agents can provide access to a wider network of suppliers, particularly in less familiar markets. However, costs and communication can be challenges.

For instance, we utilize direct sourcing for our core fabrics, guaranteeing quality and reliable supply. For less critical materials, we may use a combination of agent sourcing and online auctions to find cost-effective options.

Key Topics to Learn for Textile Sourcing and Procurement Interview

- Fiber & Fabric Knowledge: Understanding different fiber types (natural, synthetic), fabric constructions, and their properties. Practical application: Analyzing fabric composition reports and identifying potential quality issues.

- Global Supply Chains: Mapping the textile supply chain from raw material to finished product, including key players and geographical considerations. Practical application: Evaluating the efficiency and sustainability of different sourcing strategies.

- Sourcing Strategies: Developing effective strategies for identifying, evaluating, and selecting suppliers based on factors like price, quality, lead times, and ethical considerations. Practical application: Negotiating contracts and managing supplier relationships.

- Quality Control & Assurance: Implementing quality control measures throughout the supply chain to ensure products meet specifications. Practical application: Understanding and interpreting quality control reports and addressing non-conformances.

- Costing & Budgeting: Accurately estimating costs associated with sourcing, production, and transportation. Practical application: Developing a comprehensive budget for a textile project and managing costs effectively.

- Ethical & Sustainable Sourcing: Understanding and implementing ethical and sustainable practices in textile sourcing, including fair labor practices and environmental responsibility. Practical application: Evaluating suppliers’ compliance with social and environmental standards.

- Negotiation & Contract Management: Negotiating favorable terms with suppliers and managing contracts effectively. Practical application: Drafting and reviewing contracts to protect the interests of your organization.

- Technology in Sourcing: Familiarity with software and technologies used in textile sourcing and procurement, such as PLM systems and digital fabric libraries. Practical application: Utilizing technology to streamline sourcing processes and improve efficiency.

- Risk Management: Identifying and mitigating potential risks in the textile supply chain, such as disruptions, quality issues, and geopolitical factors. Practical application: Developing contingency plans to address unforeseen challenges.

Next Steps

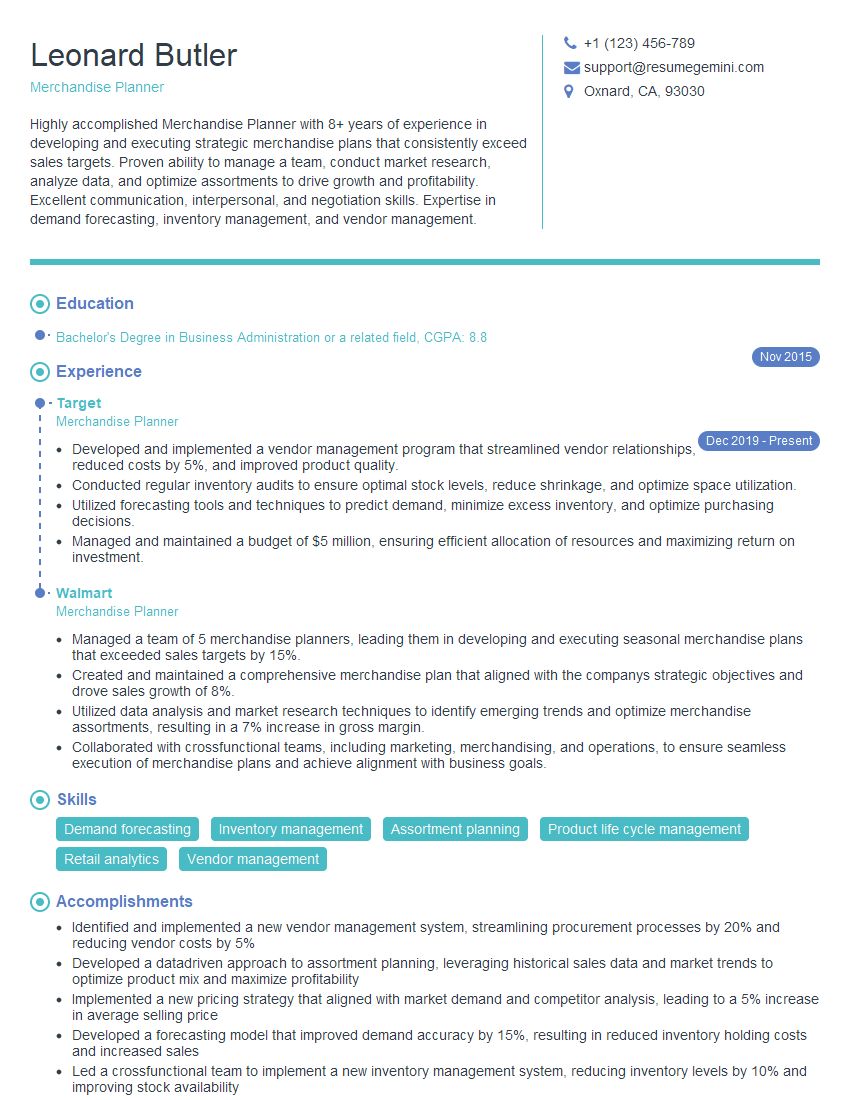

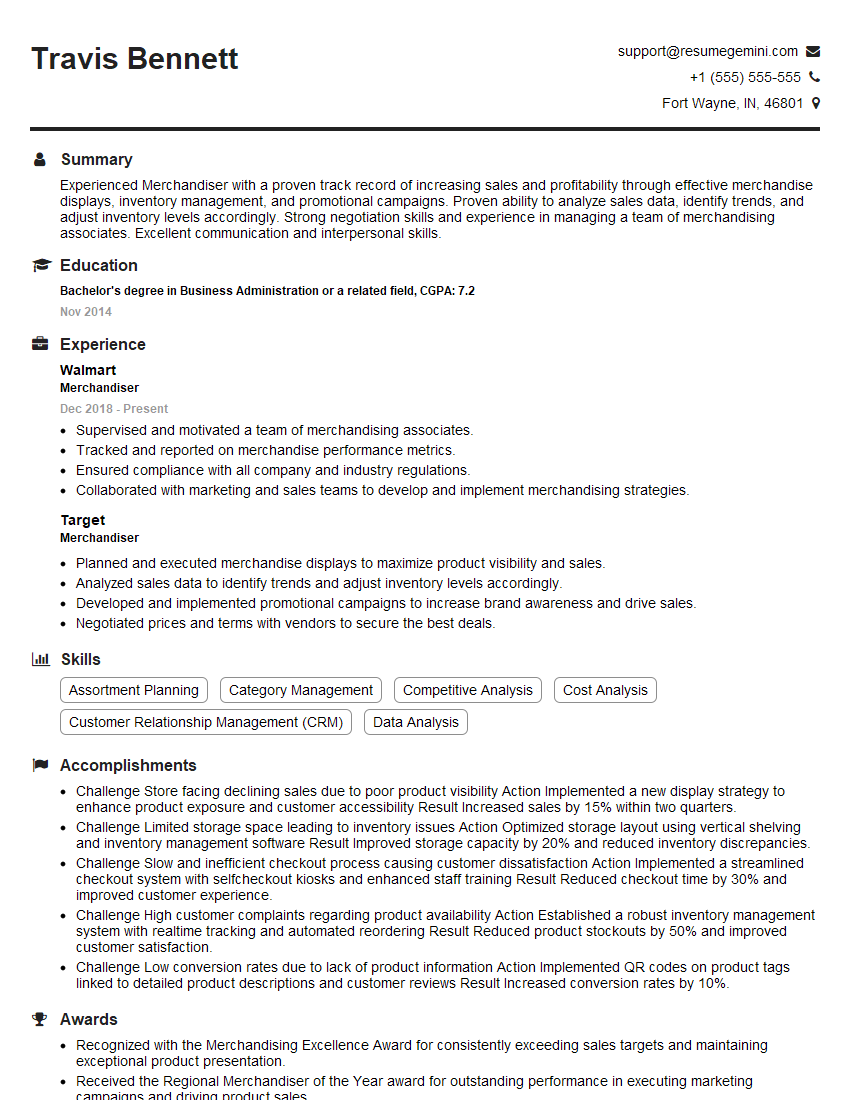

Mastering Textile Sourcing and Procurement opens doors to exciting career opportunities with significant growth potential within the dynamic fashion and textile industry. To maximize your chances of landing your dream role, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We provide examples of resumes tailored specifically to Textile Sourcing and Procurement to give you a head start. Take the next step towards your career goals today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.