Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Chalk Thermal Conductivity Testing interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Chalk Thermal Conductivity Testing Interview

Q 1. Explain the principle of thermal conductivity testing in chalk.

Thermal conductivity testing in chalk, like in any material, measures its ability to transfer heat. Imagine placing a hot plate on one side of a chalk sample; the thermal conductivity quantifies how quickly heat travels through the chalk to the other side. More precisely, it’s the rate of heat flow through a unit thickness of the material under a unit temperature gradient. This is expressed as Watts per meter-Kelvin (W/m·K). A higher value indicates a faster heat transfer.

The principle relies on establishing a known temperature difference across a chalk sample and measuring the resulting heat flow. Various methods employ different techniques to achieve this, all aiming to determine the material’s intrinsic ability to conduct heat.

Q 2. Describe different methods used for determining chalk thermal conductivity.

Several methods exist for determining chalk’s thermal conductivity. These include:

- Transient Plane Source (TPS) method: This is a widely used technique that involves a small, heated sensor placed within the chalk sample. The sensor’s temperature rise is monitored over time, allowing calculation of thermal conductivity. It’s a relatively quick and non-destructive method, well-suited for in-situ measurements.

- Heat Flow Meter method: This method employs a heat flow meter placed between two known temperature regions. The chalk sample is positioned between the meter and a heat source. The heat flow through the sample is measured, and the conductivity is determined. This method requires larger samples.

- Steady-State method: This involves establishing a constant temperature difference across a chalk sample and measuring the resulting heat flow. This usually requires a temperature-controlled environment and a significant amount of time to achieve a steady state. It can provide highly accurate results, though it is less practical for field testing.

The choice of method often depends on factors such as the size and accessibility of the sample, the required accuracy, and the available equipment.

Q 3. What are the limitations of each method for measuring chalk thermal conductivity?

Each method has its own limitations:

- TPS method: Accuracy can be affected by sample homogeneity and the presence of moisture. The sensor’s contact with the chalk needs to be optimal to ensure reliable results.

- Heat Flow Meter method: Requires larger samples and precise temperature control. Proper thermal contact between the meter and the sample is crucial, and edge effects can influence the measurements.

- Steady-State method: This is time-consuming and requires a highly controlled environment. It’s less suitable for field measurements due to its experimental complexity.

Furthermore, all methods are sensitive to the inherent variability in chalk properties, meaning that multiple measurements on different samples are essential to obtain a representative average value. Proper sample preparation is also crucial to minimize bias.

Q 4. How does porosity affect the thermal conductivity of chalk?

Porosity significantly impacts chalk’s thermal conductivity. Chalk is a porous rock, meaning it contains interconnected voids (pores). These pores are typically filled with air or water. Air is a poor conductor of heat, while water is a better conductor than air but still significantly less than the solid chalk matrix.

Increased porosity, therefore, generally leads to lower thermal conductivity. The more air or water present in the pores, the more the heat transfer is impeded. This is because the heat must traverse a more tortuous path through the material. Think of it like walking through a crowded room versus an empty one – the empty room allows for faster movement (heat transfer).

Q 5. How does moisture content influence thermal conductivity measurements in chalk?

Moisture content substantially influences chalk’s thermal conductivity. As mentioned, water is a better heat conductor than air. Therefore, increasing moisture content in the pores increases the thermal conductivity of the chalk. A saturated chalk sample will have a considerably higher thermal conductivity than a dry sample. This effect is particularly important in near-surface chalk formations where water saturation varies significantly.

The relationship is often non-linear, meaning a small increase in moisture content can lead to a disproportionately large change in conductivity. Accurate measurements, therefore, require precise determination of the moisture content of the sample under test.

Q 6. Explain the impact of temperature on chalk thermal conductivity.

Temperature influences chalk’s thermal conductivity, although the effect is typically less pronounced than the impact of porosity and moisture content. Generally, thermal conductivity tends to increase slightly with increasing temperature. This is because the vibrational energy of the atoms and molecules in the chalk increases with temperature, facilitating more efficient heat transfer. However, this effect is usually relatively small over the temperature ranges encountered in most geotechnical applications.

The magnitude of the temperature effect varies depending on the specific chalk composition and mineralogy. Therefore, when reporting thermal conductivity values, it’s essential to specify the temperature at which the measurement was taken.

Q 7. What is the significance of thermal conductivity in geotechnical engineering applications involving chalk?

Thermal conductivity is crucial in various geotechnical applications involving chalk. Understanding chalk’s thermal properties is essential for:

- Ground source heat pumps: The thermal conductivity of chalk influences the efficiency of ground source heat pumps that utilize the subsurface as a heat source or sink. Higher conductivity means more efficient heat exchange.

- Underground infrastructure design: Accurate thermal conductivity data is necessary for designing underground structures, tunnels, and pipelines, ensuring appropriate thermal management and preventing potential problems like frost heave or excessive heat buildup.

- Waste disposal: Predicting the thermal impact of waste repositories in chalk formations requires accurate knowledge of the thermal conductivity to evaluate potential temperature changes in the surrounding environment.

- Geothermal energy exploration: Understanding the thermal properties of chalk formations is critical in assessing the viability of geothermal energy extraction.

In essence, accurate thermal conductivity data ensures effective and safe engineering designs and operations related to chalk formations.

Q 8. Describe the equipment and instrumentation used in chalk thermal conductivity testing.

Chalk thermal conductivity testing typically employs transient plane source (TPS) probes or steady-state methods. TPS probes, like the ones from Decagon Devices or similar manufacturers, are most common for their ease of use and relatively fast measurement times. These probes consist of a small sensor embedded in a needle-like device that’s inserted into the chalk sample. The sensor heats up, and the probe measures the resulting temperature change over time, allowing for the calculation of thermal conductivity. Steady-state methods, while less common for chalk due to the required setup time, utilize a heat source and sinks at known temperatures, creating a temperature gradient across the sample. Temperature sensors then measure the gradient, allowing for the determination of thermal conductivity using Fourier’s Law of Heat Conduction.

Instrumentation typically includes: a data logger capable of recording temperature changes with high precision, a power supply to power the probe (for TPS methods), calipers or micrometers for precise sample dimension measurement, and potentially a thermal insulation jacket to minimize heat loss to the surroundings (especially crucial for steady-state methods).

Q 9. How do you ensure accuracy and precision in chalk thermal conductivity measurements?

Accuracy and precision in chalk thermal conductivity measurements are paramount. Several strategies ensure this:

- Calibration: Regularly calibrating the TPS probe or the temperature sensors used in steady-state methods against materials with known thermal conductivity is crucial. This eliminates systematic errors and ensures readings are traceable to standards.

- Sample Replication: Testing multiple samples from the same location or batch greatly reduces random error and provides a more representative value. The average of multiple measurements reduces the impact of individual anomalies.

- Environmental Control: Minimizing temperature fluctuations during testing is critical, as ambient temperature directly impacts measurements. Ideally, testing should be conducted in a climate-controlled environment.

- Proper Contact: Ensuring good thermal contact between the probe and the chalk sample (for TPS methods) is critical to prevent air gaps that introduce error. This often involves careful probe insertion and possibly the use of a thermal paste to improve contact.

- Data Analysis: Utilizing robust data analysis techniques that account for factors like heat capacity and probe geometry ensures that calculated thermal conductivity values are accurate. This often involves sophisticated software provided with the probe or bespoke analysis scripts.

Q 10. Explain the importance of sample preparation in chalk thermal conductivity testing.

Sample preparation is incredibly important for obtaining reliable thermal conductivity data in chalk. Chalk is a heterogeneous material with variable porosity and moisture content, both of which significantly impact thermal conductivity. Inconsistent preparation can lead to wildly different results.

- Sample Size and Shape: Samples should be of a consistent size and shape, adhering to the probe specifications or the requirements of the steady-state apparatus. This ensures consistent heat flow during testing.

- Moisture Content: The moisture content of the chalk sample strongly influences thermal conductivity. The sample should either be oven-dried to a known moisture content, or its in-situ moisture content should be precisely measured and accounted for in data analysis. This is especially important for TPS methods as water significantly increases thermal conductivity.

- Density and Porosity: Measurements of sample density and porosity are valuable for further analysis and correlation with thermal conductivity. This contextualizes the results, and helps to understand the underlying factors contributing to the obtained values.

- Sample Homogeneity: If possible, aim for a relatively homogeneous sample. Large-scale heterogeneity introduces significant uncertainties and should be addressed through sampling strategies such as taking multiple samples from different locations and then averaging the results.

Q 11. What are the common challenges encountered during chalk thermal conductivity testing?

Chalk presents unique challenges in thermal conductivity testing:

- Heterogeneity: The inherent heterogeneity of chalk makes it difficult to obtain truly representative samples. Different sections of a chalk sample can have significantly different thermal properties.

- Porosity and Moisture Content: The influence of porosity and moisture content on thermal conductivity requires careful control and measurement. Small variations in these parameters can lead to large discrepancies in results.

- Fracturing: The presence of fractures or fissures in the chalk sample can create preferential pathways for heat flow, leading to artificially high thermal conductivity readings. The best approach is to either carefully select samples with minimal fracturing or to use a methodology robust to these heterogeneities.

- Sample Disturbance: Obtaining undisturbed samples is vital, especially with methods involving drilling or coring. Any disturbance during sampling can affect the sample’s structure and thermal properties.

Q 12. How do you interpret and report thermal conductivity data obtained from chalk samples?

Thermal conductivity data obtained from chalk samples is typically reported in units of W/m·K (Watts per meter-Kelvin). Results should include:

- Mean Thermal Conductivity: The average thermal conductivity across multiple samples or measurements.

- Standard Deviation: A measure of the variability in the data, reflecting the uncertainty of the measurement.

- Moisture Content: The moisture content of the sample at the time of testing. This is crucial for interpreting the results and comparing them to data obtained under different conditions.

- Sample Details: A description of the sample location, depth, and any other relevant geological information.

- Testing Method: A clear statement of the method used (e.g., TPS probe, steady-state method), along with details about the equipment used.

Data presentation may involve tables, graphs, or statistical analysis, depending on the context and the overall aim of the investigation.

Q 13. Discuss the relationship between thermal conductivity and other geotechnical properties of chalk.

Thermal conductivity in chalk is strongly correlated with other geotechnical properties. These relationships are often complex and non-linear, and they vary according to the type and origin of the chalk formation.

- Porosity: Higher porosity generally leads to lower thermal conductivity because air has much lower thermal conductivity than the chalk matrix. Water filling the pores increases thermal conductivity, even though it remains lower than the solid chalk.

- Density: Higher density usually translates to higher thermal conductivity because there is less pore space for air or water to occupy, resulting in higher heat transfer efficiency.

- Moisture Content: Water has a significantly higher thermal conductivity than air. Therefore, the moisture content is a critical factor determining the overall thermal conductivity of the chalk. A simple correlation may not always be straightforward due to the complex interactions within the pore network.

- Mineralogy: The mineralogical composition of the chalk, even small changes in the dominant mineral phases, can influence thermal conductivity.

Understanding these relationships is essential for predicting the behavior of chalk formations in engineering applications.

Q 14. How can you validate the accuracy of your thermal conductivity measurements?

Validation of thermal conductivity measurements involves a multi-faceted approach:

- Probe Calibration: Regular calibration of the TPS probe or temperature sensors against materials with well-established thermal conductivity values is essential. These reference materials should ideally span the range of expected values for the chalk samples.

- Comparison with Established Data: Comparing results with previously published data on similar chalk formations or using established correlation equations helps build confidence in the measured values. However, always remember the limitations of these comparisons, as formations can vary widely.

- Independent Measurement Techniques: Comparing results from different measurement methods can provide a cross-check and help identify potential systematic errors. This may involve using a different type of probe or a steady-state apparatus.

- Internal Consistency Checks: Internal consistency checks can be performed by analyzing the variability within the collected data. A high degree of variability suggests potential problems with the measurement process.

A comprehensive validation strategy enhances confidence in the quality and reliability of the obtained thermal conductivity data.

Q 15. What are the typical values of thermal conductivity for various types of chalk?

The thermal conductivity of chalk, a sedimentary rock primarily composed of calcium carbonate, varies significantly depending on factors like porosity, pore fluid saturation, and grain size distribution. Generally, chalk exhibits relatively low thermal conductivity compared to other rocks. Typical values range from approximately 1.5 to 4.0 W/m·K (Watts per meter per Kelvin). Highly porous, dry chalk will have lower conductivity, while denser, water-saturated chalk will display higher values. Imagine trying to conduct heat through a sponge (porous chalk) versus a solid block of the same material – the sponge, naturally, presents more resistance to heat flow.

- Low Porosity Chalk: Closer to 4.0 W/m·K

- Average Porosity Chalk: Around 2.5 – 3.0 W/m·K

- High Porosity Chalk: Closer to 1.5 W/m·K

These values are approximate and should be considered within the context of specific experimental conditions and chalk type.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle outliers or inconsistent data during thermal conductivity testing?

Outliers and inconsistent data in thermal conductivity testing of chalk can stem from various sources, including measurement errors, sample heterogeneity, and insufficient experimental control. Handling these issues requires a robust approach.

- Visual Inspection: Begin by visually inspecting the data for obvious errors. This may reveal typos or data points that are clearly outside the expected range.

- Statistical Analysis: Employ statistical methods like box plots or scatter plots to identify outliers. The Grubb’s test or Chauvenet’s criterion can formally assess whether data points should be rejected. However, always exercise caution and justify the exclusion of any data points.

- Repeat Measurements: If outliers are identified, repeat measurements on the suspect samples are crucial. This helps determine if the outlier resulted from a measurement error or if the sample itself is truly anomalous.

- Sample Characterization: Thorough sample characterization, including porosity, density, and mineralogical composition measurements, can explain variability. Differences in these properties can significantly impact thermal conductivity.

- Error Propagation Analysis: Account for uncertainties in measurements and propagate errors through the calculations to quantify the uncertainty in the final thermal conductivity value.

Remember: Data exclusion should be justified and documented transparently. It’s essential to provide context and rationale when discarding data points, promoting the reproducibility and reliability of the results. If repeated tests still yield outliers, they might indicate true sample heterogeneity and should be reported accordingly.

Q 17. Describe the role of thermal conductivity in subsurface heat transfer modeling involving chalk formations.

Thermal conductivity is a critical parameter in subsurface heat transfer modeling involving chalk formations. It dictates the rate at which heat flows through the chalk. In geothermal energy exploration, for instance, accurate thermal conductivity values are essential for predicting reservoir temperatures and assessing the feasibility of geothermal projects.

Consider a geothermal reservoir within a chalk formation. The rate of heat extraction depends directly on the chalk’s thermal conductivity. A lower thermal conductivity implies slower heat transfer, meaning that less heat will be extracted over a given time. Accurate modeling requires precise conductivity values to predict reservoir behavior and optimize energy extraction strategies. Similarly, in CO2 storage projects, the conductivity of surrounding chalk formations influences the rate of heat dissipation, impacting the effectiveness of the storage and potentially influencing pressure and fluid flow within the reservoir.

Numerical models, such as Finite Element Analysis (FEA) or Finite Difference methods, utilize the thermal conductivity of chalk as a crucial input parameter to simulate temperature fields and predict heat transfer rates. Errors in conductivity values directly translate to inaccuracies in the model predictions, potentially leading to costly mistakes in project planning and decision-making.

Q 18. What is the effect of confining pressure on the thermal conductivity of chalk?

Confining pressure significantly affects the thermal conductivity of chalk. As confining pressure increases, the porosity of the chalk decreases, leading to a subsequent increase in thermal conductivity. This is because the reduction in pore space minimizes the heat resistance associated with pore fluids and the air within the pores. Imagine squeezing a sponge – the less air space there is, the more easily heat can travel through it.

The relationship between confining pressure and thermal conductivity isn’t always linear. At very high pressures, the effect may plateau as the porosity reaches a minimum. The influence of pore fluid also plays a significant role. For example, water-saturated chalk may show a greater sensitivity to pressure changes than dry chalk, because of the increased compressibility of water. Experimental studies frequently demonstrate this phenomenon, showing the positive correlation between confining pressure and thermal conductivity of chalk samples.

Q 19. How does the grain size distribution of chalk affect its thermal conductivity?

Grain size distribution significantly impacts the thermal conductivity of chalk. Finer-grained chalk tends to have lower thermal conductivity than coarser-grained chalk due to increased porosity and tortuosity (the winding path heat must take through the porous media). The smaller grain sizes create a more complex pore network with more interfaces that hinder heat flow.

In coarser-grained chalk, heat can more readily travel through the larger and more interconnected pores. Think of it like walking through a large, open field (coarse-grained chalk) versus navigating a dense forest (fine-grained chalk). Navigating the forest takes significantly more effort and time, representing the increased resistance to heat flow in fine-grained chalk.

Experimental studies often demonstrate a clear correlation between grain size distribution and thermal conductivity, highlighting the necessity of determining grain size characteristics for accurate conductivity measurements and subsequent modeling efforts.

Q 20. Compare and contrast different thermal conductivity measurement techniques for chalk.

Several techniques are used to measure the thermal conductivity of chalk. Each has its advantages and disadvantages:

- Transient Plane Source (TPS) Method: This method is widely used due to its relative simplicity and speed. A small heating element is placed in contact with the chalk sample, and the temperature response is measured. The thermal conductivity is then calculated from the temperature data. It’s non-destructive and suitable for various sample sizes.

- Steady-State Method: This technique involves applying a constant heat flux across a chalk sample and measuring the resulting temperature gradient. The thermal conductivity is calculated from Fourier’s law of heat conduction. It requires precise temperature control and can be time-consuming.

- Laser Flash Method: A short laser pulse heats one face of a sample, and the temperature rise on the opposite face is measured. It’s suitable for small samples and is relatively quick but requires specialized equipment.

The choice of technique often depends on factors such as the available equipment, sample size, desired accuracy, and budget constraints. For instance, the TPS method is suitable for field studies due to its portability and ease of use, whereas the steady-state method is better suited for laboratory environments requiring high precision.

Q 21. Explain the importance of quality control procedures in chalk thermal conductivity testing.

Rigorous quality control (QC) procedures are paramount in chalk thermal conductivity testing to ensure data accuracy, reliability, and the reproducibility of results. Neglecting QC can lead to significant errors with costly implications in subsurface modeling and reservoir engineering.

- Sample Preparation: Consistent sample preparation is critical. Samples should be carefully selected to represent the bulk properties of the chalk formation, with meticulous attention paid to size, shape, and surface preparation to minimize artifacts.

- Calibration and Maintenance of Equipment: Regular calibration and maintenance of testing equipment are essential to ensure accurate measurements. Any deviation from calibrated values must be carefully recorded and accounted for in the analysis.

- Data Acquisition and Processing: Implementing data acquisition protocols that minimize noise and systematic errors is crucial. Data processing should follow established procedures and incorporate error analysis to quantify uncertainties.

- Blind Sample Analysis: Including blind samples (samples whose properties are unknown to the testing personnel) can help identify and quantify biases in the measurement process.

- Documentation: Detailed documentation of all aspects of the testing procedure, including sample characteristics, equipment specifications, and data processing steps, is crucial for transparency and reproducibility.

Adhering to strict QC protocols is indispensable in guaranteeing the integrity and reliability of chalk thermal conductivity data, directly impacting the validity of subsurface modeling and the subsequent decisions made based on these data.

Q 22. How do you calibrate the equipment used for chalk thermal conductivity measurements?

Calibrating the equipment used for chalk thermal conductivity measurements is crucial for accurate results. This typically involves using a material with a known and well-established thermal conductivity, often a standard reference material like Pyrex glass or fused quartz. The process generally follows these steps:

- Preparation: Ensure the equipment (e.g., transient plane source (TPS) apparatus or guarded hot plate) is clean and functioning correctly. Check for loose connections or any potential issues.

- Reference Material Measurement: Measure the thermal conductivity of the reference material using the equipment. This involves carefully following the manufacturer’s instructions and maintaining consistent experimental conditions (temperature, pressure, etc.).

- Comparison: Compare the measured thermal conductivity of the reference material to its certified value. A small deviation is expected due to inherent measurement uncertainties.

- Calibration Adjustment (if necessary): If the deviation is outside the acceptable tolerance, adjustments may be needed. This might involve recalibrating sensors, adjusting instrument settings, or even identifying and resolving issues with the equipment itself. Calibration curves or correction factors may be developed to compensate for systematic errors.

- Documentation: Thorough documentation of the calibration process, including date, reference material used, measured values, and any adjustments made, is essential for quality control and traceability.

Think of it like calibrating a kitchen scale before baking – you need to ensure your measurement tool is accurate before you can trust the results.

Q 23. What are the safety precautions to be taken during chalk thermal conductivity testing?

Safety during chalk thermal conductivity testing is paramount. Chalk itself isn’t inherently hazardous, but the equipment and procedures require attention. Key precautions include:

- Proper Handling of Equipment: Be cautious when handling hot plates, heating elements, and other potentially hot components. Use appropriate heat-resistant gloves and safety glasses.

- Electrical Safety: Ensure all electrical connections are secure and properly grounded to prevent electrical shocks. Work in a well-ventilated area to avoid the accumulation of potentially harmful fumes or gases.

- Sample Preparation: Take care when preparing chalk samples. Avoid creating dust, and wear a dust mask if necessary. Properly secure the sample to prevent it from shifting or falling during testing.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, gloves, and lab coats, to protect against potential hazards.

- Emergency Procedures: Be aware of emergency procedures and have a fire extinguisher readily available, especially when working with heating elements. Know the location of safety showers and eyewash stations.

Remember, a safe working environment is crucial for obtaining reliable results and preventing accidents. Following these simple steps can significantly reduce the risks associated with this type of testing.

Q 24. Describe the applications of chalk thermal conductivity data in the petroleum industry.

Thermal conductivity data for chalk plays a significant role in several petroleum industry applications. Understanding how heat moves through chalk formations is critical for:

- Reservoir Simulation: Accurate thermal conductivity values are essential for building reliable reservoir models. These models are used to predict reservoir behavior, optimize production strategies, and assess the impact of enhanced oil recovery (EOR) techniques.

- Geothermal Energy Exploration: Chalk formations can be potential sources of geothermal energy. Knowing their thermal conductivity helps assess the feasibility of extracting heat from these formations efficiently.

- Wellbore Stability Analysis: Thermal stresses induced during drilling and production operations can affect wellbore stability. Accurate thermal conductivity data helps predict and mitigate these stresses.

- Heat Transfer Studies in Enhanced Oil Recovery (EOR): Several EOR methods, such as steam injection, rely on heat transfer. Understanding chalk’s thermal conductivity is crucial for designing and optimizing these techniques.

For instance, if we underestimate the thermal conductivity of chalk during reservoir simulation, our predictions on oil production rates and energy recovery could be significantly inaccurate, leading to poor investment decisions.

Q 25. How does the presence of fractures affect thermal conductivity measurements in chalk?

The presence of fractures significantly impacts thermal conductivity measurements in chalk. Fractures act as pathways for heat transfer, effectively increasing the overall conductivity of the rock mass. This is because the thermal conductivity of the fracture filling material (e.g., water, gas, or cement) is generally higher than that of the intact chalk matrix.

The impact depends on several factors:

- Fracture Density: Higher fracture density leads to a greater increase in thermal conductivity.

- Fracture Aperture: Wider fractures offer less resistance to heat flow, leading to a larger increase in conductivity.

- Fracture Orientation: The orientation of fractures relative to the heat flow direction influences the magnitude of the effect. Fractures aligned parallel to the heat flow direction have a more substantial impact.

- Fracture Filling Material: The thermal conductivity of the material filling the fractures heavily affects the overall conductivity. For instance, water-filled fractures will increase conductivity more than gas-filled fractures.

To accurately account for this, techniques like image analysis and digital rock physics can help to quantify fracture networks and incorporate their impact into thermal conductivity models.

Q 26. Discuss the use of numerical modeling techniques in conjunction with experimental measurements of chalk thermal conductivity.

Numerical modeling techniques are invaluable when combined with experimental measurements of chalk thermal conductivity. Experimental measurements provide data for a specific sample under controlled conditions, but numerical modeling allows us to extrapolate this data and simulate the behavior of the rock under various conditions and scales.

Common techniques include:

- Finite Element Method (FEM): FEM is used to solve the heat equation for complex geometries and heterogeneous materials, allowing us to simulate heat flow in a chalk sample with fractures and varying properties.

- Finite Difference Method (FDM): FDM provides a simpler approach to solving the heat equation, often used for relatively homogeneous materials.

- Discrete Fracture Network (DFN) Modeling: DFN modeling explicitly represents fractures as geometrical entities within the rock matrix, allowing for a realistic simulation of fracture effects on thermal conductivity.

By calibrating numerical models with experimental data, we can enhance the accuracy and applicability of our simulations, making more informed predictions about reservoir behavior and thermal processes in chalk formations. Think of it like a map – experimental data provides specific landmarks, and numerical modelling helps us create a complete picture of the terrain.

Q 27. How would you troubleshoot a problem during a thermal conductivity test on a chalk sample?

Troubleshooting problems during a thermal conductivity test on a chalk sample requires a systematic approach. The problem could stem from the sample, the equipment, or the procedure.

- Check the Equipment: Verify that all instruments (sensors, thermocouples, power supplies) are properly calibrated and functioning correctly. Look for any loose connections or malfunctions.

- Inspect the Sample: Examine the chalk sample for any inconsistencies. Is it properly prepared? Are there any visible cracks or defects that might affect the results? Ensure good thermal contact between the sample and the measuring apparatus.

- Review the Procedure: Double-check that the experimental procedure was followed meticulously. Was the temperature controlled accurately? Was the data acquisition system operating correctly?

- Repeat the Measurement: Conduct another measurement to confirm if the initial result was an anomaly. If the problem persists, you might need to adjust your experimental setup or explore alternate methodologies.

- Consult the Literature: Review relevant literature to identify common issues associated with chalk thermal conductivity measurements and potential solutions.

For instance, if the measured thermal conductivity is unusually high, it could indicate poor thermal contact between the sample and the apparatus, or the presence of unseen fractures in the sample.

Q 28. Explain the impact of sample heterogeneity on the accuracy of thermal conductivity measurements in chalk.

Chalk is inherently heterogeneous, meaning its properties vary spatially. This heterogeneity can significantly impact the accuracy of thermal conductivity measurements. If you measure the conductivity at one point, it might not be representative of the entire sample or the formation. Variations in porosity, mineral composition, and the presence of fractures all contribute to this heterogeneity.

The impact manifests in a few ways:

- Uncertainty in Measurements: A single measurement might not represent the average thermal conductivity of the sample, resulting in uncertainty in the reported value.

- Scale Dependence: The measured thermal conductivity can be scale-dependent, meaning a measurement at a small scale might differ from a measurement at a larger scale.

- Anisotropy: Chalk’s thermal conductivity may be directionally dependent (anisotropic) due to preferential alignment of mineral grains or fractures. This needs to be considered during measurement and modeling.

To mitigate the impact of heterogeneity, multiple measurements at different locations on the sample are recommended. Statistical analysis can then help estimate the average and variability of thermal conductivity. Advanced techniques like X-ray computed tomography (CT) scanning can help visualize the internal structure of the sample and inform the interpretation of measurements.

Key Topics to Learn for Chalk Thermal Conductivity Testing Interview

- Fundamentals of Thermal Conductivity: Understanding the principles of heat transfer and the factors influencing thermal conductivity in materials.

- Chalk as a Testing Medium: Exploring the properties of chalk that make it suitable (or unsuitable) for thermal conductivity measurements and the limitations of using chalk in this context.

- Different Testing Methods: Familiarize yourself with various techniques used to measure thermal conductivity, comparing their advantages and disadvantages (e.g., steady-state methods, transient methods).

- Data Acquisition and Analysis: Understanding how data is collected during the testing process and the techniques employed for accurate data analysis and interpretation.

- Practical Applications: Investigate real-world applications where understanding chalk’s thermal conductivity is crucial (e.g., geological studies, material science research).

- Error Analysis and Mitigation: Learn about potential sources of error in thermal conductivity measurements and strategies for minimizing these errors to ensure accuracy.

- Calibration and Instrumentation: Understanding the importance of proper calibration of instruments and the principles behind the functioning of various thermal conductivity measurement devices.

- Data Presentation and Reporting: Learn how to effectively present and communicate your findings from thermal conductivity testing using clear and concise reports.

- Advanced Concepts (if applicable): Depending on the seniority of the role, explore more advanced topics like thermal diffusivity, thermal resistance, and the influence of temperature gradients.

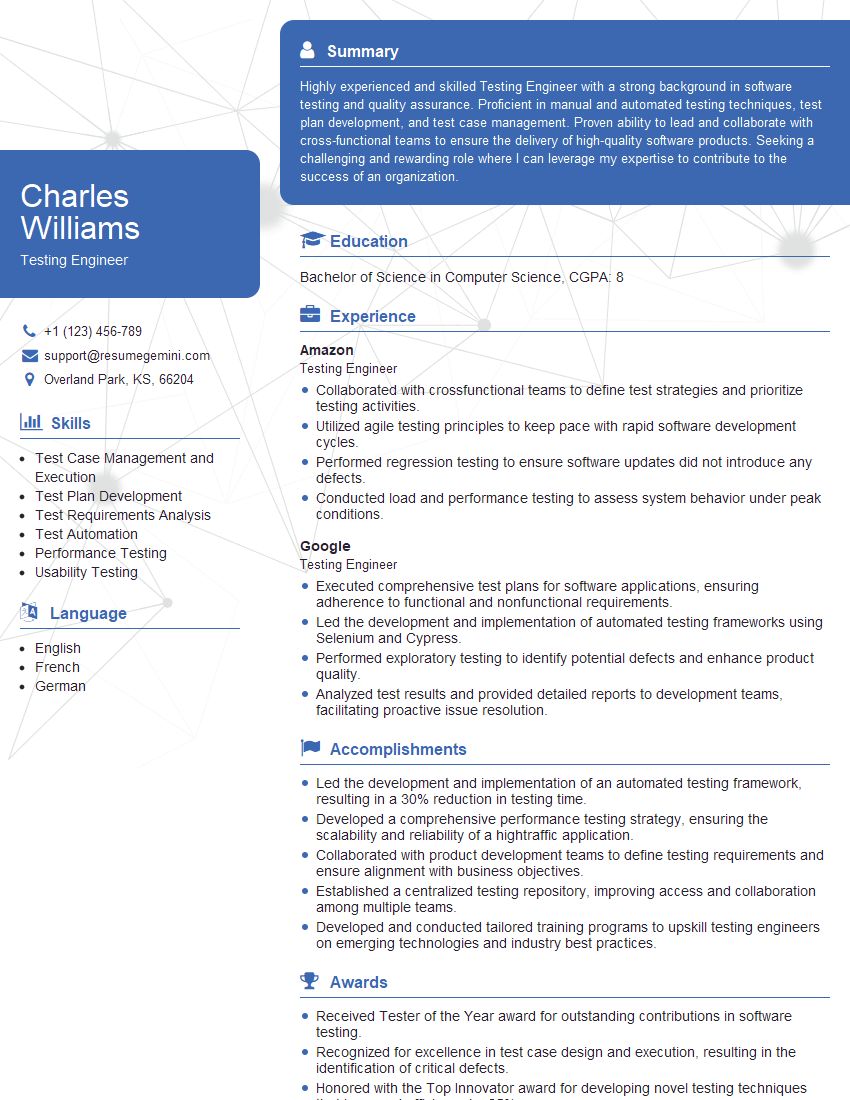

Next Steps

Mastering Chalk Thermal Conductivity Testing, or related thermal property testing, significantly enhances your career prospects in various scientific and engineering fields. It demonstrates a strong understanding of fundamental principles and practical skills highly valued by employers. To maximize your job search success, focus on creating a compelling and ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource to help you build a professional and effective resume that grabs the attention of recruiters. Examples of resumes tailored to Chalk Thermal Conductivity Testing are available through ResumeGemini to further guide your resume development.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.