Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Cementing and Completion Fluids interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Cementing and Completion Fluids Interview

Q 1. Explain the different types of cement slurries used in well cementing.

Cement slurries are the heart of well cementing, acting as a barrier to prevent fluid migration between different geological formations. The type of slurry used depends heavily on the well’s characteristics and the specific challenges. We categorize them based on several factors, including the cement type, additives, and water content.

- Portland Cement Slurries: These are the most common, utilizing ordinary Portland cement (OPC). They’re cost-effective and offer good strength development. Variations exist depending on the specific OPC used, influencing setting time and compressive strength. For example, high-early-strength (HES) cement is used when rapid setting is crucial.

- Special Cements: These are engineered to handle unique well conditions. This category includes:

- Pozzolanic Cements: These enhance long-term strength and reduce permeability.

- Oil-Well Cements: These are formulated to withstand high temperatures and pressures found in deeper wells.

- Sulfate-Resisting Cements: Crucial for wells prone to sulfate attack, which can damage the cement integrity over time.

- Lightweight Cements: Used when minimizing the weight of the cement column is critical, for instance, in shallower wells or certain completion scenarios. This reduces stress on the wellbore.

- Expansive Cements: These expand slightly as they set, helping to compensate for any shrinkage and ensure a better seal against the wellbore.

The selection process involves careful consideration of factors like temperature, pressure, formation properties, and the desired setting time. Think of it like choosing the right glue – you wouldn’t use super glue for woodworking, and similarly, you wouldn’t use standard Portland cement in a high-temperature well.

Q 2. Describe the process of designing a cementing job.

Designing a cementing job is a complex process requiring meticulous planning and a deep understanding of well conditions. It’s not just about mixing cement and pumping it down; it’s about ensuring a perfect seal.

- Well Data Analysis: This crucial first step involves thoroughly reviewing available well data, including the wellbore profile, formation pressures, temperatures at different depths, and anticipated fluid types. This forms the basis of our design.

- Cement Slurry Design: Based on the well data, we select the appropriate cement type, water ratio, and additives to achieve the desired rheological properties (flowability, viscosity) and setting time. Software simulations often aid this process.

- Casing and Tubular Design: The size and type of casing (steel pipe) and any inner tubing must be considered to ensure that the cement can flow effectively between them, displacing any unwanted fluids. Proper annular space (the space between the casing and the wellbore) is critical.

- Pumping Parameters: The design must specify the pumping rate, pressure, and displacement volumes to ensure complete and even cement placement throughout the well. This needs to account for potential friction loss and other factors.

- Testing and Quality Control: Before the job, we perform rigorous laboratory tests on the designed cement slurry to verify its properties, including setting time, compressive strength, and density.

- Post-Job Evaluation: Once the cement is placed, various tools and techniques are employed to verify the effectiveness of the job and to identify any issues, such as channeling or incomplete placement. This involves analyzing pressure measurements and potentially running cement bond logs.

A well-designed cement job is like a perfectly fitted puzzle piece – it seamlessly integrates with the well’s existing structure, ensuring long-term integrity and preventing unwanted fluid movement.

Q 3. What are the key factors influencing cement slurry rheology?

Cement slurry rheology, or its flow behavior, is paramount to successful cementing. It dictates how easily the slurry flows, its resistance to settling, and its ability to fill the wellbore effectively. Several factors influence it:

- Water-Cement Ratio: A higher water-cement ratio results in a more fluid slurry, improving pumpability but potentially reducing strength. A lower ratio gives a stiffer slurry, making it difficult to pump but enhancing strength.

- Cement Type: Different cements have inherent rheological characteristics. For example, high-early-strength cement will set quicker than a standard Portland cement.

- Additives: These are crucial for fine-tuning the rheology. Examples include:

- Retarders: Slow down the setting time, allowing for better placement in challenging wells.

- Accelerators: Speed up setting time, useful in shallower wells.

- Fluid-Loss Control Agents: Reduce the amount of water lost from the slurry into the formation, essential for preventing weak cement zones.

- Dispersants: Reduce the viscosity of the slurry, aiding in pumping.

- Temperature: Higher temperatures generally accelerate the setting process and can affect slurry viscosity.

- Pressure: High pressure in the wellbore can impact slurry viscosity.

Imagine making pancake batter. The amount of water (water-cement ratio) affects its thickness, and additives like baking powder (accelerators or retarders) control how quickly it rises. Careful control of all these factors ensures the perfect consistency for optimal cement placement.

Q 4. How do you ensure proper cement placement in a well?

Ensuring proper cement placement is critical for well integrity. It involves a combination of careful planning, precise execution, and post-job verification.

- Optimized Slurry Design: The slurry must be designed to have the right rheology for effective displacement of drilling mud and efficient filling of the annular space.

- Proper Pumping Techniques: Techniques like displacement with a spacer fluid, which is a low-viscosity fluid pumped before the cement slurry to remove any remaining drilling mud and ensure clean interfaces, are critical. The pumping rate and pressure must be carefully controlled to avoid excessive friction losses or premature setting.

- Centralizers and other Placement Aids: Centralizers are used to center the casing within the wellbore during cementing, preventing gaps between the casing and the formation where channeling could occur. Other placement aids may be used to ensure even distribution of the cement.

- Post-Cementing Evaluation: After the cementing operation, various logging tools are run in the well to evaluate the quality of cement placement. These may include cement bond logs, which measure the strength of the bond between the cement and casing or formation, and density logs, which indicate areas where cement placement may be incomplete.

Think of it as building a brick wall. You need the right mortar (cement slurry), proper placement techniques to fill the gaps effectively, and an inspection to check for any missing bricks (incomplete cement placement). Without each step, the integrity of the structure is jeopardized.

Q 5. Explain the concept of zonal isolation in well cementing.

Zonal isolation is the primary goal of well cementing. It involves creating impermeable barriers between different geological formations to prevent fluid migration between zones. This is crucial for several reasons:

- Preventing fluid contamination: Isolation prevents the mixing of fluids from different formations, which could compromise the production of hydrocarbons or lead to environmental issues.

- Maintaining pressure integrity: It ensures that pressure in each zone remains stable, preventing unwanted pressure surges that could damage the wellbore or lead to blowouts.

- Protecting aquifers and surface environments: Proper zonal isolation prevents the leakage of drilling fluids or produced hydrocarbons into freshwater aquifers or surface waters.

Imagine a multi-story building where each floor (formation) needs to be isolated from the others to prevent water from one floor from leaking into another. Zonal isolation works similarly, protecting the integrity of each formation and preventing unwanted fluid movement.

Q 6. What are the potential causes of cement channeling?

Cement channeling, where the cement slurry flows preferentially through certain paths within the annulus, leaving un-cemented regions, is a serious concern. Several factors can lead to this:

- Poor slurry design: A slurry that is too viscous or has inadequate fluid-loss control can channel easily.

- Inadequate cleaning of the annulus: Residual drilling mud or other debris can create pathways for the cement to flow preferentially.

- Poor casing centralisation: If the casing is not properly centered in the wellbore, gaps can form where the cement cannot reach.

- Formation permeability: High permeability formations can absorb the water from the cement slurry, leaving behind a weak, porous cement zone.

- Insufficient displacement volume: Insufficient cement volume may result in channeling due to the failure to completely displace mud throughout the well section.

It’s like trying to fill a container with uneven sides – the liquid tends to concentrate in certain areas, leaving others empty. Similarly, channeling leaves un-cemented areas, undermining the well’s integrity.

Q 7. How do you troubleshoot a failed cement job?

Troubleshooting a failed cement job requires a systematic approach involving careful analysis of the available data and a thorough understanding of the cementing process.

- Review the Cementing Report: Begin by thoroughly examining the cementing report to identify potential issues during the execution of the job. Pay close attention to parameters like pressure, flow rate, and any unusual events that occurred during pumping.

- Analyze Logging Data: Interpret the cement bond logs to pinpoint areas with poor cement placement or channeling. Additional logs (density, acoustic) provide further insights into the cement quality and position.

- Consider Wellbore Conditions: Review the available well data (formation pressures, temperatures, and permeabilities) and the cement slurry design. Were there any discrepancies or unusual conditions that might have influenced cement placement?

- Identify Potential Causes: Based on the data analysis, identify potential causes for the failure. This could include poor slurry design, inadequate displacement, channeling, or problems with casing centralizers.

- Develop Remedial Actions: Depending on the cause of the failure, develop appropriate remedial actions. This may involve re-cementing the affected zone, performing a squeeze cementing job to fill specific voids, or even abandoning the well in severe cases.

Troubleshooting a failed cement job is like diagnosing a medical condition – it requires a careful evaluation of symptoms (logging data, cementing report) and determining the underlying cause to develop an effective treatment (remedial action) strategy.

Q 8. Describe different methods for evaluating cement integrity.

Evaluating cement integrity is crucial for ensuring wellbore stability and preventing environmental hazards. We use several methods, each providing a different perspective on the cement’s quality and placement.

- Cement Bond Logs (CBL): This is a standard method using acoustic waves to measure the bond between the cement and the casing or formation. A strong bond shows a high amplitude signal, while a weak bond or voids show low amplitude. Think of it like tapping on a wall – a solid wall gives a clear sound, while a hollow one sounds different.

- Variable Density Logs (VDL): These logs measure the density of the cement, helping to identify any channeling (unfilled gaps) or variations in cement quality. Imagine pouring cement; uneven pouring would lead to areas of different density.

- Cement Evaluation Logs (CEL): These logs use nuclear techniques to determine the cement’s density and hydrogen index. This is a more advanced method offering detailed information on cement properties and hydration.

- Pressure Testing: This involves pressurizing the annular space between the cement and casing (or formation) to detect leaks or weaknesses. This is like testing a water pipe for leaks – pressure reveals any weaknesses.

- Formation Integrity Tests (FIT): These are used to detect communication pathways between different formations or zones, often indicative of poor cement integrity.

Often, a combination of these methods is used for a comprehensive assessment of cement integrity, offering a more robust evaluation than any single technique.

Q 9. What are the environmental concerns associated with cementing operations?

Cementing operations, while essential for oil and gas production, pose several environmental concerns. The main issue revolves around the potential for spills or leaks of cement slurry, which can contaminate soil and water sources.

- Water Contamination: Cement slurry contains various chemicals that can be harmful to aquatic life if spilled into rivers, lakes, or oceans. This can disrupt ecosystems and affect water quality.

- Soil Contamination: Spills on land can alter soil properties, affecting plant growth and potentially leaching harmful chemicals into groundwater.

- Air Emissions: The mixing and placement of cement slurry can release dust and volatile organic compounds (VOCs) into the atmosphere, contributing to air pollution.

- Waste Management: The disposal of waste cement and related materials requires careful management to prevent environmental damage. This includes appropriate containment and treatment methods.

Mitigation strategies involve implementing stringent safety protocols, using environmentally friendly cement formulations, employing efficient spill containment systems and careful waste management practices.

Q 10. Explain the importance of fluid compatibility in completion fluids.

Fluid compatibility in completion fluids is paramount to prevent formation damage, wellbore instability, and operational complications. It refers to the ability of different fluids to coexist without causing undesirable reactions or interactions.

For instance, incompatible fluids can lead to:

- Formation Damage: Reactions between completion fluids and the reservoir rock can cause permeability reduction, hindering hydrocarbon flow. Imagine mixing oil and water – they don’t mix well and can clog a pipeline similarly.

- Emulsion Formation: Mixing incompatible fluids can create emulsions (stable mixtures of liquids), which can be difficult to remove and hinder production.

- Precipitates: Reactions between certain chemicals in completion fluids can form solid precipitates, clogging pores and reducing permeability.

- Corrosion: Incompatible fluids can accelerate corrosion of wellbore components, leading to equipment failure and potential wellbore instability.

Therefore, careful selection and compatibility testing of completion fluids are essential to guarantee a successful and safe well completion.

Q 11. What are the different types of completion fluids used?

The choice of completion fluid depends on the specific well conditions and objectives. Several types are commonly used:

- Water-Based Fluids: These are often the most economical and environmentally friendly but may cause formation damage in certain reservoirs. They are usually modified with polymers, clays, and other additives to improve their properties.

- Oil-Based Fluids: These offer better lubricity and can reduce formation damage in sensitive formations. However, they are more expensive and pose environmental concerns.

- Synthetic-Based Fluids: These fluids combine the advantages of both water-based and oil-based fluids, offering good lubricity and environmental friendliness. They are often more expensive than water-based fluids but less so than oil-based fluids.

- Gases (e.g., Nitrogen, CO2): Used in specific cases such as low-pressure reservoirs or where minimal fluid invasion is required. However, they can present challenges with control and pressure management.

Each type can be further modified with various additives to tailor its properties to the specific well conditions.

Q 12. How do you select the appropriate completion fluid for a given reservoir?

Selecting the appropriate completion fluid requires a thorough understanding of the reservoir characteristics and wellbore conditions. This involves considering several factors:

- Reservoir Rock Properties: Permeability, porosity, and mineralogy determine the fluid’s interaction with the formation. A highly sensitive formation may require a low-damage fluid.

- Reservoir Pressure and Temperature: These conditions dictate the fluid’s viscosity and stability. High-temperature reservoirs may require specialized high-temperature fluids.

- Wellbore Stability: The fluid should be able to maintain wellbore stability and prevent formation collapse or fracturing.

- Environmental Considerations: Environmental regulations and concerns play a significant role in fluid selection; the environmental impact should be minimized.

- Production Objectives: The fluid should support the intended production method, whether it’s through a vertical or horizontal well.

A systematic approach involving reservoir simulation, laboratory testing, and experienced engineering judgment is crucial for accurate fluid selection.

Q 13. Describe the process of designing a completion fluid system.

Designing a completion fluid system is a multi-step process involving careful planning and analysis. It begins with a thorough understanding of the well’s geological and operational parameters.

- Define Objectives: Determine the goals of the completion fluid system, considering factors such as preventing formation damage, maintaining wellbore stability, and supporting production operations.

- Gather Data: Collect all relevant data, including reservoir properties, pressure and temperature profiles, and wellbore geometry.

- Fluid Selection: Select the base fluid type (water-based, oil-based, or synthetic) based on reservoir characteristics and environmental considerations.

- Additives Selection: Choose appropriate additives to modify the fluid’s properties to match the well’s requirements. This might involve rheology modifiers, filtration control agents, corrosion inhibitors, or other specialized additives.

- Laboratory Testing: Conduct extensive laboratory testing to evaluate the fluid’s properties and compatibility with the formation.

- Modeling and Simulation: Use numerical models to simulate the fluid’s behavior in the wellbore and reservoir.

- Optimization: Refine the fluid system based on the results of laboratory testing and simulation.

Throughout this process, communication and collaboration between engineers, geologists, and other relevant stakeholders are crucial for a successful outcome.

Q 14. What are the potential risks associated with using completion fluids?

Using completion fluids carries several potential risks, demanding meticulous planning and execution.

- Formation Damage: As discussed earlier, incompatibility between fluids and formation can reduce permeability, hindering production.

- Wellbore Instability: Poorly designed fluids can lead to wellbore collapse, particularly in unconsolidated formations.

- Environmental Contamination: Spills or leaks of completion fluids can contaminate soil and water sources, causing environmental damage.

- Health and Safety Hazards: Certain completion fluids contain hazardous chemicals that pose risks to personnel if not handled properly.

- Equipment Damage: Some fluids can cause corrosion or damage to wellbore equipment.

- Production Issues: Problems with the completion fluid system can lead to reduced production rates or premature well failure.

Risk mitigation involves comprehensive planning, rigorous quality control, proper personnel training, emergency response planning, and adherence to safety regulations.

Q 15. How do you manage the pressure and temperature challenges in completion fluids?

Managing pressure and temperature in completion fluids is crucial for a successful well completion. High temperatures can degrade fluid properties, leading to premature failure, while high pressures can cause fracturing or wellbore instability. We address these challenges through several strategies.

Fluid Selection: We choose fluids with high thermal stability and appropriate rheological properties (viscosity and yield strength) for the expected downhole temperature. For instance, high-temperature, high-pressure (HTHP) wells might require specialized synthetic-based muds or completion brines.

Pressure Management: Careful monitoring of annular pressure is essential. This involves using downhole pressure gauges and surface pressure monitoring equipment. We adjust fluid density (by adding weighting agents like barite) to maintain a proper hydrostatic pressure that prevents formation fracturing but also overcomes formation pressure.

Thermal Modeling: Before the operation, we perform thermal modeling to predict downhole temperatures. This helps us select the appropriate completion fluid and anticipate potential thermal degradation issues. This modeling uses known well parameters and expected thermal gradients to estimate temperatures at different depths.

Circulation and Cleaning: Efficient circulation of the completion fluid helps to remove heat generated by friction and compression. Regular cleaning of the wellbore prevents the buildup of solids that can insulate and increase temperature.

For example, in a deepwater well with high temperatures, we might select a high-temperature mud system with added polymers to improve its rheology and prevent settling of weighting agents. Regular pressure checks and adjustments would prevent formation damage.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of filtration control in completion fluids.

Filtration control in completion fluids is paramount to prevent formation damage and maintain wellbore integrity. Filtration refers to the loss of fluid from the completion fluid into the permeable formation. This can lead to several problems:

Formation Damage: The loss of fluid can carry solids or other damaging agents into the formation, reducing permeability and hindering production.

Reduced Well Productivity: Formation damage caused by excessive filtration leads to lower production rates.

Wellbore Instability: Excessive fluid loss can weaken the formation, leading to instability and potential wellbore collapse.

We control filtration by using various techniques:

Additives: Adding filtration control agents like polymers (e.g., polyacrylamide) to the completion fluid increases its viscosity and reduces its tendency to filter into the formation. These polymers create a filter cake that seals the pores of the formation.

Fluid Design: Careful selection of base fluids and weighting agents can minimize filtration. For example, synthetic-based muds generally have lower filtration rates compared to water-based muds.

Filter Cake Monitoring: Measuring the thickness and permeability of the filter cake during the operation allows us to monitor the effectiveness of filtration control and make necessary adjustments.

Imagine a scenario where a completion fluid with poor filtration control is used. The fluid could filter into the formation, carrying fine particles that clog the pore spaces. This would significantly reduce the permeability of the formation and negatively impact future hydrocarbon production.

Q 17. What are the different types of completion techniques?

Completion techniques vary significantly depending on the reservoir type, well design, and production objectives. However, common categories include:

Packer Completion: A packer is used to isolate different zones within the wellbore, allowing for independent production or injection from each zone. This is common in multi-zone reservoirs.

Gravel Packing: Gravel is packed around the wellbore to prevent sand production, a common issue in unconsolidated formations. This technique creates a stable filter bed to prevent formation fines from entering the wellbore and damaging production equipment.

Screen Completions: Perforated screens are cemented into the wellbore, providing support to the formation and allowing for flow while preventing sand production. Useful in unconsolidated sands.

Openhole Completions: The wellbore is left open to the reservoir, usually in stable, consolidated formations. This is simpler and less expensive, but carries the risk of sand production.

Cased Hole Completions: A steel casing is cemented into place, providing protection to the wellbore and providing a framework for later perforating and setting packers.

The choice of completion technique involves a thorough evaluation of the geological conditions, anticipated production rates, and the overall cost effectiveness of each method. For example, a horizontal well in a tight gas formation may utilize a multi-stage hydraulic fracturing stimulation following a cased-hole completion with perforations to enhance production.

Q 18. How do you assess the effectiveness of a completion job?

Assessing the effectiveness of a completion job involves a multi-faceted approach combining pre-completion planning, real-time monitoring, and post-completion analysis.

Pre-job Planning: Detailed reservoir characterization and well design are crucial. Setting realistic expectations for the job is essential. This involves defining success criteria—what constitutes a successful completion job based on anticipated production rates, wellbore stability, and other factors.

Real-time Monitoring: During the operation, we monitor parameters like pressure, temperature, flow rates, and fluid loss to ensure the completion proceeds as planned. Any deviation from the plan is carefully analyzed and corrected.

Post-completion Analysis: After the completion, production testing is carried out to determine the well’s productivity. We analyze production data, including pressure build-up tests, to understand reservoir properties and assess the overall success of the job. Data analysis also encompasses examining pressure changes, flow rates, and identifying any production issues.

Log Analysis: Post-completion logging evaluates cement bond quality, casing integrity, and the effectiveness of gravel packs or screens.

For instance, a successful completion job might be assessed by comparing the actual production rate with the predicted rate based on pre-completion reservoir models. A significant difference would indicate a problem with the completion job.

Q 19. Describe the role of additives in cement slurries and completion fluids.

Additives play a crucial role in modifying the properties of cement slurries and completion fluids to tailor them to specific well conditions. These additives are designed to improve various aspects, such as rheology, fluid loss, and setting time.

Cement Slurry Additives:

Retarders: Slow down the setting time of cement, allowing for sufficient time to place the cement and achieve proper placement.

Accelerators: Speed up the setting time, beneficial in shallower wells or warmer conditions.

Fluid Loss Additives: Reduce the amount of water loss from the cement slurry into the formation, preventing formation damage.

Dispersants: Improve the flowability and pumpability of the cement slurry.

Completion Fluid Additives:

Viscosifiers: Increase the viscosity of the fluid, improving its ability to carry cuttings and prevent settling.

Filtration Control Agents: Reduce fluid loss into the formation, preserving formation permeability.

Weighting Agents: Increase the density of the fluid to overcome formation pressure.

Corrosion Inhibitors: Protect the wellbore from corrosion.

For example, a high-temperature well might require a cement slurry with special retarders to counteract the rapid setting caused by high temperatures. A completion fluid for a highly permeable reservoir would require effective filtration control agents to prevent significant fluid loss and formation damage.

Q 20. Explain the concept of fluid loss control in cementing and completion operations.

Fluid loss control in cementing and completion operations is critical for preventing formation damage and ensuring wellbore stability. Uncontrolled fluid loss can lead to reduced well productivity and potential wellbore instability. The goal is to minimize the amount of fluid that filters into the permeable formation.

Several mechanisms contribute to fluid loss:

Permeability of the Formation: Highly permeable formations have a higher potential for fluid loss.

Pressure Differential: A large pressure difference between the fluid and the formation will increase fluid loss.

Fluid Properties: The viscosity and filtration characteristics of the fluid impact the fluid loss rate.

Strategies for fluid loss control include:

Selecting low-permeability fluids: This involves careful selection of base fluids and the use of filtration control additives.

Using filter cakes: Filter cakes are created by the interaction of fluid loss additives with the formation, which effectively act as a barrier, reducing fluid loss. The thickness and quality of the filter cake are critical in reducing fluid loss.

Controlling pressure differentials: Maintaining an appropriate pressure balance between the fluid and formation minimizes the driving force for fluid loss.

In practice, effective fluid loss control requires a comprehensive understanding of the reservoir properties and the use of appropriate fluid systems and additives. For example, in a highly permeable sandstone reservoir, a completion fluid with strong filtration control agents is essential to minimize fluid loss and prevent formation damage.

Q 21. How do you calculate the required volume of cement slurry for a well?

Calculating the required volume of cement slurry for a well is a crucial step in cementing operations. An inaccurate calculation can lead to insufficient cement, resulting in poor zonal isolation, or excess cement, causing potential problems such as pressure buildup or equipment damage.

The calculation involves several factors:

Wellbore Geometry: This includes the diameter and length of each section of the wellbore.

Annular Volume: This is the volume of the annulus between the casing and the wellbore.

Cement Slurry Density: The density of the cement slurry affects its volume.

Excess Cement: A certain amount of excess cement is usually added to ensure complete coverage and compensate for potential losses. This excess varies based on the well conditions and the type of cement used.

The calculation is typically performed using specialized software or spreadsheets. A simplified approach might involve calculating the annular volume of each section of the wellbore using geometric formulas (cylindrical volumes) and then summing up the volumes for all sections. We then add the excess cement volume to ensure sufficient coverage. However, this simplified approach does not consider many factors including mud displacement, and deviations in wellbore geometry. Therefore, use of specialized software and accounting for all parameters is preferred.

For example, a software program might take as input the wellbore geometry from logging data, cement density, and targeted displacement volumes to calculate the required cement slurry volume, factoring in potential fluid losses and ensuring complete coverage.

Q 22. What are the safety precautions associated with handling cement slurries and completion fluids?

Handling cement slurries and completion fluids requires stringent safety measures due to their inherent properties. Cement is highly alkaline and can cause severe skin and eye irritation, while some completion fluids contain hazardous chemicals.

- Personal Protective Equipment (PPE): This is paramount and includes safety glasses, gloves (chemical-resistant), respirators (for dust and fumes), and protective clothing to prevent skin contact. Specific PPE will depend on the fluid being handled.

- Spill Containment: Proper spill containment plans should be in place. This includes absorbent materials readily available to soak up spills and appropriate disposal procedures for contaminated materials to prevent environmental damage.

- Emergency Response Plan: A well-defined emergency response plan is critical, including procedures for handling spills, injuries, and equipment malfunctions. Designated personnel should be trained in emergency response protocols and the location of emergency equipment should be clearly marked.

- Ventilation: Adequate ventilation is needed, especially in confined spaces, to reduce exposure to dust and fumes. This might involve using ventilation fans or working in well-ventilated areas.

- Safe Handling Procedures: Strict adherence to safe handling procedures, including proper mixing, transferring, and disposal techniques, is essential. This includes using the correct equipment and following all manufacturer’s instructions.

- Training and Awareness: All personnel involved should receive comprehensive training on the hazards associated with handling cement slurries and completion fluids and on the appropriate safety procedures.

For instance, imagine a scenario where a cement slurry is being mixed. A lack of proper ventilation could lead to respiratory issues for workers. Similarly, a spill without appropriate containment could contaminate the surrounding environment. Safety is non-negotiable in this field.

Q 23. Discuss the regulatory requirements for cementing and completion operations.

Regulatory requirements for cementing and completion operations vary by jurisdiction but generally aim to ensure well integrity, environmental protection, and worker safety. Key regulatory bodies include the Environmental Protection Agency (EPA), the Occupational Safety and Health Administration (OSHA), and relevant state and national oil and gas regulatory commissions.

- Well Control: Regulations strictly govern well control procedures, emphasizing preventing blowouts and other well control incidents. This often involves detailed well design, casing programs, and cementing specifications.

- Environmental Protection: Regulations address the potential environmental impact of drilling fluids, including waste disposal and the prevention of groundwater contamination. This often involves permits, waste management plans, and regular environmental monitoring.

- Safety Standards: Strict safety standards govern worker safety, including the use of appropriate PPE, emergency response plans, and training programs for all personnel involved in cementing and completion operations. OSHA standards are frequently cited.

- Reporting Requirements: Operators are usually required to submit detailed reports on cementing and completion operations, including cementing logs, pressure tests, and any incidents or near misses.

- Waste Management: Regulations dictate how drilling fluids and other wastes are handled, treated, and disposed of, to minimize environmental harm. This often involves detailed waste characterization and disposal plans.

Non-compliance can result in significant penalties, including fines, operational shutdowns, and even criminal charges. Companies are expected to maintain detailed records demonstrating their adherence to all relevant regulations.

Q 24. Explain the importance of wellbore stability in relation to cementing and completion fluids.

Wellbore stability is crucial in cementing and completion operations. The goal is to ensure that the wellbore remains structurally sound and prevents issues like wellbore collapse, formation fracturing, or fluid losses, all of which can negatively impact well integrity and operational efficiency.

Cementing and completion fluids directly influence wellbore stability. Properly designed cement slurries provide support to the wellbore, preventing collapse, while completion fluids control pressure and prevent fluid migration. For example, if a high-pressure formation is not properly managed with appropriate completion fluids, the formation may fracture, leading to fluid loss and potentially compromising the well’s integrity.

Factors affecting wellbore stability include:

- Formation properties: Rock strength, porosity, permeability, and stress state influence wellbore stability.

- Mud weight: The density of the drilling mud must be appropriately controlled to prevent formation fracturing or collapse.

- Fluid pressure: Maintaining appropriate pressure within the wellbore prevents formation fracturing.

- Cement properties: The strength and properties of the cement slurry impact the wellbore’s structural integrity.

Understanding these factors allows engineers to select appropriate cement slurries and completion fluids that minimize formation damage and enhance wellbore stability.

Q 25. How do you prevent formation damage during cementing and completion operations?

Preventing formation damage during cementing and completion operations is critical to maximizing well productivity and longevity. Formation damage occurs when the well’s permeability is reduced, hindering hydrocarbon flow. Several strategies are employed:

- Optimized Cement Slurry Design: The cement slurry should be designed to minimize permeability impairment. This involves selecting cement types, additives, and rheological properties that minimize filter cake formation and ensure good fluid displacement. Low permeability cements, for example, are used in certain formations.

- Careful Fluid Placement: Efficient displacement of drilling fluids and proper placement of cement are essential to prevent contamination. This involves careful monitoring of annular pressure and the use of techniques to ensure complete cement placement.

- Formation Evaluation: A thorough understanding of the formation properties, including its permeability, pressure, and temperature, is vital to tailor cement and completion fluid choices. This often involves detailed core analysis and formation testing.

- Compatible Completion Fluids: Completion fluids should be compatible with the formation and not cause damage. This includes avoiding fluids that may swell clays, dissolve formation minerals, or reduce permeability.

- Pre-flush Treatments: Using pre-flush treatments such as acid or specialized cleaning fluids before cementing can remove damaging solids from the wellbore and improve cement bonding.

Imagine a scenario where a highly permeable formation is cemented with a slurry that creates a thick filter cake. This filter cake would significantly reduce the formation’s permeability, impacting the well’s productivity. Properly designed cement slurries and careful fluid placement are crucial to mitigate such issues.

Q 26. Describe the difference between primary and secondary cementing.

Primary and secondary cementing are distinct stages in the well completion process, each with a specific purpose:

- Primary Cementing: This is the initial cementing operation after drilling a well section. Its purpose is to isolate various formations from each other to prevent fluid migration, provide structural support to the casing, and ensure wellbore integrity. It’s typically performed after the casing is set in the wellbore. A successful primary cement job is paramount for well safety and functionality.

- Secondary Cementing: This is performed after the primary cementing job, addressing potential issues or improving wellbore integrity. This could involve remedial cementing to repair a damaged cement sheath, squeeze cementing to seal off zones, or additional cementing to support zones prone to instability.

In essence, primary cementing is the foundational step, while secondary cementing addresses specific issues that may arise after the initial cement job. Think of primary cementing as building the foundation of a house and secondary cementing as making repairs or improvements later on.

Q 27. Explain the role of annular pressure monitoring in cementing operations.

Annular pressure monitoring is crucial during cementing operations to ensure proper cement placement and wellbore integrity. It involves continuously monitoring the pressure in the annulus (the space between the casing and the wellbore) during the cementing process. This provides real-time data to assess the effectiveness of the operation and identify potential problems.

Here’s how it works:

- Pressure Indication: Pressure gauges and downhole pressure sensors are used to monitor the annular pressure. Changes in pressure indicate the progress of the cement slurry as it displaces drilling fluids and fills the annulus.

- Identifying Problems: Significant increases or decreases in annular pressure may suggest problems like channeling, poor cement displacement, or zonal fluid leaks.

- Optimization: Monitoring annular pressure helps optimize the cementing process, allowing adjustments to be made if necessary to ensure complete cement placement and good bond.

For example, a sudden drop in annular pressure during cement placement might indicate a channel that’s allowing the cement to bypass certain sections of the wellbore. This would require immediate intervention to address the issue and prevent potential future problems.

Q 28. What are some emerging technologies in cementing and completion fluids?

The field of cementing and completion fluids is constantly evolving, driven by the need for improved wellbore integrity, enhanced efficiency, and reduced environmental impact. Some emerging technologies include:

- Advanced Cement Additives: Development of new cement additives to enhance cement properties, such as strength, flowability, and thickening time, leading to improved zonal isolation and less formation damage.

- Smart Cements: These cements contain sensors that monitor their setting and hardening characteristics in real-time, providing valuable data on cement placement and quality.

- High-Performance Completion Fluids: Development of completion fluids with improved environmental compatibility, reduced formation damage potential, and enhanced ability to prevent fluid leaks.

- Nanotechnology in Cement: The use of nanomaterials in cement to improve its mechanical properties, such as strength and durability, is also being explored.

- Data Analytics and Modeling: Advanced computational modeling and data analysis techniques improve cement slurry design and placement optimization, leading to more efficient and effective cementing operations.

These advancements are not only enhancing wellbore integrity but also promoting safer and more environmentally sound operations. These new technologies represent a significant step towards more sustainable and efficient oil and gas production.

Key Topics to Learn for Cementing and Completion Fluids Interview

- Cement slurry design and rheology: Understand the factors influencing cement slurry properties (e.g., water content, cement type, additives) and their impact on placement and setting time. Be prepared to discuss different rheological models and their applications.

- Cementing techniques and equipment: Familiarize yourself with various cementing methods (e.g., primary cementing, squeeze cementing), the equipment used (e.g., pumps, mixers, centralizers), and their operational principles. Be ready to troubleshoot potential issues.

- Completion fluids: Explore the different types of completion fluids (e.g., drilling muds, fracturing fluids), their properties, and their selection criteria based on well conditions and formation characteristics. Understand their role in preventing formation damage.

- Formation damage mechanisms and mitigation: Understand how cementing and completion fluids can cause formation damage (e.g., permeability reduction, filter cake formation) and the strategies to mitigate these issues. This includes understanding the importance of fluid filtration control and minimizing pressure differentials.

- Wellbore stability and pressure management: Discuss the role of cementing and completion fluids in maintaining wellbore stability and managing pressure during various stages of well construction and completion. Understand the implications of fluid density and pressure gradients.

- Environmental considerations and regulations: Be aware of environmental regulations related to the disposal and handling of cementing and completion fluids. This includes understanding waste management practices and minimizing environmental impact.

- Troubleshooting and problem-solving: Practice diagnosing common problems encountered during cementing and completion operations, such as channeling, fluid leaks, and inadequate zonal isolation. Develop your ability to propose effective solutions.

Next Steps

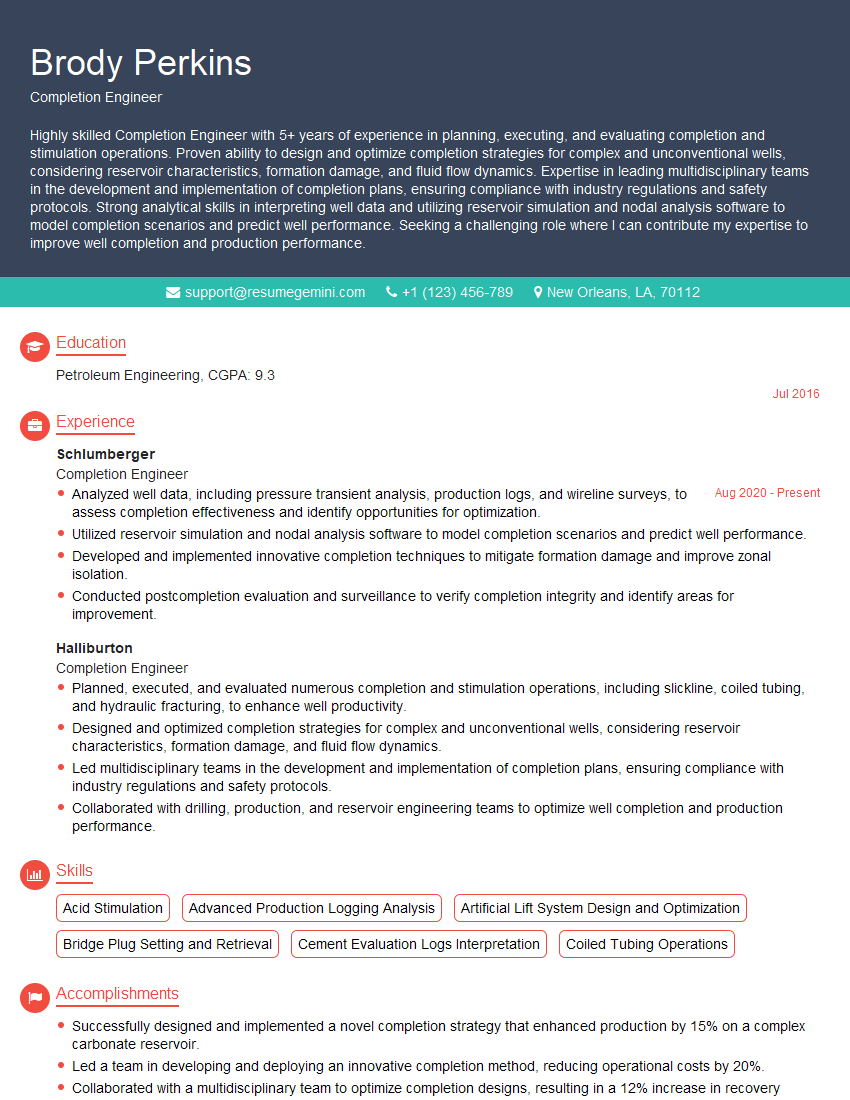

Mastering Cementing and Completion Fluids is crucial for career advancement in the oil and gas industry, opening doors to specialized roles and higher earning potential. A well-crafted resume is your key to unlocking these opportunities. An ATS-friendly resume, optimized for applicant tracking systems, significantly increases your chances of getting noticed by recruiters. We strongly recommend using ResumeGemini to build a professional and impactful resume that highlights your skills and experience in Cementing and Completion Fluids. ResumeGemini provides examples of resumes tailored to this specific field, helping you present your qualifications effectively. Take the next step towards your dream career – build your resume with ResumeGemini today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.