Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Project Site Preparation and Management interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Project Site Preparation and Management Interview

Q 1. Describe your experience in site surveying and its importance in project preparation.

Site surveying is the cornerstone of successful project preparation. It’s the process of meticulously examining the land to determine its characteristics and suitability for construction. This involves topographical surveys to map the land’s contours, identifying potential obstacles like underground utilities, trees, or rock formations. We also conduct geotechnical investigations to assess soil conditions, bearing capacity, and potential for ground instability. The importance of this detailed investigation cannot be overstated; it informs crucial decisions about site design, foundation type, and overall project feasibility. For example, on a recent project, our survey revealed an unexpected underground spring. This allowed us to adjust the foundation design, preventing costly delays and potential structural problems later on. Without thorough surveying, we might have proceeded with the original plan, leading to serious complications and potential project failure.

Key aspects of site surveying include:

- Topographic surveys: Mapping elevations and contours.

- Geotechnical investigations: Analyzing soil properties and bearing capacity.

- Utility location surveys: Identifying underground services (water, gas, electricity).

- Environmental surveys: Assessing ecological impact and compliance.

Q 2. Explain the process of obtaining necessary permits and approvals for a construction project.

Obtaining permits and approvals is a complex, multi-stage process that requires meticulous attention to detail and a deep understanding of local regulations. It typically involves:

- Preliminary Planning and Application Preparation: This stage involves gathering all the necessary information, such as site plans, architectural drawings, engineering reports, and environmental impact assessments. We carefully review zoning regulations, building codes, and environmental protection laws to ensure compliance. This often requires consultations with architects, engineers, and relevant authorities.

- Submission of Application: The complete application package is submitted to the relevant authorities (city council, county planning department, environmental agencies). This might involve multiple submissions depending on the project’s scale and complexity.

- Review and Potential Revisions: The authorities review the application for compliance. This process often takes time and may necessitate revisions based on their feedback. We proactively address any concerns raised to expedite the process.

- Permit Issuance: Upon successful review, the necessary permits and approvals are granted. These permits typically cover various aspects, such as building construction, land disturbance, and environmental protection.

- Ongoing Compliance: Maintaining compliance throughout the project is essential. This involves regular inspections and adherence to the conditions outlined in the permits.

Failing to secure necessary permits can result in significant delays, fines, and even project cessation. I’ve experienced this firsthand on a previous project where a minor oversight in the initial application led to a two-month delay in obtaining the final building permit.

Q 3. How do you manage site logistics, including material delivery and waste disposal?

Managing site logistics is crucial for efficient project execution. This involves careful planning and coordination of material delivery, waste disposal, and overall site traffic. We use a combination of strategies to optimize these processes.

- Just-in-Time Delivery: This approach ensures materials arrive only when needed, minimizing storage space requirements and reducing the risk of damage or theft. We work closely with suppliers to schedule deliveries effectively.

- Designated Storage Areas: Clearly marked storage areas are established for different materials to maintain organization and safety. This prevents congestion and simplifies material retrieval.

- Waste Management Plan: A comprehensive waste management plan is implemented, detailing waste segregation, recycling procedures, and disposal methods in compliance with environmental regulations. We aim to minimize waste generation through careful planning and efficient material usage.

- Traffic Management: Site access points and traffic flow are carefully planned to ensure smooth movement of vehicles, minimize congestion, and enhance safety. We often utilize site signage and traffic controllers to manage vehicles.

For example, on a large-scale project, we implemented a color-coded system for materials, along with clearly marked storage zones. This streamlined the entire process, improving efficiency and reducing delays.

Q 4. What safety measures do you implement to ensure a safe working environment on-site?

Safety is paramount on any construction site. We implement a comprehensive safety program that encompasses all phases of the project, starting with site preparation. This involves:

- Site-Specific Safety Plan: A detailed plan outlines potential hazards and preventive measures, tailored to the specific site conditions and project scope.

- Regular Safety Inspections: Regular inspections are conducted to identify and rectify potential hazards promptly. This involves checking equipment, working conditions, and compliance with safety regulations.

- Personal Protective Equipment (PPE): Mandatory use of appropriate PPE, including hard hats, safety glasses, high-visibility vests, and safety boots, is enforced.

- Safety Training: All site personnel receive comprehensive safety training before commencing work. This includes training on hazard identification, risk assessment, and emergency procedures.

- Emergency Response Plan: A detailed emergency response plan is in place, including procedures for handling accidents, injuries, and emergencies.

We also maintain a strict ‘no shortcuts’ policy and foster a strong safety culture where everyone is responsible for their safety and the safety of others. I always emphasize the importance of reporting near misses to prevent future incidents. This proactive approach has been instrumental in maintaining a safe working environment on all my projects.

Q 5. How do you handle unexpected site conditions or challenges during the preparation phase?

Unexpected site conditions are common. Our approach involves a multi-pronged strategy:

- Thorough Initial Assessment: While no amount of planning can entirely eliminate surprises, a thorough initial site assessment significantly reduces unexpected occurrences. This includes meticulous surveying, geotechnical investigations, and environmental studies.

- Contingency Planning: We always develop contingency plans for potential problems. This means having alternative solutions ready in case of unforeseen challenges, such as unexpected soil conditions or underground obstructions.

- Flexible Approach: Maintaining a flexible approach is crucial. We are prepared to adjust plans and procedures as needed, based on the specific challenges encountered. This might involve redesigning portions of the project or bringing in specialized equipment or personnel.

- Communication and Collaboration: Open communication among the project team, subcontractors, and relevant stakeholders is paramount. Prompt reporting and collaborative problem-solving are key to handling unexpected conditions effectively.

- Documentation: Meticulous documentation of all changes and adaptations is essential for tracking progress, managing costs, and ensuring compliance.

For example, on a recent project, we encountered unexpectedly high groundwater levels. Our contingency plan involved modifying the foundation design and implementing a dewatering system. The proactive approach minimized the impact on the project schedule and budget.

Q 6. Explain your experience with site clearing and grubbing operations.

Site clearing and grubbing are crucial initial steps in site preparation. Site clearing involves removing all above-ground obstacles, such as trees, shrubs, and other vegetation. Grubbing focuses on removing stumps, roots, and other underground obstructions. These processes are essential for creating a level and safe working platform for construction.

Key considerations in site clearing and grubbing include:

- Environmental regulations: Adhering to local environmental regulations, particularly concerning the handling and disposal of vegetation and debris, is essential. We often work with environmental consultants to ensure compliance.

- Safety measures: Implementing appropriate safety measures is crucial due to the use of heavy machinery. This includes hazard identification, operator training, and the use of personal protective equipment.

- Waste management: A clear waste management plan, including methods for disposing of the cleared vegetation and debris, should be in place.

- Equipment selection: The choice of equipment depends on site conditions and the scale of the project. This could involve excavators, bulldozers, and specialized stump grinders.

I have extensive experience overseeing these operations, including projects where careful preservation of certain trees was required. This involved utilizing selective clearing techniques and coordinating with arborists.

Q 7. Describe your knowledge of different types of soil and their implications for site preparation.

Understanding soil types is critical for successful site preparation. Different soils have varying properties affecting foundation design, drainage, and overall site stability. Some key soil types and their implications include:

- Clay: Clay soils can be problematic due to their high plasticity and susceptibility to expansion and contraction with moisture changes. This can affect foundation stability and require special foundation designs.

- Sandy soil: Sandy soils are typically well-drained but may have low bearing capacity, requiring reinforcement or deeper foundations.

- Silty soil: Silty soils have intermediate properties between clay and sand. Their behavior can be unpredictable, requiring thorough investigation.

- Rock: The presence of rock can present challenges but also advantages. While rock can provide a strong foundation, it requires specialized techniques for excavation and potentially blasting.

- Organic soil: Organic soils, containing significant amounts of decomposed organic matter, are usually weak and compressible, necessitating special foundation solutions.

We use geotechnical reports to understand the soil profile and select appropriate foundation systems. Ignoring soil conditions can lead to significant problems, such as foundation settlement, cracking, and even structural failure. A memorable example from my career involved a project where the presence of expansive clay soil necessitated the use of specialized deep foundations to prevent future problems.

Q 8. How do you ensure compliance with environmental regulations during site preparation?

Ensuring environmental compliance during site preparation is paramount. It involves a proactive, multi-stage approach starting long before the first shovel hits the ground. We begin with a thorough environmental impact assessment, identifying potential risks like endangered species habitats, wetlands, or contaminated soil. This assessment guides the development of a comprehensive environmental management plan (EMP), which details mitigation strategies and outlines adherence to all relevant local, state, and federal regulations. For example, if we identify a protected wetland, the EMP might specify avoiding it altogether, or implementing measures to minimize disturbance during construction. We then secure the necessary permits – often involving consultations with environmental agencies – before commencing any activities. Throughout the project, regular environmental monitoring is carried out, documented meticulously, and reported to the relevant authorities to ensure ongoing compliance and address any unforeseen issues. Think of it as a layered approach – risk assessment, mitigation planning, permitting, and ongoing monitoring – to ensure we’re operating within the bounds of the law and protecting the environment.

Q 9. What are the key elements of a comprehensive site preparation plan?

A comprehensive site preparation plan is the roadmap to a successful project. Key elements include a detailed site survey (topography, utilities, soil conditions), a thorough geotechnical investigation (assessing soil stability and bearing capacity), the design and engineering of earthworks (grading, excavation, drainage), utility coordination (locating and managing existing services), environmental management (as detailed in the previous answer), a detailed schedule with milestones and deadlines, a budget outlining anticipated costs and contingencies, and a risk assessment and management strategy addressing potential issues like weather delays or unforeseen site conditions. For instance, during a recent highway project, our detailed site survey identified an underground gas line that wasn’t marked on the existing plans. The geotechnical report then informed the design of retaining walls to stabilize the cut slopes and prevent erosion. This proactive approach helped us avoid cost overruns and schedule delays.

Q 10. How do you manage and monitor the budget for site preparation activities?

Budget management for site preparation involves a meticulous, proactive approach. We begin by developing a detailed budget breakdown, allocating funds to specific tasks such as earthworks, demolition, utility relocation, and environmental remediation. This budget is then closely monitored throughout the project, using project management software to track actual costs against the budget. Regular progress meetings are held to review expenditures and identify any potential cost overruns. Contingency funds are allocated to cover unforeseen expenses or delays. We use value engineering techniques to explore cost-saving measures without compromising quality or safety. For example, on a recent project, we were able to reduce excavation costs by optimizing the earthmoving strategy, using a combination of different equipment based on soil conditions and distances. This careful planning and monitoring ensure the project stays within budget.

Q 11. How do you schedule and coordinate the various tasks involved in site preparation?

Scheduling and coordinating site preparation activities requires careful planning and effective communication. We use a critical path method (CPM) scheduling technique to identify tasks, their dependencies, and their durations. This creates a visual representation of the project timeline, highlighting critical tasks that must be completed on time to avoid delays. We use a collaborative project management platform to share the schedule with all stakeholders and track progress in real-time. Regular coordination meetings with all contractors and subcontractors are essential to ensure everyone is aligned and aware of their responsibilities and deadlines. For example, we might schedule the utility relocation to occur before the main excavation to prevent damage to underground services. This proactive approach minimizes delays and ensures efficient resource allocation.

Q 12. What are your strategies for managing conflicts between different contractors or stakeholders on-site?

Conflict resolution is a crucial aspect of site preparation management. Our approach emphasizes proactive communication and collaboration. We establish clear lines of communication and hold regular meetings with all stakeholders to address concerns and potential conflicts early on. We utilize a formal dispute resolution process outlined in our contracts, emphasizing mediation and negotiation as first steps before escalating to arbitration or litigation. Strong leadership and active listening are critical in resolving disputes fairly and efficiently. For instance, in one project, a conflict arose between two subcontractors about work sequencing. Through open communication and a collaborative approach, we helped them find a mutually agreeable solution that minimized disruption to the overall project schedule.

Q 13. How do you ensure quality control during site preparation?

Quality control is built into every stage of site preparation. We establish clear quality standards at the outset, based on industry best practices and client requirements. Regular inspections are carried out by qualified personnel to verify that work is being performed to the required standards. We use checklists and documented procedures to ensure consistency and track compliance with safety protocols. Any non-conformances are documented, investigated, and corrected promptly. We also perform regular testing of materials, such as soil compaction tests, to ensure that they meet the required specifications. A comprehensive quality control plan helps us to identify and resolve issues early on, preventing costly rework and ensuring a high-quality end product. Think of it like baking a cake – you need to follow the recipe precisely, use quality ingredients, and check on it regularly to ensure it turns out perfectly.

Q 14. Describe your experience with earthworks, including grading and excavation.

I have extensive experience in earthworks, encompassing all aspects of grading and excavation. This includes planning and execution of earthmoving operations using various machinery like excavators, bulldozers, and graders. My experience covers different ground conditions, from soft clay to hard rock, requiring adjustments in technique and equipment selection. I’m proficient in using surveying equipment to ensure accurate grading and leveling according to the design specifications. I have managed projects involving large-scale excavations, often involving the implementation of sophisticated soil stabilization techniques to ensure slope stability. On a recent project involving the construction of a large dam, I oversaw the excavation of millions of cubic meters of earth, ensuring adherence to stringent safety and environmental regulations. My expertise in earthworks is complemented by a strong understanding of soil mechanics, enabling me to anticipate and manage potential geotechnical challenges effectively.

Q 15. What are the different types of site access considerations you need to address?

Site access considerations are crucial for the smooth execution of a project. They involve planning how people, equipment, and materials will get to and from the site safely and efficiently. This necessitates a multifaceted approach:

- Accessibility for Vehicles: We need to assess road conditions, weight limits, and potential obstacles like narrow streets or low bridges. For example, on a recent project in a densely populated area, we had to arrange for deliveries to occur during off-peak hours to minimize traffic disruption.

- Pedestrian Access: Safe walkways and designated pedestrian zones are vital for worker and public safety. This often includes temporary fencing, clearly marked pathways, and potentially even designated crossing points.

- Emergency Vehicle Access: Ensuring fire trucks, ambulances, and other emergency vehicles have unimpeded access to the site is paramount. This might involve pre-planning access routes and coordinating with local emergency services.

- Site Security: Implementing measures to control access and prevent unauthorized entry is crucial to protect both personnel and materials. This can include security personnel, access gates, and surveillance systems.

- Environmental Impact: Site access planning must consider minimizing environmental disruption, like minimizing soil erosion and protecting local flora and fauna. For instance, we used designated routes for heavy vehicles to avoid damaging sensitive ecosystems on a recent project.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you utilize technology in site preparation and management (e.g., BIM, GPS)?

Technology plays a vital role in modern site preparation and management. We leverage several key technologies:

- Building Information Modeling (BIM): BIM allows for the creation of a 3D model of the site, including existing utilities, structures, and proposed construction. This enables clash detection and coordination between different trades, preventing costly rework later in the project. For example, we used BIM to identify a conflict between a planned foundation and an underground utility line, allowing us to adjust the design before excavation.

- Global Positioning System (GPS): GPS technology is used for accurate surveying and mapping of the site. This allows for precise location of utilities, setting out building lines, and monitoring the progress of earthworks. It helps in minimizing errors and ensures accurate alignment of structures.

- Drone Surveys: Drone technology offers cost-effective and time-efficient means to capture high-resolution aerial imagery of the site. This is especially useful in large projects to assess topography, identify potential hazards, and monitor progress quickly. We employed drones on a recent project to monitor excavation progress and identify any potential slope instability issues.

- Project Management Software: Tools like Primavera P6 or MS Project are invaluable for scheduling, resource allocation, and monitoring the project’s progress. This enables better planning and proactive risk management.

Q 17. Explain your experience with utility coordination and relocation.

Utility coordination and relocation are critical aspects of site preparation. My experience involves:

- One-Call Centers: Initiating requests for utility locates through the appropriate one-call center to mark the locations of underground utilities (gas, electric, water, communication lines) before any excavation begins is mandatory and the first step. Failing to do so can lead to significant safety hazards and project delays.

- Coordination with Utility Companies: Direct communication with utility companies to discuss relocation needs, schedules, and costs. This often involves detailed negotiations and potentially the preparation of detailed relocation plans.

- Design Review and Modifications: Reviewing the design plans to minimize conflicts with existing utilities. If relocation is necessary, modifying plans to accommodate the new utility locations, ensuring structural integrity and avoiding disruptions to neighboring properties.

- Supervision of Relocation: Overseeing the actual relocation process to ensure it is done safely and according to specifications. This includes rigorous safety checks and proper documentation of all work.

- Permitting and Inspections: Coordinating with relevant authorities to obtain the necessary permits for utility relocation work and ensuring all work meets required standards.

For instance, on a recent highway project, we successfully coordinated the relocation of a high-voltage power line, minimizing service interruptions and ensuring worker safety.

Q 18. How do you mitigate environmental risks associated with site preparation?

Mitigating environmental risks is a key priority. Our approach involves:

- Pre-construction Environmental Assessments: Conducting thorough environmental assessments to identify potential risks such as presence of endangered species, contaminated soil, or wetlands. This guides risk mitigation strategies.

- Erosion and Sediment Control: Implementing erosion and sediment control measures such as silt fences, sediment basins, and straw bales to prevent soil erosion and water pollution. We always ensure compliance with all local and national regulations.

- Waste Management: Developing a comprehensive waste management plan to minimize waste generation, and properly dispose or recycle construction debris. This often includes separating different types of waste materials.

- Air Quality Control: Implementing dust control measures like using water trucks and covering stockpiles of materials to mitigate air pollution.

- Stormwater Management: Ensuring proper management of stormwater runoff to prevent pollution and protect water resources. This might involve installing temporary stormwater controls.

- Contaminated Soil Remediation: If contaminated soil is found, we implement a remediation plan which might involve excavation and removal of contaminated soil or in situ treatment.

A recent project involved working near a sensitive wetland area. We employed specialized techniques and obtained the necessary permits to ensure the project didn’t negatively impact the environment.

Q 19. How do you manage waste generation and disposal on a construction site?

Effective waste management is essential for both environmental and logistical reasons. Our process includes:

- Waste Minimization Strategies: Implementing strategies to minimize waste generation at the source, such as precise material ordering and efficient construction practices. This reduces overall project costs and environmental impact.

- Waste Segregation: Establishing a clear system for segregating different types of waste (wood, metal, concrete, etc.) to facilitate proper recycling or disposal. This often involves the use of clearly marked containers on site.

- Recycling and Reuse: Prioritizing the recycling and reuse of materials whenever possible. This is both cost-effective and environmentally responsible. We aim for maximum material reuse and recycling to reduce our environmental footprint.

- Disposal of Hazardous Waste: Following strict procedures for the disposal of hazardous waste, including proper labeling, storage, and transportation to licensed facilities. This ensures compliance with all relevant regulations.

- Waste Management Records: Maintaining meticulous records of waste generation, recycling, and disposal. This provides transparency and accountability throughout the project.

For a large-scale project, we implemented a color-coded waste segregation system which resulted in a significant increase in recycling rates compared to previous projects.

Q 20. What is your approach to ensuring the safety of both workers and the public during site preparation?

Safety is paramount throughout the project lifecycle. Our approach includes:

- Site Safety Plans: Developing detailed site safety plans that address all potential hazards associated with site preparation, taking into account specific site conditions and project activities.

- Pre-start Meetings: Conducting daily toolbox talks and pre-start meetings with all workers to discuss safety procedures and potential hazards for the day.

- Personal Protective Equipment (PPE): Ensuring all workers have appropriate PPE (hard hats, safety glasses, high-visibility clothing, etc.) and understand how to use it properly.

- Hazard Identification and Risk Assessment: Regularly identifying and assessing potential hazards on site, implementing control measures to mitigate the identified risks.

- Safety Training: Providing comprehensive safety training for all workers before starting any work, including specific training related to the work they will perform.

- Public Safety Measures: Implementing measures to protect the public from hazards associated with the construction site, such as fencing, warning signs, and traffic management.

- Emergency Response Plan: Developing a comprehensive emergency response plan to handle any accidents or emergencies on site, ensuring efficient response and communication.

For a recent project near a busy road, we implemented a robust traffic management plan with clear signage, flaggers, and temporary road closures to ensure the safety of both workers and the public.

Q 21. Describe your experience with erosion and sediment control measures.

Erosion and sediment control (ESC) is crucial for environmental protection and regulatory compliance. My experience involves implementing a range of measures:

- Silt Fences: Installing silt fences around the perimeter of the site and along drainage pathways to intercept sediment-laden runoff.

- Sediment Basins: Constructing sediment basins to trap sediment from runoff before it reaches natural waterways.

- Straw Bales: Using straw bales to stabilize slopes and prevent erosion. This is particularly effective on temporary access roads.

- Mulching: Applying mulch to exposed soil to reduce erosion and promote vegetation growth. This helps to stabilize the soil and prevent erosion long-term.

- Temporary Seeding and Vegetative Stabilization: Seeding disturbed areas with fast-growing vegetation to stabilize the soil and reduce erosion. We often use native species adapted to local conditions.

- Stormwater Management: Implementing measures to manage stormwater runoff effectively, preventing it from eroding the soil and carrying sediment into water bodies. This might include installing temporary swales or diverting water around the site.

On a hillside project, we implemented a comprehensive ESC plan that included silt fences, sediment basins, and slope stabilization measures, preventing significant erosion and ensuring compliance with environmental regulations.

Q 22. How do you monitor and control the impact of site preparation on surrounding areas?

Monitoring and controlling the impact of site preparation on surrounding areas is crucial for minimizing disruption and maintaining positive community relations. This involves a multi-pronged approach encompassing pre-planning, real-time monitoring, and post-preparation assessment.

- Pre-planning: This includes detailed surveys of the surrounding area, identifying sensitive ecosystems, residential zones, and businesses. We establish buffer zones, develop dust and noise mitigation plans, and communicate our preparation schedule to affected parties. For instance, if a project is near a school, we’d schedule noisy activities outside of school hours.

- Real-time monitoring: We deploy various monitoring techniques, including air quality sensors for dust levels, noise level meters, and regular site inspections to ensure compliance with environmental regulations and our mitigation plans. Any deviations are addressed immediately.

- Post-preparation assessment: Once the site preparation phase concludes, a thorough assessment is conducted to evaluate the actual impact on surrounding areas. This may involve soil testing, noise level measurements, and surveys of local businesses and residents to gauge their experiences. This feedback is invaluable for future projects.

For example, during a recent highway construction project, we implemented a comprehensive dust suppression system and established regular communication channels with neighboring residents. This proactive approach minimized complaints and fostered a positive relationship with the community.

Q 23. What is your process for identifying and addressing potential hazards on the site?

Identifying and addressing potential hazards is paramount for ensuring worker safety and project success. My process is a systematic one, integrating several key steps:

- Site survey and risk assessment: A detailed site survey is conducted to identify potential hazards, including underground utilities, unstable ground conditions, hazardous materials, and potential sources of contamination. This information feeds into a comprehensive risk assessment, prioritizing hazards based on likelihood and severity.

- Hazard communication and control: Once hazards are identified, a communication plan is implemented to inform all workers of the risks. Control measures are put in place, which could include engineering controls (e.g., barriers, trench shoring), administrative controls (e.g., work permits, safety training), and personal protective equipment (PPE).

- Regular inspections and monitoring: Regular safety inspections are conducted throughout the site preparation phase to ensure the effectiveness of the control measures and identify any new hazards. This involves daily site safety checks as well as weekly walk-throughs.

- Incident reporting and investigation: A clear protocol for reporting incidents and near misses is implemented. Any incidents are thoroughly investigated to identify root causes and implement corrective actions to prevent recurrence.

For instance, on a recent project involving excavation, we conducted ground penetrating radar surveys to pinpoint underground utilities before excavation commenced. This prevented accidental damage to these critical systems and ensured worker safety.

Q 24. How do you handle changes or revisions to the site preparation plan during the project?

Handling changes to the site preparation plan requires a flexible yet controlled approach. This ensures that changes are implemented efficiently while maintaining project objectives and safety standards.

- Change request process: A formal process for submitting, reviewing, and approving change requests is essential. This typically involves documenting the proposed change, assessing its impact on cost, schedule, and safety, and obtaining necessary approvals from stakeholders.

- Impact assessment: Any proposed change must undergo a thorough impact assessment to evaluate its potential consequences. This may involve reviewing drawings, specifications, and schedules. For instance, a change might require updating the project schedule and costing.

- Revision control: All changes to the plan must be documented and controlled to maintain consistency and clarity. We use version control systems to track changes and ensure everyone is working with the latest approved version.

- Communication: Clear and timely communication is vital to ensure all stakeholders are aware of changes and their implications. This might involve regular project meetings, email updates, or formal notifications.

For example, a recent project encountered unexpected subsurface conditions. Following the change request process, we adjusted the excavation plan, updated the schedule, and communicated the changes to all team members and stakeholders. This ensured the project continued smoothly and effectively despite the unexpected change.

Q 25. Describe your experience with temporary site infrastructure establishment (e.g., fencing, access roads).

Establishing temporary site infrastructure is a critical aspect of site preparation, directly impacting safety, efficiency, and environmental protection. My experience encompasses a wide range of elements:

- Fencing: I’ve managed the installation of various types of fencing, from temporary chain-link for perimeter security to more robust options for specific areas (e.g., construction zones around excavation). This includes ensuring appropriate signage and compliance with safety regulations.

- Access roads: This ranges from simple gravel roads for limited access to more complex paved roads capable of handling heavy construction equipment. This involves careful planning of traffic flow, ensuring adequate drainage, and maintaining the roads throughout the project.

- Storage areas: Secure and organized storage for materials and equipment are crucial. We implement systems to prevent theft, damage, and environmental contamination.

- Utilities: Temporary power, water, and sanitation facilities are essential. I have experience in planning, installing, and maintaining temporary utilities to support the construction activities.

In one project, we had to construct temporary access roads across a wetland area. We used geotextiles and strategically placed culverts to minimize environmental impact and ensure smooth traffic flow for construction equipment. This approach ensured efficient project execution while prioritizing environmental responsibility.

Q 26. How do you document the site preparation process and ensure accurate record-keeping?

Accurate and comprehensive documentation is the cornerstone of effective site preparation management. This involves a layered approach, combining both physical and digital records.

- Daily logs: Daily logs record work performed, materials used, equipment operated, and any issues encountered. This provides a granular record of progress and challenges faced.

- Photographs and videos: Visual documentation, especially during key stages of the project, provides a valuable record. It can be used for progress reporting, safety audits, and dispute resolution. Time-lapse cameras can offer valuable insights.

- As-built drawings: These drawings show the final layout of the site, incorporating any deviations from the original plan. They are essential for future reference and maintenance.

- Digital records: Centralized digital records are crucial for efficient access and collaboration. This often involves using project management software to store documents, schedules, and other relevant information.

For example, during a recent project, we implemented a cloud-based document management system, allowing all team members to access the latest drawings, permits, and other relevant information. This streamlined communication and prevented conflicts stemming from outdated information.

Q 27. What are your strategies for managing time constraints and deadlines during site preparation?

Managing time constraints in site preparation necessitates a proactive and organized approach. This involves strategic planning, efficient execution, and continuous monitoring.

- Detailed scheduling: A well-defined project schedule, broken down into tasks with realistic durations, is fundamental. This aids in identifying potential bottlenecks and scheduling resources effectively. Critical Path Method (CPM) analysis can help identify the most crucial tasks.

- Resource allocation: Proper allocation of resources (personnel, equipment, materials) is essential to meet deadlines. This includes forecasting resource needs, managing procurement, and addressing any resource shortages proactively.

- Progress monitoring and control: Regular monitoring of progress against the schedule allows for early identification of delays. This could involve using Gantt charts or other project management tools. Any delays require prompt investigation and corrective action.

- Contingency planning: Incorporating a buffer for unforeseen delays is essential. This might include extra time allocated in the schedule or a reserve of resources.

In one project, we faced a delay in material delivery. Our contingency plan, which included having backup suppliers and adjusting the schedule, allowed us to mitigate the impact of the delay and complete the site preparation on time.

Q 28. Describe your experience with stormwater management and compliance.

Stormwater management and compliance are critical aspects of responsible site preparation. This involves minimizing runoff, preventing erosion, and protecting water quality.

- Erosion and sediment control: Implementing measures such as silt fences, sediment basins, and erosion control blankets prevents soil erosion and protects nearby water bodies from sedimentation. These measures are often mandated by local regulations.

- Stormwater detention and retention: These systems manage stormwater runoff by temporarily storing it, allowing it to infiltrate the ground or slowly release it, reducing the volume and velocity of runoff. This minimizes the risk of flooding and erosion.

- Best management practices (BMPs): Following BMPs, specific guidelines for minimizing pollution, is crucial. This may involve measures such as using straw bales for erosion control, minimizing the use of chemicals, and properly storing and handling hazardous materials.

- Permitting and compliance: Obtaining necessary permits and ensuring compliance with all relevant regulations is vital. This often involves working closely with regulatory agencies to ensure adherence to local stormwater management ordinances.

In a recent project near a sensitive river ecosystem, we implemented a sophisticated stormwater management system, including a large sediment basin and several bioretention areas. This ensured compliance with stringent environmental regulations and prevented any negative impact on the river.

Key Topics to Learn for Project Site Preparation and Management Interview

- Site Surveys and Assessments: Understanding the importance of thorough site analysis, including geotechnical investigations, environmental impact assessments, and utility location. Practical application: Describing your experience in identifying potential risks and developing mitigation strategies during site surveys.

- Permitting and Regulatory Compliance: Navigating the complexities of obtaining necessary permits and adhering to local, state, and federal regulations. Practical application: Explaining your process for ensuring compliance throughout the project lifecycle, including proactive communication with regulatory bodies.

- Site Logistics and Planning: Developing comprehensive site logistics plans, including material handling, access roads, temporary utilities, and waste management strategies. Practical application: Illustrating how you’ve optimized site logistics to enhance efficiency and safety.

- Safety and Risk Management: Implementing robust safety protocols and risk mitigation plans to ensure a safe working environment for all personnel. Practical application: Describing your experience in conducting site-specific risk assessments and implementing control measures.

- Budgeting and Cost Control: Developing accurate project budgets and implementing cost-control measures to manage expenses effectively. Practical application: Explaining your methods for tracking expenses, identifying cost overruns, and implementing corrective actions.

- Stakeholder Communication and Collaboration: Effectively communicating with project stakeholders, including clients, contractors, and regulatory agencies. Practical application: Describing your experience in facilitating collaborative relationships and resolving conflicts effectively.

- Project Scheduling and Sequencing: Creating realistic project schedules and sequencing tasks effectively to meet deadlines. Practical application: Illustrating your experience in utilizing scheduling software and managing project timelines.

- Site Mobilization and Demobilization: Efficiently managing the mobilization and demobilization of equipment, personnel, and materials. Practical application: Describing your strategies for minimizing disruption and maximizing resource utilization during these phases.

Next Steps

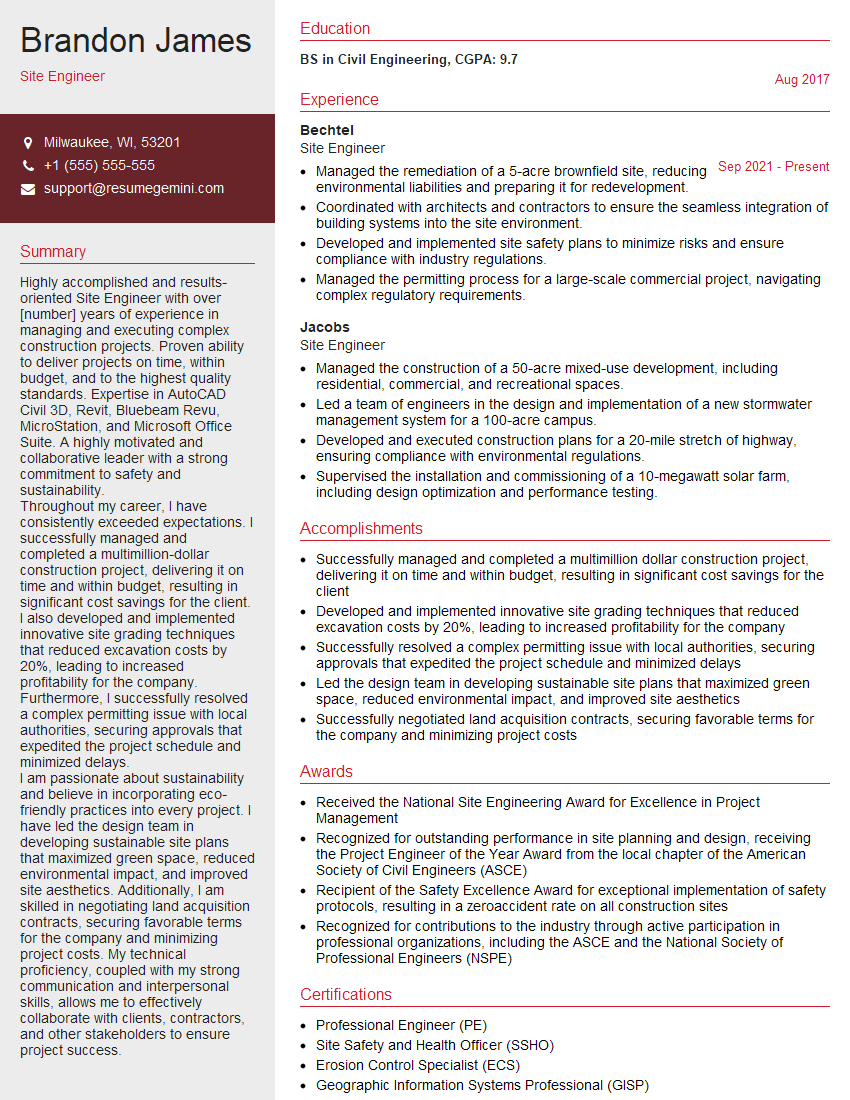

Mastering Project Site Preparation and Management is crucial for career advancement in the construction and engineering industries. It demonstrates your ability to manage complex projects efficiently and safely, leading to increased responsibility and higher earning potential. To maximize your job prospects, create an ATS-friendly resume that highlights your key skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to Project Site Preparation and Management are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.