Cracking a skill-specific interview, like one for Safety Culture and Compliance, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Safety Culture and Compliance Interview

Q 1. Describe your experience developing and implementing safety programs.

Developing and implementing safety programs requires a multi-faceted approach, starting with a thorough risk assessment. This involves identifying potential hazards, analyzing their likelihood and severity, and determining appropriate control measures. I’ve been involved in developing programs ranging from simple workplace housekeeping improvements to complex risk management systems for high-hazard industries.

For example, at my previous role in a manufacturing plant, we implemented a new lockout/tagout (LOTO) procedure. This involved a comprehensive review of existing procedures, training all employees on the new standard, regular audits to ensure compliance, and a robust reporting system to track near-misses and incidents. We saw a significant reduction in workplace accidents after implementing the new LOTO program. Another project involved designing a safety training module for operating heavy machinery, incorporating interactive simulations and real-world case studies to improve engagement and knowledge retention.

The implementation phase is crucial and often involves securing buy-in from all levels of the organization. This requires effective communication, clear documentation of procedures, and ongoing monitoring and evaluation. Success hinges on making safety a shared responsibility, not just the responsibility of a safety officer.

Q 2. How do you measure the effectiveness of a safety culture?

Measuring the effectiveness of a safety culture isn’t simply about counting accidents. It’s about assessing the underlying beliefs, values, and behaviors that influence safety performance. I use a multi-pronged approach:

- Lagging Indicators: These are data points that reflect past events, such as accident rates, lost-time injury (LTI) frequency, and near-miss reports. While important, they only show the consequences of a safety culture, not its inherent strength.

- Leading Indicators: These measure the factors that *predict* future safety outcomes. Examples include the number of safety training hours completed, employee participation in safety meetings, the number of safety suggestions submitted, and safety observation scores. These offer a more proactive way to understand safety performance.

- Employee Surveys and Interviews: These provide qualitative data, assessing employee perceptions of safety, their trust in management’s commitment to safety, and their willingness to report hazards without fear of retribution. A strong safety culture is characterized by open communication and a willingness to speak up.

- Safety Observation Programs: Observing employees’ adherence to safety procedures provides a direct measure of the effectiveness of the programs and the overall safety consciousness.

By analyzing these different data points, I can gain a holistic understanding of the safety culture’s health and identify areas for improvement. It’s like checking a car’s engine; you need to look at more than just the miles driven to understand its overall health.

Q 3. Explain your understanding of OSHA regulations.

My understanding of OSHA regulations (Occupational Safety and Health Administration) is comprehensive. OSHA sets minimum workplace safety and health standards to ensure a safe and healthful working environment. I’m familiar with a wide range of standards, including those covering hazard communication, personal protective equipment (PPE), machine guarding, fall protection, lockout/tagout, and emergency action plans.

I’m aware that OSHA’s regulations are not static; they evolve to address emerging hazards and technological advancements. Staying current with these changes is crucial, through means like regular training, participation in professional organizations, and close monitoring of OSHA’s website and publications. Moreover, I understand the enforcement mechanisms, including inspections, citations, and penalties, and the importance of proactive compliance to prevent potential workplace hazards. For example, I understand the requirements for creating and maintaining a comprehensive safety data sheet (SDS) program to accurately identify and manage chemical hazards within a workspace.

Q 4. How do you handle employee resistance to safety protocols?

Employee resistance to safety protocols can stem from various factors: lack of understanding, perceived inconvenience, or even mistrust of management’s commitment. Addressing this requires a tailored approach.

- Understanding the Root Cause: I start by actively listening to employees’ concerns. Why are they resistant? Is it a genuine safety concern, a lack of training, or something else? Open communication is key.

- Education and Training: Effective training that highlights the ‘why’ behind safety rules is crucial. I often use real-world examples, case studies, or interactive simulations to make the training relatable and engaging.

- Addressing Concerns: If employees have legitimate concerns, I address them directly and collaboratively seek solutions. This might involve modifying a procedure or providing additional resources.

- Leading by Example: Management’s visible commitment to safety is critical. If leaders don’t follow the rules, employees are less likely to.

- Incentivizing Compliance: Positive reinforcement, such as recognition programs or safety incentives, can motivate employees.

- Addressing Underlying Issues: Sometimes, resistance is a symptom of a larger problem—perhaps a lack of trust in management or inadequate resources. Identifying and addressing these issues is essential.

Remember, safety isn’t just a rule; it’s a shared value. Building trust and fostering a collaborative relationship with employees is crucial to overcoming resistance.

Q 5. Describe a time you identified and mitigated a safety risk.

In a previous role, we identified a significant risk associated with a particular machine’s operation. The machine’s guard was poorly designed, allowing access to moving parts. We initially relied on employee vigilance to prevent accidents, but this was inherently risky.

My approach involved a multi-step process: First, I conducted a thorough risk assessment, documenting the potential hazards, likelihood of injury, and severity of the potential outcome. Then, I collaborated with the engineering team to redesign the machine’s guard, ensuring it met OSHA standards and completely prevented access to moving parts. This involved sourcing new parts, modifying the machine’s design, and testing the new guard’s effectiveness. Finally, I implemented a training program for all operators on the new machine guard and safety procedures. This training included hands-on demonstrations and regular checks to ensure that procedures were being followed correctly. By proactively addressing this safety hazard, we prevented a potentially serious accident.

Q 6. What are your strategies for promoting a positive safety culture?

Promoting a positive safety culture requires a holistic approach, focusing on leadership commitment, employee engagement, and continuous improvement.

- Leadership Commitment: Leaders must visibly champion safety, making it a top priority and allocating the necessary resources. This includes actively participating in safety initiatives, regularly communicating about safety performance, and holding employees and managers accountable for safety performance.

- Employee Empowerment: Encourage employees to report hazards, participate in safety meetings, and provide suggestions for improvement. Create a culture where employees feel comfortable raising concerns without fear of reprisal.

- Effective Communication: Regular communication about safety performance, new procedures, and any near misses is essential. Utilize various channels, including meetings, newsletters, and visual aids, to ensure that safety messages reach everyone.

- Recognition and Rewards: Celebrate successes and acknowledge individuals who demonstrate outstanding safety performance. This can range from simple verbal praise to formal recognition programs.

- Continuous Improvement: Regularly review and update safety programs based on data and feedback. Conduct regular safety audits and inspections to identify potential hazards and areas for improvement. Use near miss reporting to prevent future accidents.

- Training and Education: Ensure all employees receive adequate training on relevant safety procedures and regulations. Regular refreshers and specialized training are important to address evolving risks.

Essentially, it’s about creating a workplace where safety is not just a set of rules, but a core value shared and actively practiced by everyone.

Q 7. How do you conduct safety audits and inspections?

Safety audits and inspections are crucial for identifying potential hazards and ensuring compliance with regulations. My approach involves a systematic and comprehensive process:

- Planning: I begin by defining the scope of the audit, identifying the areas to be inspected, and determining the methodology. This includes identifying the applicable regulations, standards, and procedures.

- Data Collection: The inspection process involves a thorough examination of the workplace, including equipment, processes, and working conditions. I use checklists, observation forms, and interviews to gather data. This also incorporates review of incident reports and near-miss records.

- Analysis and Reporting: After gathering data, I analyze the findings to identify potential hazards, non-compliances, and areas for improvement. I then prepare a comprehensive report summarizing the findings, including recommendations for corrective actions.

- Corrective Actions: Based on the audit findings, I work with management and employees to develop and implement corrective actions to address identified hazards. This involves setting timelines, assigning responsibilities, and verifying that the corrective actions are effective.

- Follow-up: I conduct follow-up inspections to verify that corrective actions have been implemented effectively and to assess the overall effectiveness of the safety program.

The goal isn’t just to find problems, but to use the audit as a learning opportunity to strengthen the overall safety program and prevent future incidents. Regular inspections are a key component of a proactive safety culture.

Q 8. Explain your experience with incident investigation and reporting.

Incident investigation and reporting are crucial for continuous improvement in safety. My approach involves a thorough, multi-faceted investigation following a structured methodology, not just assigning blame. I utilize techniques such as root cause analysis (RCA), 5 Whys, and fault tree analysis to identify the underlying causes of incidents, not just the immediate events. This goes beyond simply filling out forms; it’s about understanding the systemic issues that contribute to accidents.

For example, in a previous role, we had a near-miss incident involving a forklift. A simple ‘near miss’ report might have stopped at ‘driver fatigue.’ However, my investigation uncovered a larger issue: inadequate shift scheduling leading to chronic fatigue across the team, combined with insufficient training on safe forklift operation in tight spaces. The solution wasn’t just retraining the driver, but revising the scheduling process and providing refresher training with a focus on operating in confined areas. The reporting process ensured that this information was disseminated throughout the organization, impacting future scheduling and training protocols.

My reports are detailed, objective, and include recommendations for preventative measures. They are always communicated transparently to all relevant stakeholders, fostering a culture of learning and accountability.

Q 9. How do you ensure compliance with environmental regulations?

Ensuring compliance with environmental regulations requires a proactive and multifaceted approach. It starts with a thorough understanding of all applicable regulations – this involves staying updated on changes and amendments. I leverage resources like the EPA website and industry-specific compliance guides to maintain a current knowledge base.

Secondly, it involves implementing robust environmental management systems (EMS). These systems outline procedures for waste management, emissions control, and pollution prevention. Regular audits – both internal and external – are essential to verify compliance. I utilize checklists, data logging, and sampling to track environmental performance and identify areas for improvement. For example, we might monitor water quality regularly and compare it to regulatory limits, adjusting our procedures as needed.

Crucially, compliance isn’t just about avoiding penalties; it’s about protecting the environment and demonstrating corporate social responsibility. Open communication and employee training are vital for fostering a culture of environmental stewardship within the organization. Employees need to understand their role in preventing pollution and adhering to environmental best practices. This often involves role-playing scenarios and regular refresher training sessions to keep knowledge current.

Q 10. Describe your experience with safety training and development.

Safety training and development are not one-time events; they are ongoing processes crucial for building a strong safety culture. My approach focuses on needs analysis, tailored content, and effective delivery methods. I start by identifying specific safety hazards and risks within the workplace, then designing training programs that directly address those concerns. This includes a mix of methods: classroom training, online modules, hands-on simulations, and job shadowing.

For example, I’ve developed a comprehensive training program for construction workers covering hazard identification, fall protection, and lockout/tagout procedures. This included interactive simulations that allowed participants to practice real-life scenarios in a safe environment. The program also incorporated gamification elements to boost engagement and knowledge retention. Post-training assessments and ongoing feedback mechanisms are used to measure effectiveness and make improvements.

I’m also experienced in developing leadership training programs focusing on safety management responsibilities. Leaders must understand their roles in promoting a safe work environment and fostering a culture where safety is a priority.

Q 11. What are the key elements of an effective safety management system?

An effective Safety Management System (SMS) is the backbone of a safe workplace. It’s not simply a collection of policies; it’s a living, breathing system that integrates leadership commitment, risk assessment, hazard control, training, and continuous improvement. Key elements include:

- Leadership Commitment: Senior management must visibly champion safety, setting the tone from the top. This is more than just words; it’s about allocating resources, time, and personnel to safety initiatives.

- Hazard Identification & Risk Assessment: Proactively identifying potential hazards and evaluating their associated risks is critical. Methodologies like HAZOP (Hazard and Operability Study) and Job Safety Analyses (JSAs) are used.

- Hazard Control: Implementing appropriate controls to eliminate or mitigate identified hazards. This can include engineering controls (e.g., machine guards), administrative controls (e.g., work permits), and personal protective equipment (PPE).

- Training & Communication: Employees must receive adequate training on safety procedures and be kept informed about safety issues.

- Emergency Preparedness & Response: Having well-defined emergency procedures and conducting regular drills is crucial.

- Monitoring & Review: Regularly reviewing the SMS’s effectiveness through audits, incident investigations, and key performance indicators (KPIs).

- Continuous Improvement: Using data and feedback to identify areas for improvement and make necessary changes.

Think of an SMS as a holistic framework – all the elements work together to create a robust safety net. A weak link in one area compromises the entire system.

Q 12. How do you communicate safety information effectively to diverse audiences?

Communicating safety information effectively to diverse audiences requires tailoring the message to the audience’s understanding and preferred communication styles. I use a multi-channel approach, leveraging different methods to reach everyone.

For example, visual aids (posters, infographics) are highly effective for visual learners, while hands-on demonstrations work well for kinesthetic learners. For workers with limited literacy skills, verbal instructions, demonstrations and visual aids are essential. Using multiple languages and employing interpreters ensures inclusivity. Regular safety meetings, toolbox talks, and email updates help keep everyone informed. Feedback mechanisms are important to ensure that messages are understood and that there is room for two-way communication.

In addition to the method, the message itself is vital. It should be clear, concise, and actionable. Using storytelling and real-life examples can make safety information more relatable and memorable.

Q 13. How do you manage safety-related data and metrics?

Managing safety-related data and metrics is crucial for demonstrating effectiveness and identifying areas for improvement. I utilize a combination of methods to ensure data accuracy, accessibility, and usability.

Data is collected through various sources – incident reports, near-miss reports, audit findings, and training records. I utilize data management systems and spreadsheets to organize and analyze this data. This data is then used to track key performance indicators (KPIs) such as incident rates, lost time injury frequency rates (LTIFR), and near-miss rates. Data visualization tools (charts, graphs) are used to present this information clearly and concisely to stakeholders.

Regular reporting and trend analysis help to identify potential safety concerns and track the effectiveness of safety interventions. This data-driven approach enables proactive measures to prevent future incidents and demonstrates continuous improvement in safety performance. Data privacy and confidentiality are always paramount.

Q 14. Describe your understanding of risk assessment methodologies.

Risk assessment methodologies are systematic processes for identifying hazards and evaluating the associated risks. Several methodologies exist, each with its strengths and weaknesses. I’m proficient in several, including qualitative and quantitative approaches.

Qualitative methods, like HAZOP, focus on brainstorming potential hazards and evaluating their likelihood and severity through expert judgment. This is often used in early stages of project planning or when limited quantitative data is available. Quantitative methods, such as Fault Tree Analysis (FTA), use numerical data to estimate the probability of events and their consequences. This provides a more precise risk assessment, suitable for complex systems with available historical data.

A key aspect of any risk assessment is the development of control measures to mitigate identified risks. The hierarchy of controls – elimination, substitution, engineering controls, administrative controls, and PPE – guides the selection of the most effective control measures. For example, eliminating a hazardous chemical is preferable to simply providing PPE.

Risk assessments aren’t static documents; they need to be regularly reviewed and updated to reflect changes in the workplace or processes. A dynamic approach ensures the ongoing effectiveness of the risk management program.

Q 15. How do you prioritize safety initiatives within budgetary constraints?

Prioritizing safety initiatives within budgetary constraints requires a strategic approach that balances risk mitigation with available resources. It’s not about doing everything, but about doing the right things.

My approach involves a three-step process:

- Risk Assessment and Prioritization: I begin by conducting a thorough risk assessment, identifying potential hazards and their associated likelihood and severity. This helps prioritize initiatives based on their potential impact. For instance, a high-likelihood, high-severity risk (like unprotected machinery) would take precedence over a low-likelihood, low-severity risk (like minor office clutter).

- Cost-Benefit Analysis: For each prioritized initiative, I conduct a cost-benefit analysis, comparing the cost of implementation with the potential savings from reduced accidents, injuries, and associated costs (medical expenses, lost productivity, legal fees). This ensures that resources are allocated effectively to yield the greatest return on investment.

- Phased Implementation: Instead of trying to implement everything at once, I break down initiatives into manageable phases. This allows for flexibility, and the opportunity to adapt the plan based on the effectiveness of each phase and available resources. For example, we might start with essential PPE upgrades before moving to more advanced safety training programs.

This phased approach also allows for better tracking of progress and demonstrating ROI to stakeholders, which is crucial for securing future funding for safety initiatives.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you stay current with changes in safety regulations and best practices?

Staying current with evolving safety regulations and best practices is vital for maintaining a robust safety program. I employ a multi-pronged approach:

- Subscription to Regulatory Updates: I subscribe to relevant government agencies and professional organizations (like OSHA, NIOSH, etc.) to receive timely notifications about updates and changes in legislation and guidelines.

- Professional Development: I actively participate in industry conferences, webinars, and training courses to stay informed about emerging trends, technologies, and best practices in safety management. This includes attending workshops on specific hazards relevant to our industry.

- Networking with Peers: I maintain a network of contacts within the safety profession, sharing knowledge and best practices. This allows me to learn from others’ experiences and stay abreast of emerging challenges and solutions.

- Regular Audits and Reviews: I perform regular internal audits of our safety programs and policies to ensure alignment with current standards. These audits help identify gaps and areas for improvement, triggering further research into the latest best practices.

Essentially, it’s a continuous learning process. Safety is a dynamic field, and staying stagnant is a recipe for incidents.

Q 17. Explain your experience with safety-related software or technology.

My experience with safety-related software and technology is extensive. I’ve worked with various systems, including:

- Incident Reporting Systems: I’m proficient in using software for tracking safety incidents, conducting root cause analyses, and generating reports for management and regulatory compliance. For example, I’ve used systems that allow for immediate reporting of near misses, facilitating proactive hazard mitigation.

- Environmental Monitoring Systems: I have experience with software and hardware that monitor environmental conditions (temperature, noise levels, air quality) to ensure compliance with safety regulations. Real-time data allows for quick interventions before conditions become hazardous.

- Training Management Systems: I’ve used software to manage safety training programs, track employee certifications, and ensure that all personnel are adequately trained. This includes creating and delivering online training modules and assessments.

- Near Miss Reporting and Analysis: Systems that allowed detailed recording, analysis and trending of near-miss incidents, using this data to identify potential hazards before they cause accidents.

My proficiency extends beyond just using the software; I understand the importance of data integrity, accurate reporting, and how the data generated can be used for continuous improvement of our safety management system.

Q 18. Describe your experience with safety committees or teams.

I have extensive experience working with safety committees and teams, both in a leadership and participatory role. I believe that a collaborative approach is fundamental to building a strong safety culture.

My contributions typically include:

- Facilitating Meetings: I effectively lead meetings, ensuring that all members participate actively and constructively. I encourage open communication and ensure that decisions are made transparently and collaboratively.

- Developing and Implementing Safety Programs: I collaborate with the team to develop and implement safety programs that address identified hazards and risks. This includes devising action plans, assigning responsibilities, and establishing timelines for achieving goals.

- Promoting a Culture of Safety: I actively foster a culture of safety within the team by encouraging open communication, promoting a blame-free environment for reporting incidents, and providing ongoing training and support.

- Monitoring and Evaluation: I work with the team to monitor the effectiveness of safety initiatives, track key performance indicators (KPIs), and make necessary adjustments to ensure continuous improvement. This often involves using data from safety software to track our progress.

A successful safety committee thrives on trust, open communication, and a shared commitment to safety. My role is to nurture that environment.

Q 19. How do you ensure compliance with company safety policies?

Ensuring compliance with company safety policies requires a multifaceted approach that combines proactive measures with robust monitoring and enforcement.

My strategy includes:

- Clear Communication and Training: I ensure that all employees receive thorough training on company safety policies and procedures. This involves clear communication, readily accessible documentation, and regular refresher courses. I often employ multiple methods, including videos, presentations, and hands-on demonstrations.

- Regular Inspections and Audits: I conduct regular inspections and audits to verify adherence to safety policies and identify any non-compliance issues. These inspections are not punitive, but rather an opportunity to provide coaching and address potential hazards.

- Corrective Actions: When non-compliance is identified, I work with employees to implement corrective actions. This might involve additional training, improvements to procedures, or equipment upgrades. The focus is on preventing recurrence.

- Documentation and Reporting: Meticulous documentation is key. I maintain accurate records of training, inspections, audits, and corrective actions to demonstrate compliance and identify trends. This documentation is essential for internal and external audits.

- Employee Involvement: Actively encouraging employee feedback and participation in safety initiatives fosters a culture of ownership and enhances compliance. Regular safety meetings and suggestions boxes allow for proactive identification of risks.

Compliance is not a checklist, but a continuous process that requires constant vigilance and improvement.

Q 20. How do you handle safety emergencies or incidents?

Handling safety emergencies or incidents requires a well-defined and practiced emergency response plan. My approach is based on established emergency response protocols, coupled with decisive action and clear communication.

My steps include:

- Immediate Response: In the event of an emergency, my immediate priority is ensuring the safety of all personnel. This involves assessing the situation, activating emergency services if necessary, and initiating emergency response procedures as outlined in our plan.

- Incident Control: I work to control the incident, preventing further harm and protecting the environment. This often involves coordinating with emergency responders and providing information about the situation.

- First Aid and Medical Attention: I ensure that injured personnel receive appropriate first aid and medical attention. This includes managing the scene and facilitating transportation to a hospital if required.

- Investigation and Root Cause Analysis: Following the incident, a thorough investigation is conducted to determine the root cause of the event. This involves gathering information from eyewitnesses, reviewing records, and using data analysis techniques. This analysis is crucial for preventing future incidents.

- Corrective Actions: Based on the root cause analysis, I develop and implement corrective actions to prevent similar incidents from occurring in the future. This might involve modifying procedures, improving equipment, or providing additional training.

- Documentation: I maintain meticulous records of the incident, including details about what happened, the actions taken, and the lessons learned. This information is crucial for reporting purposes and future safety improvements.

Effective emergency response is a blend of planning, training, and decisive action. It’s not something that can be improvised. Regular drills and practice are paramount.

Q 21. What is your approach to continuous improvement in safety?

Continuous improvement in safety is an ongoing journey, not a destination. My approach focuses on using data, feedback, and innovative solutions to constantly refine our safety program.

Key strategies include:

- Data-Driven Decision Making: I utilize data from safety incident reports, inspections, and other sources to identify trends, patterns, and areas for improvement. This data-driven approach allows for targeted interventions rather than reacting to isolated events.

- Regular Reviews and Audits: Regular reviews and audits of our safety program are essential to ensure that it remains effective and aligned with best practices. This involves both internal reviews and external audits, offering a balanced perspective.

- Proactive Hazard Identification: I actively encourage employees to report near misses and potential hazards. This proactive approach allows for the identification and mitigation of risks before they lead to incidents. This includes implementing proactive hazard hunting programs.

- Feedback Mechanisms: I establish clear channels for employees to provide feedback on safety procedures and practices. This could include suggestion boxes, safety meetings, or anonymous surveys. Their input is invaluable for continuous improvement.

- Benchmarking: I regularly benchmark our safety performance against industry best practices and other organizations. This helps identify areas where we can improve and learn from other successful safety programs.

- Investing in New Technologies: I explore and implement new safety technologies, such as wearable sensors, predictive analytics, and virtual reality training, to enhance our safety program’s effectiveness. Technology allows for a more proactive and data-rich approach to safety management.

Safety is a dynamic field. Continuous improvement is not just desirable; it’s essential for maintaining a safe and productive workplace.

Q 22. How do you collaborate with other departments to promote safety?

Promoting safety is a cross-functional endeavor. Effective collaboration hinges on open communication and shared responsibility. I approach this by actively engaging with various departments, including operations, engineering, HR, and management. For example, I’d work with operations to identify and mitigate workplace hazards by conducting joint safety audits and providing training on risk assessments. With engineering, I’d collaborate on the design and implementation of safety features in new equipment or processes. HR plays a crucial role in embedding safety into company culture through targeted training programs and communication campaigns. Finally, working with management is critical for securing necessary resources and buy-in for safety initiatives.

I utilize regular meetings, shared safety data, and joint problem-solving sessions to ensure everyone is informed and actively participates in building a robust safety culture. This collaborative approach helps to identify blind spots and fosters a collective ownership of safety, which is ultimately more effective than a siloed approach.

Q 23. How do you ensure the accuracy and completeness of safety documentation?

Maintaining accurate and complete safety documentation is paramount for accountability and continuous improvement. My approach involves a multi-layered strategy that prioritizes clear procedures, regular audits, and robust record-keeping systems. This begins with establishing standardized templates and formats for all safety-related documents, such as incident reports, risk assessments, and training records. Regular internal audits are conducted to verify the accuracy and completeness of the documentation against established standards and regulatory requirements. We use a digital document management system to ensure version control, easy access, and searchability, minimizing the risk of outdated or missing information.

Furthermore, we implement a system of cross-checking and verification, where multiple individuals review critical documents before finalization. Finally, regular training is provided to staff on proper documentation procedures and the importance of meticulous record-keeping. This comprehensive approach minimizes errors and ensures the integrity of safety information, which is essential for effective safety management.

Q 24. Describe your experience with safety performance indicators (KPIs).

Safety performance indicators (KPIs) are essential tools for measuring the effectiveness of safety programs and identifying areas for improvement. My experience involves selecting, tracking, and analyzing a range of KPIs, including leading indicators and lagging indicators. Leading indicators, such as the number of safety training hours completed or the frequency of safety audits, predict future safety performance. Lagging indicators, such as the number of lost-time accidents or the severity rate, reflect past safety performance.

For instance, in a previous role, we tracked the number of near misses reported as a leading indicator. A decrease in reported near misses suggested an improvement in employee awareness and proactive hazard identification. We also monitored the lost-time injury frequency rate (LTIFR) as a lagging indicator. By analyzing trends in both leading and lagging indicators, we could identify areas where safety interventions were effective and areas needing further attention. Data visualization dashboards were used to present these KPIs in a clear and concise manner, facilitating better decision-making and demonstrating the impact of safety initiatives to stakeholders.

Q 25. Explain your understanding of different types of safety hazards.

Safety hazards can be broadly categorized into several types. Understanding these classifications is crucial for implementing targeted preventative measures.

- Physical hazards: These involve tangible sources of harm, such as noise, extreme temperatures, radiation, vibration, and ergonomic hazards (e.g., repetitive strain injuries). A factory worker exposed to excessive noise is an example.

- Chemical hazards: These include exposure to hazardous substances that can cause harm through ingestion, inhalation, or skin contact. Working with solvents or handling corrosive materials are examples.

- Biological hazards: These are risks associated with exposure to living organisms, such as bacteria, viruses, or fungi. Healthcare workers are particularly vulnerable to this hazard.

- Ergonomic hazards: These result from improper work design or work practices that can lead to musculoskeletal disorders. Repetitive tasks or awkward postures are examples.

- Psychosocial hazards: These relate to stress, harassment, violence, and other factors affecting mental and emotional well-being. High workload and bullying are examples.

Understanding these hazard types allows for the development of specific risk controls tailored to each unique situation. For example, engineering controls for physical hazards, personal protective equipment (PPE) for chemical hazards, and stress management programs for psychosocial hazards.

Q 26. How do you investigate near-miss incidents?

Investigating near-miss incidents is critical for proactive safety management. A near miss is an unplanned event that did not result in injury or damage but had the potential to do so. My approach involves a systematic investigation that aims to understand the circumstances and contributing factors, preventing a similar incident from causing harm in the future.

The investigation typically involves the following steps:

- Gathering information: Interviewing witnesses, reviewing relevant documentation (e.g., work permits, maintenance logs), and conducting site inspections.

- Analyzing the root causes: Employing root cause analysis techniques, such as the 5 Whys or fault tree analysis, to identify the underlying causes of the near miss.

- Identifying corrective actions: Developing and implementing solutions to prevent recurrence. These could include engineering controls, administrative controls, or changes in work practices.

- Reporting and communication: Documenting the findings and recommendations and communicating them to relevant personnel to ensure appropriate actions are taken.

For example, a near miss involving a dropped tool near a production line would trigger a thorough investigation to identify the reasons for the drop (e.g., inadequate tool storage, slippery floor). Corrective actions could range from improving tool storage to implementing a slip-resistant flooring system.

Q 27. Describe your experience with conducting root cause analysis of safety incidents.

Root cause analysis (RCA) is a crucial part of any effective safety incident investigation. It’s not enough to address the symptoms of an incident; we need to understand the underlying causes to prevent recurrence. My experience encompasses using various RCA techniques, including the 5 Whys, fault tree analysis, and Fishbone diagrams (Ishikawa diagrams).

The 5 Whys method involves repeatedly asking “why” to progressively drill down to the root cause. For example, if a worker was injured due to a machine malfunction, we’d ask:

- Why was the worker injured? (Machine malfunction)

- Why did the machine malfunction? (Faulty part)

- Why was the faulty part not replaced? (Lack of maintenance)

- Why was there a lack of maintenance? (Insufficient training)

- Why was there insufficient training? (Inadequate safety procedures).

Other techniques like Fault Tree Analysis provide a more structured and visual approach to identifying multiple contributing factors. The choice of technique depends on the complexity of the incident. After identifying the root cause(s), corrective and preventative actions are developed and implemented to ensure the incident doesn’t reoccur. This process fosters a continuous improvement cycle, leading to a safer work environment.

Q 28. How do you balance safety with productivity?

Balancing safety and productivity is not a trade-off; it’s a synergistic relationship. A safe workplace is a productive workplace. Unsafe practices ultimately lead to accidents, injuries, and downtime, negatively impacting productivity. My approach focuses on integrating safety into all aspects of work processes, rather than treating it as a separate entity.

This involves several strategies:

- Investing in preventative measures: Implementing ergonomic designs, providing appropriate PPE, and investing in safety training are all proactive steps that enhance both safety and productivity in the long run. Preventing accidents saves time and resources.

- Promoting a positive safety culture: A culture that prioritizes safety empowers employees to identify and report hazards without fear of reprisal, leading to early problem detection and fewer disruptions.

- Continuous improvement: Regularly reviewing safety performance data, investigating near misses, and conducting risk assessments allow for identifying areas of improvement and streamlining operations, leading to increased efficiency and safety.

- Effective communication: Open communication ensures everyone understands safety procedures and expectations, leading to improved compliance and reduced risk.

In essence, prioritizing safety is not a cost; it’s an investment that leads to a more efficient, productive, and profitable operation.

Key Topics to Learn for Your Safety Culture and Compliance Interview

- Defining Safety Culture: Understanding the components of a strong safety culture, including leadership commitment, employee involvement, communication, and continuous improvement.

- Compliance Frameworks: Familiarity with relevant regulations (OSHA, ISO 45001, etc.) and their practical application within different industries. Understanding the differences between regulatory compliance and exceeding expectations.

- Risk Assessment and Management: Proficiency in identifying, analyzing, and mitigating workplace hazards. Demonstrate understanding of different risk assessment methodologies and practical application.

- Incident Investigation and Reporting: Knowledge of root cause analysis techniques and best practices for reporting and documenting incidents. Understanding the importance of learning from past events to prevent future occurrences.

- Training and Development: Experience in developing and delivering safety training programs. Understanding different learning styles and the importance of ongoing training and competency assessments.

- Performance Measurement and Auditing: Ability to track key safety metrics, conduct audits, and identify areas for improvement. Understanding the value of data-driven decision-making in safety management.

- Communication and Engagement Strategies: Experience in effectively communicating safety information to diverse audiences. Demonstrating an understanding of how to foster a culture of open communication and reporting.

- Emergency Preparedness and Response: Understanding the development and implementation of emergency response plans and procedures, including drills and simulations.

Next Steps: Elevate Your Career with a Strong Safety Culture and Compliance Profile

Mastering Safety Culture and Compliance is crucial for career advancement in today’s competitive job market. Demonstrating a deep understanding of these principles showcases your commitment to workplace safety and your ability to contribute to a productive and secure work environment. This translates to higher earning potential and increased career opportunities.

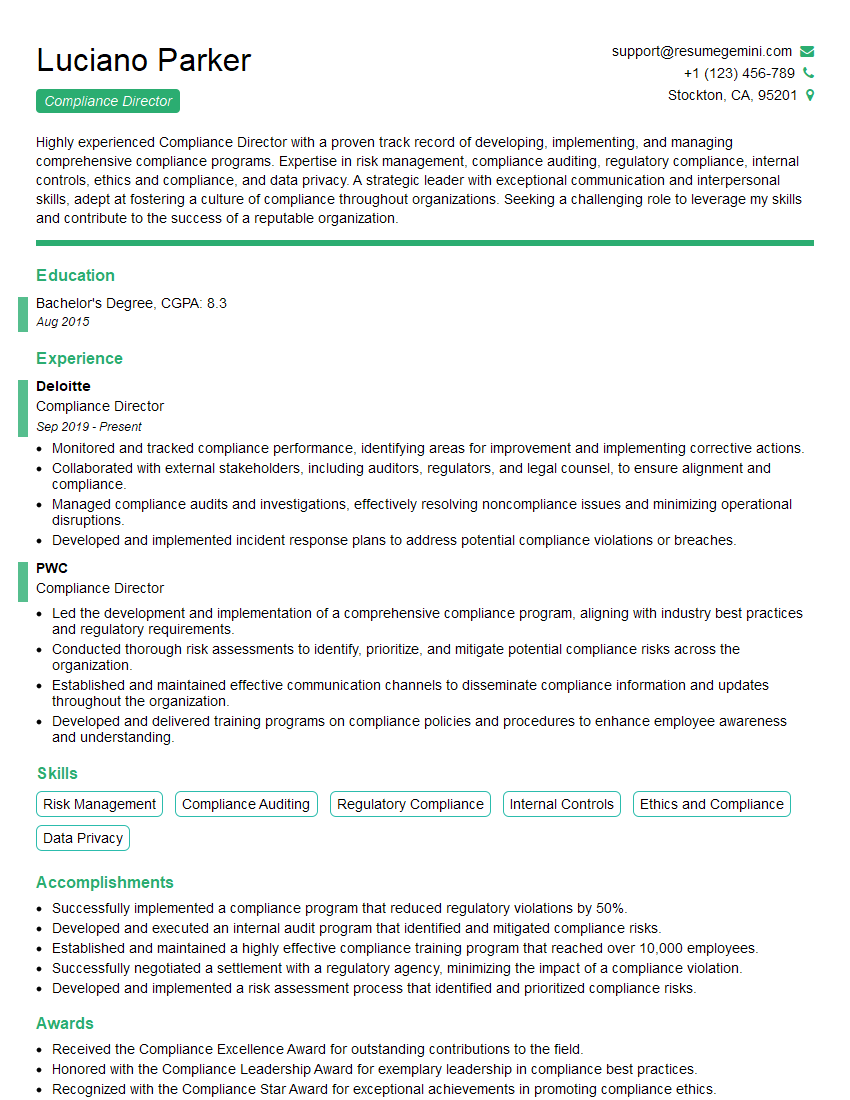

To maximize your job prospects, focus on creating an ATS-friendly resume that highlights your relevant skills and experience. A well-crafted resume is your first impression – make it count! We recommend using ResumeGemini, a trusted resource for building professional resumes. ResumeGemini provides you with the tools and templates needed to craft a compelling document that captures the attention of hiring managers. Examples of resumes tailored to Safety Culture and Compliance are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.