The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Crystallization and Filtration Techniques interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Crystallization and Filtration Techniques Interview

Q 1. Explain the difference between nucleation and crystal growth.

Nucleation and crystal growth are two distinct but interconnected stages in the crystallization process. Think of it like building a sandcastle: nucleation is the formation of the first tiny sand grains (crystal nuclei), while crystal growth is the process of adding more sand grains to these nuclei, making them larger and more defined.

Nucleation is the initial formation of a stable, solid crystal from a supersaturated solution or melt. This involves the spontaneous arrangement of molecules into a specific, ordered structure. There are two main types: primary nucleation (occurring from a homogeneous solution without existing crystals) and secondary nucleation (occurring on the surface of existing crystals).

Crystal growth, on the other hand, is the subsequent increase in the size of these crystals. Molecules from the surrounding solution or melt are added to the surface of the existing nuclei, following a specific crystallographic structure. The rate of crystal growth depends on factors such as supersaturation, temperature, and the presence of impurities.

In simpler terms: Nucleation is the ‘starting’ process, creating the first tiny crystals, while growth is the ‘building’ process, expanding these crystals to the desired size.

Q 2. Describe different types of crystallizers and their applications.

Various crystallizers are designed for different applications based on factors like the solubility of the substance, required crystal size and shape, and production scale. Here are some examples:

- Batch Crystallizers: These are relatively simple, used for small-scale production or when flexibility is required. A tank is filled with a solution, cooled or evaporated, and crystals are harvested when the process is complete. Good for producing high-quality crystals but less efficient for large-scale operations.

- Mixed-Suspension, Mixed-Product Removal (MSMPR) Crystallizers: These are continuous crystallizers, ideal for large-scale production. A magma (mixture of crystals and liquor) is continuously mixed, with crystals and liquor removed simultaneously. They produce a consistent crystal size distribution, which is easy to analyze.

- Draft-Tube Baffle (DTB) Crystallizers: These are another type of continuous crystallizer offering improved mixing and crystal size control by using a draft tube and baffles to control flow patterns and prevent agglomeration.

- Fluidized Bed Crystallizers: In these, crystals are suspended in a fluidized bed by an upward flow of solution. They are particularly suitable for growing large, uniform crystals.

- Evaporative Crystallizers: These crystallizers remove water from the solution, increasing the supersaturation and driving the crystallization process, enhancing productivity and enabling larger scale operations.

The choice of crystallizer depends heavily on the specific application and desired crystal properties. For example, a pharmaceutical company producing a drug with strict purity and morphology requirements might opt for a batch crystallizer, while a large-scale chemical manufacturer might prefer an MSMPR crystallizer for its high throughput.

Q 3. How do you determine the optimal operating parameters for a crystallization process?

Determining optimal operating parameters is crucial for efficient and high-quality crystallization. This involves a systematic approach, often combining experimental work and modeling.

- Understanding the system: Begin by thoroughly characterizing the solution’s behavior, including solubility curves and metastable zone width (discussed later). This involves carefully examining solubility curves at different temperatures and concentrations.

- Defining objectives: Specify the desired crystal size, shape, purity, and yield. Consider throughput and production costs alongside quality.

- Experimental design: Conduct carefully designed experiments to study the impact of key parameters (temperature, supersaturation, agitation rate, seeding, etc.). Use techniques such as Design of Experiments (DOE) to optimize efficiency.

- Process simulation and modeling: Employ population balance models or other computational methods to predict crystal size distribution and other outcomes based on the chosen parameters. This allows for virtual experimentation before proceeding to large-scale production.

- Process optimization: Based on experimental results and simulations, select the operating parameters that best meet the defined objectives. This may involve iterative adjustments and further experimentation to fine-tune the process.

For instance, increasing the supersaturation generally leads to faster crystallization but might also result in smaller, less uniform crystals. Careful balancing is required to achieve the desired outcomes.

Q 4. What are the common methods used to control crystal size and morphology?

Controlling crystal size and morphology is a key challenge in crystallization. Here are common methods:

- Seeding: Introducing small, pre-formed crystals (seeds) into the solution provides nucleation sites, reducing the chance of uncontrolled nucleation and promoting more uniform crystal growth. The size and quality of seeds profoundly impact the final product.

- Supersaturation control: Precise control of supersaturation (the degree of oversaturation of the solution) is crucial. Slow, controlled supersaturation increases lead to larger, more uniform crystals. Techniques include cooling, evaporation, or addition of antisolvents.

- Agitation: Appropriate mixing ensures uniform supersaturation throughout the crystallizer, preventing localized high supersaturation zones that lead to secondary nucleation and unwanted crystal growth.

- Additives: Specific additives (polymers, surfactants) can modify crystal growth kinetics and influence crystal morphology. For example, some additives prevent aggregation or promote the growth of specific crystal faces.

- Temperature control: Precise temperature profiles during the crystallization process can be used to create controlled supersaturation, leading to the desired crystal size and morphology. A classic example involves slow cooling to achieve large crystals.

The optimal strategy often involves a combination of these methods. For example, seeding with high-quality seeds, coupled with precise temperature and supersaturation control, can produce extremely uniform crystals.

Q 5. Explain the concept of metastable zone width and its significance.

The metastable zone width is the region between the solubility curve and the nucleation curve on a solubility diagram. It represents the range of supersaturation where crystals will not spontaneously nucleate. Imagine it as a ‘safe zone’ for growing crystals. Within this zone, existing crystals can grow without forming new ones.

Its significance is substantial because it dictates the achievable crystal size and uniformity. If the solution’s supersaturation exceeds the metastable zone width, uncontrolled nucleation occurs, resulting in a large number of small crystals (a phenomenon called ‘snowing’). Conversely, if the supersaturation remains within this zone, it facilitates controlled crystal growth, leading to larger, more uniform crystals.

Understanding the metastable zone width is vital for optimizing crystallization processes. Accurate determination of this zone, through experimental methods or simulations, enables better control over crystal size distribution and overall product quality.

Q 6. How do impurities affect crystallization processes?

Impurities in the solution can significantly affect the crystallization process in various ways:

- Inhibition of crystal growth: Some impurities can adsorb onto the crystal surface, hindering the attachment of solute molecules and slowing down crystal growth. This can lead to smaller crystals or irregular morphologies.

- Modification of crystal morphology: Impurities can affect the relative growth rates of different crystal faces, leading to changes in crystal shape. This can be advantageous in some cases (e.g., creating more easily filterable crystals) but detrimental in others (e.g., reducing the drug’s bioavailability).

- Formation of solid solutions or inclusion compounds: Impurities might incorporate into the crystal lattice, altering its properties, such as melting point or solubility. This often negatively impacts product quality.

- Nucleation promotion: Certain impurities act as nucleation sites, resulting in an increased number of crystals and decreased crystal size. In many cases, this is highly undesirable, affecting quality and yield.

Careful purification of the solution before crystallization is often essential to minimize the negative effects of impurities. Strategies such as filtration, ion exchange, or solvent extraction can be employed to remove or reduce impurity levels, enhancing the efficiency and quality of the crystallization process.

Q 7. Describe different types of filtration techniques and their applications.

Filtration techniques are crucial for separating crystals from the mother liquor after crystallization. The choice of technique depends on factors such as crystal size, slurry viscosity, desired purity, and production scale.

- Vacuum Filtration: This is a simple and widely used method, suitable for separating relatively large crystals from low-viscosity slurries. A vacuum is applied to pull the liquid through a filter medium, leaving the crystals behind.

- Pressure Filtration: This method uses pressure to force the liquid through the filter medium, making it suitable for slurries with higher viscosities or smaller crystals. It’s often used in industrial settings due to its higher throughput compared to vacuum filtration.

- Centrifugation: This technique utilizes centrifugal force to separate solids from liquids. It’s particularly effective for separating small crystals or those from high-viscosity slurries and offers a high throughput. However, it is often more expensive than filtration.

- Cross-flow Filtration: In this method, the slurry flows tangentially across the filter membrane, which reduces the buildup of filter cake and enhances the filtration rate. It’s particularly useful for fine particles or high-concentration slurries.

- Membrane Filtration (Microfiltration, Ultrafiltration): These methods use membranes with different pore sizes to separate solids based on their size. They are often used for fine particle separation and often used for post-processing to further purify the crystals.

The selection of the optimal filtration method involves considering the specific characteristics of the crystal slurry and the desired level of separation. For example, while vacuum filtration is suitable for a simple laboratory setup, industrial applications might necessitate pressure filtration or centrifugation for higher efficiency and throughput.

Q 8. What are the factors affecting filtration rate?

Filtration rate, essentially how quickly a liquid passes through a filter, is governed by several interconnected factors. Think of it like trying to drain a bathtub – the speed depends on the size of the drain (filter media), the pressure of the water (pressure difference), and how much gunk is clogging the drain (cake resistance and filter media resistance).

- Pressure Difference: A larger pressure difference across the filter accelerates the flow. Imagine using a stronger pump to drain that bathtub faster. This is often expressed as ΔP (delta P).

- Filter Media Resistance: The filter medium itself presents resistance to flow. A fine mesh will slow things down more than a coarse one. Think of a screen with tiny holes versus one with large holes.

- Cake Resistance: As filtration progresses, solids accumulate on the filter, forming a ‘cake’. This cake adds significant resistance, slowing the filtration rate over time. The more concentrated the solids and the finer their particles, the higher the cake resistance.

- Filter Area: A larger filter area allows more liquid to pass through simultaneously, increasing the rate. It’s like using multiple drains to empty the bathtub quicker.

- Fluid Viscosity: Thick, viscous liquids flow more slowly, reducing the filtration rate. Think honey versus water.

- Particle Size and Shape: Finer particles and irregularly shaped particles tend to create a denser, more resistant cake.

Understanding these factors is crucial for optimizing filtration processes in various industrial settings, from wastewater treatment to pharmaceutical production.

Q 9. Explain cake filtration and its advantages and disadvantages.

Cake filtration is a type of filtration where a layer of solid particles (the ‘cake’) builds up on the filter medium. This cake itself acts as an additional filtration layer. Think of it like making a coffee filter: the ground coffee forms a cake on the filter paper, which traps the finer particles.

Advantages:

- High clarity filtrate: Cake filtration is effective at removing very fine particles, resulting in a highly clarified filtrate.

- Simple design: Cake filtration systems are relatively straightforward to design and operate.

- Cost-effective for large volumes: It’s efficient for processing large quantities of slurries.

Disadvantages:

- Slow filtration rate: Cake buildup progressively slows the filtration rate, especially in the later stages.

- Cake disposal: Managing and disposing of the solid cake can be challenging and costly, depending on its properties.

- Blinding: Fine particles can clog the filter medium, reducing the filtration rate significantly.

Cake filtration is commonly used in various industries such as mining, chemical processing, and food processing, where removing a large amount of solid from a liquid stream is crucial.

Q 10. How do you select the appropriate filter media for a given application?

Selecting the right filter media is critical for effective filtration. The choice depends heavily on the specific application and the characteristics of the slurry, including the particle size, concentration, and chemical properties. It’s like choosing the right tool for a job.

Factors to consider:

- Particle size distribution: The filter media pore size should be smaller than the smallest particles to be removed. A slurry with very fine particles requires a filter with a very small pore size.

- Chemical compatibility: The filter media must be chemically inert to the slurry to prevent degradation or contamination.

- Temperature and pressure: The filter media should withstand the operating temperature and pressure of the filtration process.

- Filtrate clarity requirements: The desired clarity of the filtrate influences the choice of the filter medium. Higher clarity needs a finer filter.

- Flow rate requirements: The desired flow rate influences pore size and surface area. High flow rates might need larger pore sizes, but it compromises filtrate clarity.

- Cost: Different filter media have different costs; this needs to be balanced with other factors.

Common filter media include cellulose, polyester, nylon, ceramic, and various types of membrane filters. The selection process often involves testing different media to find the optimal balance between flow rate, clarity, and cost.

Q 11. What are the common problems encountered in filtration and how do you solve them?

Several common problems plague filtration processes. Think of them as troubleshooting a leaky faucet – you need to identify the source of the problem and find the appropriate fix.

- Clogging/Blinding: Fine particles can block the pores of the filter media, reducing the flow rate. Solution: Pre-filtration, filter aid addition, or using a filter media with larger pores.

- Cake cracking: Cracks in the filter cake can allow unfiltered liquid to bypass the cake. Solution: Optimizing the filtration parameters, using a filter aid, or employing a different filter type.

- Membrane fouling: In membrane filtration, the membrane can become fouled by the accumulation of particles. Solution: Regular cleaning or replacement of membranes, optimizing operating conditions, or using pre-treatment steps.

- Low flow rate: A low filtration rate can be due to various factors. Solution: Troubleshoot the issues mentioned above, increase the pressure difference, or increase filter area.

- Leakage: Leaks in the filtration system can lead to loss of filtrate and reduced efficiency. Solution: Proper sealing and regular inspection of the system.

Systematic troubleshooting, starting with a careful analysis of the process parameters and the nature of the feed stream, is key to resolving these problems effectively.

Q 12. Explain the concept of filter aid and its role in filtration.

Filter aids are inert, porous materials added to slurries before filtration to improve the filtration process. Imagine adding sand to a muddy puddle before straining it – the sand helps create a more permeable layer, allowing for faster drainage.

Role of filter aids:

- Increased permeability: Filter aids create a more porous cake layer, reducing cake resistance and increasing the filtration rate.

- Improved cake structure: They improve the cake’s structure, making it less prone to cracking and channeling.

- Reduced blinding: They prevent fine particles from blinding the filter media.

- Improved filtrate clarity: A well-structured cake allows for more efficient removal of smaller particles.

Common filter aids include diatomaceous earth (DE), perlite, and cellulose. The choice of filter aid depends on the specific application and the properties of the slurry. Proper selection and dosage of the filter aid is crucial for achieving optimal filtration performance.

Q 13. Describe different types of filter presses and their operating principles.

Filter presses are widely used for solid-liquid separation. They come in various designs, each with its operating principle. Think of them as different types of clamps holding a filter cloth to squeeze the liquid out of a solid.

- Plate and Frame Filter Press: This classic design consists of alternating plates and frames. The slurry is pumped into the chambers formed between the plates and frames, and the solid builds up as a cake on the filter cloth. The plates are then squeezed together to increase pressure and further dewater the cake. Simple and versatile.

- Chamber Filter Press: Similar to plate and frame, but each chamber is self-contained, allowing for higher pressure and more efficient filtration. Offers flexibility in cake thickness.

- Recessed Chamber Filter Press: The chambers are recessed into the plates, allowing for a compact design and potentially higher throughput. Economizes space.

- Membrane Filter Press: This utilizes membranes integrated into the plates to further dewater the cake by applying pressure. This achieves much drier cakes compared to the others.

The operating principles largely involve filling the chambers with slurry, allowing cake formation, applying pressure, and finally opening the press to remove the cake. The choice depends on factors like slurry properties, desired cake dryness, and capacity needs.

Q 14. How do you scale up a crystallization process from lab to production scale?

Scaling up crystallization from lab to production is a complex process requiring careful consideration of various factors. It’s not simply increasing the batch size; it’s about maintaining consistent product quality and efficiency.

Key steps:

- Solubility Data: Accurate solubility data over a wide range of temperatures and concentrations is essential. This informs the design of the larger system.

- Crystallization Kinetics: Understanding nucleation and growth rates at the lab scale helps predict and control these processes at larger scales. Changes in mixing or heat transfer might affect this greatly.

- Heat and Mass Transfer: Scaling up often involves changes in heat and mass transfer rates. Larger vessels might have less efficient mixing, requiring adjustments to achieve the same level of supersaturation.

- Mixing and Agitation: Adequate mixing is vital to prevent local supersaturation and achieve uniform crystal size distribution. Scale-up must maintain similar mixing patterns.

- Crystal Size Distribution (CSD): Maintaining a desired CSD across scales is crucial for downstream processing (filtration, drying, etc.). This requires precise control of supersaturation and residence time.

- Process Control and Instrumentation: Robust process control systems with appropriate instrumentation are essential for monitoring and controlling the crystallization process at larger scales. This helps maintain consistency despite fluctuations.

Computational Fluid Dynamics (CFD) modeling can be invaluable in predicting and optimizing the process at larger scales. Pilot plant trials are also often necessary to validate the scale-up before committing to a full-scale production facility. This stepwise approach, with meticulous attention to detail, minimizes risks and ensures a successful scale-up.

Q 15. What are the common methods for analyzing crystal size distribution?

Analyzing crystal size distribution (CSD) is crucial for understanding and controlling crystallization processes. It impacts product quality, downstream processing, and overall yield. We use several methods, each with its strengths and weaknesses:

Microscopy: This is a direct method, offering visual information about crystal shape and size. We can use optical microscopy for larger crystals or electron microscopy for smaller ones. Image analysis software then quantifies the size distribution from the captured images. Think of it like carefully examining a sample under a powerful magnifying glass to count and measure individual crystals. This is great for visual confirmation but can be time-consuming and may not be statistically representative of the entire batch.

Sieving: A simple and rapid technique suitable for larger crystals. Crystals are passed through a series of sieves with progressively smaller mesh sizes. The weight retained on each sieve gives us the size fraction. It’s like sorting grains of sand by using sieves with different sized holes. This is a low-cost method but doesn’t give a precise size distribution for smaller crystals and can damage fragile ones.

Laser Diffraction: This technique uses a laser beam to measure the scattering of light by the crystals. The scattering pattern is analyzed to determine the CSD. It’s a fast, non-destructive method suitable for a wide range of crystal sizes. Imagine shining a laser pointer on the crystals – how the light bends tells us about their size. It’s widely used in industry due to its speed and accuracy.

Image Analysis: Advanced image analysis software can process large numbers of microscopic images, generating detailed and statistically robust CSD data quickly and efficiently. It’s the modern and accurate way to analyse large samples

Career Expert Tips:

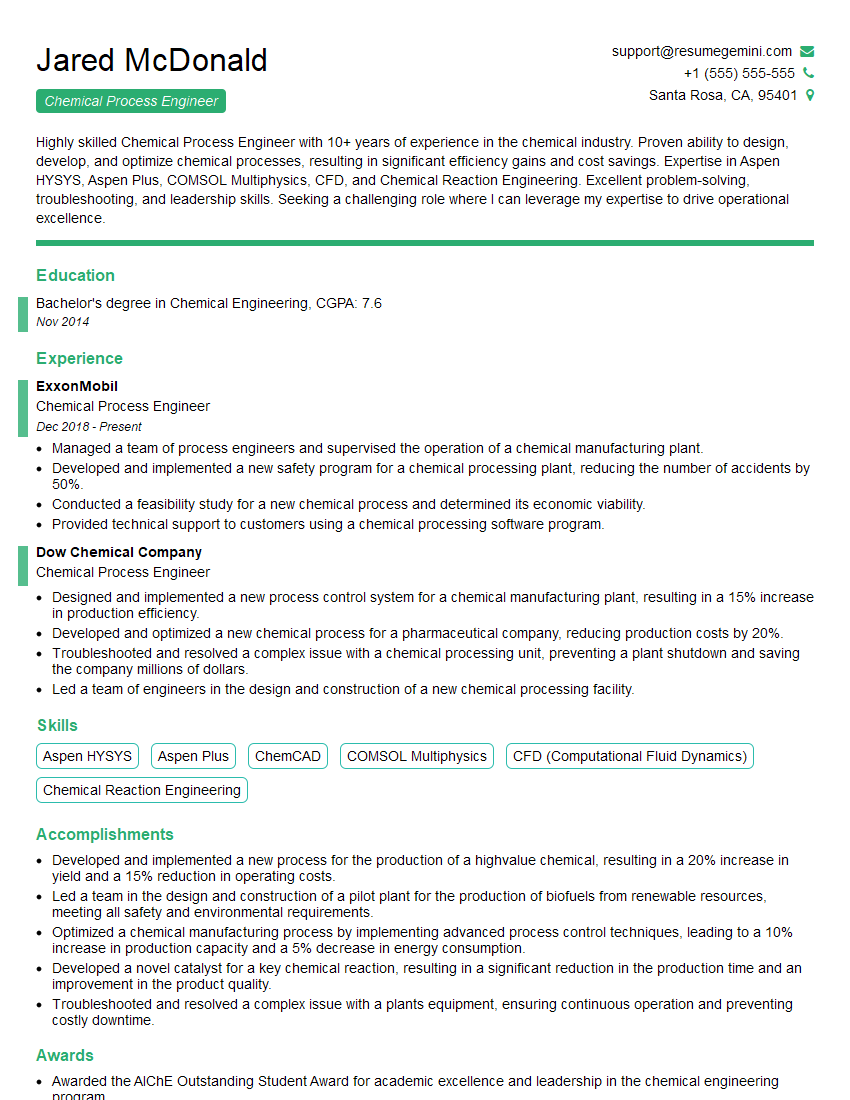

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of solid-liquid separation in chemical processes.

Solid-liquid separation is a cornerstone of many chemical processes, particularly those involving crystallization. It’s the process of separating solid crystals from the liquid solution (mother liquor). Its importance stems from several factors:

Product Purification: The solid crystals often contain impurities. Separation allows for the isolation of the purified product.

Yield Improvement: Efficient separation maximizes the recovery of the desired product from the reaction mixture.

Waste Management: Separation facilitates the disposal or recycling of the mother liquor, reducing waste and environmental impact.

Downstream Processing: Separated solids are ready for subsequent processing steps such as drying, milling, or packaging, while the liquid can be recycled or treated.

Process Optimization: By effectively removing solid products, you allow the remaining process steps to work efficiently and avoid interference.

For example, in the pharmaceutical industry, separating the crystallized drug from the solution is crucial for obtaining a pure and potent medicine. Inefficient separation can lead to lower drug efficacy or even harmful impurities.

Q 17. What are the different types of centrifugal filters and their applications?

Centrifugal filters utilize centrifugal force to accelerate the separation of solids from liquids. Several types exist:

Batch Centrifuges: These process batches of slurry sequentially. They are simple to operate and versatile but have lower throughput compared to continuous units. Think of a washing machine spinning clothes – the water (liquid) is separated from the clothes (solids).

Continuous Centrifuges: These process slurries continuously, offering high throughput. Subtypes include decanter centrifuges (for high-solids slurries), scroll centrifuges (for fine solids), and pusher centrifuges (for high-capacity separation).

Disc Stack Centrifuges: These have a stack of conical discs that increase the surface area for separation. They’re efficient for fine solids and high-speed separation. Imagine a stack of cones spinning rapidly, forcing the solid to collect on the outer edge. These are extremely effective for clarifying liquids.

Applications: Centrifugal filtration finds use in diverse industries, including pharmaceuticals (purification of drug crystals), chemicals (separation of reaction products), food processing (clarification of juices), and wastewater treatment (removal of suspended solids).

Q 18. How do you optimize a filtration process for maximum yield and efficiency?

Optimizing a filtration process for maximum yield and efficiency requires a multi-faceted approach:

Filter Media Selection: Choose a filter medium with appropriate pore size, permeability, and chemical compatibility for the specific slurry.

Pre-filtration: Removing large particles upstream reduces filter clogging, extending its lifespan and enhancing throughput.

Pressure Optimization: Increased pressure increases filtration rate but can damage the filter medium. Finding the optimal pressure is crucial.

Filter Aid: Adding filter aids (e.g., diatomaceous earth) to the slurry can enhance the filter cake’s permeability, improving filtration rate and yield.

Cake Washing: Washing the filter cake with a suitable solvent removes residual impurities, improving product purity.

Process Monitoring and Control: Real-time monitoring of pressure drop, flow rate, and filtrate clarity allows for prompt adjustments to maintain optimal performance.

Example: In a pharmaceutical setting, optimizing filtration might involve using a specific filter aid to prevent clogging during the purification of a drug crystal, maximizing the recovery of the active pharmaceutical ingredient. Poor filtration could lead to a significant loss of the valuable product and increased production costs.

Q 19. What are the safety considerations for operating crystallization and filtration equipment?

Safety is paramount when operating crystallization and filtration equipment. Key considerations include:

Rotating Equipment: Centrifuges and other rotating equipment present significant risks due to high speeds and potentially unbalanced loads. Lockout/Tagout procedures are critical before maintenance or repairs.

Pressure Vessels: Crystallizers and filter vessels often operate under pressure. Regular inspection and pressure testing are necessary to prevent leaks or explosions.

Hazardous Materials: Many crystallization and filtration processes involve handling hazardous chemicals. Proper personal protective equipment (PPE) must be used, and appropriate ventilation and spill control measures must be in place.

Heat Transfer Equipment: Crystallization often involves heating and cooling. Appropriate safeguards against burns and scalding are necessary.

Electrical Hazards: Proper grounding and electrical safety measures must be followed to prevent electrical shock.

Noise Control: High-speed equipment generates significant noise. Engineering controls or hearing protection may be required to mitigate noise hazards.

Example: In a chemical plant, failing to use appropriate PPE during the operation of a centrifuge could lead to exposure to hazardous chemicals or injury from rotating parts. A thorough safety assessment and adherence to strict operating procedures are indispensable.

Q 20. Explain the concept of mother liquor and its role in crystallization.

Mother liquor is the saturated solution remaining after crystallization is complete. It’s the liquid phase from which the crystals have precipitated. Its role is multifaceted:

Impurity Retention: The mother liquor often contains impurities that did not incorporate into the crystal lattice during the crystallization process.

Crystal Washing: The mother liquor can be used to wash the crystals, removing impurities and improving product purity.

Crystal Growth: The mother liquor can still support crystal growth under appropriate conditions, sometimes used to optimize the final crystal size.

Recycling: The mother liquor can be recycled back into the crystallization process, reducing solvent waste and material costs.

The composition and properties of the mother liquor significantly influence crystal size, purity, and yield. Controlling its parameters is key to optimizing the crystallization process.

Q 21. How do you troubleshoot a clogged filter?

Troubleshooting a clogged filter requires a systematic approach:

Identify the Cause: Determine the cause of the clog. Is it due to excessive solids loading, inadequate filter media, filter cake compaction, or the presence of sticky or gelatinous materials?

Increase Pressure (Carefully): If possible, cautiously increase the filtration pressure to overcome minor clogs. However, excessive pressure can damage the filter medium.

Backwashing: Reverse the flow of filtrate to dislodge the cake. This works effectively for certain filter types but may not always be possible.

Chemical Cleaning: If backwashing fails, consider using a suitable solvent to dissolve or break down the clogging material. Carefully choose a solvent compatible with both the filter medium and the product to avoid damage.

Mechanical Cleaning: If all else fails, the filter may need mechanical cleaning using compressed air, water jets, or other mechanical tools. This should only be done by trained personnel to prevent damage or injury.

Filter Replacement: In some cases, a severely clogged filter may require replacement.

Example: A clogged filter in a juice processing plant could be caused by pectin in the fruit juice. Using a specific enzyme to break down the pectin before filtration could prevent clogging and improve efficiency. If simple methods fail then filter replacement might be the only solution.

Q 22. Describe the different types of membrane filtration and their applications.

Membrane filtration is a separation technique that uses semi-permeable membranes to separate components based on size and/or charge. Several types exist, each with specific applications:

- Microfiltration (MF): Removes particles larger than 0.1-10 µm. Common applications include clarification of liquids, pretreatment for other membrane processes, and removal of bacteria from pharmaceutical solutions. Think of it like a very fine sieve.

- Ultrafiltration (UF): Separates particles and macromolecules in the range of 0.01-0.1 µm. This is frequently used in the biotechnology industry to concentrate proteins or remove contaminants from bioreactor effluent. Imagine it as a finer sieve, capable of removing even smaller particles.

- Nanofiltration (NF): Rejects dissolved multivalent ions and larger organic molecules (sizes down to 0.001 µm). Used extensively in water treatment to remove hardness, color, and pesticides; also valuable in food and beverage processing.

- Reverse Osmosis (RO): The most stringent, removing dissolved salts and small organic molecules (below 0.001 µm). It’s widely employed in desalination and high-purity water production for pharmaceuticals or electronics manufacturing; it’s like squeezing water through an extremely tight membrane.

The choice of membrane type depends on the specific application and the desired level of separation. For instance, while MF might be sufficient for clarifying a juice, RO is necessary for producing sterile, pyrogen-free water for injection.

Q 23. What are the advantages and disadvantages of using vacuum filtration?

Vacuum filtration is a widely used technique to separate solids from liquids using pressure difference. Think of it as a faster, more efficient way of draining water from pasta.

- Advantages: Relatively inexpensive equipment, simple operation, suitable for large volumes, efficient solid-liquid separation for many applications, often easily scalable.

- Disadvantages: Can be slow for fine particles, cake formation can clog the filter, potential for uneven cake formation leading to channeling (and thus reduced separation efficiency), not suitable for high-viscosity fluids.

For example, in a pharmaceutical setting, vacuum filtration is ideal for isolating a crystalline product after a crystallization step. However, if the crystals are very fine or the slurry is highly viscous, other techniques might be more suitable.

Q 24. How do you validate a crystallization or filtration process?

Validating a crystallization or filtration process ensures it consistently delivers the desired product quality and meets regulatory requirements. This usually involves a combination of approaches:

- Process Characterization: Defining critical process parameters (CPPs) like temperature, concentration, and agitation rate, and critical quality attributes (CQAs) such as crystal size, shape, and purity.

- Design of Experiments (DOE): Systematic experimentation to assess the impact of CPPs on CQAs. This helps to establish a robust process window.

- Analytical Method Validation: Verifying that the methods used to measure CQAs are accurate, precise, and reliable.

- Process Performance Qualification (PPQ): Demonstrating that the process consistently performs within the defined specifications under real-world conditions.

- Documentation: Meticulous record-keeping throughout the validation process, including all experimental data, analysis results, and deviations.

For example, in validating a crystallization process, we might use DOE to optimize cooling rates to achieve a desired crystal size distribution. Then, PPQ would confirm that the optimized process consistently produces crystals meeting the required specifications in multiple batches.

Q 25. Describe your experience with process analytical technology (PAT) in crystallization.

Process Analytical Technology (PAT) significantly enhances crystallization control by providing real-time data on critical process parameters and quality attributes during the process. My experience involves using tools like:

- In-line Particle Size Analyzers: Provide continuous measurements of particle size distribution, allowing for adjustments to prevent undesirable crystal growth or aggregation.

- Spectroscopy (e.g., Raman, NIR): Offers real-time monitoring of concentration and polymorph formation, enabling early detection of process deviations.

- Image Analysis: Provides detailed information on crystal shape and morphology, allowing for adjustments to achieve desired product attributes.

For example, in a recent project, using in-line Raman spectroscopy allowed us to identify the formation of an unwanted polymorph early in the crystallization process. This enabled us to adjust the process parameters (like temperature) and avoid a complete batch failure. The result was increased yield and a reduction in production costs.

Q 26. Explain different techniques for characterizing crystals (e.g., microscopy, XRD).

Crystal characterization is crucial to ensure product quality and consistency. Various techniques are employed:

- Microscopy (Optical, SEM, etc.): Provides visual information about crystal size, shape, and morphology. Optical microscopy is great for quick assessments, while SEM offers higher resolution for detailed morphological analysis.

- Powder X-ray Diffraction (XRD): Identifies crystalline phases (polymorphs) and assesses crystallinity. This is essential for confirming the desired crystalline form and detecting impurities.

- Differential Scanning Calorimetry (DSC): Measures the heat flow associated with phase transitions (melting, etc.), giving information about purity and polymorphism.

- Dynamic Light Scattering (DLS): Determines particle size distribution in solution, useful for characterizing the early stages of crystallization.

Combining different techniques provides a comprehensive understanding of the crystal structure and properties. For instance, XRD identifies the polymorph while microscopy visualizes the crystal habit, providing a complete picture.

Q 27. How do you handle crystallization problems such as scaling and fouling?

Scaling and fouling are common crystallization problems, significantly affecting process efficiency and product quality. Here’s how I approach them:

- Scaling: This refers to the deposition of crystals on the equipment surfaces. Solutions involve optimizing process parameters (like supersaturation, temperature, and agitation), using anti-scalants, or employing surface modifications.

- Fouling: A more general term for the accumulation of unwanted materials on surfaces. It’s often tackled by using prefiltration steps to remove impurities, optimizing cleaning procedures, or modifying the equipment design.

For example, in a case of scaling, we might reduce supersaturation by controlling the cooling rate or using a seed crystal addition strategy. If that’s not sufficient, we might incorporate an anti-scalant to inhibit crystal growth on the equipment surfaces. For fouling, we might implement a more robust cleaning-in-place (CIP) system. A careful analysis of the root cause of scaling or fouling is crucial for finding the best solution.

Key Topics to Learn for Crystallization and Filtration Techniques Interview

- Nucleation and Crystal Growth: Understanding the mechanisms driving crystal formation, including factors influencing crystal size and morphology. Consider the theoretical models and their practical implications in process optimization.

- Crystallization Processes: Explore different crystallization techniques (e.g., cooling, evaporation, anti-solvent) and their suitability for various applications. Be prepared to discuss process parameters and their effects on product quality.

- Crystal Habit Modification: Discuss techniques used to control crystal shape and size distribution, and their impact on downstream processing, such as filtration and drying.

- Filtration Mechanisms: Understand the principles behind different filtration methods (e.g., pressure filtration, vacuum filtration, centrifugation). Be able to compare their efficiency and suitability for various solids and liquids.

- Filter Media Selection: Discuss the factors influencing the choice of filter media (e.g., pore size, material compatibility, flow rate). Consider the trade-offs between filtration efficiency and cost.

- Filtration Optimization: Explore strategies for improving filtration efficiency, including pre-treatment of the feed stream and optimization of filter parameters.

- Scale-up and Process Design: Discuss the challenges and strategies involved in scaling up crystallization and filtration processes from laboratory to industrial scale. Be ready to discuss considerations like equipment selection and process control.

- Troubleshooting and Problem Solving: Be prepared to discuss common problems encountered in crystallization and filtration processes (e.g., fouling, cake formation, low yield) and strategies for troubleshooting.

- Quality Control and Characterization: Understand techniques for analyzing crystal size distribution, purity, and morphology. Discuss the importance of these analyses in ensuring product quality.

- Safety and Environmental Considerations: Discuss the importance of safety protocols and environmental impact assessment in crystallization and filtration processes.

Next Steps

Mastering Crystallization and Filtration Techniques is crucial for career advancement in many scientific and engineering fields. A strong understanding of these techniques demonstrates valuable problem-solving skills and practical expertise highly sought after by employers. To maximize your job prospects, creating a compelling and ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume that showcases your skills and experience effectively. Examples of resumes tailored to Crystallization and Filtration Techniques are available to help you craft your own compelling application materials.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.