The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Water Treatment and Discharge interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Water Treatment and Discharge Interview

Q 1. Describe the different stages of a conventional water treatment process.

A conventional water treatment process typically involves several stages to transform raw water into safe, potable water. Think of it as a multi-step cleaning process, each stage refining the water further. These stages are not always present in every plant, and the specifics vary based on the source water quality and treatment goals.

- Intake and Pre-treatment: Raw water is collected from a source (river, lake, reservoir) and often undergoes preliminary treatments like screening (removing large debris) and aeration (removing dissolved gases).

- Coagulation and Flocculation: Chemicals are added to destabilize suspended particles, causing them to clump together into larger flocs (explained further in the next question).

- Sedimentation: The heavier flocs settle out of the water under gravity in large basins called clarifiers. This process removes a significant portion of the suspended solids.

- Filtration: Water passes through filters (sand, gravel, or membrane filters) that remove the remaining suspended solids and some dissolved impurities. (More detail on filtration types in question 3).

- Disinfection: A disinfectant like chlorine, chloramine, ozone, or UV light is added to kill harmful microorganisms such as bacteria and viruses. (More detail in question 4).

- Storage and Distribution: Treated water is stored in reservoirs and then distributed through a network of pipes to consumers.

Q 2. Explain the principles of coagulation, flocculation, and sedimentation.

Coagulation, flocculation, and sedimentation are crucial steps in water treatment aimed at removing suspended solids. Imagine stirring a muddy glass of water; these processes work similarly to clarify it.

- Coagulation: This involves adding a coagulant, often aluminum sulfate (alum) or ferric chloride, to the water. These chemicals neutralize the electrical charges on the suspended particles, reducing their repulsive forces and allowing them to come together.

- Flocculation: Gentle mixing after coagulation promotes the formation of larger aggregates, called flocs, from the smaller destabilized particles. Think of it like slowly stirring the muddy water to clump the sediment together. This is often achieved using mechanical flocculators.

- Sedimentation: Once flocs are formed, they are heavy enough to settle out of the water under the influence of gravity in sedimentation basins. This leaves a clearer water layer on top, ready for further treatment. The settled solids, or sludge, are removed from the bottom of the basin.

For example, imagine treating river water with high turbidity (cloudiness). Adding alum during coagulation neutralizes the charges of clay particles, allowing them to clump together during flocculation. These larger flocs then settle quickly in the sedimentation basin, leaving the water clearer for subsequent filtration.

Q 3. What are the common types of filtration used in water treatment?

Several filtration methods are used in water treatment, each with its own strengths and weaknesses, depending on the water quality and treatment goals.

- Rapid Sand Filtration: The most common type, where water flows through a bed of sand and gravel. This removes suspended solids and some microorganisms.

- Slow Sand Filtration: A more natural process using a shallower sand bed and relying on biological processes within the filter to remove contaminants. It produces very high-quality water but is slower than rapid sand filtration.

- Diatomaceous Earth Filtration: Uses a filter medium made from diatoms (microscopic algae fossils), providing a very fine filtration capable of removing very small particles.

- Membrane Filtration: Uses specialized membranes (microfiltration, ultrafiltration, nanofiltration, reverse osmosis) with progressively smaller pore sizes to remove a wider range of contaminants, including dissolved solids and bacteria.

For instance, a municipal water treatment plant might use rapid sand filtration as a primary filtration method, followed by membrane filtration to further remove pathogens before disinfection. A smaller facility might rely solely on slow sand filtration for its simpler operation and excellent water quality.

Q 4. How does disinfection work, and what are the different methods used?

Disinfection is the final crucial step in water treatment, aimed at eliminating harmful microorganisms that can cause waterborne diseases. The goal is to inactivate or kill bacteria, viruses, and protozoa.

- Chlorination: The most widely used method, using chlorine gas or hypochlorite solutions to disinfect water. Chlorine is a powerful oxidizing agent that kills microorganisms.

- Chloramination: Combining chlorine with ammonia creates chloramine, a longer-lasting disinfectant that provides residual disinfection in the distribution system.

- Ozonation: Using ozone, a powerful oxidizing agent that is effective in inactivating microorganisms and removing taste and odor compounds. However, it leaves no residual disinfection, requiring another disinfectant as a secondary measure.

- Ultraviolet (UV) Disinfection: Exposing water to UV light damages the DNA of microorganisms, preventing their reproduction and effectively inactivating them. UV disinfection does not leave a residual effect and is often used in conjunction with other methods.

For example, a large city water treatment plant might use chlorination as the primary disinfection method, supplemented by chloramination to maintain disinfection throughout the distribution network. Smaller facilities might opt for UV disinfection combined with another method for added safety.

Q 5. What are the key parameters monitored in water quality control?

Water quality control involves the regular monitoring of various parameters to ensure water safety and meet regulatory standards. These parameters provide a snapshot of water’s overall health and suitability for intended use.

- pH: Measures acidity or alkalinity, influencing the effectiveness of other treatment processes.

- Turbidity: Measures water cloudiness, indicating the presence of suspended solids.

- Temperature: Affects microbial growth and the efficiency of some treatment processes.

- Dissolved Oxygen (DO): Important for aquatic life and influences the efficiency of some biological treatment processes.

- Total Dissolved Solids (TDS): Indicates the amount of dissolved minerals and salts.

- Total Suspended Solids (TSS): Measures the amount of suspended particles in the water (more detail in question 6).

- Biochemical Oxygen Demand (BOD): A measure of the amount of oxygen needed by microorganisms to break down organic matter (more detail in question 6).

- Coliform bacteria: Indicates fecal contamination and potential presence of pathogens.

- Disinfectant residual: Ensures sufficient disinfectant remains to protect against microbial regrowth.

Regular monitoring using automated sensors and laboratory testing ensures treated water meets quality standards.

Q 6. Explain the significance of Total Suspended Solids (TSS) and Biochemical Oxygen Demand (BOD).

Total Suspended Solids (TSS) and Biochemical Oxygen Demand (BOD) are two critical indicators of water quality, particularly relevant in wastewater treatment.

- Total Suspended Solids (TSS): This refers to the total amount of solid material suspended in the water that can be removed by filtration. High TSS indicates pollution, reducing water clarity and affecting aquatic life. Think of the muddiness of a river – high TSS. It’s measured by filtering a water sample and weighing the remaining solids.

- Biochemical Oxygen Demand (BOD): This measures the amount of oxygen consumed by microorganisms as they decompose organic matter in the water. High BOD indicates significant organic pollution, which can deplete oxygen levels in water bodies, harming aquatic life. Think of decaying leaves in a stream – high BOD.

For example, industrial wastewater often has high TSS and BOD values due to the presence of suspended solids and organic pollutants. Effective wastewater treatment aims to reduce these parameters to acceptable levels before discharge.

Q 7. What are the different types of wastewater treatment processes?

Wastewater treatment processes vary in complexity depending on the source and desired level of treatment. The goal is to remove pollutants and render wastewater safe for discharge or reuse.

- Primary Treatment: Physical processes like screening, sedimentation, and grit removal remove large solids and some suspended matter.

- Secondary Treatment: Biological processes using microorganisms break down organic matter in wastewater, significantly reducing BOD and TSS. Common methods include activated sludge and trickling filters.

- Tertiary Treatment: Advanced treatments like filtration, disinfection, and nutrient removal (nitrogen and phosphorus) are used to further improve wastewater quality for reuse or discharge to sensitive environments. This might involve membrane filtration, advanced oxidation processes, or wetland systems.

- Anaerobic Digestion: A biological process used to treat sludge (solids removed during primary and secondary treatment). It produces biogas, a renewable energy source.

Municipal wastewater treatment plants typically employ a combination of primary, secondary, and sometimes tertiary treatment, while industrial wastewater treatment might require specialized processes tailored to the specific pollutants generated.

Q 8. Describe the activated sludge process in detail.

The activated sludge process is a widely used secondary wastewater treatment method that utilizes microorganisms to break down organic matter. Imagine a miniature ecosystem within a tank! It works by aerating a mixture of wastewater and microorganisms (activated sludge), allowing the microbes to consume organic pollutants.

Here’s a breakdown:

- Wastewater Influent: Wastewater enters the aeration tank.

- Aeration: Oxygen is pumped into the tank, promoting aerobic microbial growth. These microbes consume organic matter, converting it into carbon dioxide, water, and new microbial biomass.

- Clarification: The mixture flows into a clarifier, where the activated sludge (containing the microbes) settles at the bottom. Think of it like letting sediment settle in a glass of water.

- Sludge Return: A portion of the settled sludge is recycled back to the aeration tank to maintain a high concentration of active microbes. This is crucial for efficient treatment.

- Effluent Discharge: The clarified water (effluent) is then discharged after disinfection.

- Excess Sludge: The remaining settled sludge (excess sludge) is removed for further processing (sludge digestion or dewatering).

The activated sludge process is highly effective at reducing BOD (Biochemical Oxygen Demand) and COD (Chemical Oxygen Demand), indicators of organic pollution. Different variations exist, such as extended aeration processes or modifications to optimize nutrient removal (nitrogen and phosphorus).

Q 9. What are the roles of primary, secondary, and tertiary wastewater treatment?

Wastewater treatment typically involves three stages: primary, secondary, and tertiary. Each stage plays a vital role in cleaning the wastewater before it’s safely discharged.

- Primary Treatment: This is the initial physical process that removes large solids and grit. Imagine a sieve filtering out larger debris. Techniques include screening, grit removal, and sedimentation. This step reduces the total suspended solids (TSS) but doesn’t significantly reduce dissolved organic matter.

- Secondary Treatment: This is where the biological treatment takes place, primarily using microorganisms to break down organic matter. The activated sludge process described earlier is a common secondary treatment method. This stage significantly reduces BOD and COD, improving water quality.

- Tertiary Treatment: This is an advanced treatment stage aimed at polishing the effluent from secondary treatment to achieve a higher level of purity. Processes can include filtration, disinfection, nutrient removal (nitrogen and phosphorus), and advanced oxidation processes. Tertiary treatment is often necessary to meet stringent discharge requirements, especially for sensitive receiving waters like lakes or rivers.

Think of it like cleaning a house: primary treatment is like sweeping and removing large trash, secondary treatment is like mopping and disinfecting, and tertiary treatment is like polishing the floors and furniture for a spotless finish.

Q 10. Explain the importance of sludge management in wastewater treatment.

Sludge management is a critical aspect of wastewater treatment. The sludge produced during the treatment process contains a significant amount of organic matter, pathogens, and nutrients. Improper management can lead to environmental pollution and public health risks.

Effective sludge management involves several steps:

- Thickening: Reducing the water content in the sludge to make it easier to handle and transport.

- Digestion: Breaking down organic matter using anaerobic or aerobic processes to stabilize the sludge and reduce its volume.

- Dewatering: Further reducing the water content to produce a cake-like solid that can be disposed of or reused.

- Disposal or Reuse: Sludge can be disposed of in landfills, incinerated, or used as a soil amendment (biosolids) in agriculture after proper treatment.

Careful sludge management is essential for minimizing environmental impact, complying with regulations, and potentially recovering valuable resources from the waste stream.

Q 11. What are the common methods for wastewater disinfection?

Disinfection is the final step in wastewater treatment, aimed at eliminating harmful pathogens before discharge. Several methods are commonly employed:

- Chlorination: Using chlorine gas or hypochlorite to kill bacteria and viruses. It’s a cost-effective and widely used method but can produce disinfection byproducts (DBPs) which may be harmful.

- UV Disinfection: Using ultraviolet light to damage the DNA of pathogens, rendering them inactive. This method is environmentally friendly and doesn’t produce DBPs, but it’s less effective against some resistant organisms.

- Ozone Disinfection: Using ozone gas, a powerful oxidant, to kill pathogens. Ozone is effective and doesn’t produce persistent DBPs, but it requires specialized equipment and is more expensive.

The choice of disinfection method depends on factors such as effluent quality, regulatory requirements, cost, and environmental considerations.

Q 12. What are the key regulations governing water discharge?

Regulations governing water discharge vary significantly depending on the location and the type of discharge. However, some common elements include:

- Water Quality Standards: These define acceptable limits for various pollutants in discharged water. Examples include limits on BOD, COD, TSS, nutrients, and specific toxic substances.

- Effluent Limitations: These specify the maximum amount of pollutants that can be discharged from a specific facility. They are often based on technology-based standards or water quality-based standards.

- Monitoring and Reporting Requirements: Facilities are typically required to monitor their discharges regularly and submit reports to the regulatory agency, documenting compliance.

- Permitting Processes: Most jurisdictions require permits before a facility can discharge wastewater. The permit specifies the allowed discharge limits and other conditions.

Failing to comply with these regulations can result in significant penalties, including fines and legal action.

Q 13. Describe the Clean Water Act and its implications for wastewater treatment.

The Clean Water Act (CWA) is a landmark piece of US environmental legislation that aims to restore and maintain the chemical, physical, and biological integrity of the nation’s waters. It sets national goals for water quality and establishes a regulatory framework for controlling pollution from various sources, including wastewater discharges.

Implications for wastewater treatment:

- National Pollutant Discharge Elimination System (NPDES): The CWA established the NPDES permit program, which requires industrial and municipal facilities to obtain permits before discharging wastewater. Permits specify discharge limits and other conditions to protect water quality.

- Water Quality Standards: The CWA requires states to set water quality standards for their waters, which provide the basis for developing effluent limitations.

- Enforcement Provisions: The CWA empowers regulatory agencies to enforce compliance, including imposing penalties for violations.

The CWA has been instrumental in improving water quality in the US, though challenges remain in addressing certain types of pollution and ensuring compliance across all sectors.

Q 14. How do you ensure compliance with water discharge permits?

Ensuring compliance with water discharge permits requires a comprehensive and proactive approach:

- Regular Monitoring: Conduct frequent monitoring of wastewater effluent to ensure that discharge limits are met. This includes testing for various parameters specified in the permit.

- Proper Operation and Maintenance: Ensure that wastewater treatment facilities are operated and maintained effectively. Regular inspections, equipment upgrades, and operator training are crucial.

- Record Keeping: Maintain detailed records of monitoring data, facility operations, and maintenance activities. These records are essential for demonstrating compliance and responding to any regulatory inquiries.

- Reporting: Submit regular reports to the regulatory agency, providing monitoring data and other relevant information. Meet all reporting deadlines and ensure accuracy.

- Contingency Planning: Develop plans to address unexpected events that could affect wastewater treatment operations and potentially lead to permit violations.

- Continuous Improvement: Strive to continuously improve the efficiency and effectiveness of the wastewater treatment process to minimize environmental impact and ensure compliance.

Proactive compliance is not just about avoiding penalties; it’s about protecting the environment and safeguarding public health. A strong commitment to compliance builds trust with regulators and the community.

Q 15. What are the common effluent parameters that need to be monitored?

Monitoring effluent parameters is crucial for ensuring treated wastewater meets regulatory standards and doesn’t harm the receiving environment. Common parameters include:

- pH: Measures acidity or alkalinity. A balanced pH is essential for aquatic life.

- Dissolved Oxygen (DO): Indicates the amount of oxygen available in the water. Low DO levels can suffocate aquatic organisms.

- Biochemical Oxygen Demand (BOD): Measures the amount of oxygen consumed by microorganisms while decomposing organic matter. High BOD indicates pollution from organic waste.

- Chemical Oxygen Demand (COD): Measures the total amount of oxygen required to oxidize organic and inorganic matter. Provides a broader picture than BOD.

- Total Suspended Solids (TSS): Represents the amount of solid particles suspended in the water. High TSS can cloud the water and harm aquatic life.

- Turbidity: Measures the clarity of the water. High turbidity indicates suspended solids.

- Nutrients (Nitrogen and Phosphorus): Excess nutrients can lead to eutrophication, causing algal blooms and oxygen depletion.

- Specific Pollutants: Depending on the source of wastewater, specific pollutants like heavy metals (e.g., lead, mercury), pesticides, or pharmaceuticals might need to be monitored.

- Temperature: Elevated temperatures can reduce dissolved oxygen and harm aquatic life.

- Fecal Coliforms/E. coli: Indicate the presence of fecal contamination and potential health risks.

Regular monitoring of these parameters helps maintain compliance, identify potential problems early, and optimize treatment processes.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is the difference between point source and non-point source pollution?

Point source and non-point source pollution differ significantly in their origin and how they enter the water system. Think of it like this: a point source is like a single tap dripping into a lake, whereas non-point source pollution is like rain washing pollutants from a large area into the lake.

- Point Source Pollution: This refers to pollution originating from a single, identifiable source. Examples include:

- Industrial discharge pipes

- Municipal wastewater treatment plant outfalls

- Stormwater outfalls from specific locations

- Non-Point Source Pollution: This type of pollution comes from multiple, diffuse sources and is difficult to pinpoint. Examples include:

- Agricultural runoff (fertilizers, pesticides)

- Urban runoff (oil, grease, litter)

- Atmospheric deposition (acid rain)

- Erosion from construction sites

The difference is key for regulatory purposes and pollution control strategies. Point sources are easier to regulate and monitor, often requiring permits and discharge limits. Controlling non-point source pollution requires broader approaches like land management practices, erosion control, and public awareness campaigns.

Q 17. Explain the concept of water reuse and its benefits.

Water reuse, also known as water reclamation, involves treating wastewater to a level suitable for beneficial purposes beyond its traditional discharge into the environment. This is becoming increasingly important due to growing water scarcity and environmental concerns.

Benefits of water reuse include:

- Reduced strain on freshwater resources: Recycled water can supplement freshwater supplies for irrigation, industrial processes, or even toilet flushing.

- Environmental protection: Less freshwater is withdrawn from rivers and aquifers, protecting these vital resources. It also reduces the environmental impact of wastewater discharge.

- Cost savings: Reuse can be more cost-effective than solely relying on freshwater sources, particularly in water-stressed regions.

- Improved water security: Diversification of water sources enhances overall water security and resilience to droughts or other water shortages.

Examples of water reuse include:

- Agricultural irrigation: Treated wastewater is used to irrigate crops, reducing the demand for freshwater.

- Industrial processes: Recycled water is used in cooling towers or other industrial applications.

- Toilet flushing and landscape watering: Highly treated wastewater can be used for non-potable purposes.

Careful planning and treatment are crucial to ensure the reused water is safe for its intended purpose and does not pose health or environmental risks.

Q 18. What are some emerging technologies in water treatment?

The field of water treatment is constantly evolving, with several emerging technologies offering improved efficiency, sustainability, and cost-effectiveness.

- Membrane technologies (forward osmosis, nanofiltration): These advanced membrane processes offer enhanced removal of contaminants and greater energy efficiency compared to traditional methods.

- Advanced oxidation processes (AOPs): Using powerful oxidants like ozone or UV radiation to break down pollutants, AOPs are particularly effective for treating complex organic compounds.

- Electrocoagulation: This electrochemical process uses electrodes to generate coagulants, improving coagulation and flocculation efficiencies.

- Bioaugmentation: Enhancing the microbial community in wastewater treatment systems to improve treatment effectiveness for specific pollutants.

- Artificial intelligence (AI) and machine learning (ML): AI and ML are being integrated into water treatment operations for real-time monitoring, predictive maintenance, and process optimization.

- Solar disinfection (SODIS): A simple, low-cost method using sunlight to disinfect water, particularly useful in developing countries.

These emerging technologies offer significant potential for improving water quality and addressing the challenges of water scarcity and pollution.

Q 19. How do you troubleshoot common problems in water treatment plants?

Troubleshooting water treatment plant problems requires a systematic approach. Here’s a framework I use:

- Identify the problem: Start by pinpointing the specific issue. Is it related to effluent quality, process efficiency, or equipment malfunction? Use monitoring data and observations to narrow down the possibilities.

- Analyze the data: Review historical data on effluent parameters, process variables (e.g., flow rates, chemical dosages), and equipment performance. Look for trends or anomalies.

- Check equipment: Inspect pumps, filters, membranes, and other equipment for signs of wear, damage, or malfunction. Maintenance logs can be invaluable.

- Investigate process variables: Assess whether the process parameters (e.g., pH, DO, chemical dosages) are within the optimal range. Adjustments may be needed.

- Consider external factors: Changes in influent quality, weather conditions, or other external factors can affect plant performance.

- Implement corrective actions: Based on the analysis, take appropriate actions. This could involve equipment repair, process adjustments, or chemical adjustments.

- Monitor and evaluate: After implementing corrections, monitor the system closely to evaluate the effectiveness of the changes.

Example: If TSS is consistently high, I might first check the performance of the clarifier, then the effectiveness of the coagulant dosage, and finally consider whether influent quality has changed.

Q 20. Describe your experience with SCADA systems in water treatment.

I have extensive experience with SCADA (Supervisory Control and Data Acquisition) systems in water treatment. SCADA systems are the backbone of modern water treatment plants, providing real-time monitoring, control, and data management.

My experience includes:

- System design and implementation: I’ve participated in projects involving the selection, installation, and configuration of SCADA systems, ensuring they meet the specific needs of the water treatment plant.

- Data acquisition and analysis: I’m proficient in using SCADA systems to acquire and analyze data from various sensors and instruments, identifying trends and potential problems.

- Process control and automation: I have experience programming and configuring SCADA systems to automate various plant processes, such as chemical dosing, valve operation, and pump control.

- Alarm management and response: I’ve developed and implemented strategies for managing alarms generated by the SCADA system, ensuring prompt and effective responses to critical events.

- Data reporting and visualization: I’m skilled in generating reports and creating dashboards to visualize key performance indicators (KPIs) and track plant performance.

SCADA systems are essential for optimizing plant operations, ensuring regulatory compliance, and managing emergency situations.

Q 21. How do you handle emergency situations in a water treatment plant?

Handling emergency situations in a water treatment plant requires a well-defined emergency response plan and a calm, decisive approach. The plan should include procedures for various scenarios, such as power outages, equipment failures, chemical spills, or extreme weather events.

My approach to handling emergencies includes:

- Activate the emergency response plan: Immediately initiate the predetermined procedures for the specific emergency.

- Assess the situation: Quickly determine the extent of the problem and potential risks.

- Isolate the affected area: If possible, isolate the affected section of the plant to prevent further damage or contamination.

- Notify relevant personnel: Inform all necessary personnel, including plant operators, maintenance staff, regulatory agencies, and emergency services as needed.

- Implement corrective actions: Take immediate actions to mitigate the emergency, based on the established procedures.

- Document everything: Maintain a detailed record of the incident, including the cause, actions taken, and outcomes. This is essential for future analysis and improvement.

- Post-incident review: Following the resolution of the emergency, conduct a thorough review to identify areas for improvement in the emergency response plan and plant operations.

Regular emergency drills and training are vital to ensuring the effectiveness of the emergency response plan and the preparedness of the plant personnel.

Q 22. What are your skills in maintaining and troubleshooting water treatment equipment?

Maintaining and troubleshooting water treatment equipment requires a multifaceted approach encompassing preventative maintenance, diagnostic skills, and problem-solving abilities. My expertise spans various equipment types, including:

- Filtration systems: I’m proficient in inspecting and maintaining sand filters, multimedia filters, and membrane filtration systems (microfiltration, ultrafiltration, reverse osmosis). This includes tasks like backwashing, media replacement, membrane cleaning, and troubleshooting pressure drops or flow rate issues.

- Disinfection systems: I’m experienced with UV disinfection, chlorination (including gas and liquid feed systems), and ozonation, encompassing routine checks, chemical feed adjustments, lamp replacement (UV), and troubleshooting issues related to disinfection efficacy. For example, I’ve successfully diagnosed and fixed a chlorine leak in a gas chlorination system by isolating the section, replacing a faulty valve, and verifying proper operation after repair.

- Chemical feed systems: My skills extend to maintaining and troubleshooting various chemical feed pumps, including adjusting flow rates, ensuring proper chemical mixing and preventing clogging. I understand the importance of precise chemical dosage for optimal treatment and compliance with regulations.

- Instrumentation and control systems: I am adept at interpreting data from various sensors (pressure, flow, turbidity, pH, chlorine residual) and troubleshooting issues with programmable logic controllers (PLCs) and other automated systems. I can use data analysis to identify trends and predict potential failures.

My approach to troubleshooting involves systematic diagnosis – identifying the symptoms, isolating the problem, and implementing corrective actions, always prioritizing safety and regulatory compliance. For instance, if a filter shows unexpectedly high pressure, I systematically investigate backwash effectiveness, check for media fouling, and examine the filter’s structural integrity before deciding on a solution.

Q 23. How do you ensure the safety of personnel working in a water treatment plant?

Ensuring personnel safety in a water treatment plant is paramount. My approach focuses on a multi-layered strategy combining preventative measures, training, and emergency response planning:

- Safety Training: Comprehensive training programs covering hazard identification (chemical exposure, confined space entry, electrical hazards, etc.), safe work practices, emergency procedures (chemical spills, equipment failure), and the proper use of personal protective equipment (PPE) are essential. I ensure all staff are properly trained and certified.

- Lockout/Tagout Procedures: Stringent lockout/tagout (LOTO) procedures are strictly enforced during maintenance or repair of equipment to prevent accidental startup and injuries. Regular audits ensure compliance.

- Personal Protective Equipment (PPE): Providing and enforcing the use of appropriate PPE, including gloves, respirators, safety glasses, and protective clothing, based on the specific hazards encountered in different tasks, is crucial. I ensure the availability and proper maintenance of PPE.

- Emergency Response Plan: A detailed emergency response plan, including procedures for chemical spills, equipment malfunctions, and medical emergencies, must be developed, regularly reviewed, and practiced through drills. This plan includes contact information for emergency services and designated personnel.

- Regular Inspections and Maintenance: Regular inspections of equipment and facilities, along with preventative maintenance programs, minimize the risk of accidents. I would be involved in creating and enforcing these programs.

Safety is not just a program; it’s a culture. I believe in fostering a safety-conscious work environment where employees feel empowered to report hazards and participate actively in safety improvements.

Q 24. Explain your understanding of water chemistry and its importance in treatment.

Water chemistry is the foundation of effective water treatment. It involves understanding the physical and chemical properties of water, including its pH, alkalinity, hardness, dissolved oxygen, and the presence of various contaminants (heavy metals, organic matter, pathogens).

Importance in Treatment:

- Optimizing Treatment Processes: Understanding water chemistry allows us to select and optimize appropriate treatment processes. For example, the pH of the water significantly impacts the effectiveness of coagulation and disinfection. Adjusting pH to an optimal range ensures maximum removal of suspended solids and effective disinfection.

- Chemical Dosing: Accurate chemical dosing is crucial for effective treatment. Water chemistry parameters dictate the amount and type of chemicals needed for coagulation, flocculation, disinfection, and pH adjustment. Incorrect dosing can lead to ineffective treatment or even adverse effects.

- Predicting and Preventing Problems: Monitoring water chemistry parameters helps to predict and prevent potential problems. For example, changes in alkalinity can signal changes in source water quality or potential equipment malfunction.

- Ensuring Discharge Compliance: Understanding water chemistry is essential for ensuring that treated wastewater meets discharge permit requirements. Regular monitoring and adjustment ensure compliance with effluent standards.

A thorough understanding of water chemistry principles, coupled with experience in analyzing and interpreting water quality data, is vital for efficient and effective water treatment management. It allows for proactive management to prevent problems and ensure consistent, high-quality treated water.

Q 25. How do you interpret water quality test results?

Interpreting water quality test results requires a systematic approach. I begin by reviewing the full range of parameters tested, including physical, chemical, and biological indicators:

- Physical Parameters: Turbidity, temperature, color, odor, and taste provide insights into the overall quality and potential sources of contamination.

- Chemical Parameters: pH, alkalinity, hardness, dissolved solids, specific ions (e.g., chloride, sulfate, nitrate), and the presence of metals (e.g., lead, arsenic, iron) provide information on the chemical composition and potential health risks.

- Biological Parameters: Presence and concentration of bacteria, viruses, and other microorganisms indicate biological contamination and the potential need for disinfection. Total coliform and E.coli counts are significant indicators of fecal contamination.

Interpretation Process:

- Compare to Standards: First, I compare the results against established standards and regulations (e.g., drinking water standards, wastewater discharge permits). This identifies any parameters exceeding limits.

- Identify Trends: I then analyze trends in the data over time to identify patterns and potential problems. A sudden increase in turbidity, for example, might suggest equipment failure or a change in source water quality.

- Correlate Parameters: Correlation between different parameters helps in diagnosis. For instance, high turbidity often correlates with high levels of suspended solids. High iron levels may correlate with low pH values.

- Identify Sources of Contamination: Based on the pattern of exceeding standards, I identify the most likely sources of contamination (industrial discharge, agricultural runoff, etc.).

Through careful interpretation, we can take corrective actions, optimize treatment processes, and ensure the treated water meets the required standards.

Q 26. Describe your experience with different types of water treatment chemicals.

My experience encompasses a wide range of water treatment chemicals, each with its specific application and properties:

- Coagulants: Aluminum sulfate (alum) and ferric chloride are commonly used to destabilize suspended solids, facilitating their removal through sedimentation or filtration. I understand the impact of dosage and pH on their effectiveness.

- Flocculants: Polymeric flocculants enhance the aggregation of destabilized particles, improving sedimentation and filtration efficiency. The selection of flocculant depends on water characteristics and the desired outcome.

- Disinfectants: Chlorine (gas and liquid), chlorine dioxide, and ozone are commonly used disinfectants to kill harmful microorganisms. I am experienced in handling, dosing, and monitoring the effectiveness of each. I’m also familiar with the use of UV disinfection.

- pH Adjusters: Lime (calcium hydroxide) and sulfuric acid are used to adjust the pH of the water to optimal levels for various treatment processes. Precise dosing is essential to avoid undesirable effects.

- Corrosion Inhibitors: Phosphate-based and other corrosion inhibitors are sometimes used to protect water distribution systems from corrosion. I’m experienced in selecting the appropriate inhibitor based on the system’s materials.

Understanding the properties and handling requirements of each chemical, along with safe handling and storage practices, is critical for effective and safe water treatment. I always ensure strict adherence to safety protocols during chemical handling and storage.

Q 27. How familiar are you with different types of water meters and their applications?

I am familiar with a variety of water meters and their applications, each offering specific advantages based on the measurement requirements:

- Electromagnetic Flow Meters: These meters measure flow rate by detecting the voltage induced by the movement of conductive water through a magnetic field. They are suitable for large pipes and require minimal pressure drop, making them ideal for main lines.

- Ultrasonic Flow Meters: These meters use sound waves to measure flow velocity. They offer non-invasive measurement and are suitable for various pipe materials and sizes. They are less susceptible to wear and tear.

- Turbine Flow Meters: These meters contain a rotating turbine that spins proportionally to flow rate. They are accurate and reliable for a wide range of flow rates but may be sensitive to debris.

- Positive Displacement Meters: These meters measure flow by precisely capturing and counting discrete volumes of water. They are highly accurate for small flows but have a higher pressure drop than some other meter types.

- Venturi Meters: These meters measure flow based on the pressure difference caused by a constriction in the pipe. They are relatively simple and reliable but require a significant pressure drop.

The choice of water meter depends on factors like accuracy requirements, flow range, pipe size, fluid characteristics (e.g., temperature, viscosity), and pressure limitations. My selection criteria prioritize the most suitable type for the specific application and ensures accurate flow monitoring.

Q 28. Describe a challenging situation you faced in water treatment and how you solved it.

During a period of heavy rainfall, our plant experienced a significant surge in influent turbidity, exceeding the capacity of our existing coagulation-filtration system. This resulted in a noticeable decline in treated water quality, threatening to violate our discharge permit.

Problem-Solving Approach:

- Immediate Action: I immediately initiated emergency procedures, including temporarily reducing the plant’s treatment capacity to manage the influx of turbid water. We also implemented enhanced monitoring of all parameters to accurately assess the extent of the problem.

- Root Cause Analysis: We analyzed historical rainfall data and influent characteristics to understand the causes of the increased turbidity. The analysis showed that runoff from a nearby construction site significantly contributed to the increase in suspended solids.

- Solution Implementation: Short-term solutions included deploying additional coagulants and adjusting the treatment process to optimize coagulation and sedimentation efficiency. A long-term solution involved collaborating with the construction site managers to implement erosion control measures to mitigate future turbidity surges.

- Monitoring and Evaluation: Following the implementation of the solutions, we continuously monitored the influent and effluent quality. The measures were successful in bringing the turbidity levels to within permissible limits.

This experience highlighted the importance of thorough planning for extreme weather events and the need for robust emergency response protocols. It also emphasized the benefit of collaborating with stakeholders external to the water treatment plant to manage potential sources of water quality issues.

Key Topics to Learn for Water Treatment and Discharge Interview

- Water Quality Parameters: Understanding key indicators like pH, turbidity, dissolved oxygen, and various chemical constituents. Knowing how these parameters impact treatment processes and discharge compliance.

- Treatment Processes: Familiarize yourself with common treatment methods including coagulation/flocculation, sedimentation, filtration (various types), disinfection (chlorination, UV, ozone), and advanced oxidation processes. Be prepared to discuss the advantages and disadvantages of each.

- Unit Operations and Process Control: Understand the practical aspects of operating water treatment plants, including process monitoring, instrumentation, and control systems. Be ready to discuss troubleshooting and optimization strategies.

- Discharge Regulations and Compliance: Thorough knowledge of environmental regulations (e.g., NPDES permits) and effluent discharge standards is crucial. Understanding permit requirements and reporting procedures is essential.

- Wastewater Treatment Fundamentals: Even if the focus is on potable water, understanding basic wastewater treatment principles is beneficial, particularly regarding pretreatment and industrial wastewater considerations.

- Membrane Technology: Explore the role of membrane filtration (microfiltration, ultrafiltration, reverse osmosis) in water treatment and purification processes.

- Water Chemistry and Balancing: A strong understanding of chemical reactions and equilibrium principles as they apply to water treatment.

- Problem-Solving and Troubleshooting: Prepare to discuss your approach to identifying and resolving issues in water treatment and discharge systems. Be ready to provide examples from your experience.

Next Steps

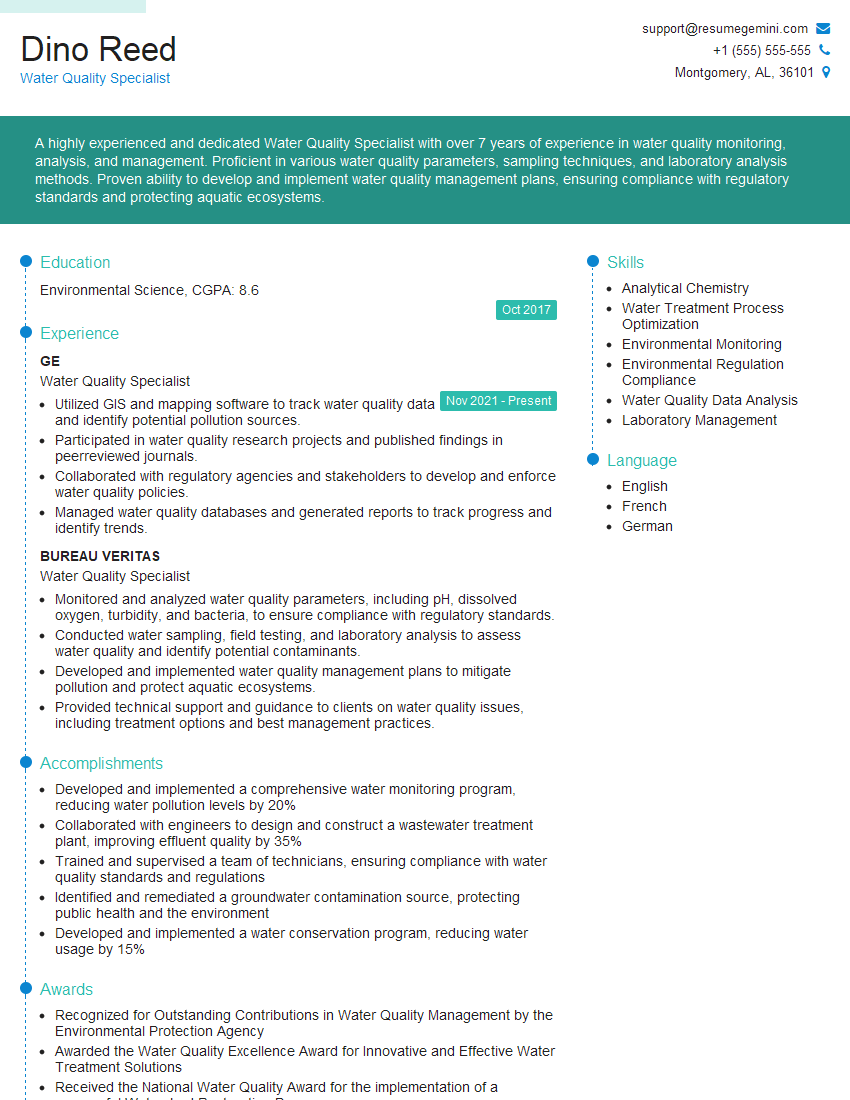

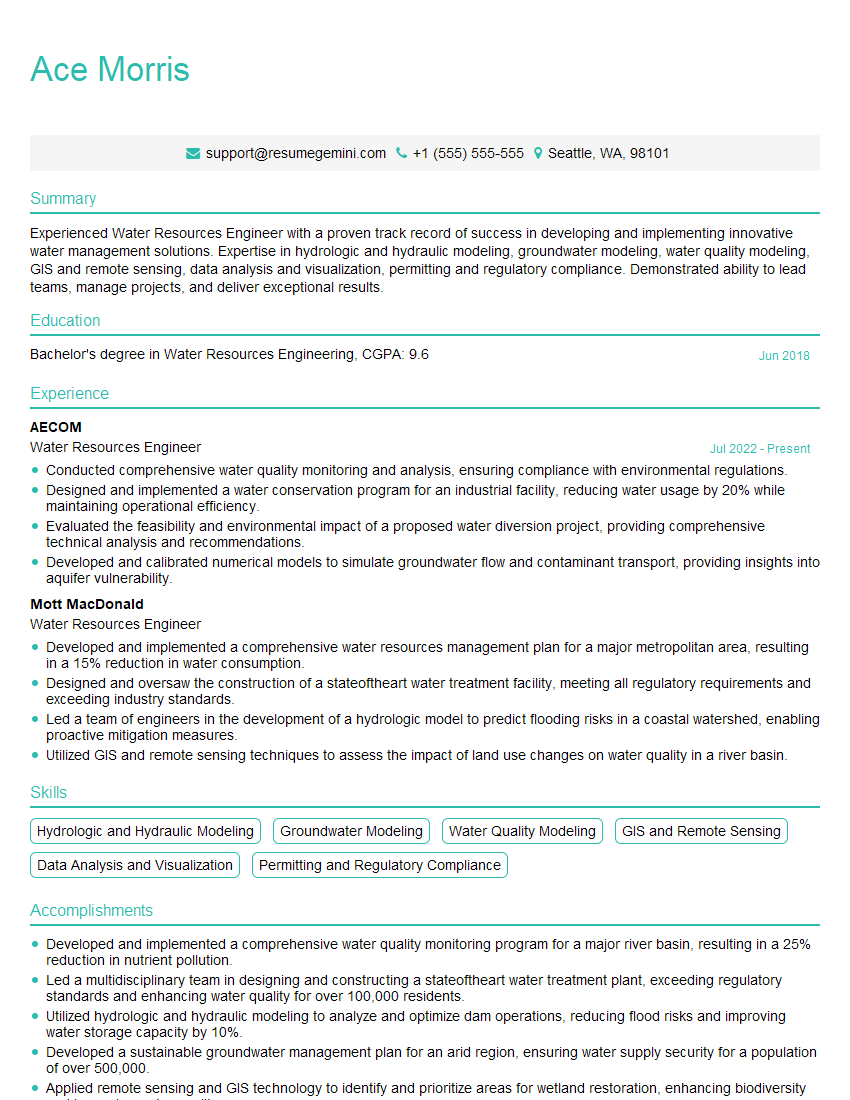

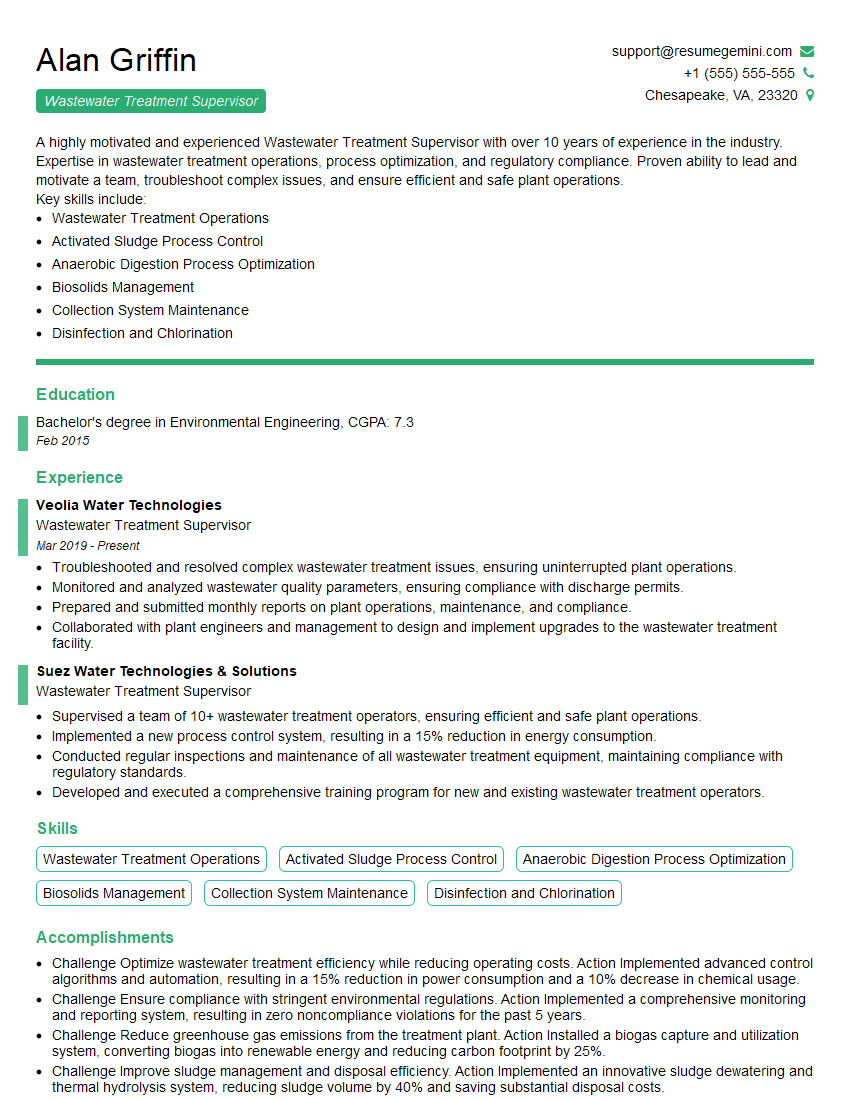

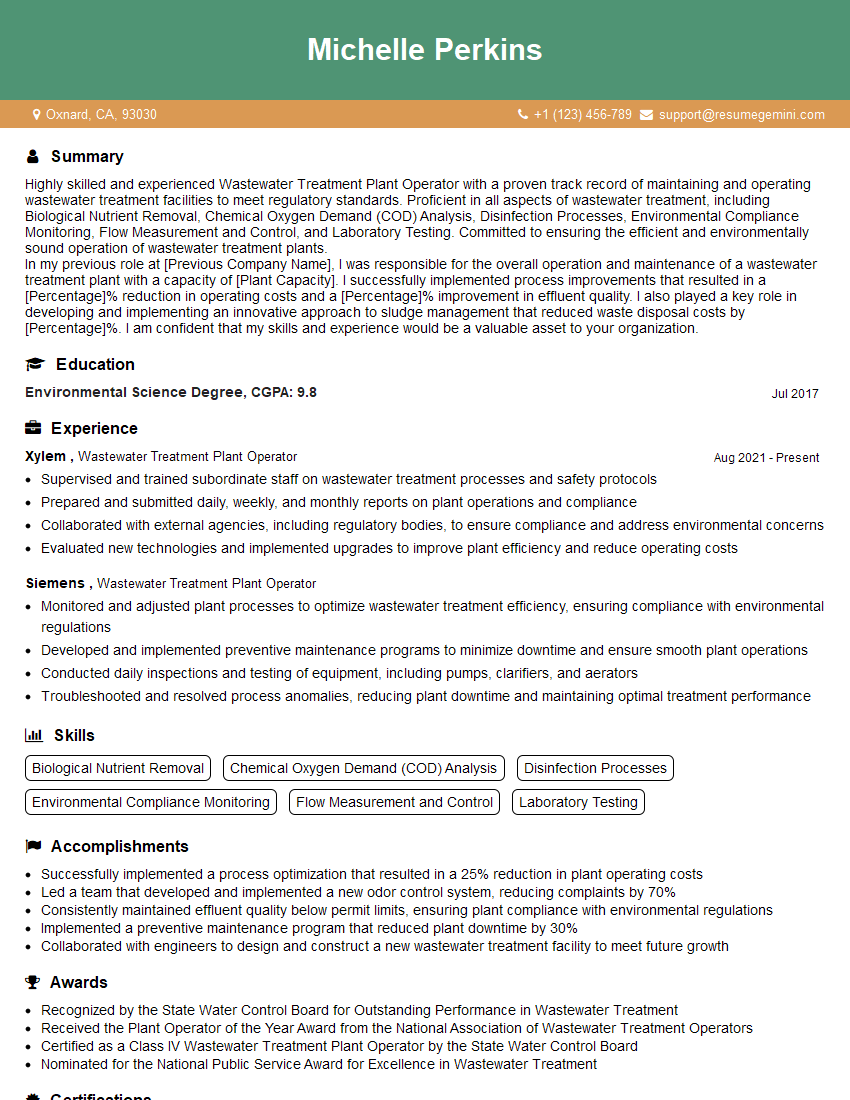

Mastering Water Treatment and Discharge principles is vital for advancing your career in this essential field. A strong understanding of these concepts will significantly improve your interview performance and open doors to exciting opportunities. To maximize your job prospects, creating a well-structured, ATS-friendly resume is paramount. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your skills and experience. We provide examples of resumes specifically designed for the Water Treatment and Discharge sector to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.