Unlock your full potential by mastering the most common Enphase IQ Installer interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Enphase IQ Installer Interview

Q 1. Describe the Enphase IQ system architecture.

The Enphase IQ system architecture is a decentralized, microinverter-based system. Unlike traditional string inverters, each solar panel has its own microinverter, converting DC power from the panel to AC power independently. These microinverters communicate wirelessly with the Enphase Envoy, a communication gateway that sends data to the Enphase Enlighten monitoring platform. Think of it like this: each solar panel is its own little power plant, managed individually. This contrasts with a centralized string inverter system where a single point of failure can impact the whole system.

The Envoy acts as the central hub, collecting data from all the microinverters and transmitting it to the cloud. This data is then accessible through the Enlighten platform, allowing installers and homeowners to monitor system performance, diagnose problems, and receive alerts. The system’s decentralized nature makes it highly reliable and efficient.

Q 2. Explain the function of Enphase microinverters.

Enphase microinverters are the heart of the Enphase IQ system. Their primary function is to convert the DC electricity generated by a single solar panel into AC electricity suitable for use in your home. This conversion happens individually for each panel. Beyond just conversion, they perform crucial monitoring and optimization tasks. They constantly monitor the panel’s performance, adjusting to maximize energy production and detecting any issues, such as shading or panel faults. This individual monitoring allows the system to continue functioning even if one panel or microinverter has a problem—the rest of the system keeps working!

Think of them as tiny, intelligent power transformers, each dedicated to a single solar panel. They improve system efficiency, protect panels, and provide granular data for monitoring.

Q 3. How do you troubleshoot communication errors within an Enphase IQ system?

Troubleshooting communication errors in an Enphase IQ system involves a systematic approach. First, check the physical connections of the microinverters and the Envoy. Loose wiring or damaged cables are common culprits. Verify that the Envoy has a stable internet connection, either through Ethernet or cellular. The Enlighten platform often provides diagnostic information pinpointing the problem area.

Next, check for signal interference. Certain materials or devices could be disrupting the wireless communication. If you find a specific microinverter isn’t communicating, start by power-cycling it (turning it off and on). Inspect the microinverter for any error codes displayed on its LED lights. Enphase provides detailed documentation on these codes. Finally, if the issue persists, contact Enphase support or a qualified installer. A systematic approach from the physical to the software level typically helps quickly isolate the source of the communication problem.

Q 4. What are the key benefits of using Enphase microinverters compared to string inverters?

Enphase microinverters offer several key advantages over traditional string inverters. The most significant is their enhanced reliability. With a string inverter, a single faulty panel or a shaded section can bring down the entire string. However, with microinverters, each panel operates independently, ensuring the rest of the system continues to function even if one panel or microinverter malfunctions. This reduces system downtime and maximizes energy production.

- Improved efficiency: Microinverters optimize the energy production of each panel individually, resulting in higher overall system efficiency, especially in partially shaded conditions.

- Enhanced safety: Microinverters operate at low DC voltage, reducing the risk of electrical shocks.

- Granular monitoring: Individual performance data for each panel allows for precise diagnostics and troubleshooting.

- Easier installation on complex roofs: Microinverters offer flexibility in panel placement, which is beneficial for rooftops with varying angles or shading conditions.

Essentially, microinverters provide a more resilient, efficient, and safer solar energy system.

Q 5. Explain the process of commissioning an Enphase IQ system.

Commissioning an Enphase IQ system is a crucial step to ensure optimal performance. It involves verifying all system components are correctly installed and functioning. This begins with confirming that all microinverters are communicating with the Envoy. You’ll use the Enlighten platform to check the system status and identify any errors or warnings. Inspect all wiring connections, ensuring they’re secure and properly grounded. Then, you’ll check individual panel production using the Enlighten platform or by inspecting the microinverter’s LED indicators.

Next, verify the Envoy’s connection to the internet and its proper registration in the Enlighten platform. This allows for remote monitoring and data logging. Finally, review all the system’s production data for any anomalies. The commissioning process often includes a thorough visual inspection of the entire array to ensure proper orientation and absence of any physical damage. Proper commissioning ensures long-term system reliability and optimizes energy harvesting.

Q 6. How do you monitor the performance of an Enphase IQ system?

Monitoring the performance of an Enphase IQ system is straightforward thanks to the Enphase Enlighten monitoring platform. This web-based platform provides a comprehensive overview of the system’s performance, including energy production, individual panel performance, and system efficiency. You can monitor daily, monthly, and annual energy generation and identify any underperforming panels.

Enlighten also provides alerts for potential issues, such as low production or communication errors. This enables proactive maintenance and prevents potential problems from escalating. You can generate reports to track energy consumption and identify areas for improvement. Think of Enlighten as a dashboard providing real-time insights into your solar system’s health and productivity.

Q 7. Describe the different types of Enphase IQ system components.

Enphase IQ systems consist of several key components working together seamlessly. The core components include:

- Microinverters: These are the individual inverters attached to each solar panel, converting DC to AC power.

- Enphase Envoy: This communication gateway collects data from the microinverters and transmits it to the Enlighten monitoring platform. It provides the crucial link between the solar panels and the cloud.

- Solar Panels: These are the photovoltaic panels that capture sunlight and convert it into DC electricity.

- Mounting System: This secures the solar panels to the roof.

- Wiring and Connectors: These are used to connect the components together.

- Enlighten Monitoring Platform: This web-based platform allows you to monitor system performance, receive alerts, and generate reports.

Each component plays a vital role in the system’s overall efficiency and reliability. Understanding the role of each helps with both installation and troubleshooting.

Q 8. How do you handle a situation where a single microinverter is malfunctioning?

Troubleshooting a malfunctioning Enphase microinverter begins with identifying the problem. The Enphase Enlighten monitoring platform is invaluable here. It provides real-time data on each microinverter’s performance, including voltage, current, and power output. A malfunctioning unit will often show significantly reduced or zero power production, or display an error code.

My first step is to verify the problem isn’t something simple like a shading issue. Sometimes a leaf, bird droppings, or even snow can temporarily block sunlight. I’ll visually inspect the panel and the microinverter connections. If the issue persists, I’ll check the microinverter’s LED indicators for error codes. These codes, detailed in the Enphase IQ Installer troubleshooting guide, pinpoint the specific problem.

For example, a flashing red light might indicate a communication error or a fault within the microinverter itself. Based on the error code, I’ll then follow Enphase’s recommended troubleshooting steps, often involving checking wiring connections, ensuring proper grounding, and confirming the microinverter is properly communicating with the Envoy. If the problem persists, replacing the faulty microinverter is usually necessary. This is a straightforward process; I simply disconnect the faulty unit, ensuring the system is safely de-energized, and connect the replacement. Finally, I’ll verify the system’s functionality and confirm the new microinverter is reporting correctly on Enlighten.

Q 9. Explain the role of the Envoy in an Enphase IQ system.

The Envoy is the central communication hub in an Enphase IQ system. Think of it as the brain that connects all the microinverters to the internet, allowing you to monitor system performance and production data remotely. Each microinverter communicates its individual performance data wirelessly to the Envoy. The Envoy then transmits this aggregated data to the Enphase Enlighten cloud platform.

Beyond data communication, the Envoy also plays a crucial role in system monitoring and diagnostics. It detects faults and error conditions within the system, notifying installers or owners of potential problems through Enlighten. It’s essential for monitoring production, identifying potential issues early, and ensuring the system operates optimally. It essentially translates the individual conversations of hundreds of microinverters into a coherent report for us to analyze.

Q 10. How do you interpret the data presented on the Enphase Enlighten monitoring platform?

Enphase Enlighten provides a wealth of information. I start by reviewing the overall system production, comparing it to historical data and expected production based on weather conditions. Significant drops in energy production are immediately flagged for investigation.

Then, I drill down to the individual panel and microinverter level. I look for any microinverters reporting low or zero production, paying close attention to any error codes reported. Enlighten presents this data in easy-to-understand graphs and charts. For example, a production graph might show a sudden drop in output, which, when coupled with individual microinverter data, can point to a shading problem or a faulty component.

Furthermore, Enlighten allows for detailed analysis of system performance over time. We can identify trends like seasonal variations or the impact of weather events on production. This data is invaluable for both system optimization and troubleshooting. Let’s say a client notices declining production, Enlighten can pinpoint the problem. Maybe the panels are accumulating more dirt and grime, or there’s a gradual degradation of the system. This data allows for proactive maintenance.

Q 11. Describe the safety precautions you take while working with Enphase IQ systems.

Safety is paramount when working with any electrical system, and Enphase IQ systems are no exception. My safety protocols always start with a thorough site assessment. This includes checking for any potential hazards, like overhead power lines or underground utilities.

Before starting any work, I always disconnect the system from the grid using the appropriate disconnect switches. I use personal protective equipment (PPE), including insulated gloves and eye protection. I also ensure my tools are properly insulated. I adhere to all relevant electrical codes and regulations. Furthermore, I regularly check my equipment for any damage or wear and tear. Regular training on the latest safety procedures is critical, particularly since technology in this field is ever-evolving.

When troubleshooting, I use non-contact voltage detectors to verify that the system is de-energized before touching any components. Once the work is complete, I perform thorough visual inspections to ensure all connections are secure and that no damage has occurred. Detailed documentation of all work performed is vital for compliance and future reference. We don’t cut corners here – safety comes first.

Q 12. What are the common causes of production losses in an Enphase IQ system?

Production losses in Enphase IQ systems can stem from various sources. One common culprit is shading. Even partial shading of a single solar panel can significantly impact the overall system output because Enphase systems are string-less. Another common issue is soiling—dirt, bird droppings, snow, or leaves accumulating on the panels can reduce their efficiency.

Faulty microinverters are another potential source of production loss, either through complete failure or reduced performance. Improper installation, such as loose connections or grounding issues, can also cause problems. Finally, environmental factors like temperature extremes can impact overall energy production. Heat can decrease efficiency, and intense cold can temporarily reduce the output. Therefore, regular monitoring and maintenance, leveraging the Enlighten platform, are key to identifying and addressing these issues promptly.

Q 13. How do you address issues related to grid interconnection compliance with Enphase IQ systems?

Grid interconnection compliance is critical. Enphase IQ systems must meet all the requirements set by the local utility company and regulatory bodies. These requirements often involve specific safety standards, anti-islanding protection, and compliance with specific voltage and frequency parameters.

Before connecting an Enphase IQ system to the grid, I always ensure that the system is designed and installed according to the utility’s interconnection agreement. This agreement will typically outline the specific requirements that must be met. Enphase provides resources and tools to help meet these requirements, such as the system’s anti-islanding capabilities and compliance testing reports. I ensure these are properly documented and submitted to the utility for approval. Furthermore, I ensure the system is properly grounded and the wiring meets all applicable codes.

Post-installation, I often work with the utility to perform the final interconnection testing and obtain the necessary permits. This process usually involves submitting system data and undergoing inspection to verify everything is up to code and compliant. This ensures the safety of both the client’s system and the broader power grid.

Q 14. Explain the process of upgrading the firmware on Enphase microinverters.

Upgrading microinverter firmware is a straightforward process, typically done remotely through the Enlighten platform. Enphase regularly releases firmware updates to improve performance, add new features, or address any bugs.

The process usually involves selecting the microinverters or the entire system that needs an update within the Enlighten platform. Once selected, I initiate the update process. Enlighten will then automatically push the new firmware to the microinverters. The process is generally seamless and requires minimal intervention. I monitor the progress through Enlighten. Once the process is complete, Enlighten will confirm the successful upgrade. It’s important to note that during an update, system performance might be briefly affected, and it’s crucial to avoid any maintenance or disconnections during the upgrade process.

In rare cases, where remote updating fails, a manual firmware update might be necessary, which usually involves using a special tool to connect directly to the microinverter and upload the firmware. However, this is uncommon, and Enphase’s remote update process is typically very reliable and efficient. Following Enphase’s guidelines ensures a successful and safe firmware update every time.

Q 15. How do you diagnose and resolve issues related to AC output from Enphase microinverters?

Diagnosing AC output issues from Enphase microinverters begins with using the Enphase Enlighten monitoring platform. This provides real-time data on each microinverter’s performance, showing AC output in watts. If a microinverter shows zero or significantly reduced output, the troubleshooting process involves a systematic approach.

- Check the Enlighten platform for error codes: Each microinverter reports its status, and error codes pinpoint the problem. For instance, a common error might indicate a mismatch between the panel and microinverter or a shading issue.

- Visual inspection: Examine the microinverter, its connections, and the associated solar panel for any visible damage, loose connections, or signs of overheating. Look for burn marks, loose wires, or anything out of the ordinary.

- Verify connections: Carefully check all wiring connections—from the solar panel to the microinverter and from the microinverter to the combiner box. Loose or corroded connections are common culprits. Ensure proper torque on all connectors.

- Test the solar panel: If a microinverter isn’t producing power, test the connected solar panel with a multimeter to ensure it’s generating voltage. A faulty panel could be the root cause.

- Inspect the combiner box: Ensure all connections within the combiner box are secure and functioning correctly. Check for any signs of overheating or damage.

- Check for shading: Even partial shading can significantly reduce the output of a microinverter. Carefully examine the panel for any obstructions that might be casting shadows, especially during peak sunlight hours. Consider using microinverter optimization software to analyze shade effects.

Resolving the issue involves correcting the identified problem. This might include replacing a faulty microinverter, repairing or replacing a damaged solar panel, tightening loose connections, addressing shading issues, or resolving any grounding problems. Always ensure to disconnect the system from the grid and utilize proper lockout/tagout procedures before working on any live electrical components.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different Enphase IQ system configurations.

My experience encompasses a wide range of Enphase IQ system configurations, from small residential installations to larger commercial projects. I’ve worked with systems utilizing different numbers of microinverters, various panel types and sizes, and different grid interconnection schemes. This includes:

- Standard residential systems: These typically involve a relatively small number of microinverters and solar panels, often with a single combiner box and straightforward wiring.

- Larger residential systems: These often necessitate multiple combiner boxes and more complex wiring arrangements to manage the increased number of microinverters and panels.

- Commercial systems: These can involve hundreds of microinverters and multiple string inverters, demanding careful planning and execution to ensure optimal system performance and compliance with relevant codes.

- Systems with different panel orientations: I’ve worked with systems incorporating both portrait and landscape orientations of solar panels, requiring attention to matching microinverter placement for optimal compatibility.

- Systems incorporating energy storage: My experience includes integrating Enphase Encharge storage solutions into the IQ system, requiring expertise in battery management systems and their integration into the overall system design.

Understanding the specific requirements and limitations of each configuration is critical for successful system design, installation, and troubleshooting. For example, a large commercial system necessitates meticulous planning for efficient cable routing and optimized combiner box placement to minimize energy losses.

Q 17. How do you ensure the proper grounding and bonding of an Enphase IQ system?

Proper grounding and bonding are paramount for safety and optimal Enphase IQ system performance. This involves a multi-step process that follows all applicable codes and regulations. The primary goal is to provide a low-impedance path for fault currents to safely ground, preventing electrical shock and fire hazards.

- Grounding the array: The solar array needs a dedicated ground wire connected to the grounding electrode system at the building’s main panel. This provides a safe path for fault currents that might occur within the solar array itself. The ground wire should be sized appropriately according to the NEC and local codes.

- Grounding the microinverters: While Enphase microinverters have their own grounding points, they should be connected to the overall grounding system, typically through the combiner box. This ensures a complete grounding path for the entire system.

- Grounding the combiner box: The combiner box requires a dedicated ground connection, tied into the main grounding electrode system. This is essential for grounding the entire string of microinverters and panels.

- Bonding: Bonding ensures that all metallic components of the system—including the racking, conduits, and the building’s metal structure—are electrically connected to provide a continuous path for fault currents. This minimizes the risk of voltage potential differences that could lead to arcing and other hazards.

- Grounding electrode system: A properly installed grounding electrode system is the foundation of the entire grounding and bonding strategy. This often involves a ground rod driven into the earth and connected to the building’s grounding system.

Regular testing with a ground resistance meter is essential to verify the integrity of the grounding system. Non-compliance with grounding and bonding requirements can lead to serious safety hazards and system malfunction, making this a crucial aspect of every installation.

Q 18. Explain the importance of using the Enphase IQ installer app.

The Enphase IQ Installer app is an indispensable tool for installing and commissioning Enphase IQ systems. It streamlines various aspects of the installation process, making it more efficient and reliable.

- System design and planning: The app assists in system design by providing tools for calculating system size and optimizing panel placement. This helps avoid potential issues before installation even begins.

- Microinverter pairing and configuration: The app simplifies the pairing of microinverters with solar panels and allows for easy configuration of system settings. This eliminates manual configuration, reducing errors and saving time.

- System monitoring and troubleshooting: The app provides real-time monitoring of system performance, enabling quick identification and diagnosis of any issues. This allows for proactive problem-solving before they impact system performance.

- Data logging and reporting: The app logs key installation data, creating a comprehensive report for documentation purposes. This simplifies compliance with various regulatory requirements.

- Firmware updates: The app allows for remote firmware updates of the microinverters, ensuring optimal performance and access to the latest features. This minimizes downtime and keeps the system running smoothly.

Using the Enphase IQ Installer app minimizes installation time, reduces errors, and provides invaluable real-time insights for efficient system management. In essence, it’s the digital backbone for a successful Enphase installation.

Q 19. What are the limitations of Enphase IQ systems?

While Enphase IQ systems offer many advantages, they also have limitations:

- Higher initial cost: Enphase microinverters are typically more expensive than string inverters, resulting in a higher initial investment.

- Potential for more points of failure: With individual microinverters per panel, there are more potential points of failure compared to a string inverter system. However, the modular design means that only a single panel’s output is affected by a faulty microinverter, rather than the whole string.

- Limited DC voltage range: Enphase microinverters have a specific DC voltage range they can handle. Using panels outside this range can lead to performance issues or system failure.

- Complexity for large systems: Managing and troubleshooting large Enphase systems can be more complex than string inverter systems, necessitating robust monitoring and a strong understanding of the system’s architecture.

- Dependence on communication network: System monitoring and management rely on a functioning communication network. Issues with network connectivity can hinder monitoring and troubleshooting capabilities.

Understanding these limitations is crucial for making informed decisions during system design and selection. Proper planning and the use of monitoring tools can mitigate many of these challenges.

Q 20. How do you handle warranty claims for Enphase IQ components?

Handling warranty claims for Enphase IQ components involves a straightforward process. It begins with confirming that the component is indeed under warranty and the failure is covered by the terms of the warranty.

- Gather information: Collect all necessary documentation, including purchase records, installation details, system serial numbers, and clear evidence of the component failure. High-quality photos or videos of the faulty component are invaluable.

- Contact Enphase support: Initiate a warranty claim through Enphase’s designated support channels. This usually involves providing the gathered documentation and details of the issue.

- Provide diagnostic information: Enphase may request diagnostic data from the Enlighten platform to help assess the nature of the failure. Providing this information efficiently speeds up the process.

- Replacement process: Once the claim is approved, Enphase will typically arrange for the replacement of the faulty component. The process may involve receiving the replacement part directly from Enphase or through an authorized distributor.

- Proper documentation: Thorough documentation throughout the process is critical. Maintain records of all communication, approvals, and shipment details.

Proactive communication and providing all necessary information to Enphase support significantly streamlines the warranty claim process. It’s essential to follow their guidelines carefully for a smooth resolution.

Q 21. Describe your experience working with different types of solar panels compatible with Enphase microinverters.

My experience extends to working with various solar panel types compatible with Enphase microinverters. This includes monocrystalline, polycrystalline, and thin-film panels from multiple manufacturers. The key is understanding the panel’s specifications and ensuring compatibility with the chosen Enphase microinverter model.

- Panel power rating and voltage: It’s crucial to match the panel’s power rating and voltage range with the microinverter’s specifications. Using panels outside the recommended range can lead to performance degradation or system failure.

- Panel size and dimensions: While Enphase microinverters are generally compatible with a wide range of panel sizes, physical considerations like racking compatibility must be factored in during installation.

- Panel temperature coefficients: Panel temperature coefficients affect the output of the solar panels under varying temperature conditions. This should be considered when selecting panels and designing the overall system.

- Manufacturer’s specifications: Always refer to the manufacturer’s specifications for both the panels and the Enphase microinverters to ensure compatibility and optimal performance.

- String sizing: Understanding string sizing guidelines is critical for optimal performance. Excessive string length can lead to voltage drops and reduced energy output.

Understanding these factors ensures that the selected panels work seamlessly with the Enphase microinverters, maximizing the system’s efficiency and reliability. This often involves thorough pre-installation planning and utilizing Enphase’s design tools to optimize the panel and microinverter configurations.

Q 22. What are the best practices for designing an Enphase IQ system for optimal performance?

Designing a high-performing Enphase IQ system hinges on careful planning and consideration of several key factors. It’s not just about plugging in microinverters; it’s about optimizing energy production and system longevity.

- Microinverter Placement: Evenly distribute microinverters across the array to balance shading and ensure consistent power output. Shading on even one microinverter can impact the entire string. We use specialized software to model shading and optimize placement.

- String Sizing: While Enphase systems are inherently robust to string mismatch, adhering to manufacturer guidelines on string length and number of microinverters is crucial for optimal efficiency. Overly long strings can lead to voltage drops.

- Wiring and Cabling: Using appropriately sized wiring is paramount. Undersized wiring leads to voltage drop and reduced efficiency. Careful planning and adhering to NEC standards are non-negotiable.

- Monitoring and Communication: Ensuring a robust communication path between the microinverters and the IQ Gateway is vital. This often involves considering signal strength, avoiding interference, and properly grounding the system.

- Grounding and Safety: Correct grounding is a safety paramount. We follow all applicable codes and regulations to ensure that the system is properly grounded to protect both equipment and personnel.

For example, on a recent project with a complex roof layout and significant shading, we used 3D modeling software to simulate shading throughout the day, optimizing the placement of microinverters to maximize energy harvest, even with partial shading.

Q 23. How do you manage multiple Enphase IQ systems within a large-scale installation?

Managing multiple Enphase IQ systems in a large-scale installation requires a systematic approach. Think of it like managing a fleet of vehicles – each needs individual attention, but you also need an overview of the whole fleet.

- Enlighten Manager: Enphase Enlighten is our central management platform. We use it to monitor the performance of each individual system, identify any issues, and generate reports for clients.

- System Segmentation: For large installations, we often segment systems logically (by building, phase, or client) to simplify monitoring and troubleshooting. This makes identifying issues much faster and more efficient.

- Data Aggregation: Enlighten allows us to aggregate data from multiple systems, providing a holistic view of the entire installation’s performance. This is crucial for proactive maintenance and performance analysis.

- Remote Access & Diagnostics: The remote access features of Enlighten are invaluable for troubleshooting. We can remotely diagnose problems without needing to visit each site, saving time and resources.

- Organized Documentation: Meticulous documentation, including system schematics, component lists, and commissioning reports, is crucial for managing multiple installations.

In one large commercial project involving several buildings, we utilized Enlighten’s multi-system view to monitor energy production across all sites. This allowed us to identify a recurring issue with one specific microinverter model in a timely fashion, preventing widespread performance degradation.

Q 24. Explain your experience with troubleshooting Enphase IQ system integration with other smart home technologies.

Integrating Enphase IQ systems with other smart home technologies is becoming increasingly common. We’ve worked with a range of systems, including home automation platforms and energy management systems. The key is understanding the communication protocols and data formats.

- API Integration: Many smart home platforms offer APIs that allow integration with Enphase Enlighten. This enables data sharing, allowing users to monitor solar production alongside other energy usage data.

- Data Formatting: Careful attention to data formatting and conversion is crucial. Different systems use different units and data structures. We need to map Enphase data to the requirements of the other system.

- Troubleshooting Connectivity: Network issues are a common cause of integration problems. We ensure strong network connectivity between the Enphase system, the smart home hub, and the internet.

- Compatibility: Checking for compatibility between Enphase IQ and the specific smart home technology is essential before attempting integration. The Enphase website provides a list of compatible systems.

For instance, we integrated an Enphase system with a client’s home automation system to automatically adjust lighting and HVAC based on solar power availability, resulting in optimized energy consumption and cost savings.

Q 25. How do you ensure the system meets all local codes and regulations?

Compliance with local codes and regulations is non-negotiable. It’s about ensuring safety, preventing potential hazards, and following the rules of the jurisdiction.

- NEC Compliance: We meticulously adhere to the National Electrical Code (NEC) and all relevant local amendments. This is a fundamental aspect of safe and legal system installation.

- Permitting and Inspections: We obtain all necessary permits before starting work and schedule inspections at each stage of the installation process. This ensures compliance with local building codes.

- Grounding and Bonding: Proper grounding and bonding practices are critical for safety. We rigorously follow the relevant codes to ensure the safety of the equipment and personnel.

- Listing and Labeling: We ensure all components used in the system are listed and labeled appropriately. This provides evidence that the components meet the required safety and performance standards.

- Documentation: We maintain thorough documentation of the installation, including permits, inspection reports, and system schematics. This ensures compliance traceability.

In one project, we had to work closely with local authorities to obtain the required permits for a complex rooftop installation. Understanding and adhering to their specific guidelines enabled a smooth and compliant project completion.

Q 26. Describe your experience with using the Enphase Enlighten mobile app.

The Enphase Enlighten mobile app is an essential tool for monitoring and managing Enphase IQ systems. It’s intuitive and provides real-time data at your fingertips.

- Real-time Monitoring: I regularly use the app to monitor system performance, including energy production, microinverter status, and system alerts. It gives immediate visibility into system health.

- Performance Analysis: The app provides valuable data for performance analysis, allowing identification of trends and potential issues. This enables us to proactively address any concerns.

- Remote Troubleshooting: The app allows us to remotely troubleshoot many common issues, significantly reducing the need for on-site visits.

- Client Communication: I often use the app to share real-time system performance data with clients, increasing their transparency and trust in the system.

- Alerts and Notifications: The app sends alerts for critical events like microinverter failures or power outages. This allows for quick intervention and minimizes system downtime.

Recently, the Enlighten app alerted me to a microinverter failure on a remote system. This allowed me to dispatch a technician immediately, minimizing the client’s energy loss and restoring the system quickly.

Q 27. What are some common challenges you’ve faced while working with Enphase IQ systems, and how did you overcome them?

Working with Enphase IQ systems has been largely positive, but there are occasional challenges. Effective problem-solving is key.

- Communication Issues: Intermittent communication problems between microinverters and the gateway can occur, often due to network issues or signal interference. We use signal strength analyzers and optimize system placement to mitigate this.

- Shading Issues: Incorrect microinverter placement or unexpected shading can significantly impact energy production. Thorough site assessment and 3D modeling are vital in preventing this.

- Software Updates: While Enphase regularly releases updates, sometimes these cause temporary glitches. Careful testing and firmware management are crucial.

- Component Failures: Like any electronic system, components can fail. Enphase provides excellent support and RMA processes to facilitate replacement.

For example, on one occasion, I encountered intermittent communication problems due to interference from a nearby radio tower. By relocating the gateway and optimizing antenna positioning, we resolved the issue. Learning to anticipate and troubleshoot potential problems, rather than just reacting to them, is a big part of mastering Enphase IQ systems.

Q 28. Explain your understanding of the Enphase IQ Gateway

The Enphase IQ Gateway is the central communication hub for the entire Enphase microinverter system. Think of it as the brains of the operation, connecting the individual microinverters to the internet for monitoring and data analysis.

- Communication Bridge: The gateway provides the communication bridge between the microinverters and the Enphase Enlighten platform. It collects data from all connected microinverters and transmits it to the cloud.

- Data Aggregation and Transmission: It aggregates data from all the microinverters on the system, allowing for a comprehensive overview of the system’s performance.

- Network Connectivity: The gateway must have a reliable internet connection, either wired or wireless, to send data to Enlighten. Proper configuration of the network is crucial for seamless operation.

- System Monitoring: The gateway facilitates real-time monitoring of the system’s performance, including energy production, voltage, and current readings. It is the data source that informs the Enlighten platform.

- Firmware Updates: The gateway receives firmware updates that enhance its functionality and system stability. Keeping firmware updated is crucial for optimal system operation.

Without the IQ Gateway, you wouldn’t have the real-time monitoring and data analysis capabilities that make Enphase systems so powerful. It’s a vital component for system functionality and remote management.

Key Topics to Learn for Enphase IQ Installer Interview

- System Design & Monitoring: Understanding the fundamental principles of designing and monitoring Enphase IQ systems, including microinverter placement, system sizing, and performance analysis.

- Troubleshooting & Diagnostics: Gaining practical experience in identifying and resolving common issues within Enphase IQ systems, utilizing the monitoring platform effectively for diagnostic purposes.

- Enphase IQ Platform Navigation: Mastering the navigation and functionality of the Enphase IQ platform, including accessing system data, generating reports, and understanding key performance indicators (KPIs).

- Safety Procedures & Regulations: Demonstrating a thorough understanding of safety protocols and relevant industry regulations when working with solar energy systems and the Enphase IQ platform.

- Communication & Collaboration: Highlighting effective communication skills for collaborating with homeowners, engineers, and other stakeholders on Enphase IQ projects.

- Data Interpretation & Reporting: Practicing analyzing data from Enphase IQ to identify trends, diagnose issues, and create insightful reports for clients and supervisors. This includes understanding energy production, consumption, and system efficiency.

- Commissioning & Activation: Understanding the process of commissioning and activating Enphase IQ systems, ensuring proper functionality and optimal performance from installation to handover.

- Software Updates & Firmware Management: Familiarizing yourself with procedures for managing software updates and firmware upgrades within Enphase IQ systems to ensure optimal performance and security.

Next Steps

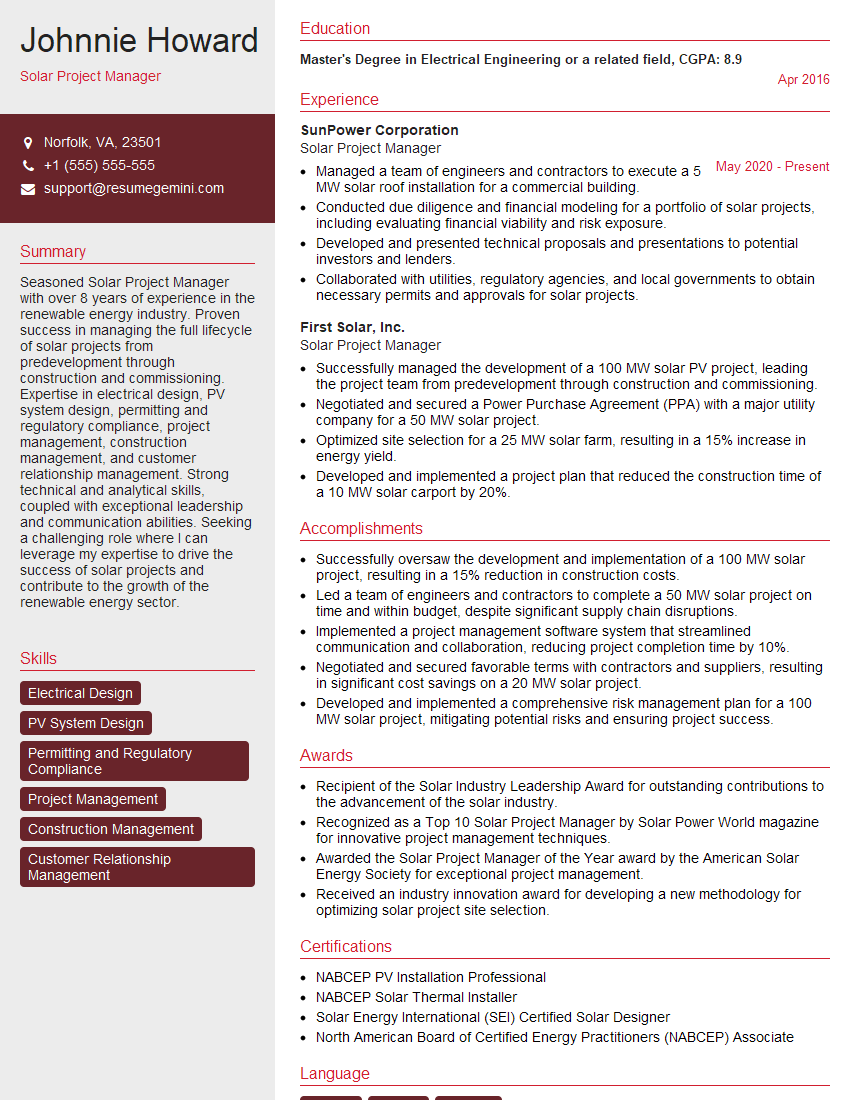

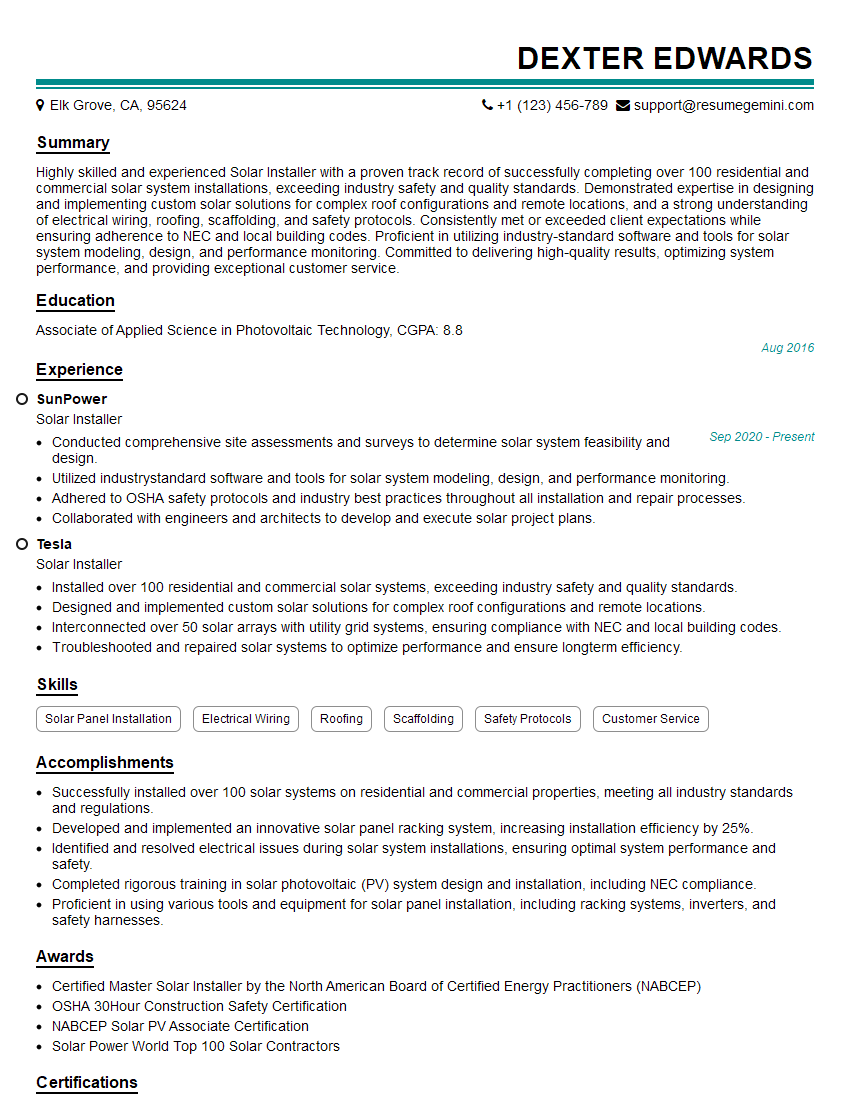

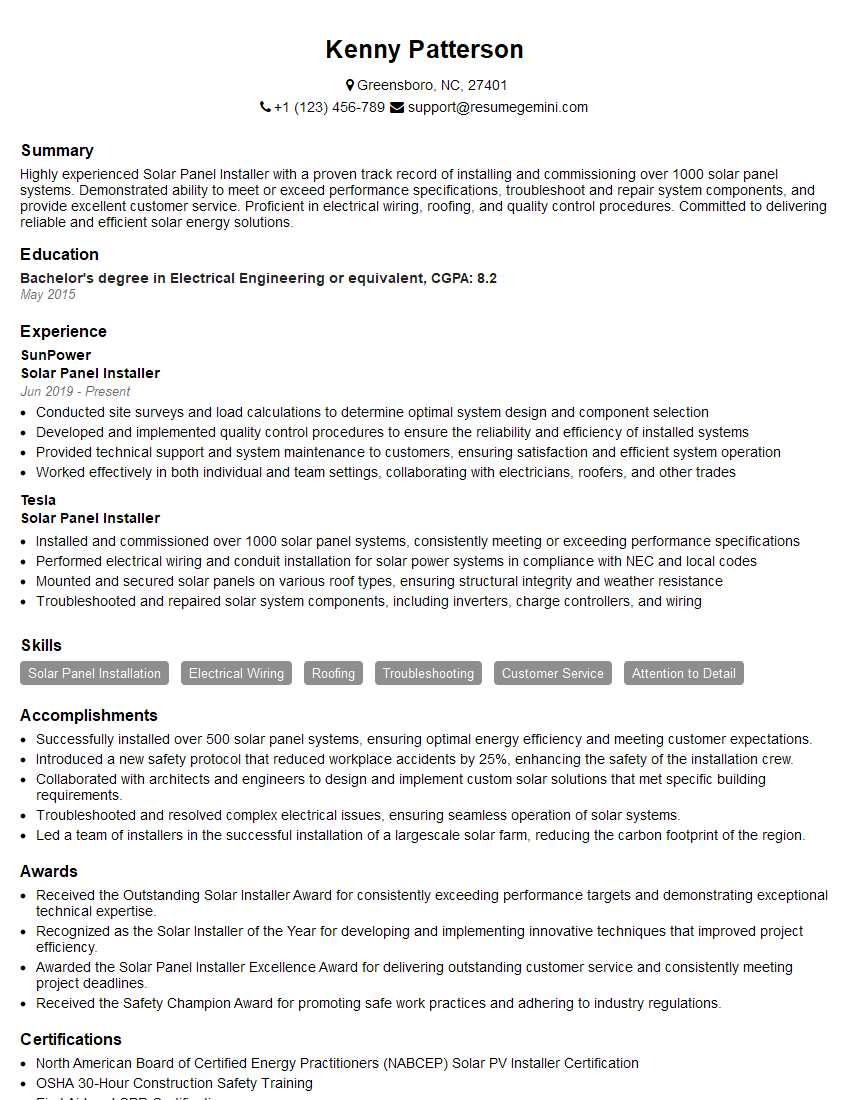

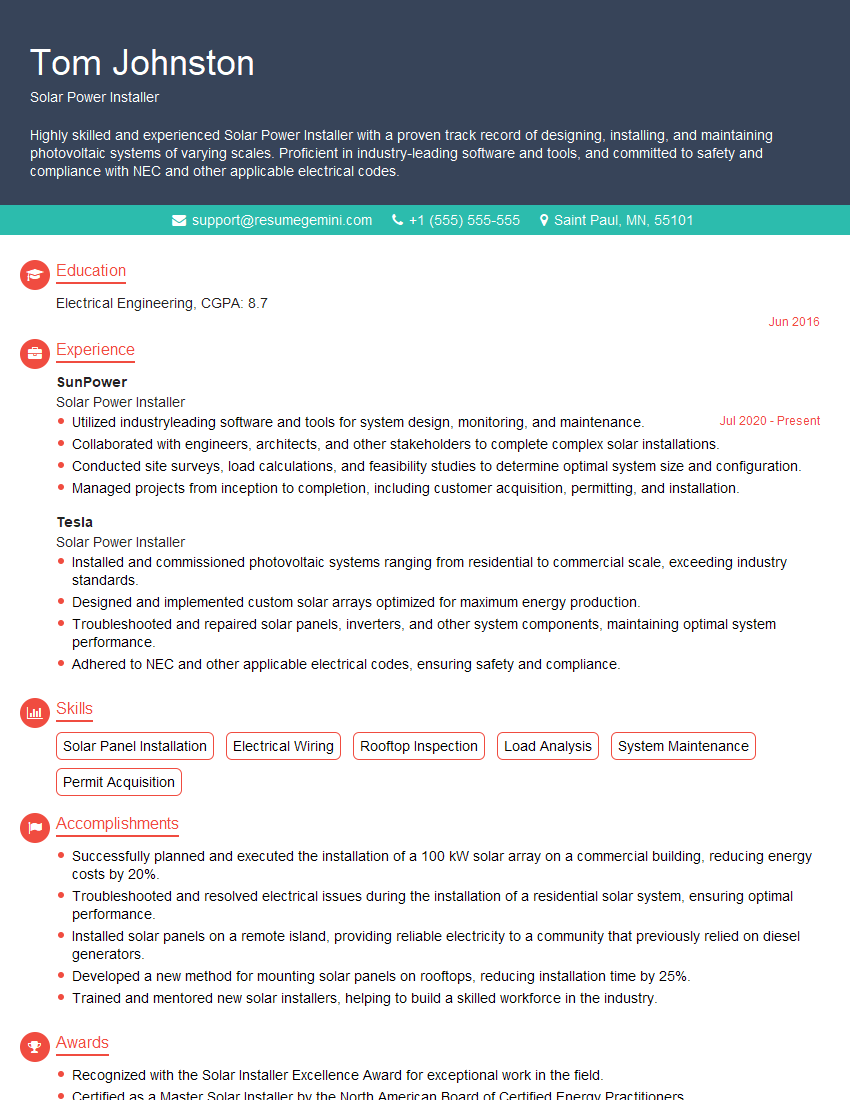

Mastering Enphase IQ Installer opens doors to exciting opportunities in the rapidly growing solar energy industry. Your expertise in this platform will significantly enhance your value to potential employers and pave the way for career advancement. To maximize your job prospects, it’s crucial to create a resume that effectively showcases your skills and experience to Applicant Tracking Systems (ATS). We highly recommend using ResumeGemini to build a professional and ATS-friendly resume that highlights your Enphase IQ Installer proficiency. ResumeGemini provides tools and examples of resumes tailored to Enphase IQ Installer roles, ensuring you present yourself in the best possible light to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.