Preparation is the key to success in any interview. In this post, we’ll explore crucial Laminating and Molding Processes interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Laminating and Molding Processes Interview

Q 1. Explain the difference between hand lay-up and vacuum bagging in laminating.

Hand lay-up and vacuum bagging are both methods for creating composite laminates, but they differ significantly in their approach to resin application and consolidation. Hand lay-up is a simpler, more manual process, while vacuum bagging offers superior control over resin distribution and void content.

In hand lay-up, resin is manually applied to reinforcement fibers (like fiberglass or carbon fiber) placed in a mold. Layers are built up one by one, with the resin being brushed or rolled onto the fibers. This process is labor-intensive, and achieving uniform resin distribution can be challenging, leading to potential variations in thickness and mechanical properties. Think of it like painting a wall – you’re carefully applying layers, but you might miss some spots.

Vacuum bagging, on the other hand, uses a vacuum to draw air out of a sealed bag placed over the laminate in a mold. This process removes excess resin and ensures close contact between the fibers and resin, leading to improved fiber saturation, reduced voids, and better mechanical properties. It’s like pressing a sandwich – the vacuum acts like the weight, squeezing everything together to create a uniform, compact structure. It’s more expensive in terms of equipment, but the results are superior in consistency and performance.

Q 2. Describe the various types of molding processes (e.g., injection, compression, transfer).

Molding processes are used to shape materials into desired forms. Different processes are suited to different materials and geometries.

- Injection Molding: Molten material is injected under high pressure into a closed mold cavity. This process is highly automated, ideal for high-volume production of complex parts with precise tolerances. Think of plastic bottles or toys – they’re often created using injection molding.

- Compression Molding: Material (often thermoset resin and reinforcement fibers) is placed in a heated mold and compressed until it cures. This is commonly used for larger parts with less intricate designs. Imagine making a large, flat sheet of composite material; compression molding is a good choice.

- Transfer Molding: Similar to compression molding, but the material is first pre-heated and transferred into the mold before compression. This offers better control over the flow and distribution of material, leading to more consistent parts. It’s a middle ground between injection and compression, offering better control and quality than compression but lower throughput than injection.

Other molding methods include blow molding, rotational molding, and resin transfer molding (RTM), each with its own advantages and applications.

Q 3. What are the common resins used in laminating, and what are their properties?

Several resins are used in laminating, each with unique properties affecting the final product’s performance.

- Polyester Resins: Relatively inexpensive, easy to work with, and have good chemical resistance. However, they offer lower mechanical strength compared to other options.

- Epoxy Resins: Known for their high strength, excellent adhesion, and good chemical resistance. They are more expensive than polyesters and require careful handling due to their longer curing times and potential for exothermic reactions.

- Vinyl Ester Resins: Offer a balance between the properties of polyester and epoxy resins. They provide good strength, chemical resistance, and are easier to work with than epoxies.

- Phenolic Resins: Often used in high-temperature applications due to their excellent heat resistance. They tend to be brittle.

The choice of resin depends on the application’s specific requirements for strength, chemical resistance, temperature tolerance, and cost.

Q 4. How do you ensure proper fiber orientation during the laminating process?

Proper fiber orientation is crucial for achieving the desired mechanical properties in a laminate. Fibers aligned in the direction of the applied load provide maximum strength. Consider a wooden beam – it’s much stronger when the grain runs along its length rather than across.

Methods to ensure proper fiber orientation include:

- Pre-preg materials: Using pre-impregnated fibers with resin already applied and the fibers already oriented.

- Lay-up techniques: Carefully placing each layer of fibers in the designated direction. Templates and guides can help maintain consistent orientation.

- Automated fiber placement (AFP): For high-volume applications, using automated machines for precise placement and orientation of fibers.

Incorrect fiber orientation will weaken the structure, potentially leading to failure under load. Careful planning and execution are paramount in achieving the desired fiber alignment.

Q 5. Explain the concept of void content in laminated parts and its impact on performance.

Void content refers to the presence of air pockets or gaps within a laminated part. These voids negatively impact the part’s performance.

High void content reduces the composite’s stiffness, strength, and fatigue resistance. It also makes the composite more susceptible to moisture absorption, leading to degradation over time. Imagine a brick wall with gaps – it’s significantly weaker than a wall with solid bricks.

Minimizing void content is essential. Techniques like vacuum bagging, autoclave curing, and proper resin application contribute to reducing voids. Non-destructive testing methods such as ultrasonic inspection can be used to assess the void content in the finished part. A low void content is critical for achieving the desired mechanical and durability properties.

Q 6. What are the different types of molds used in molding processes?

The type of mold used depends on the molding process and the complexity of the part.

- Open molds: Simple, less expensive molds used for hand lay-up and other open molding techniques.

- Closed molds: Used for processes like injection and compression molding, offering better control over the part’s shape and surface finish.

- Matched metal molds: Precise, expensive molds used for high-quality parts with tight tolerances. Often used in injection molding and transfer molding.

- Composite molds: Molds made of composite materials, offering a cost-effective alternative to metal molds for smaller production runs.

The selection of the mold depends on factors such as production volume, required part accuracy, and cost constraints.

Q 7. Describe the importance of mold release agents.

Mold release agents are crucial for easily removing the cured part from the mold without damaging either. They create a thin barrier between the mold surface and the part, preventing adhesion. Think of baking a cake in a pan – you grease it to prevent sticking.

Without a release agent, the part might become embedded in the mold, requiring significant force or potentially damaging both the part and the mold. This wastes time and materials.

Release agents are chosen based on the mold material and the cured part material to ensure compatibility. There are wax-based, silicone-based, and fluorocarbon-based release agents, each suited to different materials and applications. The correct selection and application of a release agent is vital for efficient and successful molding processes.

Q 8. How do you troubleshoot common issues encountered during laminating (e.g., air bubbles, delamination)?

Troubleshooting lamination issues like air bubbles and delamination requires a systematic approach. Air bubbles are often caused by trapped air during the layup process, insufficient resin wetting of the fibers, or too rapid a cure cycle. Delamination, on the other hand, results from poor adhesion between layers, often due to contamination, insufficient resin, or improper surface preparation.

- Air Bubbles: To solve air bubbles, ensure proper vacuum bagging or pressure application during the cure to remove trapped air. Use a release agent to prevent adhesion to the bagging materials. Carefully wet out the reinforcement fibers to ensure complete resin penetration. Slow down the curing process slightly, giving the resin more time to flow and release air.

- Delamination: For delamination, meticulous surface preparation is key. Ensure all surfaces are clean, dry, and free of dust or contaminants before applying the resin. Use a sufficient amount of resin to ensure complete saturation of the fibers and proper bonding between layers. Consider a primer if adhesion between layers is challenging. Inspect the laminates during the cure to address issues as early as possible.

Think of it like baking a cake: If you don’t mix the batter thoroughly (resin wetting), you’ll get lumps (air bubbles). If you don’t grease the pan properly (surface preparation), the cake will stick (delamination).

Q 9. How do you troubleshoot common issues encountered during molding (e.g., flash, short shots)?

Molding defects like flash and short shots stem from different aspects of the molding process. Flash is excess material squeezed out beyond the mold cavity, while short shots indicate incomplete filling of the mold.

- Flash: Flash usually indicates excessive molding pressure, improper mold closure, or defects in the mold itself. Solutions include adjusting the molding pressure, ensuring the mold is properly closed and aligned, and inspecting the mold for wear or damage. Consider using appropriate mold release agents.

- Short Shots: Short shots point to insufficient injection pressure, improper gating, or high viscosity of the molding compound. Increasing the injection pressure, optimizing the gating system, and preheating the molding compound to lower its viscosity can typically address this. Ensuring the mold is free of obstructions is also vital.

Imagine squeezing toothpaste from a tube: Too much force (pressure) leads to overflow (flash), while insufficient pressure results in an incomplete dispensing (short shot).

Q 10. Explain the importance of curing cycles in both laminating and molding.

Curing cycles are critical in both laminating and molding, determining the final properties of the composite part. They define the temperature and time profile required for the resin to fully polymerize and achieve its desired mechanical and chemical properties.

In laminating, the cure cycle must be carefully controlled to avoid premature curing which can trap air or cause uneven resin distribution, and to achieve full cure for optimal strength and durability.

In molding, the cure cycle ensures the resin completely cures within the mold cavity, avoiding internal stresses and achieving the desired dimensional accuracy and mechanical performance. A poorly controlled cure cycle can lead to warping, cracking, or incomplete curing of the molded part. The choice of cycle is highly material-specific and may involve different temperatures and hold times. Using a data logger to record temperatures throughout the curing cycle can help verify the process and improve repeatability.

Q 11. What are the safety precautions to be taken while working with resins and curing agents?

Working with resins and curing agents demands strict adherence to safety protocols. Many resins and curing agents are hazardous, potentially causing skin irritation, respiratory problems, or even more severe health issues.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves, safety glasses, respirators (especially when dealing with volatile compounds), and protective clothing.

- Ventilation: Ensure adequate ventilation in the work area to minimize exposure to fumes. Work in a well-ventilated area or use a local exhaust ventilation system.

- Material Safety Data Sheets (MSDS): Thoroughly review the MSDS for each resin and curing agent before handling them to understand their hazards and necessary precautions.

- Waste Disposal: Dispose of waste materials according to local regulations. Never pour resins or curing agents down the drain.

- Emergency Procedures: Be aware of and prepared for emergency procedures in case of spills or accidents. Have readily available emergency eyewash stations and safety showers.

Safety should never be compromised. Treat all materials as potentially harmful until proven otherwise. Proper training and adherence to safety guidelines are paramount.

Q 12. How do you perform quality control checks on laminated and molded parts?

Quality control checks for laminated and molded parts involve both visual inspection and testing. Visual checks assess the part for defects such as air bubbles, voids, delamination, cracks, and surface imperfections. Testing is crucial to verify the part’s mechanical properties meet the design specifications.

- Visual Inspection: A careful visual examination can reveal many defects. Use appropriate lighting and magnification as needed.

- Dimensional Measurements: Verify that the part’s dimensions are within the specified tolerances using precision measuring instruments.

- Mechanical Testing: Perform relevant tests such as tensile strength, flexural strength, impact strength, and hardness tests, to confirm the part’s mechanical performance.

- Non-destructive Testing (NDT): Methods such as ultrasonic inspection or X-ray radiography can reveal internal defects not visible to the naked eye.

Regular calibration of testing equipment is essential for accurate and reliable results. Maintain detailed records of all inspections and tests.

Q 13. Explain the concept of drape and its importance in laminating.

Drape refers to the ability of a fiber reinforcement to conform to the shape of a mold or part during the layup process. It’s crucial for achieving a uniform thickness and avoiding wrinkles, which can affect the structural integrity of the finished laminate.

Good drape means the fabric conforms smoothly and easily to the mold’s curvature. Poor drape leads to uneven resin distribution, wrinkles, and potential stress concentrations in the final part, making it weaker and more prone to failure. Factors affecting drape include fiber type, weave pattern, resin viscosity, and the mold’s surface finish. For instance, a softer fabric with a lower stiffness will generally have a better drape than a stiff, densely woven fabric.

Imagine trying to drape a cloth over a curved surface. A soft, pliable fabric will drape easily, while a stiff fabric will wrinkle and create unevenness. The same principle applies to fiber reinforcement in laminating.

Q 14. Describe the different types of reinforcement fibers used in composite materials.

Reinforcement fibers are essential components of composite materials, providing strength and stiffness. Several types are commonly used, each with unique properties:

- Glass Fiber: The most common and cost-effective, offering a good balance of strength and stiffness. Available in various forms, including continuous filaments, chopped strands, and mats.

- Carbon Fiber: Known for its high strength-to-weight ratio, making it ideal for applications where weight reduction is critical. More expensive than glass fiber.

- Aramid Fiber (Kevlar): Exceptional strength and impact resistance, often used in ballistic protection and high-performance applications.

- Basalt Fiber: A relatively new fiber with properties similar to glass fiber but potentially higher heat resistance.

- Natural Fibers: Such as flax, hemp, and sisal, increasingly used in eco-friendly composite materials. They have lower strength and stiffness compared to glass or carbon fiber but are renewable and biodegradable.

The choice of fiber depends on the specific application’s performance requirements and cost considerations. Some applications may even employ hybrid fiber combinations to optimize performance.

Q 15. What are the advantages and disadvantages of using different types of resins?

Choosing the right resin is crucial in laminating and molding, as it directly impacts the final product’s properties. Different resins offer a unique blend of advantages and disadvantages.

- Epoxy Resins: Excellent mechanical strength, chemical resistance, and adhesion. However, they can be more expensive and have a longer cure time compared to some alternatives. Example: Commonly used in high-performance composite parts for aerospace and automotive applications.

- Polyester Resins: Relatively inexpensive and easy to work with, offering good strength and UV resistance. However, they are less chemically resistant than epoxies and have lower mechanical properties. Example: Widely used in fiberglass boats and other less demanding applications.

- Vinyl Ester Resins: A compromise between epoxy and polyester, offering good chemical resistance and mechanical strength at a more affordable price than epoxies. Example: Suitable for corrosion-resistant tanks and pipes.

- Phenolic Resins: Known for their excellent heat resistance and insulation properties. They are often used in high-temperature applications but can be brittle. Example: Used in electrical components and high-temperature molding.

The best resin depends on the specific requirements of the application, balancing cost, performance, and processing considerations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you determine the appropriate resin to fiber ratio for a given application?

Determining the optimal resin-to-fiber ratio is critical for achieving the desired mechanical properties and processing characteristics. This ratio, often expressed as a weight percentage, significantly influences the final composite’s strength, stiffness, and toughness.

The process involves considering several factors:

- Desired Mechanical Properties: Higher fiber volume fraction generally leads to greater strength and stiffness, but it can also make the composite more brittle and difficult to process.

- Processing Method: Hand layup requires a higher resin content for proper wetting and consolidation compared to automated processes like resin transfer molding (RTM).

- Fiber Type: Different fibers have different surface areas and wetting characteristics, influencing the required resin content.

- Application Requirements: The intended use of the composite dictates the necessary balance of strength, stiffness, toughness, and other properties.

Often, a series of test samples with varying resin-to-fiber ratios are prepared and tested to determine the optimal value. This involves mechanical testing (tensile, flexural, impact) and potentially other characterizations, such as density measurements.

Imagine building a brick wall. Too much mortar (resin), and it’s weak and crumbly. Too little, and the bricks (fibers) don’t bond well. Finding the right balance is key.

Q 17. Explain the concept of prepreg materials and their use in laminating.

Prepreg materials are essentially pre-impregnated fibers, where reinforcing fibers (e.g., carbon, glass, aramid) are already saturated with a resin system and cured to a specific level (B-stage). This allows for efficient and controlled layup during the lamination process.

Advantages of using prepreg:

- Improved Process Control: Consistent resin content and fiber distribution lead to reproducible part quality.

- Enhanced Efficiency: Faster layup compared to wet layup methods.

- Reduced Resin Waste: Pre-impregnation minimizes resin waste.

- Better Fiber-Resin Interfacial Bond: Controlled impregnation ensures a strong bond.

Applications of Prepreg:

- Aerospace: High-performance parts in aircraft and spacecraft.

- Automotive: Lightweight and high-strength components.

- Wind Energy: Blades for wind turbines.

In lamination, prepreg sheets are carefully laid up according to engineering drawings, then cured under controlled temperature and pressure to consolidate the laminate and complete the resin cure.

Q 18. Describe the different types of mold materials and their applications.

Mold materials play a crucial role in determining the quality, surface finish, and cost-effectiveness of the molding process. The selection depends on several factors including the part geometry, material being molded, production volume, and temperature requirements.

- Steel Molds: Durable, precise, and offer excellent surface finish. They’re suitable for high-volume production but are expensive to manufacture. Example: Used in automotive and aerospace industries for high-precision parts.

- Aluminum Molds: Lighter and less expensive than steel, but with lower thermal conductivity. They are suitable for medium-to-high volume production. Example: Used for less demanding applications.

- Epoxy-Based Molds: These are relatively inexpensive and easy to fabricate, often used for prototyping or low-volume production. However, they have lower thermal conductivity and limited temperature tolerance. Example: Used for low-volume production runs and prototyping.

- Composite Molds: Lightweight and offering design flexibility, suitable for complex geometries. However, their durability and thermal properties might be inferior to metal molds. Example: Used for prototyping and specialized applications.

The choice of mold material is a trade-off between cost, precision, and durability, carefully considered based on the specific application needs.

Q 19. How do you maintain and clean molds to ensure their longevity?

Proper mold maintenance is essential for prolonging their lifespan and ensuring consistent part quality. Neglecting maintenance leads to premature wear, defects in molded parts, and increased downtime.

Maintenance and Cleaning Procedures:

- Regular Cleaning: After each molding cycle, remove any residual material or release agent from the mold surface using appropriate solvents and cleaning tools. Avoid abrasive materials that might scratch the mold surface.

- Inspection: Regularly inspect the mold for any signs of damage, such as cracks, pitting, or erosion. Address these issues promptly to prevent further damage.

- Proper Storage: When not in use, store the mold in a clean, dry, and protected environment to prevent corrosion or damage.

- Release Agent Application: Apply a suitable release agent to facilitate easy demolding and prevent sticking. Use the recommended agent for the mold material and resin system.

- Periodic Polishing: For high-precision molds, periodic polishing might be necessary to maintain surface finish and prevent buildup of microscopic defects.

A well-maintained mold is a key factor in ensuring the cost-effectiveness and consistent high quality of the molding process.

Q 20. Explain the significance of process parameters (e.g., temperature, pressure, time) in both laminating and molding.

Process parameters—temperature, pressure, and time—are critical in both laminating and molding. They directly impact the resin cure, fiber consolidation, and the final properties of the composite part. Think of baking a cake; the oven temperature, baking time, and even the pressure (although less directly in this case) determine the final product’s texture and taste.

Laminating:

- Temperature: Controls the resin cure rate. Too low, and the cure is incomplete; too high, and it can cause degradation or burning.

- Pressure: Compresses the laminate, removing air voids and ensuring good fiber-to-fiber contact and fiber-resin impregnation. Insufficient pressure results in porosity and reduced mechanical properties.

- Time: Allows for complete resin cure and consolidation. Insufficient cure time leads to weak parts.

Molding:

- Temperature: Affects the viscosity of the resin, the cure rate, and the overall flow within the mold. Precise temperature control is essential for proper filling and cure.

- Pressure: Ensures complete filling of the mold cavity, removes air bubbles, and consolidates the composite structure. Insufficient pressure results in voids and weakened parts.

- Time: Allows for the resin to flow completely into the mold cavity and then cure properly. Improper timing leads to incomplete cure or trapped volatiles.

Optimizing these parameters is crucial for achieving the desired properties and a high-quality final product. This often involves experimentation and iterative adjustments based on process monitoring and testing.

Q 21. How do you interpret engineering drawings for laminating and molding?

Interpreting engineering drawings for laminating and molding requires a good understanding of technical drawings, materials science, and manufacturing processes. The drawings typically contain detailed information about the part’s geometry, material specifications, and layup sequence.

Key Aspects to Interpret:

- Part Geometry: Understanding the overall shape and dimensions of the part to be manufactured.

- Material Specifications: Identifying the types and quantities of fibers and resin systems to be used.

- Layup Sequence: Following the prescribed order and orientation of the different fiber layers. This is crucial for achieving the desired mechanical properties and optimizing the structural performance.

- Tolerances: Understanding the allowable deviations from the specified dimensions. This impacts the fit and function of the manufactured component.

- Surface Finish Requirements: Defining the acceptable surface roughness and appearance of the final product.

Often, drawings include detailed cross-sections showing the ply orientation and thickness, allowing the manufacturer to accurately replicate the design. It also includes information on required finishing, such as drilling or machining of holes or other features.

Incorrect interpretation can lead to significant issues, from improper part strength to wasted materials and production delays. A thorough understanding of the drawing is critical to a successful manufacturing process.

Q 22. Describe your experience with different types of automated equipment used in laminating and molding.

My experience encompasses a wide range of automated equipment used in laminating and molding processes. This includes automated fiber placement (AFP) systems for precise fiber deposition, tape laying machines for high-speed composite manufacturing, resin transfer molding (RTM) machines with automated resin injection and pressure control, and automated compression molding presses with programmable cycle times and temperature profiles. I’ve also worked extensively with robotic arms for material handling, part placement, and post-processing operations, such as trimming and deburring. For instance, in a previous role, I oversaw the implementation of a new AFP system that increased our production rate by 40% while simultaneously improving part consistency. The system’s automated fiber path planning software allowed us to optimize material usage and minimize waste.

- Automated Fiber Placement (AFP): Precise fiber placement for complex geometries.

- Tape Laying Machines: High-speed deposition of prepreg tapes.

- Resin Transfer Molding (RTM) Machines: Automated resin injection and pressure control for liquid resin composites.

- Automated Compression Molding Presses: Programmable cycle times and temperature profiles for thermoset composites.

- Robotic Systems: Material handling, part placement, and post-processing.

Q 23. Explain your understanding of different types of quality control methods (e.g., visual inspection, dimensional measurement, destructive testing).

Quality control in laminating and molding is crucial. We employ a multi-faceted approach including visual inspection, dimensional measurement, and destructive testing. Visual inspection checks for surface defects like voids, delaminations, or resin bleed. This is often the first line of defense and requires trained personnel to identify subtle imperfections. Dimensional measurements, typically using CMMs (Coordinate Measuring Machines) or other precision instruments, ensure the part conforms to the design specifications. Destructive testing, such as tensile strength, flexural strength, and impact tests, assesses the mechanical properties of the finished part. For instance, if we are manufacturing aircraft parts, we must meet stringent aerospace standards which might include ultrasonic testing to detect internal flaws.

- Visual Inspection: Detects surface imperfections like voids, delaminations, or resin bleed.

- Dimensional Measurement: CMMs or other precision instruments ensure parts meet specifications.

- Destructive Testing: Tensile, flexural, and impact tests assess mechanical properties.

- Non-Destructive Testing (NDT): Ultrasonic, X-ray, or thermographic testing detect internal flaws.

Q 24. Describe your experience with troubleshooting process issues and implementing corrective actions.

Troubleshooting is an integral part of the job. My approach is systematic and data-driven. When an issue arises, I start by gathering data – production records, quality control reports, machine logs – to identify trends and patterns. Then, I use a root cause analysis (RCA) methodology, like the 5 Whys, to drill down to the underlying cause. Once the root cause is identified, I collaborate with the team to develop and implement corrective actions. For example, we once experienced a significant increase in delaminations. Through data analysis and RCA, we discovered a problem with the curing cycle in the autoclave. By adjusting the temperature and pressure profiles, we eliminated the issue.

Example: In a previous role, we encountered a high rate of fiber misalignment in our AFP process. After a thorough investigation, it was found that the vibration of the machine was causing this problem. Implementing vibration dampers solved the issue.

Q 25. How do you ensure that the finished parts meet the required specifications?

Ensuring finished parts meet specifications requires a combination of proactive measures and robust quality control. This begins with careful selection of raw materials, meticulous process control, and continuous monitoring of the manufacturing process. We use statistical process control (SPC) charts to track key process parameters and identify potential deviations early on. Stringent quality checks at each stage – from material inspection to final testing – are critical. Additionally, we maintain detailed documentation and traceability throughout the entire production process, enabling us to quickly identify and address any issues. Any deviation from specifications triggers a thorough investigation using the methods mentioned earlier.

Q 26. How familiar are you with different industry standards and certifications related to composite manufacturing?

I am highly familiar with various industry standards and certifications related to composite manufacturing, including those from ASTM International (e.g., ASTM D3039 for tensile testing), ISO (e.g., ISO 9001 for quality management systems), and industry-specific standards relevant to aerospace (e.g., AS9100) or automotive applications. Understanding and adhering to these standards is vital to ensure product quality, safety, and compliance. In my previous role, we implemented AS9100 certification to improve quality management and streamline processes, which led to significant improvements in efficiency and reduced waste.

Q 27. Describe your experience with different types of software used in composite manufacturing (e.g., CAD, CAE).

My experience with software in composite manufacturing includes CAD software (e.g., CATIA, SolidWorks) for design and modeling, CAE software (e.g., Abaqus, ANSYS) for simulation and analysis, and specialized software for process planning and optimization (e.g., software specific to AFP or RTM machines). I am proficient in using these tools to create detailed part designs, predict part behavior under load, optimize manufacturing processes, and generate production reports. For example, I utilized finite element analysis (FEA) in ANSYS to simulate the stress distribution in a complex aerospace component, allowing us to optimize the design for strength and weight reduction.

Q 28. Explain your approach to continuous improvement in a manufacturing environment.

My approach to continuous improvement is based on the principles of Lean Manufacturing and Six Sigma. I believe in a data-driven approach, utilizing tools like Kaizen events, value stream mapping, and DMAIC (Define, Measure, Analyze, Improve, Control) to identify areas for improvement. This involves actively seeking feedback from the team, engaging in regular process reviews, and utilizing data analysis to track progress and measure the effectiveness of implemented changes. We continuously seek to improve efficiency, reduce waste, and enhance the quality of our products. For instance, we implemented a Kaizen event to streamline the layup process for a particular part, resulting in a 15% reduction in production time and material waste.

Key Topics to Learn for Laminating and Molding Processes Interview

- Laminating Processes: Understanding various types of laminates (e.g., thermoset, thermoplastic), adhesive selection, pressure and temperature control, quality control methods (visual inspection, adhesion testing), and troubleshooting common lamination defects.

- Molding Processes: Familiarity with different molding techniques (e.g., injection molding, compression molding, transfer molding), material properties and selection, mold design considerations, cycle time optimization, and understanding of common molding defects (e.g., sink marks, flash, short shots).

- Material Science Fundamentals: A strong grasp of polymer chemistry, material properties (strength, elasticity, thermal stability), and the relationship between material properties and processing parameters. This is crucial for understanding why certain processes are selected for specific materials.

- Process Optimization: Knowledge of lean manufacturing principles, statistical process control (SPC), and data analysis techniques for improving process efficiency and reducing defects. Be prepared to discuss how you’d approach improving a specific process based on given data.

- Safety and Quality Control: Understanding safety protocols within a manufacturing environment, quality control measures, and documentation practices (e.g., maintaining process logs and inspection reports). Demonstrate awareness of relevant industry standards and regulations.

- Troubleshooting and Problem-Solving: Be ready to discuss your approach to identifying and resolving common issues encountered in lamination and molding processes. Use examples from your experience to showcase your analytical and problem-solving skills.

- Equipment Operation and Maintenance: Familiarity with the operation and basic maintenance of relevant machinery used in lamination and molding processes. Mentioning specific equipment you’ve worked with (if applicable) will be beneficial.

Next Steps

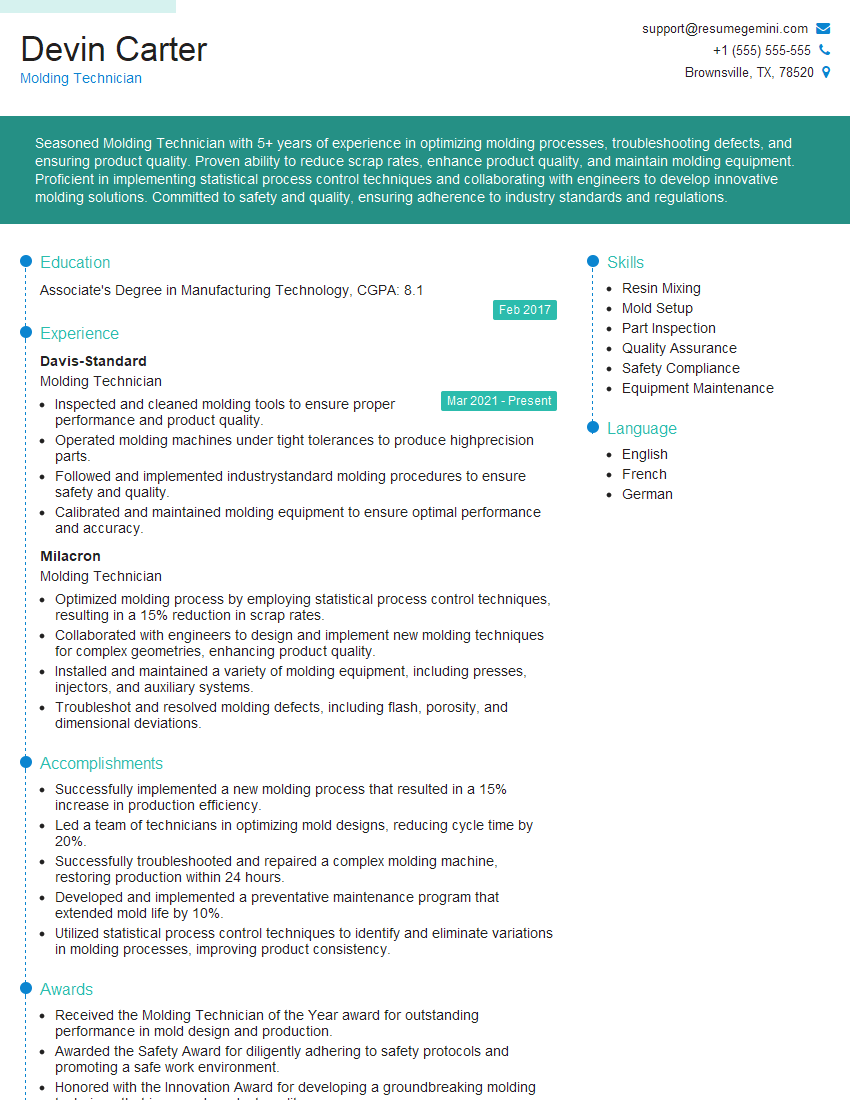

Mastering Laminating and Molding Processes opens doors to exciting career opportunities in manufacturing, composite materials, and related fields. A strong understanding of these processes demonstrates valuable technical skills highly sought after by employers. To maximize your chances of landing your dream job, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your specific skills and experience. We provide examples of resumes specifically designed for candidates in Laminating and Molding Processes to guide you through the process. Invest time in building a strong resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.