The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Ability to operate heavy equipment in a safe and responsible manner interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Ability to operate heavy equipment in a safe and responsible manner Interview

Q 1. Describe your experience operating different types of heavy equipment.

My experience encompasses a wide range of heavy equipment, including excavators, bulldozers, loaders, and articulated dump trucks. I’ve operated excavators of varying sizes, from compact machines used in tight urban spaces to larger models for extensive earthmoving projects. My bulldozer experience includes both tracked and wheeled machines, used for tasks ranging from land clearing to fine grading. Loader operation has involved both wheel loaders and skid steers, utilized in material handling and construction site logistics. Finally, I’ve operated articulated dump trucks in various terrains, transporting materials efficiently across challenging landscapes.

For example, on one project, I used a 30-ton excavator to excavate a large basement for a residential building, requiring precise control and awareness of underground utilities. On another project, I used a bulldozer to clear a heavily forested area, demanding both strength and precision to avoid damaging nearby structures.

Q 2. What safety protocols do you follow when operating heavy equipment?

Safety is paramount in my work. My safety protocols begin with a thorough pre-operational check, always wearing appropriate Personal Protective Equipment (PPE), including hard hats, safety glasses, high-visibility clothing, and steel-toe boots. I always follow site-specific safety rules and maintain a safe distance from other equipment and personnel. I regularly check my surroundings, including blind spots, before moving equipment. Communication is key; I use hand signals and two-way radios to coordinate with other operators and workers. Before starting any task, I assess potential hazards and plan accordingly, ensuring that all safety procedures are followed diligently.

For instance, I never operate equipment when fatigued or under the influence of drugs or alcohol. I always secure the equipment properly before leaving it unattended.

Q 3. Explain the pre-operational checks you perform before starting a machine.

My pre-operational checks are meticulous and follow a checklist. This involves checking fluid levels (engine oil, hydraulic oil, coolant, fuel), tire pressure, and the overall condition of the machine, looking for any damage or leaks. I inspect the braking system, lights, and safety features, ensuring they are all functioning correctly. I then test the controls, including steering, hydraulics, and brakes, ensuring smooth operation. Finally, I visually inspect the work area to identify any potential hazards, like uneven terrain, obstacles, or overhead power lines.

Think of it like pre-flight checks for an airplane – every detail counts. Missing a single step could lead to a serious incident.

Q 4. How do you handle unexpected equipment malfunctions?

If I encounter an unexpected equipment malfunction, my first step is to immediately shut down the machine and assess the situation. If the malfunction poses an immediate safety risk, I will evacuate the area and warn others. I then contact the appropriate maintenance personnel or supervisor to report the problem. Depending on the severity, I may attempt basic troubleshooting, such as checking fluid levels or fuses. However, I avoid attempting any repairs beyond my capabilities to prevent further damage or injury. Documentation is essential; I always report malfunctions accurately and promptly.

For example, if the hydraulic system fails, I would immediately stop the machine, engage the parking brake, and then notify my supervisor rather than attempting to fix it myself.

Q 5. Describe your experience with preventative maintenance on heavy equipment.

Preventative maintenance is crucial for keeping heavy equipment in optimal condition. I perform daily checks on machines, including lubrication, fluid level checks, and inspections for wear and tear. This extends to regular scheduled maintenance involving more complex tasks such as filter changes, belt adjustments, and component inspections, often based on the manufacturer’s recommendations and service schedules. I meticulously document all maintenance activities.

This proactive approach significantly reduces downtime, extends the lifespan of the equipment and minimizes the risk of breakdowns on the job site, ensuring operational efficiency and safety.

Q 6. What are the common causes of equipment accidents and how can they be avoided?

Common causes of equipment accidents include operator error (fatigue, lack of training, disregard for safety rules), mechanical failures (poor maintenance, inadequate inspections), and environmental factors (inclement weather, uneven terrain). These can be avoided through comprehensive training programs for operators, regular preventative maintenance, adherence to safety protocols, and thorough risk assessments before commencing any work. Proper communication between operators and ground personnel is vital.

For example, inadequate training can lead to operators misjudging the stability of the equipment on slopes, potentially resulting in rollovers. Regular inspections and maintenance can prevent equipment failures, and clear communication between the operator and spotter can prevent collisions with other vehicles or personnel.

Q 7. How do you ensure the stability of heavy equipment on uneven terrain?

Ensuring stability on uneven terrain requires careful assessment of the ground conditions and appropriate operating techniques. This involves choosing a stable working area, avoiding slopes exceeding the machine’s stability limits and using appropriate counterweights or ballast where necessary. Smooth and gradual movements are crucial to prevent tipping or instability. I always use the machine’s features carefully, such as outriggers or stabilizers when available. A clear understanding of the machine’s operational limits and the terrain is essential. If unsure, I always seek guidance from more experienced operators or supervisors.

Think of it like balancing a seesaw: proper weight distribution and gradual movements are key to maintaining stability.

Q 8. How familiar are you with load capacity limits and safe working loads?

Understanding load capacity limits and safe working loads is paramount for safe heavy equipment operation. It’s essentially knowing the maximum weight a piece of equipment can handle without compromising its structural integrity or stability. Every piece of equipment – be it a crane, excavator, or forklift – has a clearly defined load capacity, often displayed on a data plate. This plate specifies the maximum weight the equipment can lift or carry under ideal conditions. The safe working load (SWL) is usually a slightly lower figure, accounting for potential variations in conditions like uneven terrain or wind. Ignoring these limits can lead to catastrophic equipment failure, injuries, and even fatalities.

For example, if a crane’s data plate indicates a maximum load capacity of 10 tons, operating it with a 12-ton load is reckless and dangerous. Similarly, I always ensure that the SWL is never exceeded, regardless of the task at hand. I meticulously check the load charts and specifications before undertaking any lifting operation, accounting for factors like the boom length, angle, and load distribution.

Regular inspections of the equipment are crucial to ensure that it’s in good working order and capable of handling the intended load. This includes checking for any signs of wear and tear or damage to the structural components.

Q 9. What are your procedures for working around power lines and underground utilities?

Working near power lines and underground utilities demands extreme caution and adherence to strict safety protocols. My procedure always starts with thorough site preparation. Before commencing any work, I meticulously identify the location of all power lines and underground utilities using available site plans, calling utility companies for precise locations, and conducting on-site surveys using locating tools.

A safe working distance is maintained at all times, typically well beyond the minimum clearance required. This distance varies depending on the voltage of the power lines; higher voltage requires a significantly larger safety zone. I never operate equipment near power lines without proper authorization and supervision. For underground utilities, I always ensure that I’m aware of their location and take appropriate steps to avoid damaging them. This often involves using hand tools or non-mechanical methods for excavation in the proximity of these lines. Clear communication with other workers about the location of these hazards is paramount to maintaining a safe working environment.

Q 10. Describe your experience working with blueprints and site plans.

Experience with blueprints and site plans is essential for effective and efficient heavy equipment operation. I am proficient in interpreting various types of construction drawings, including site plans, grading plans, utility plans, and equipment placement diagrams. I can easily identify key features such as elevations, dimensions, utility lines, and designated work areas.

For example, I regularly use blueprints to plan the movements of heavy machinery, ensuring that excavation is carried out to the correct depth and that all structures are built in their designated locations. I carefully study the plans to understand the sequencing of tasks and how my work impacts other trades. If ambiguities arise in the plans, I always seek clarification from the project engineer or supervisor before proceeding. Using my understanding of the plans, I can anticipate potential obstacles and develop mitigation plans to address them proactively.

Q 11. How do you communicate effectively with other workers on a construction site?

Effective communication is the cornerstone of safety on any construction site, especially when operating heavy equipment. I prioritize clear and concise communication with other workers using a variety of methods. This includes using hand signals, two-way radios, and face-to-face communication. Before starting any task that involves other workers, I ensure that everyone is aware of the plan and potential risks.

I use standardized hand signals to communicate with those assisting in guiding the equipment. When working near other equipment or personnel, I use radio communication to maintain open lines of contact and update everyone on my position and intended movements. I also actively listen to others and provide feedback, ensuring that there is no ambiguity in instructions or warnings. I believe in establishing a collaborative environment where everyone feels comfortable communicating concerns and potential problems immediately.

Q 12. Explain your understanding of different types of soil and their impact on equipment operation.

Understanding different soil types is critical for safe and efficient heavy equipment operation. Soil composition directly impacts the equipment’s performance, traction, and stability. For instance, operating a heavy excavator on soft, clay-rich soil can lead to ground instability and equipment bogging down. Conversely, rocky or hardpan soils can cause excessive wear and tear on equipment components.

I am familiar with various soil classifications, including sandy soils, silty soils, clay soils, and rocky soils. I can identify these different types by their visual characteristics, as well as by their bearing capacity. My experience enables me to adjust the equipment’s operation, including speed, traction, and digging techniques, to suit the prevailing soil conditions. In situations involving unstable soil, I would implement measures to improve ground stability, such as using ground mats or other support structures, before commencing work.

Q 13. How do you handle challenging weather conditions during operation?

Challenging weather conditions can significantly impact the safety and efficiency of heavy equipment operation. My approach involves assessing the weather conditions before starting any task. High winds, heavy rain, snow, or ice can affect visibility, equipment stability, and the safety of personnel.

In case of severe weather, I will halt operations immediately to ensure the safety of myself and others. I am trained to operate heavy equipment in various weather conditions, but safety remains my priority. I use appropriate safety measures like slower operation speeds, increased spacing between personnel and equipment, and enhanced visibility measures. I also carefully assess the ground conditions to avoid slips, falls, or equipment damage. For example, in icy or snowy conditions, I might use tire chains or reduce speed to maintain control and avoid skidding.

Q 14. What is your experience with GPS-guided equipment?

I have significant experience operating GPS-guided equipment, which enhances precision and efficiency. This technology provides real-time location data and allows for automated guidance, resulting in improved accuracy in tasks like grading, excavation, and land clearing. I’m familiar with various GPS systems and their applications in heavy equipment.

For example, I’ve used GPS-guided systems to ensure precise excavation depths and grades in large-scale infrastructure projects. The system enables me to follow pre-programmed paths, reducing the need for manual adjustments and improving accuracy. This translates to reduced material waste, improved productivity, and a better overall project outcome. I am also adept at troubleshooting and calibrating GPS systems to ensure their accurate and reliable functioning. Regular maintenance and calibration checks are vital to maintaining the accuracy of the system.

Q 15. How do you ensure the safety of yourself and others in your work area?

Safety is paramount in heavy equipment operation. My approach is multi-faceted and begins before I even start the engine. It involves a thorough pre-operation inspection of the machine, ensuring all safety features are functioning correctly – lights, horns, brakes, and emergency stops. I then conduct a site assessment, identifying potential hazards like uneven terrain, overhead obstructions, or the presence of other workers or equipment. This includes establishing clear communication protocols with anyone in the vicinity, using hand signals or radios to coordinate movements and avoid collisions. Throughout operation, I maintain a safe speed appropriate to the conditions, consistently scan my surroundings, and never operate the equipment beyond my skill or training level. If any unsafe condition arises, I immediately stop work and report the issue to my supervisor. Think of it like driving a car – defensive driving techniques apply here, multiplied by the potential for much greater damage. Constant awareness and proactive hazard mitigation are key.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with different types of attachments for heavy equipment?

My experience encompasses a wide variety of attachments, including but not limited to: buckets (various sizes and types for excavation and material handling), rippers (for breaking up hard ground), forks (for lifting and moving palletized materials), augers (for drilling holes), and hydraulic hammers (for demolition). I am proficient in the safe and efficient operation of each, understanding their specific limitations and the necessary adjustments to operating techniques based on the attachment. For example, operating with a ripper requires a slower, more controlled approach compared to using a standard bucket. My knowledge extends to understanding the proper maintenance procedures for each attachment, ensuring they are securely attached and in good working order before operation. Proper attachment selection is crucial for project efficiency and safety; choosing the wrong attachment can lead to equipment damage or accidents.

Q 17. Describe a time you had to make a quick decision to prevent an accident.

During a road construction project, I was operating an excavator near a steep embankment. While excavating, I noticed a section of the embankment beginning to slide. It was a split-second decision, but I immediately stopped the excavator, engaged the parking brake, and alerted the nearby crew. Had I continued excavating, the slide likely would have involved the equipment and potentially injured workers. This emphasized the importance of constant vigilance and the ability to quickly assess and respond to potentially hazardous situations. Immediate action is often the difference between a near-miss and a serious accident. After the incident, we re-evaluated the excavation plan and employed additional safety measures to prevent similar occurrences.

Q 18. What is your understanding of OSHA regulations related to heavy equipment operation?

My understanding of OSHA regulations concerning heavy equipment operation is extensive. I am familiar with regulations concerning pre-operation inspections, operator training and certification, personal protective equipment (PPE) requirements, safe operating procedures, and emergency response protocols. This includes knowledge of specific standards regarding fall protection, lockout/tagout procedures, and the proper use of warning devices and signaling systems. I am also aware of regulations related to the transportation and storage of heavy equipment. Staying up-to-date on OSHA standards is critical, and I regularly review updated materials to ensure compliance and the safety of myself and others. I treat adherence to OSHA regulations not just as compliance but as a critical component of responsible and safe operation.

Q 19. How do you maintain accurate records of your work and equipment usage?

I maintain accurate records of my work and equipment usage through a combination of methods. I typically use daily logs to document operating hours, fuel consumption, maintenance performed, and any incidents or near misses encountered. For larger projects, I utilize digital equipment monitoring systems that record operational data automatically, creating detailed reports on equipment performance and utilization. Additionally, I diligently document all pre-operation and post-operation inspections, including any repairs or maintenance performed. This meticulous record keeping is essential for ensuring equipment longevity, identifying potential issues early, optimizing efficiency, and providing accurate data for billing and project management. Accurate records are not just good practice; they are essential for accountability and demonstrating responsible equipment management.

Q 20. How do you adapt your operating techniques to different types of projects?

Adaptability is crucial in heavy equipment operation. My experience spans various projects, including road construction, site preparation, demolition, and material handling. For each project, I adjust my operating techniques based on the specific requirements, terrain, and the type of equipment being used. For example, precise control and finesse are required for delicate work such as trenching near underground utilities, while aggressive digging techniques are appropriate for large-scale excavation projects. I also consider the environmental conditions, adjusting speed and techniques based on factors such as weather and soil conditions. The key is to approach each project with a thorough understanding of the task and to adapt my skills and techniques to achieve optimal results safely and efficiently.

Q 21. Describe your experience with troubleshooting hydraulic systems.

I possess considerable experience in troubleshooting hydraulic systems. My approach is systematic, starting with a visual inspection for leaks, loose connections, or damage to hoses and lines. I then check fluid levels and examine the hydraulic pump for proper operation. Using pressure gauges and diagnostic tools, I can pinpoint leaks or malfunctions within the system. I am familiar with various hydraulic components, including valves, cylinders, and pumps, and can identify and address common problems such as blocked filters, faulty sensors, or worn seals. I understand the importance of safety when working with high-pressure hydraulic systems, and always follow proper lockout/tagout procedures before attempting any repairs. My troubleshooting skills allow me to minimize downtime and maintain the efficient operation of the equipment.

Q 22. What is your experience with engine diagnostics and repair?

My experience with engine diagnostics and repair is extensive, encompassing both preventative maintenance and troubleshooting complex issues. I’m proficient in using diagnostic tools like engine analyzers to identify faults, from simple sensor malfunctions to more intricate problems with fuel injection systems or turbochargers. For example, on a recent project involving a Caterpillar 777 dump truck experiencing erratic idling, I used a diagnostic scanner to pinpoint a faulty crankshaft position sensor. Replacing the sensor immediately resolved the issue. My experience also includes hands-on repair, including replacing components, performing cylinder head work, and understanding the intricacies of various engine types, including diesel, gasoline, and even some specialized propane engines used in certain types of heavy equipment. I’m comfortable working with both mechanical and electronic control systems and have a strong understanding of engine operating parameters and their impact on overall performance and efficiency.

Q 23. Explain your experience with different types of fuel systems in heavy equipment.

I’ve worked with a variety of fuel systems in heavy equipment, from the simpler mechanical systems found in older machinery to the sophisticated electronic common rail systems in modern equipment. My experience includes working with mechanical fuel injection pumps, electronic control units (ECUs) that manage fuel injection, and various fuel delivery methods. For instance, I’ve extensively worked on both mechanical and electronic diesel fuel systems, understanding the differences in their functionality, maintenance requirements, and troubleshooting techniques. I am familiar with the intricacies of fuel filtering, high-pressure fuel lines, and fuel injectors, and how these components impact fuel efficiency and engine performance. Understanding the specific characteristics of different fuels, such as biodiesel blends or ultra-low sulfur diesel, and their impact on the fuel system is also part of my expertise. I’ve also encountered and successfully troubleshooted issues related to fuel contamination, injector clogging, and fuel pressure regulation.

Q 24. Describe your understanding of environmental regulations related to heavy equipment operation.

My understanding of environmental regulations is crucial to my work. I’m familiar with emissions standards, such as EPA Tier 4 regulations for diesel engines, and how these standards impact the operation and maintenance of heavy equipment. This includes knowledge of emission control systems like diesel particulate filters (DPFs), selective catalytic reduction (SCR) systems, and exhaust gas recirculation (EGR). I understand the importance of regular maintenance to ensure compliance with these standards and am knowledgeable about the proper disposal of used oils and other hazardous materials. For example, I know the procedures for safely regenerating DPFs and the importance of using the correct exhaust fluid (DEF) in SCR systems. I’m also aware of local and regional regulations regarding noise pollution and land disturbance, always prioritizing environmentally responsible practices.

Q 25. How do you handle difficult or demanding work environments?

Handling difficult or demanding work environments is something I excel at. I thrive in situations that require adaptability, resourcefulness, and problem-solving skills. For example, working on a remote construction site during a blizzard required quick thinking to protect equipment from the harsh weather and ensure the safety of myself and my team. This involved creative solutions to keep the equipment functioning optimally under extreme conditions. My approach in challenging environments emphasizes proactive planning, effective communication, and a commitment to safety. I’m comfortable working long hours, dealing with unexpected problems, and maintaining a positive attitude even under pressure. I value teamwork and know that collaboration is key to overcoming obstacles in challenging environments.

Q 26. What are your salary expectations for this position?

My salary expectations are commensurate with my experience and qualifications, and I’m open to discussing a competitive compensation package that aligns with the responsibilities of this role and the market value for similar positions. I’m confident that my skills and contributions would be a valuable asset to your team.

Q 27. What are your long-term career goals?

My long-term career goals involve becoming a leading expert in heavy equipment maintenance and repair. I’m keen to continue my professional development by staying updated on the latest technologies and industry best practices. I aspire to take on increased responsibility and leadership roles within the company, potentially mentoring junior technicians and contributing to process improvement initiatives. Ultimately, I want to contribute to a company that values safety, efficiency, and environmental responsibility in its heavy equipment operations.

Q 28. Do you have any questions for me?

Yes, I do have a few questions. First, could you elaborate on the company’s training and development opportunities? Second, what are the typical career progression paths for someone in this role? And finally, what are the company’s safety protocols and procedures?

Key Topics to Learn for Ability to Operate Heavy Equipment Safely and Responsibly Interview

- Pre-Operational Checks and Safety Procedures: Understanding and demonstrating knowledge of pre-shift inspections, including fluid levels, tire pressure, and overall equipment functionality. Knowing how to identify and report mechanical issues.

- Safe Operating Practices: Detailed knowledge of safe operating procedures specific to the type of heavy equipment (e.g., excavators, bulldozers, loaders). This includes understanding blind spots, safe lifting techniques, and proper communication protocols.

- Environmental Awareness: Understanding the impact of heavy equipment operation on the environment and adhering to regulations related to ground stability, erosion control, and fuel efficiency.

- Emergency Procedures: Familiarity with emergency shutdown procedures, reporting protocols in case of accidents, and knowledge of first aid and safety protocols in relation to heavy machinery.

- Maintenance and Repair Basics: Basic understanding of routine maintenance tasks and the ability to identify potential maintenance needs to prevent breakdowns and accidents.

- Regulations and Compliance: Knowledge of relevant safety regulations, permits, and licensing requirements for operating heavy equipment.

- Problem-Solving and Decision-Making: Demonstrating the ability to analyze situations, troubleshoot problems, and make informed decisions in challenging or unexpected scenarios while prioritizing safety.

- Communication and Teamwork: Highlighting skills in communicating effectively with colleagues, supervisors, and other personnel on the job site to ensure a safe and productive work environment.

Next Steps

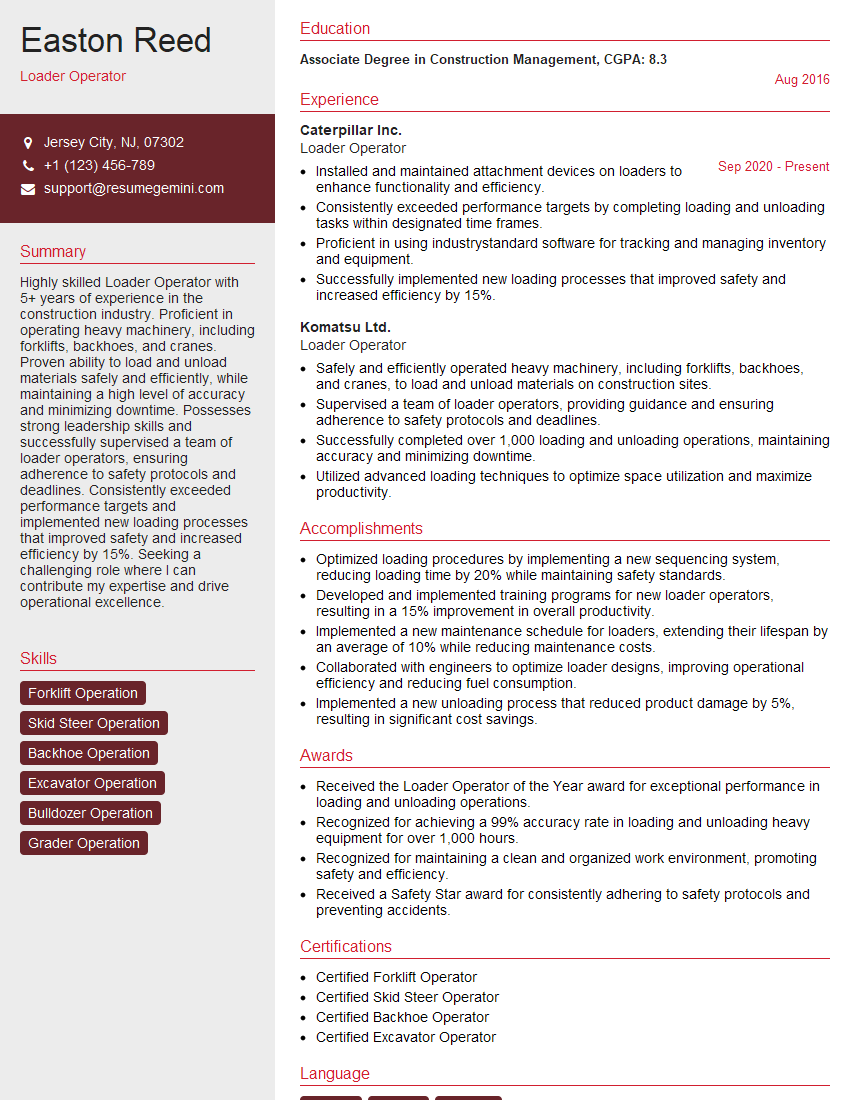

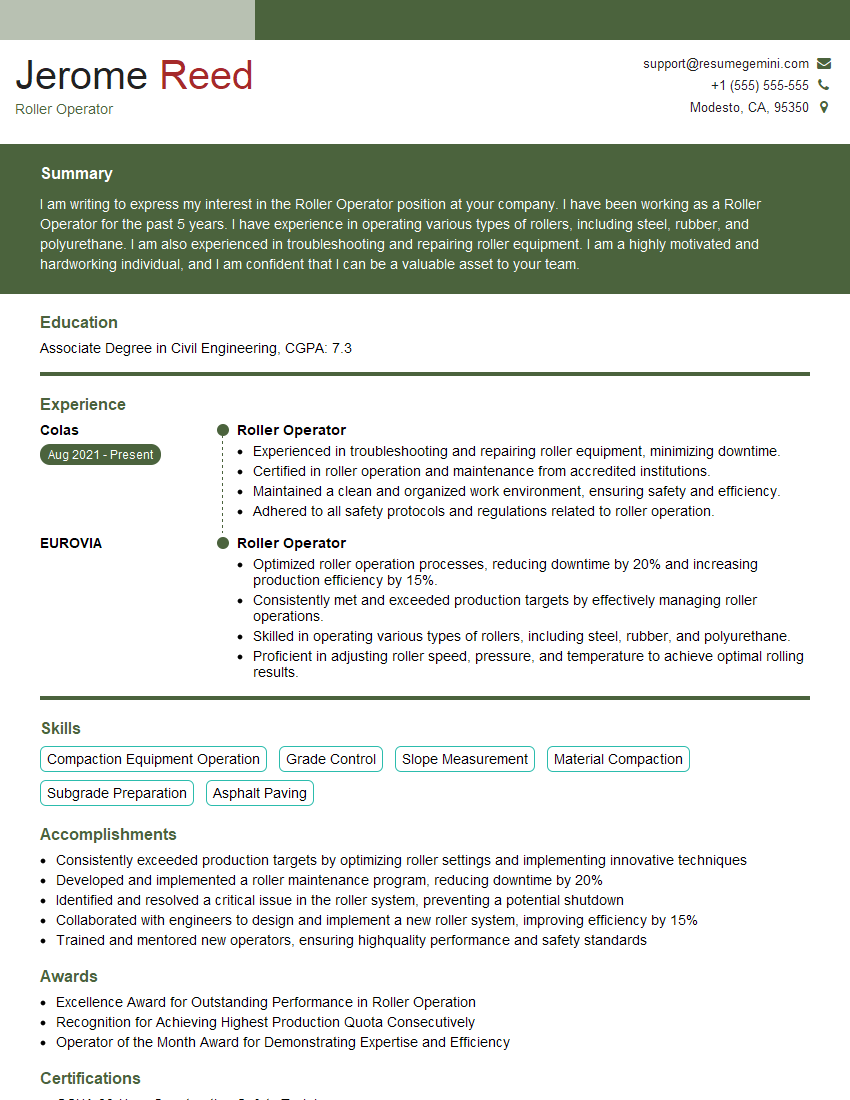

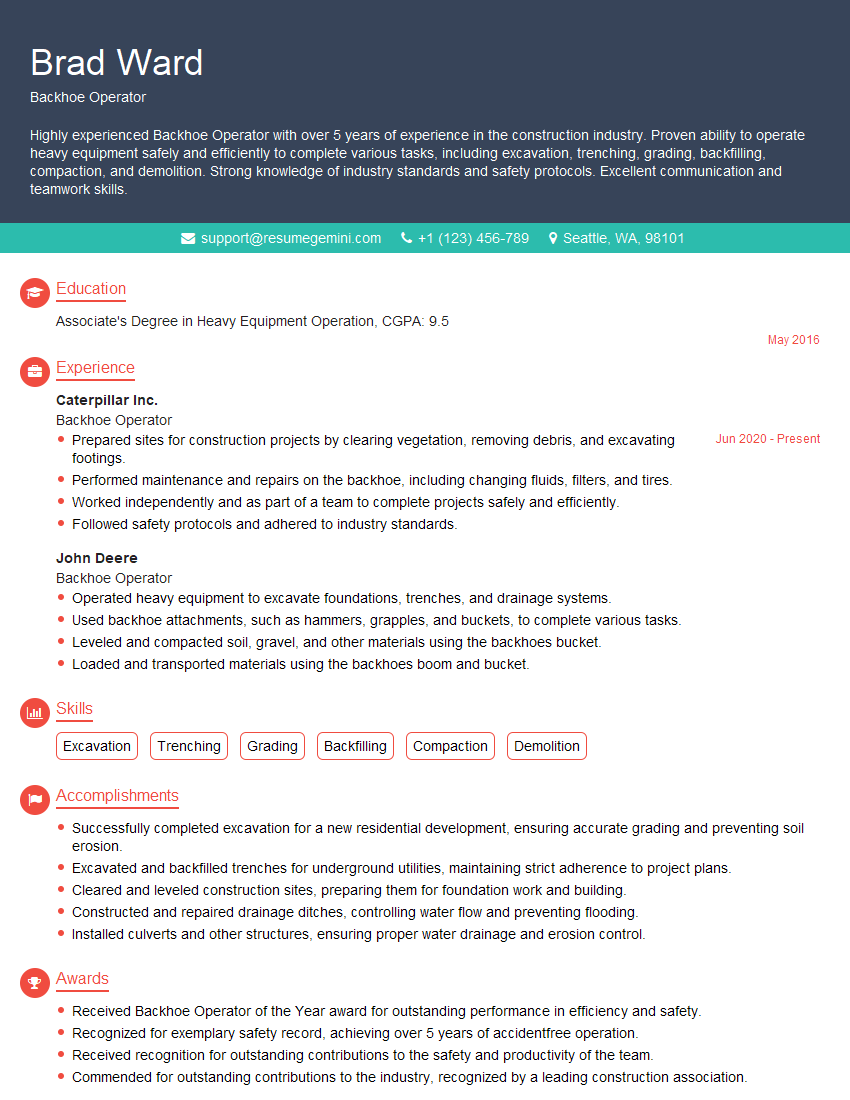

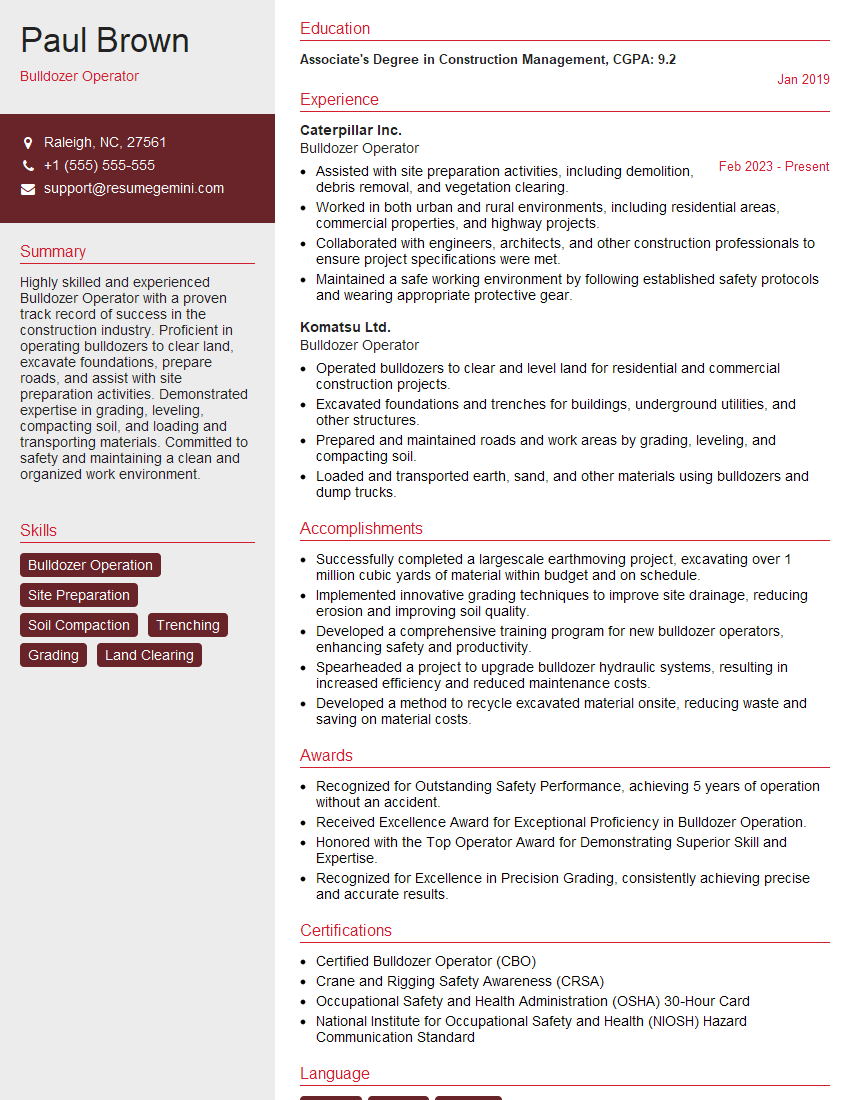

Mastering the ability to operate heavy equipment safely and responsibly is crucial for career advancement in construction, mining, and other related industries. It signifies your commitment to safety, efficiency, and professionalism. To increase your chances of landing your dream job, crafting a strong, ATS-friendly resume is essential. ResumeGemini can help you build a professional and impactful resume that highlights your skills and experience effectively. ResumeGemini provides examples of resumes tailored to this specific skillset, helping you showcase your expertise convincingly. Invest time in building a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.