Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Ability to operate heavy equipment in various soil conditions interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Ability to operate heavy equipment in various soil conditions Interview

Q 1. Describe your experience operating heavy equipment in various soil types (e.g., clay, sand, gravel).

My experience encompasses operating a wide range of heavy equipment, including excavators, bulldozers, and loaders, across diverse soil types. I’ve worked extensively on projects involving clay, sandy, and gravelly soils, each presenting unique challenges. For instance, while excavating a foundation in heavy clay soil, I adjusted the excavator’s bucket to a narrower width and utilized a slower, more deliberate digging technique to prevent the bucket from getting stuck. In contrast, working with sandy soil requires a faster operation, as it’s less cohesive and easier to move, but requires careful monitoring to prevent erosion and instability. In gravelly areas, I’ve had to be particularly mindful of potential rock strikes and adjusted the machine’s settings to better manage the impact and avoid damage to the equipment.

I’ve also gained experience working in mixed soil conditions, where layers of different soil types can be encountered during a single project. This requires a flexible approach and adapting my techniques on the fly. The ability to quickly assess the soil composition and adjust my operation accordingly is a crucial skill I’ve honed over the years.

Q 2. Explain the differences in operating techniques required for different soil conditions.

Operating techniques vary significantly depending on soil conditions. Clay soils, being cohesive and sticky, necessitate slower, more controlled movements. Using the correct bucket type and maintaining optimal machine speed is crucial to avoid getting bogged down. Overly aggressive operation can lead to the bucket becoming completely stuck. Sandy soils are more easily moved, allowing for faster operation. However, this speed needs to be carefully managed to avoid erosion and loss of material. Gravelly soils demand careful control to avoid damaging the equipment with rocks, as well as preventing significant ground disturbance beyond the work area. Each soil type requires a different approach, and understanding the soil’s properties is essential for efficient and safe operation.

For example, when excavating a trench in clay, I would use a smaller bucket and make short, controlled passes. In sand, a larger bucket and faster passes would be suitable, but with careful attention to the surrounding area. With gravel, a ripper attachment might be used to break up large rocks before using the bucket to load the material.

Q 3. How do you adjust your operating techniques for wet, muddy, or unstable soil?

Wet, muddy, or unstable soil significantly increases the risk of equipment becoming stuck or tipping over. My approach in such conditions prioritizes safety and reduced ground pressure. I reduce speed considerably, carefully choosing my path to avoid soft spots identified by visual inspection and observation. I often utilize wider tracks or specialized attachments, such as mats or tracks with wider bases, to distribute the weight of the machine more evenly, reducing the risk of sinking. In extreme conditions, I would use a different piece of equipment entirely or cease operations until the ground conditions improve.

Imagine trying to drive a car through deep mud – you’d need to go very slow and choose your path very carefully, right? It’s the same principle with heavy equipment but with potentially much more significant consequences.

Q 4. What safety precautions do you take when operating heavy equipment in challenging soil conditions?

Safety is paramount when operating heavy equipment in challenging soil conditions. Before commencing any work, I conduct a thorough site inspection to identify potential hazards, such as soft spots, underground utilities, or unstable slopes. I ensure all safety features on the equipment are functioning correctly, including lights, brakes, and alarms. I use appropriate Personal Protective Equipment (PPE), including hard hats, safety glasses, and high-visibility clothing. Maintaining clear communication with spotters and other personnel on the site is essential, especially in areas with limited visibility. Regular equipment maintenance is crucial to avoid unexpected breakdowns, which can create further safety risks. Finally, always adhering to company safety procedures and reporting any potential hazards or safety concerns immediately are key components of my safety approach.

Q 5. How do you identify potential hazards related to soil conditions before operating equipment?

Identifying potential hazards before operation involves a multi-faceted approach. I begin with a detailed site survey, visually assessing the terrain for soft spots, changes in ground elevation, signs of previous ground instability (like cracks or subsidence), and potential obstructions such as rocks or buried objects. If there are any concerns, I’ll utilize additional tools like ground penetrating radar (GPR) to get a better understanding of the subsoil conditions. Local knowledge and historical site data, such as past excavation reports, also offer valuable insights. I also pay close attention to weather conditions as rainfall can significantly impact soil stability. Finally, consulting with experienced engineers or geologists can provide expert assessments when needed.

Q 6. Describe your experience with ground stabilization techniques.

My experience with ground stabilization techniques includes working with various methods to improve soil bearing capacity and prevent instability. This includes using compacted fill material to increase the strength and bearing capacity of a soil layer. I’ve also assisted with installing geogrids or geotextiles to reinforce weak soils, and witnessed the use of ground improvement techniques like deep soil mixing or vibro-compaction. Understanding the properties of the soil and selecting the appropriate stabilization method is critical for the success of the project. For instance, on a project with very loose soil, we used geogrids to prevent settlement and compaction before building a road. I understand the limits of my expertise regarding ground stabilization, and I always defer to geotechnical engineers for comprehensive design and evaluation.

Q 7. What are the signs of soil instability, and how do you react to them?

Signs of soil instability can include visible cracks in the ground, ground settlement or bulging, saturated soil with standing water, or evidence of previous landslides or erosion. Changes in ground elevation, even subtle ones, can indicate instability. Unusual sounds, such as cracking or settling noises, can also be warning signs. If I observe any of these indicators while operating equipment, I immediately stop operation and report the issue to the supervisor. I then maintain a safe distance from the affected area and do not continue work until a geotechnical assessment is completed and any necessary remediation measures are implemented. The safety of myself and others is paramount; a small delay is much better than a serious accident.

Q 8. How do you maintain equipment in various soil conditions to prevent damage?

Maintaining heavy equipment across diverse soil conditions is crucial for preventing costly repairs and downtime. It’s all about proactive care tailored to the specific challenges each soil type presents.

- Regular Cleaning: After each use, thoroughly clean the equipment, removing mud, clay, and debris that can clog components and cause corrosion. Think of it like washing your car – a quick rinse prevents long-term damage. Pay special attention to undercarriage components, tracks, and hydraulic systems.

- Lubrication: Different soil conditions impact lubrication needs. Sandy soils can lead to increased wear, demanding more frequent lubrication. Clay soils can trap moisture, potentially impacting grease consistency. Regularly check and replenish lubricants according to the manufacturer’s recommendations, adjusting the frequency based on soil conditions.

- Undercarriage Inspection: Regularly inspect tracks or wheels for damage, wear, and misalignment. Loose or damaged components can be exacerbated by tough soil conditions. Think of the tracks as the ‘shoes’ of the machine – worn or damaged shoes make walking difficult, and can cause injury.

- Fluid Checks: Monitor engine oil, hydraulic fluid, and coolant levels frequently. Harsh soil conditions can increase stress on these systems. Regular checks are like a health checkup for your equipment.

- Protective Coatings: In highly corrosive environments (e.g., salty soils), consider applying protective coatings to vulnerable metal parts. This adds a layer of defense against rust and decay.

For instance, working with highly abrasive, rocky soil necessitates more frequent checks of undercarriage components, while working in constantly wet clay soil requires extra attention to lubrication and potential corrosion.

Q 9. What are the common causes of equipment malfunctions in different soil types?

Equipment malfunctions are often linked directly to soil conditions. The wrong approach for a specific soil type can lead to serious problems.

- Clay Soils: High stickiness and moisture content can lead to clogged hydraulic systems, increased wear on tracks/wheels, and difficulty with excavation. The weight of the wet soil can also put immense stress on the undercarriage.

- Sandy Soils: While less sticky, sandy soils are abrasive and can cause accelerated wear on moving parts like tracks, sprockets, and bearings. The loose nature can also lead to instability and ground loss.

- Rocky Soils: Rocks can severely damage tracks, cutting edges of buckets, and other vulnerable components. This is exacerbated by high impact forces during operation.

- Organic Soils: These soils tend to be unstable and have low bearing capacity. This may lead to ground loss, sinking, and increased stresses on structural components.

Imagine trying to dig a hole with a shovel in solid rock versus loose sand; the forces and challenges are vastly different. Similarly, different soil types present unique obstacles to heavy equipment operation.

Q 10. How do you troubleshoot equipment issues related to soil conditions?

Troubleshooting equipment issues related to soil conditions requires a systematic approach. This is done in a series of steps:

- Identify the Problem: Pinpoint the specific malfunction: is it reduced power, a hydraulic leak, track damage, or something else?

- Assess Soil Conditions: Analyze the type of soil and its properties (e.g., moisture content, consistency, abrasiveness). This context is crucial.

- Visual Inspection: Carefully examine the affected area of the equipment. Look for obvious damage, leaks, or blockages.

- Check Fluid Levels: Verify levels of engine oil, hydraulic fluid, coolant, and transmission fluid. Low levels are a common indicator of a problem.

- Test Systems: Run diagnostic tests, if available, to check for malfunctions within the specific system.

- Consult Operator Manuals: The machine’s manual provides valuable insights into troubleshooting procedures and common issues.

- Call for Expert Assistance: If the issue is beyond your expertise, seek help from qualified mechanics or technicians.

Example: If you notice reduced power and excessive track wear, the soil may be excessively abrasive (rocky or sandy). This would point to the need for a new set of tracks and maybe checking the drive system.

Q 11. Explain your understanding of soil compaction and its impact on equipment operation.

Soil compaction is the process of soil particles being squeezed together, reducing the pore spaces between them. This has major implications for equipment operation.

- Reduced Bearing Capacity: Compacted soil is less stable and cannot support the weight of heavy equipment as well as uncompacted soil, leading to potential sinking or damage.

- Increased Wear and Tear: The increased resistance in compacted soil puts extra strain on equipment components, leading to accelerated wear and tear on tracks, tires, and other moving parts.

- Difficult Excavation: Compacted soil requires more energy and effort to excavate, reducing productivity and potentially damaging the equipment.

- Water Infiltration: Compacted soil has reduced water permeability. This can lead to ponding and increase ground instability.

Think of it like walking on packed sand versus loose sand. The packed sand is harder to move through and you might sink more. Similarly, compacted soil poses significant challenges for heavy machinery operation.

Q 12. Describe your experience with different types of excavation techniques in various soil conditions.

My experience encompasses a wide range of excavation techniques, adapted to varying soil conditions. I’m proficient in:

- Trenching: Utilizing excavators and backhoes with various bucket sizes and configurations to create trenches of various depths and widths in diverse soil types, adjusting techniques based on soil stability and moisture content.

- Mass Excavation: Employing larger excavators and bulldozers to move large volumes of earth efficiently in situations with less stringent precision requirements.

- Precise Excavation: Using smaller excavators and specialized attachments for tasks requiring meticulous control, such as foundation work or utility installations, altering technique as needed for rocky, sandy, or clay conditions.

- Rock Breaking: Utilizing hydraulic breakers or specialized rock-cutting equipment to efficiently break up rock formations before excavation, a crucial step in many challenging projects.

For example, in a project involving clay soil, I’d use a wider bucket and possibly a ripper attachment to break up the soil before excavation to prevent issues with clogging and reduce stress on the equipment. In a sandy area, I’d concentrate on machine stability by using wider tracks or even deploying a specialized, lightweight machine.

Q 13. How do you determine the appropriate equipment for specific soil conditions?

Selecting the right equipment for specific soil conditions is paramount for safety, efficiency, and cost-effectiveness. Several factors need consideration:

- Soil Type: Clay, sand, rock, or organic soils demand differing equipment capabilities.

- Soil Moisture: Wet soil requires different techniques than dry soil; for example, wet clay can be very difficult to excavate.

- Project Requirements: The depth, width, and precision required influence the size and type of equipment.

- Ground Conditions: Level, sloped, or rocky terrain affects equipment maneuverability and stability.

- Accessibility: The size and maneuverability of the equipment must suit the worksite’s accessibility.

For example, rocky soil might necessitate an excavator with a powerful hydraulic hammer, while soft, wet soil may benefit from a lighter machine with wider tracks to prevent sinking. A detailed soil analysis is often a valuable investment before starting a project.

Q 14. What are the limitations of different types of heavy equipment in various soil conditions?

Different types of heavy equipment have inherent limitations when working in various soil conditions. Understanding these is critical to successful operation.

- Excavators: While versatile, excavators struggle with extremely rocky soil or excessively soft, wet ground. Their effectiveness depends on the soil’s strength and consistency.

- Bulldozers: Effective for moving large volumes of soil, bulldozers can be less precise than excavators and may experience challenges in very rocky or unstable ground.

- Wheel Loaders: Best suited for relatively level terrain and well-drained soils. They can struggle in muddy or steep conditions.

- Track Loaders: Offer better stability and traction than wheel loaders, but still have limitations in excessively soft or rocky ground.

A crawler excavator might be less effective in sandy soil due to the loose nature of the soil creating reduced traction. Conversely, a wheel loader might be inappropriate in swampy conditions due to its poor ground clearance and potential for sinking. Knowing these limitations is as crucial as understanding their strengths.

Q 15. Explain your understanding of soil mechanics and its relevance to equipment operation.

Soil mechanics is the study of how soils behave under stress and strain. Understanding soil mechanics is crucial for operating heavy equipment because soil properties directly impact machine performance, safety, and project efficiency. Different soil types – like clay, sand, gravel, or silt – exhibit varying strengths, drainage characteristics, and compaction properties. For example, operating a bulldozer on saturated clay requires a significantly different approach than operating it on dry, compacted gravel. The former might necessitate reduced speed and a gentler approach to avoid excessive ground disturbance and equipment bogging, while the latter allows for higher speeds and heavier loads.

Specifically, knowledge of soil bearing capacity (the maximum load a soil can support without failure), shear strength (resistance to sliding or deformation), and permeability (how easily water flows through the soil) is critical. This knowledge informs decisions about ground preparation, equipment selection, and operational techniques to prevent ground instability, equipment damage, and accidents.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the safety of yourself and others while operating equipment in challenging soil conditions?

Safety is paramount. My safety protocols begin before I even start the engine. This includes a thorough pre-operational check (detailed in my next answer) and a site assessment to identify potential hazards – unstable slopes, overhead power lines, underground utilities, or the presence of other personnel or equipment. I always wear appropriate Personal Protective Equipment (PPE), including hard hats, safety glasses, hearing protection, and high-visibility clothing.

While operating, I maintain a safe speed, avoid sudden movements, and constantly monitor the equipment’s condition and surroundings. I establish clear communication with other personnel on site using hand signals or radios to prevent collisions or mishaps. If I encounter unexpectedly challenging conditions, I immediately stop the operation, reassess the situation, and implement appropriate safety measures before continuing. I never compromise safety for productivity.

Q 17. Describe your experience with pre-operational checks for heavy equipment.

My pre-operational checks are meticulous and follow a standardized checklist. This includes verifying fluid levels (engine oil, hydraulic fluid, coolant, fuel), inspecting tires for wear and pressure, checking brakes and steering responsiveness, and ensuring all safety systems (lights, horns, alarms) are functioning correctly. I also inspect the undercarriage for any damage or debris, and I look for leaks. I pay close attention to the condition of the attachments – buckets, blades, etc. – checking for wear, damage, or loose components. Finally, I conduct a visual inspection of the surrounding area to identify any potential obstacles or hazards. A comprehensive pre-operational check is not just a routine; it’s a critical safety measure that prevents costly downtime and potential accidents.

For example, I once noticed a small crack in a hydraulic line during my pre-operational check. Addressing this early prevented a major hydraulic failure during operation, saving significant repair time and costs.

Q 18. How do you manage fuel consumption in different soil conditions?

Fuel efficiency varies dramatically depending on soil conditions. Operating in soft, wet soil requires more power and therefore consumes more fuel than working on firm, dry ground. To manage fuel consumption, I adjust my operating techniques accordingly. In soft soil, I use lower gears, avoid unnecessary idling, and optimize the machine’s weight distribution to minimize slippage. In firmer soil, I can use higher gears and increase speed where safe and appropriate. Regular maintenance, such as keeping tires properly inflated, contributes significantly to better fuel economy. Excessive idling is a major fuel waster, so I switch off the engine whenever the machine is stationary for any length of time.

Furthermore, understanding the load-bearing capacity of the soil allows me to optimize the amount of material moved per pass, reducing the number of cycles required and subsequently the fuel consumption. Effective planning and efficient work methods are crucial in this regard.

Q 19. What is your experience with GPS-guided heavy equipment operation?

I have extensive experience operating GPS-guided heavy equipment. This technology significantly enhances precision and efficiency. GPS systems allow for automated steering, grade control, and precise material placement. This leads to reduced material waste, improved accuracy in construction projects, and reduced operator fatigue. The systems I’ve worked with typically involve a GPS receiver integrated into the machine’s control system, providing real-time location data and guidance.

For instance, on a recent project involving road grading, the GPS guidance system enabled us to maintain the precise grade and alignment within a very tight tolerance, resulting in a smoother, more accurate finished product and fewer corrections.

Q 20. How do you handle unexpected changes in soil conditions during operation?

Unexpected changes in soil conditions are a common challenge. My response involves a combination of observation, assessment, and adaptation. If I encounter unexpectedly soft ground, I immediately reduce speed and load, possibly switching to a lower gear to prevent bogging or equipment damage. Conversely, if I encounter unexpectedly hard or rocky ground, I may need to adjust my operating techniques to prevent equipment damage. Communication is key; I would inform the supervisor or site manager immediately about the change in conditions and seek guidance on the best course of action. In extreme cases, changing equipment or modifying the work plan might be necessary.

For example, encountering unexpected bedrock during excavation required switching to a rock breaker attachment and a modified digging strategy to avoid damaging the equipment.

Q 21. Explain your experience with operating equipment at different grades and slopes.

Operating equipment on slopes and grades requires extra caution and skill. The steeper the grade, the greater the risk of equipment rollover or slides. My experience involves using techniques such as counterbalancing the load, maintaining a safe speed, and always being aware of the machine’s center of gravity. I also understand the limitations of the equipment and the soil, avoiding exceeding safe operating limits. Working on slopes often involves specialized techniques, such as using counterweights or using techniques that reduce the risk of slippage. The specific approach is always dictated by the slope angle, soil conditions, and the type of work being undertaken.

For instance, while working on a steep embankment, I meticulously planned each movement, ensuring that I always maintained a safe working distance from the edge of the slope, preventing both machine and personnel accidents.

Q 22. How do you maintain optimal productivity in varying soil conditions?

Maintaining optimal productivity in varying soil conditions requires a multifaceted approach. It’s not just about operating the machine; it’s about understanding the soil and adapting your techniques.

- Soil Analysis: Before starting any project, understanding the soil type (clay, sand, silt, etc.) is crucial. Different soils have vastly different compaction levels, moisture content, and bearing capacity, impacting machine performance and fuel efficiency. For example, clay soil, when wet, can be extremely sticky and difficult to excavate, requiring a slower pace and potentially different attachments. Sandy soil, on the other hand, might be easy to dig but prone to collapse.

- Equipment Selection: Choosing the right equipment for the job is paramount. A smaller excavator might be ideal for precise work in confined spaces with firm soil, whereas a larger bulldozer is better suited for large-scale earthmoving in looser soil. The right bucket type also makes a difference; a narrow bucket is more effective in tight spaces or rocky areas, while a wider bucket is better for bulk excavation in soft soil.

- Operational Adjustments: You need to adjust your operating techniques based on the soil. This includes adjusting the machine’s speed, depth of cut, and the angle of the bucket. In very soft soil, shallower cuts are needed to prevent the machine from sinking or getting stuck. For hard, rocky soil, you may need to use a ripper or rock breaker attachment.

- Pre-emptive Maintenance: Regular maintenance prevents costly breakdowns that disrupt productivity. This includes frequent inspections of tracks, tires, and hydraulic systems, especially when working in harsh conditions. For example, in sandy or rocky conditions, tracks wear faster and require more frequent lubrication.

Think of it like this: a chef wouldn’t use the same knife to chop vegetables as they would to carve a roast. Similarly, you need the right tools and techniques for each type of soil to maximize productivity.

Q 23. Describe your experience with working with other trades in challenging soil conditions.

Collaboration with other trades is essential in challenging soil conditions. On a recent highway construction project, we were working in expansive clay soil. The surveyors needed precise ground level readings, and the drainage team needed to lay pipes accurately.

- Communication: Clear, consistent communication is paramount. Daily briefings allowed us to coordinate our activities, ensuring that the excavator’s work didn’t interfere with the pipe-laying process or the surveying measurements.

- Coordination: We established designated work zones and utilized signal persons to guide the movement of heavy equipment around workers and utility lines. This prevented accidents and maintained a safe working environment.

- Problem-solving: On one occasion, unexpected bedrock was encountered. The geotechnical engineer was consulted to develop a revised plan which involved blasting. The excavation team carefully cleared the area before the blasting commenced, ensuring the safety of everyone involved.

Working collaboratively not only ensures the project progresses smoothly but also fosters a sense of shared responsibility and improves safety.

Q 24. How do you handle equipment breakdowns in remote locations?

Equipment breakdowns in remote locations are a serious concern. My approach is always proactive, emphasizing preventative maintenance. However, when a breakdown occurs, a systematic approach is crucial:

- Safety First: Secure the area and assess the situation. This includes ensuring the machine is safely shut down and that no one is at risk.

- Assessment and Diagnosis: I try to pinpoint the problem. If possible, I use onboard diagnostics or contact the equipment manufacturer’s support line. Experience helps recognize common problems quickly.

- Repair or Evacuation: If the problem is minor and repairable in the field (e.g., a simple hydraulic leak), I will attempt to fix it. However, for major repairs, I contact the appropriate support services. This often involves arranging for a mobile repair team or having the equipment towed back to a workshop.

- Documentation: Detailed documentation of the breakdown, repair, and downtime is essential for insurance purposes and for improving maintenance procedures in the future.

Having a well-stocked emergency kit, including basic tools, spare parts, and communication equipment, is essential in remote areas. A satellite phone can be a lifesaver.

Q 25. Explain your understanding of load capacity and its importance in different soil conditions.

Understanding load capacity is fundamental to safe and efficient earthmoving. The load capacity refers to the maximum weight a machine can safely lift or carry. This is directly impacted by the soil conditions.

- Soil Bearing Capacity: Soft soils have a lower bearing capacity than hard soils. This means that a machine operating on soft soil can sink or become unstable if carrying an excessive load. For example, an excavator might be capable of lifting 10 tons on firm ground, but only 5 tons on very soft clay.

- Ground Conditions: Factors like slope, moisture content, and the presence of underground utilities or obstacles all affect the effective load capacity. Working on a slope reduces the machine’s stability, thus decreasing its safe load capacity.

- Safe Operating Practices: Operators should always consult the machine’s load charts and never exceed the recommended load capacity for the given soil conditions. Using load-monitoring systems can provide real-time information about the machine’s load, helping prevent overloading.

Ignoring load capacity can lead to catastrophic equipment failure, injury, or even death. It’s a non-negotiable aspect of safe operation.

Q 26. How do you prevent ground subsidence or soil erosion during operations?

Preventing ground subsidence and soil erosion is a key element of responsible earthmoving. Strategies include:

- Proper Drainage: Effective drainage systems minimize water accumulation which weakens soil structure and increases the risk of erosion and subsidence. This often involves the creation of ditches, swales, or culverts to divert water away from the work area.

- Soil Stabilization: Techniques such as compaction, adding stabilizing agents, or using geotextiles can increase soil strength and reduce the risk of subsidence. Compaction ensures the soil particles are tightly packed, making it more resistant to settling.

- Erosion Control Measures: Temporary erosion control measures such as silt fences, straw bales, or vegetative cover are essential, especially on sloped areas. These prevent soil from being washed away by rainfall or wind.

- Minimizing Disturbance: Careful planning of excavation paths and minimizing unnecessary soil disturbance can reduce the risk of both subsidence and erosion.

Thinking proactively about soil stability is crucial to preventing costly repairs and environmental damage later on.

Q 27. What are your strategies for minimizing environmental impact during earthmoving operations?

Minimizing environmental impact during earthmoving operations is a high priority. This requires careful planning and execution:

- Dust Suppression: Using water sprays or dust suppressants during dry conditions minimizes dust emissions which can cause air pollution and respiratory problems.

- Noise Reduction: Using quieter equipment and scheduling noisy operations during less sensitive times can minimize noise pollution affecting wildlife and nearby communities.

- Soil and Water Management: Proper management of excavated soil and water prevents contamination of waterways or damage to natural habitats. This includes careful disposal of waste materials and implementation of effective erosion control measures.

- Vegetation Protection: Protecting existing vegetation wherever possible is important for biodiversity and erosion control. Where vegetation must be removed, efforts are made to replant.

- Compliance with Regulations: Adhering to environmental regulations and permits ensures the project is conducted in a sustainable manner.

Sustainability isn’t just a buzzword; it’s about ensuring the long-term health of our environment and future generations.

Q 28. Describe your understanding of relevant safety regulations for operating heavy equipment in various soil conditions.

Safety regulations for operating heavy equipment vary by region and jurisdiction, but some common themes include:

- Operator Training and Certification: Operators must possess the necessary training and certifications to operate heavy equipment. These qualifications demonstrate competency in safe operating procedures and emergency response.

- Pre-operational Inspections: Regular pre-operational inspections of the equipment are mandatory to identify any mechanical defects that could cause accidents.

- Personal Protective Equipment (PPE): Operators must wear appropriate PPE, including hard hats, safety glasses, high-visibility clothing, and hearing protection.

- Safe Operating Procedures: Strict adherence to safe operating procedures, including speed limits, load limits, and right-of-way protocols, is paramount. This minimizes the risk of collisions and other accidents.

- Emergency Procedures: Operators should be familiar with emergency procedures for accidents, breakdowns, and other unforeseen events. This involves knowing how to use the equipment’s safety features and emergency communication systems.

- Site-Specific Safety Rules: Every job site will have its own specific safety rules related to the environment and the project. These rules are important and must be followed carefully.

Safety isn’t optional; it’s an integral part of every operation, and compliance with regulations is non-negotiable.

Key Topics to Learn for Ability to operate heavy equipment in various soil conditions Interview

- Understanding Soil Types and Properties: Learn to identify different soil types (clay, sand, silt, loam) and their impact on equipment operation, including bearing capacity, traction, and stability.

- Equipment Selection and Operation for Varying Soil Conditions: Discuss the appropriate selection of heavy equipment (e.g., excavators, bulldozers, loaders) based on soil type and project requirements. Explain the adjustments needed to machine settings and operating techniques for optimal performance in diverse soils.

- Ground Pressure and Stability: Understand the principles of ground pressure and how it relates to soil compaction, equipment stability, and potential for ground damage. Explain techniques for minimizing ground disturbance and maximizing equipment stability.

- Dealing with Challenging Soil Conditions: Describe your experience handling difficult soil conditions such as soft ground, rocky terrain, or extremely wet or dry conditions. Explain problem-solving approaches and safety precautions implemented.

- Safety Procedures and Best Practices: Highlight your understanding and adherence to safety regulations and best practices for operating heavy equipment in various soil conditions, including pre-operation checks, site assessments, and emergency procedures.

- Maintenance and Troubleshooting: Discuss routine maintenance procedures necessary for operating heavy equipment effectively and safely in diverse soil conditions, along with troubleshooting common issues arising from varying soil types.

- Environmental Considerations: Demonstrate your awareness of environmental regulations and best practices related to soil erosion, compaction, and the use of heavy equipment in sensitive environments.

Next Steps

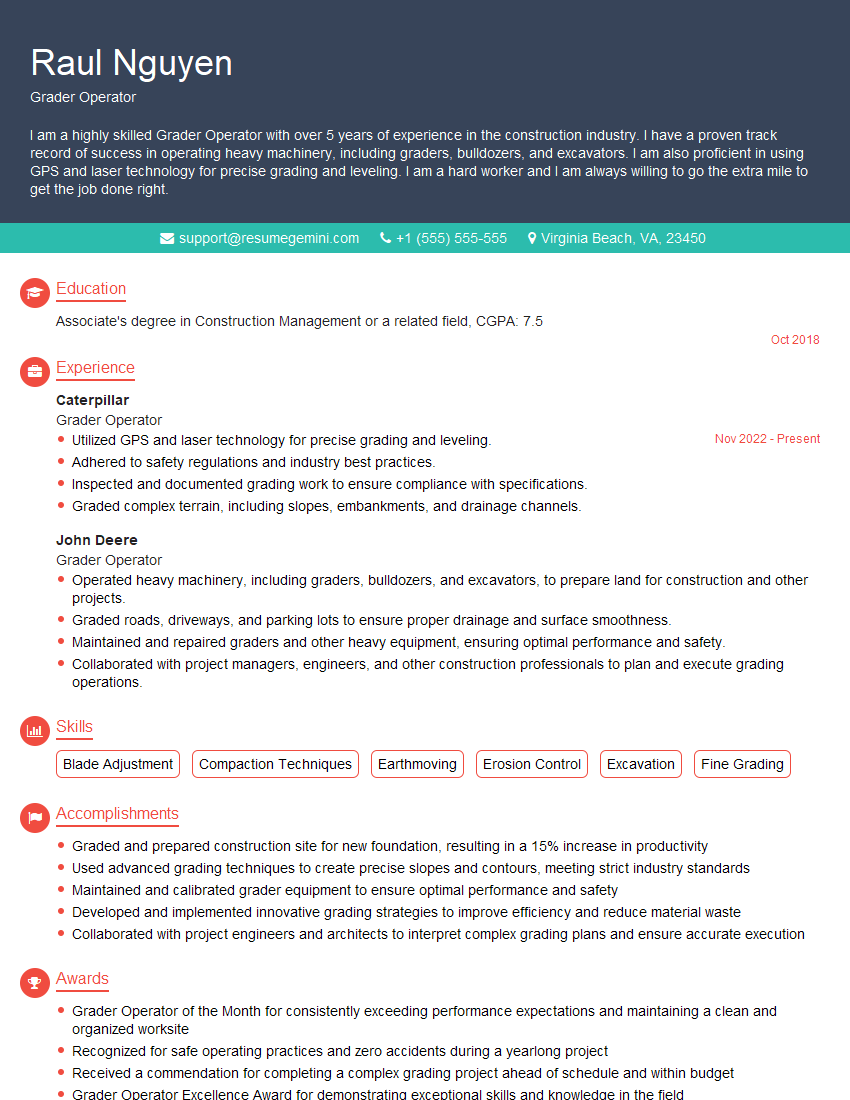

Mastering the ability to operate heavy equipment in various soil conditions is crucial for career advancement in construction, mining, and other related industries. It showcases your adaptability, problem-solving skills, and commitment to safety. To increase your chances of landing your dream job, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, tailored to highlight your skills and experience. Examples of resumes tailored to showcasing “Ability to operate heavy equipment in various soil conditions” are available, helping you craft a document that grabs the attention of recruiters.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.