Cracking a skill-specific interview, like one for Ability to Work in High Places, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Ability to Work in High Places Interview

Q 1. Describe your experience with fall protection equipment.

My experience with fall protection equipment spans over 15 years, encompassing various industries including construction, telecommunications, and wind energy. I’ve worked extensively with a wide range of equipment, from basic harnesses and lanyards to more complex systems like self-retracting lifelines (SRLs), and fall arrest blocks. This experience includes not only using the equipment but also inspecting, maintaining, and training others on its proper use. For example, during a recent project involving the installation of communication towers, I was responsible for ensuring all crew members used and inspected their equipment daily, adhering strictly to OSHA standards. This included regularly checking for fraying, damage, and proper functioning of all components.

Q 2. What are the different types of fall protection systems?

Fall protection systems are categorized into several types, each designed for different situations and work environments. The most common include:

- Guardrail Systems: These offer a physical barrier preventing falls, usually consisting of top rails, mid-rails, and toe boards.

- Personal Fall Arrest Systems (PFAS): These systems catch a worker after a fall has occurred. Key components include a harness, lanyard, and anchorage point. Sub-types include self-retracting lifelines (SRLs), shock-absorbing lanyards, and vertical lifelines.

- Positioning Systems: Designed to keep a worker in a safe position, preventing them from falling. Often used in situations requiring hands-free work at heights.

- Safety Nets: Provide a safety net below the work area, catching a worker in the event of a fall. They’re effective for larger areas and require careful planning and installation.

- Fall Restraint Systems: Prevent a worker from reaching the edge where a fall could occur. Usually involves a lanyard and a device attached to a fixed point, restricting movement.

The choice of system depends heavily on the specific job, the environment, and the potential fall distance.

Q 3. Explain the hierarchy of fall protection controls.

The hierarchy of fall protection controls prioritizes eliminating the hazard entirely, followed by progressively less effective but still important measures. It’s a sequential approach:

- Elimination: Completely removing the fall hazard. For instance, redesigning a building to eliminate the need for working at heights.

- Substitution: Replacing a hazardous task with a safer one. Using a boom lift instead of climbing a ladder.

- Engineering Controls: Implementing physical modifications to minimize fall risks, such as installing guardrails or platforms.

- Administrative Controls: Implementing procedures and training to reduce risk, including job safety analysis (JSA) and ongoing training.

- Personal Protective Equipment (PPE): Utilizing fall protection equipment such as harnesses, lanyards, and SRLs. This is the last resort after all other controls have been considered.

This hierarchy ensures that the safest possible measures are employed first, with PPE being a last line of defense.

Q 4. How do you perform a pre-task inspection of fall protection equipment?

A pre-task inspection is crucial for ensuring equipment safety and preventing accidents. My inspection process involves a detailed visual check of every component, following a checklist. This includes:

- Harness: Checking for tears, cuts, fraying, and proper functioning of buckles and straps. Inspecting stitching and ensuring all labels are legible.

- Lanyard/SRL: Checking for damage to the webbing, corrosion of metal parts, and proper functioning of the braking mechanism (in the case of SRLs). Confirming the lanyard’s length is appropriate for the work.

- Anchorage Point: Verifying the point’s structural integrity, ensuring it’s rated for the intended load, and that it’s securely attached.

- Connectors: Inspecting carabiners, snap hooks, and other connectors for damage, corrosion, and proper closure. Ensuring they are correctly attached and locked.

Any damaged or questionable equipment is immediately taken out of service and replaced. Documentation of the inspection is essential, often using a digital inspection system, to provide a record of equipment condition and maintenance.

Q 5. What are the limitations of different fall protection systems?

Each fall protection system has limitations. Understanding these limitations is crucial for safe work practices:

- Guardrails: Ineffective if a worker falls over or under the guardrail.

- PFAS: The effectiveness of a PFAS relies on the proper selection and maintenance of equipment and a suitable anchorage point. A fall can still result in injuries due to the impact forces.

- Positioning Systems: Only effective for preventing falls, not arresting them if a failure occurs.

- Safety Nets: Require significant space below and can be ineffective if a worker falls outside the net’s area. They also pose a risk of impact injury upon contact.

- Fall Restraint Systems: Restrict movement, potentially hindering work efficiency and increasing the risk of other hazards if workers try to circumvent the limitations.

It is essential to understand the limitations and select the most appropriate system for the specific task and environment, always considering the potential for system failure and mitigating the impact.

Q 6. Describe your experience working with harnesses and lanyards.

I have extensive experience with harnesses and lanyards, having used them regularly in various high-altitude operations. My experience includes the proper selection of harnesses to fit different body types and work requirements, ensuring a secure and comfortable fit. I’m proficient in inspecting harnesses for wear and tear, proper adjustment, and ensuring all buckles and straps are securely fastened. With lanyards, my expertise includes understanding the different types (shock-absorbing, non-shock-absorbing) and their appropriate applications. I’m also familiar with inspecting lanyards for any signs of damage, fraying, or weakening of the webbing, paying close attention to the connection points to ensure they are secure and free of damage.

For example, during a recent project on a wind turbine, I trained the crew on the proper donning and adjusting of harnesses, ensuring correct fit and minimizing discomfort to maximize safety and productivity.

Q 7. How do you ensure proper anchorage points for fall protection systems?

Ensuring proper anchorage points is critical for the effectiveness and safety of fall protection systems. The anchorage point must be structurally sound and capable of withstanding the forces generated during a fall (often significantly greater than the worker’s weight). My process involves:

- Structural Assessment: Determining the structural capacity of the potential anchorage point, often consulting engineering drawings or performing a load calculation.

- Material Selection: Choosing appropriate anchor points based on material strength and corrosion resistance. This often includes considerations for environmental conditions.

- Secure Attachment: Utilizing appropriate hardware (such as anchor bolts or eye-bolts) and ensuring they are correctly installed and rated for the required load.

- Inspection: Regularly inspecting the anchorage point for any signs of wear, damage, or deterioration, ensuring its continued integrity.

It’s important to remember that not all structural points are suitable anchorage points. Improperly selected or installed anchorage points can lead to catastrophic failure during a fall. Therefore, proper engineering judgment and adherence to safety regulations are essential.

Q 8. What are the signs of damaged or worn fall protection equipment?

Identifying damaged fall protection equipment is crucial for preventing accidents. Regular inspections are paramount. Signs of damage can be subtle or obvious. For harnesses, look for fraying or cuts in webbing, broken stitching, damaged buckles or D-rings, and excessive wear on padding. For lanyards, check for cuts, abrasions, burns, or excessive stretching. Damaged shock absorbers should be immediately replaced. For fall arresters, examine the braking mechanism for signs of damage or wear. A visual inspection alone isn’t enough; always refer to the manufacturer’s instructions for specific inspection criteria and retirement guidelines. Any doubt about the integrity of the equipment warrants its immediate removal from service.

- Example: A frayed lanyard near a connecting point is a clear indication of potential failure, demanding immediate replacement.

- Example: A corroded snap hook on a harness can weaken significantly, compromising its ability to withstand a fall.

Q 9. What actions do you take if you identify a safety hazard while working at heights?

Identifying a safety hazard at height requires immediate action. My first step is to immediately cease work in the affected area. Next, I would clearly communicate the hazard to my supervisor and colleagues, ensuring everyone is aware of the potential danger. This involves a concise description of the hazard and its location. Then, I would isolate the hazard to prevent further exposure, implement temporary control measures such as barriers or warning signs if possible. Finally, I would collaborate with the supervisor to develop and implement a corrective action plan to eliminate the hazard before resuming work. The solution may involve modifying the work procedure, acquiring additional safety equipment, or requesting engineering controls. Documentation of the hazard, the corrective actions taken, and the date of resolution is critical.

Q 10. Describe your experience with rescue procedures for falls from heights.

My experience with rescue procedures includes participation in regular training exercises and practical simulations. I am proficient in the use of various rescue systems, including rope rescue techniques and the operation of appropriate lifting equipment, depending on the situation. I understand the importance of a well-coordinated rescue team and the need for clear communication during an emergency. My training emphasizes a systematic approach to rescue, prioritizing the safety of both the rescuers and the victim. This includes risk assessment, securing the scene, establishing communication, and carefully extracting the fallen person, providing immediate first aid while ensuring our own safety. We practice different scenarios, including rescues from various heights and different types of fall protection systems. I have also received training in emergency response protocols, including recognizing and managing different types of injuries related to falls.

Q 11. What are your responsibilities regarding confined space entry at heights?

My responsibilities regarding confined space entry at heights involve strict adherence to all relevant safety regulations and protocols. This includes ensuring that a confined space entry permit is obtained before entering a space at height. This permit specifies the hazards, the control measures, and the emergency procedures to be followed. Before entering, I ensure that adequate ventilation is available and that atmospheric monitoring is conducted to detect any potential hazards such as oxygen deficiency or toxic gases. The use of appropriate personal protective equipment (PPE), such as fall protection gear, respiratory equipment, and confined space entry suits, is mandatory. I am responsible for conducting regular checks of the equipment and for ensuring that a designated attendant is present outside the confined space to monitor our safety. A communication system is also essential for maintaining contact with the attendant. Any anomaly necessitates immediate exit from the confined space and re-evaluation of the risk.

Q 12. Explain the importance of regular training and certification in working at heights.

Regular training and certification in working at heights are not just important, they are absolutely essential for safety. The work is inherently dangerous, and proper training mitigates these risks. Certifications ensure that workers are competent to handle the various challenges and hazards of working at heights. Training covers essential topics like hazard identification and risk assessment, proper selection and use of fall protection equipment, rescue procedures, and emergency response planning. It also provides practical experience with working at heights using different techniques and equipment. Outdated knowledge is dangerous; periodic refresher courses are crucial to maintain up-to-date knowledge of best practices, equipment advancements, and evolving safety regulations. Certifications demonstrate a commitment to safety and professionalism, reducing the likelihood of accidents.

Q 13. How do you communicate effectively with colleagues while working at heights?

Effective communication is paramount when working at heights, where miscommunication can have devastating consequences. I use clear, concise language, avoiding jargon that might not be universally understood. I utilize visual aids or hand signals when noise levels are high, which is frequently the case in industrial settings. Before starting any task, I conduct briefings with my colleagues to confirm our understanding of the plan, identifying any potential concerns or ambiguities. Regular check-ins throughout the work are necessary to monitor progress, assess safety, and address any emerging issues. In high-risk situations, I may use a designated communication system, such as a two-way radio, to ensure clear and constant communication. This ensures everyone stays informed and coordinated.

Q 14. How do you handle emergency situations while working at heights?

Handling emergency situations at heights requires a calm, systematic approach. My first response is to activate emergency procedures, including alerting my supervisor and emergency services. I would then focus on securing the immediate area to prevent further accidents. Depending on the nature of the emergency, I’ll prioritize immediate first aid to any injured personnel, always ensuring the safety of the rescuers. If a fall has occurred, we’ll use the appropriate rescue procedures, taking into account the height, location and nature of the situation. Following the rescue, a thorough investigation will be conducted to determine the root cause of the emergency and implement corrective actions to prevent future incidents. Accurate documentation of the entire event is crucial for learning from mistakes and making improvements in safety protocols.

Q 15. What are the weather conditions that necessitate suspending work at heights?

Suspending work at heights is crucial for worker safety. Several weather conditions necessitate this action, primarily those that compromise stability and visibility. High winds, for instance, can destabilize scaffolding, ladders, and even the worker themselves, increasing the risk of falls. Heavy rain or snow significantly reduces traction, creating slippery surfaces and increasing the likelihood of slips and falls. Similarly, fog, heavy snow, or thunderstorms severely limit visibility, making it incredibly difficult to navigate the work area safely and accurately assess potential hazards. The presence of lightning also presents an immediate and extreme danger. In essence, any weather condition that significantly impacts visibility, structural stability, or worker safety mandates a work stoppage until conditions improve.

For example, during a project involving roof repairs, I once had to halt operations due to unexpectedly strong gusts of wind. The wind was so forceful that it threatened to blow the scaffolding off the building. The safety of the crew was my top priority, and we resumed only after the wind subsided and conditions were deemed safe.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you assess and mitigate risks associated with working at heights?

Risk assessment and mitigation for working at heights is a systematic process. It starts with a thorough site survey to identify all potential hazards, including the height of the work area, surrounding obstructions, weather conditions, and the type of equipment to be used. Next, a detailed risk assessment is conducted considering these factors, assigning levels of risk to each hazard identified. Based on this assessment, appropriate control measures are implemented. These controls follow a hierarchy of risk control, prioritizing elimination, substitution, engineering controls, administrative controls, and finally, personal protective equipment (PPE).

For example, if a task requires working on a steep roof, we would likely use a fall arrest system instead of relying solely on a ladder. This is substituting a higher-risk method with a safer one. We would also implement engineering controls like scaffolding or edge protection to further minimize the risk of falls. This whole process involves not only following standard safety procedures but also adapting strategies based on the specific circumstances of the project.

Q 17. Describe your experience using different types of access equipment (e.g., ladders, scaffolding).

My experience with access equipment is extensive. I’m proficient with various ladders (extension, step, and single), and I understand the critical importance of proper setup and securing techniques for each type. My experience with scaffolding is particularly noteworthy, as I’ve erected, inspected, and worked on various types, including mobile tower scaffolds, and tube and fitting scaffolds. I am thoroughly familiar with the regulations surrounding their safe use, including proper base plates, bracing, guardrails, and toe boards. I also have experience with aerial work platforms (AWPs), including both scissor lifts and boom lifts, and I am certified to operate several models. I am always meticulous about inspecting equipment before and during use, ensuring everything is in optimal condition and securely fastened.

For instance, during one project, we needed to replace some damaged window panels on a tall building. I opted to use a boom lift instead of scaffolding because of its maneuverability, making access to different areas safer and more efficient. Prior to deployment, I performed a thorough inspection of the boom lift’s hydraulics, controls, and safety features, ensuring everything was up to code. This thorough approach guarantees not only the safety of the worker but also the longevity of the equipment.

Q 18. What are the safety regulations and standards you follow while working at heights?

My work always adheres strictly to relevant safety regulations and standards. These include, but are not limited to, OSHA (Occupational Safety and Health Administration) regulations in the United States, and any relevant national or local codes. These regulations cover aspects such as fall protection systems, the proper use of personal protective equipment (PPE), including harnesses, lanyards, and helmets, and the safe erection and use of access equipment. I’m also familiar with the requirements for emergency procedures, including rescue plans and communication systems. Furthermore, I routinely participate in safety training and refresher courses to ensure my knowledge remains current and best practices are employed.

Regular inspections are a core part of our adherence to safety standards. We always check the equipment before and during work, following checklists to ensure everything is structurally sound and in safe working condition. Regular training and compliance reviews are also critical in maintaining a safe work environment.

Q 19. How do you ensure the stability of your work platform while working at heights?

Ensuring the stability of the work platform is paramount. This starts with selecting the appropriate equipment for the job and the conditions. For instance, ensuring that scaffolding is erected on a level, stable base, with proper bracing and outriggers where necessary. Regular inspections are conducted throughout the project to identify any signs of instability or damage. Loading the platform evenly is also critical, avoiding overloading any one section. In addition, ensuring proper tie-off points for fall protection systems are available and correctly utilized enhances the overall stability and security of the work area. This meticulous attention to detail guarantees a secure and safe workspace for all involved.

During one scaffolding project, we noticed a slight unevenness in the base plates. Instead of proceeding, we immediately corrected the issue. This quick intervention prevented a potentially dangerous situation and ensured the project’s continued safety.

Q 20. Describe your experience with different types of lifting and handling equipment used at heights.

My experience encompasses various lifting and handling equipment used at heights. This includes hoists, winches, and cranes for heavier materials. I’m proficient in their safe operation, understanding the weight limits, load capacities, and proper rigging techniques. I’m also familiar with using smaller, more manual lifting devices like come-alongs and chain blocks for lighter materials. Safety is always the priority, and I strictly adhere to all relevant safety procedures for each piece of equipment, which includes thorough pre-use inspections and adherence to manufacturers’ guidelines.

For instance, on a recent project, we needed to lift heavy roofing materials to the roof. We used a hoist system that was meticulously inspected before use, ensuring the cables were sound and the winch was properly functioning. The load was evenly distributed and secured, following proper rigging procedures and ensuring the safety of both the equipment and workers below.

Q 21. How do you maintain awareness of your surroundings while working at heights?

Maintaining situational awareness while working at heights is crucial. This involves a multi-faceted approach. Firstly, it requires regular visual scans of the surroundings to identify any potential hazards such as falling objects, changing weather conditions, or approaching equipment. Secondly, effective communication with ground crew is essential for coordinating movements and alerting others to potential dangers. Thirdly, the use of appropriate PPE including helmets and high-visibility clothing enhances safety and awareness. Finally, taking regular breaks to avoid fatigue and maintain focus is extremely important. This awareness reduces risks and safeguards both myself and my colleagues.

I often employ a system of regular checks, scanning my surroundings at least every 15 minutes while performing a task, to ensure I remain aware of potential changes in the environment. I also take regular breaks to rest and re-evaluate the safety of the situation.

Q 22. What are the common causes of falls from heights?

Falls from heights are a serious concern in many industries. They’re primarily caused by a combination of human error and inadequate safety measures. Let’s break down the common causes:

- Lack of proper fall protection: This includes not using harnesses, lifelines, or anchor points correctly, or not using them at all. Imagine a painter neglecting to clip their harness onto a secure lifeline – a single misstep could be devastating.

- Slippery or unstable surfaces: Working on wet, icy, or uneven surfaces dramatically increases the risk of slips and falls. Think of a roofer working on a snowy roof without proper footwear or anti-slip measures.

- Improper equipment use: Using faulty or incorrectly assembled equipment, like scaffolding or ladders, significantly increases the risk. A ladder that’s not properly secured or extended far enough can easily topple over.

- Human error: Distraction, fatigue, rushing, and improper training are major contributors. For example, a worker who is tired might lose their focus and fail to secure themselves properly.

- Environmental factors: Strong winds, poor visibility, and unexpected weather conditions can increase the risk of falls. Imagine a window washer unexpectedly facing strong gusts of wind.

Addressing these causes through proper training, equipment maintenance, and adherence to safety protocols is crucial to preventing falls from heights.

Q 23. Explain your understanding of the different types of rescue plans.

Rescue plans for working at heights vary depending on the specific circumstances and the potential hazards. Generally, they involve a combination of strategies and equipment to safely bring a fallen worker to the ground. These plans can be categorized as follows:

- Self-rescue plans: These involve the worker using their own equipment, such as a self-retracting lifeline, to safely descend to the ground. This requires proper training and the correct equipment.

- Assisted rescue plans: This involves another worker or rescue team assisting the fallen worker. This might include using ropes, harnesses, and specialized rescue equipment to pull the worker to safety.

- Emergency services rescue plans: In some situations, emergency services (fire department, etc.) will be necessary to perform the rescue. These plans involve coordinating with emergency services and ensuring clear communication of the situation and location.

A comprehensive rescue plan considers factors such as the location of the fall, the type of fall protection used, and the available resources for rescue. Each plan must be reviewed, practiced, and updated regularly to ensure its effectiveness and maintain its relevance with the changing work environment.

Q 24. What are your personal safety measures when working at heights?

My personal safety measures when working at heights are paramount. They go beyond simply wearing PPE; they represent a commitment to proactive safety. Here’s my approach:

- Thorough inspection: Before starting any work, I thoroughly inspect all equipment, including harnesses, lifelines, anchor points, and scaffolding, to ensure they are in good condition and correctly set up.

- Proper use of PPE: I always wear the appropriate PPE, including a full-body harness, a securely attached lifeline, and appropriate footwear. This is not just a matter of compliance but of self-preservation.

- Maintaining three points of contact: When using ladders or scaffolding, I always maintain three points of contact to ensure stability and avoid falls. This means that at least three parts of my body are in contact with the structure at any given time.

- Awareness of surroundings: I maintain constant awareness of my surroundings, including potential hazards like weather conditions, obstacles, and the presence of other workers. Distraction is the enemy of safety.

- Following procedures: I strictly follow all established safety procedures and communicate clearly with my colleagues. This includes pre-work meetings and hazard identification.

- Regular training: I prioritize regular training and refreshers to stay up-to-date with the latest safety standards and best practices. Height safety is a constantly evolving field, and continuous learning is key.

My approach is based on the principle that safety is not just a set of rules to be followed but a mindset to be embraced.

Q 25. Describe a time you had to overcome a challenge while working at heights.

During a project involving the installation of communication equipment on a tall cell tower, a sudden, unexpected thunderstorm rolled in. The wind intensified, making the work exceptionally dangerous. Our initial plan was disrupted, as we couldn’t safely continue using the regular system of fall protection due to the risk of being struck by lightning.

My immediate response was to prioritize safety and halt operations immediately. We convened a brief team meeting and assessed the situation, considering the increased risks associated with the intense weather and the potential danger of working in such conditions. After a detailed discussion, we adopted a different approach. We secured the equipment that had been already installed and moved to a designated shelter, ensuring everyone’s safety. We decided to postpone the task until the weather improved, ensuring we could complete the task safely without endangering anyone. This wasn’t just about completing the job but about doing so responsibly and prioritizing our safety above everything else. This incident highlighted the importance of adaptability, strong communication, and strict adherence to weather safety protocols.

Q 26. What is your experience with using Personal Protective Equipment (PPE) while working at heights?

My experience with Personal Protective Equipment (PPE) is extensive. I’m proficient in the selection, inspection, and proper use of all necessary PPE for working at heights. This includes:

- Full-body harnesses: I understand the importance of proper fit and adjustment, and I’m skilled in performing regular inspections to identify any wear and tear.

- Anchors and lifelines: I know how to select appropriate anchor points and ensure that lifelines are correctly installed and maintained, free of any snags or damage.

- Fall arrest systems: I’m familiar with different types of fall arrest systems and their limitations and know how to use them appropriately to minimize the impact of a fall.

- Safety helmets, gloves, and footwear: I always wear the appropriate protective gear to minimize the risk of injuries from falling objects or slips.

Beyond the practical application, I understand the underlying principles of PPE selection – ensuring the right equipment is used for the specific task and environment. I can clearly demonstrate the proper inspection procedure for all PPE, and I wouldn’t hesitate to stop work if any equipment is deemed unsafe.

Q 27. How would you respond to a colleague who is not following safety procedures at heights?

My response to a colleague not following safety procedures at heights would be direct, yet constructive. It’s a crucial situation requiring immediate action. My approach would be as follows:

- Address the situation privately: I would pull the colleague aside and calmly explain the specific safety violation and the potential consequences, emphasizing the importance of adhering to safety procedures for their own safety and the safety of others.

- Explain the risks: I would clearly explain the specific risks involved with not following the procedures, providing real-world examples if possible to emphasize the seriousness of the situation.

- Offer assistance and guidance: I would offer assistance and guidance to ensure the colleague understands how to follow the correct procedures and any necessary refresher training.

- Report the incident if necessary: If the behavior continues or represents a significant risk, I would report the incident to the supervisor to ensure appropriate action is taken.

My aim would be to correct the behavior and prevent future incidents, focusing on education and collaboration rather than confrontation. Safety is a shared responsibility.

Q 28. Explain your understanding of the relevant legislation and standards for working at heights.

My understanding of relevant legislation and standards for working at heights is thorough. The specific regulations vary by jurisdiction, but common themes revolve around risk assessment, fall protection, training, and rescue plans. Some key areas include:

- OSHA (Occupational Safety and Health Administration) in the US: OSHA has detailed standards for fall protection, including requirements for fall protection systems, training, and emergency action plans. They emphasize hazard assessment and risk mitigation.

- CSA (Canadian Standards Association) in Canada: The CSA provides standards for fall protection equipment and procedures, focusing on equipment specifications, inspections, and safe work practices.

- International standards (e.g., ISO): International standards, such as those from the ISO (International Organization for Standardization), provide guidance on fall protection, outlining best practices across various industries and environments.

These regulations and standards mandate thorough risk assessments before commencing any work at heights, emphasizing the need for proper planning, training, and ongoing monitoring to ensure compliance and worker safety. I stay updated on these regulations and ensure my practices reflect the most current standards. Compliance is not just a legal requirement but a moral obligation.

Key Topics to Learn for Ability to Work in High Places Interview

- Safety Regulations and Procedures: Understanding and adhering to OSHA regulations, company-specific safety protocols, and the proper use of safety equipment (harnesses, ropes, lifelines, etc.).

- Risk Assessment and Mitigation: Identifying potential hazards at height, evaluating risk levels, and implementing appropriate control measures to minimize the likelihood of accidents.

- Equipment Knowledge and Operation: Demonstrating proficiency in using various equipment relevant to working at heights, including but not limited to scaffolding, aerial lifts, and fall protection systems.

- Physical Fitness and Health: Understanding the physical demands of working at heights and maintaining the necessary physical fitness and stamina to perform tasks safely and effectively. This includes discussing any limitations and accommodations needed.

- Communication and Teamwork: Highlighting the importance of clear communication with colleagues and supervisors, especially in high-pressure situations. Emphasizing collaborative problem-solving skills within a team environment.

- Emergency Procedures: Demonstrating knowledge of emergency response protocols, including recognizing signs of distress, initiating rescue procedures, and providing first aid if necessary.

- Problem-Solving and Decision-Making: Showcasing your ability to quickly assess and resolve unexpected issues that may arise while working at heights, emphasizing your ability to make sound, safe decisions under pressure.

Next Steps

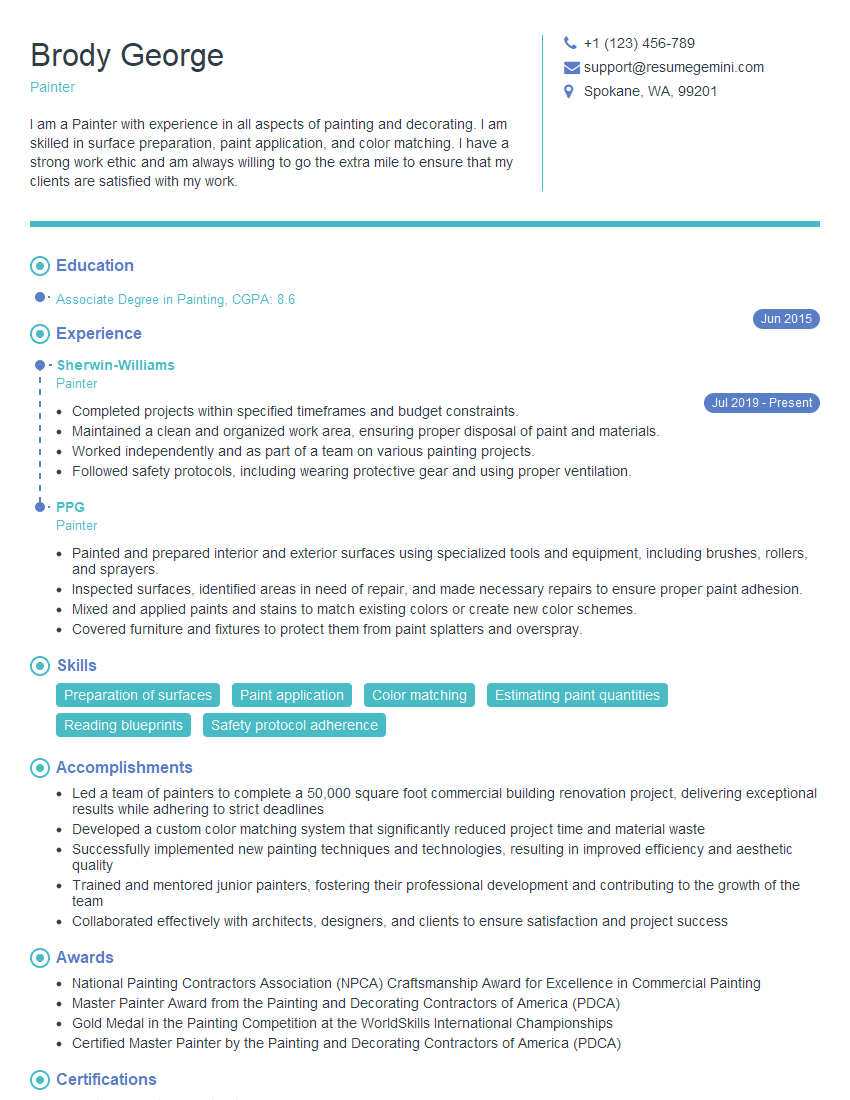

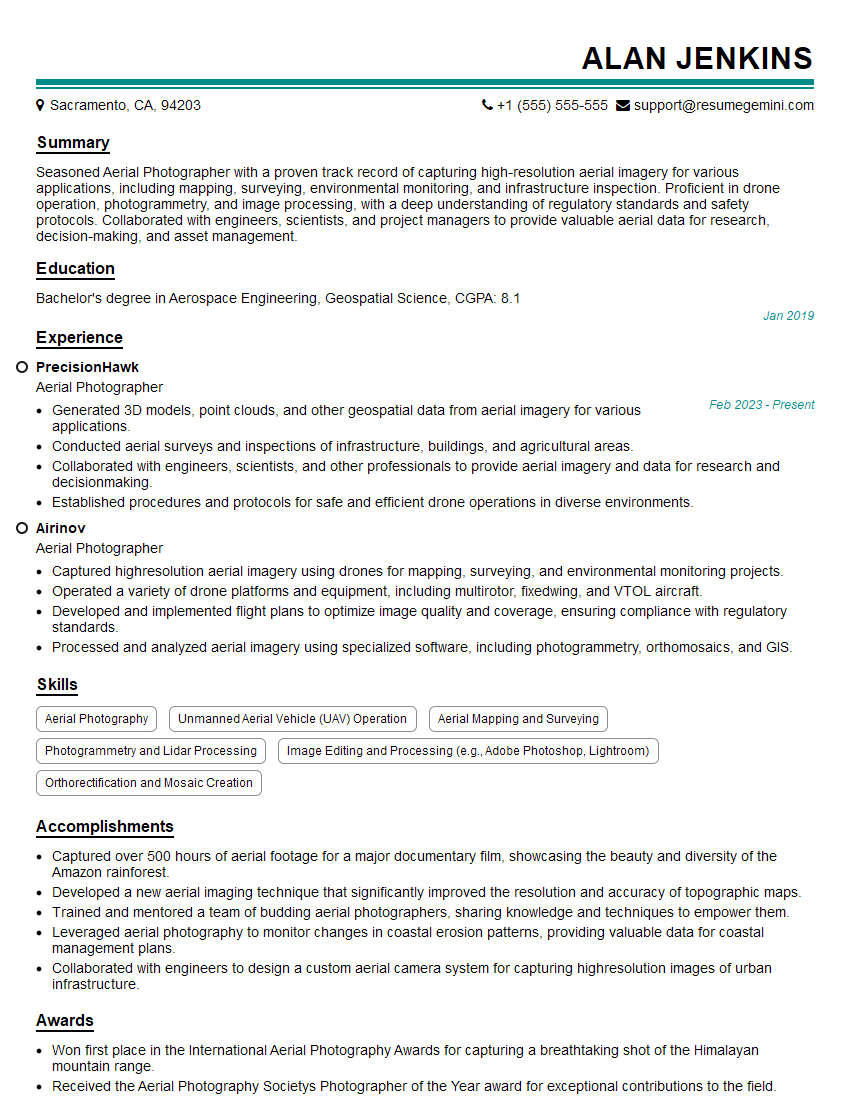

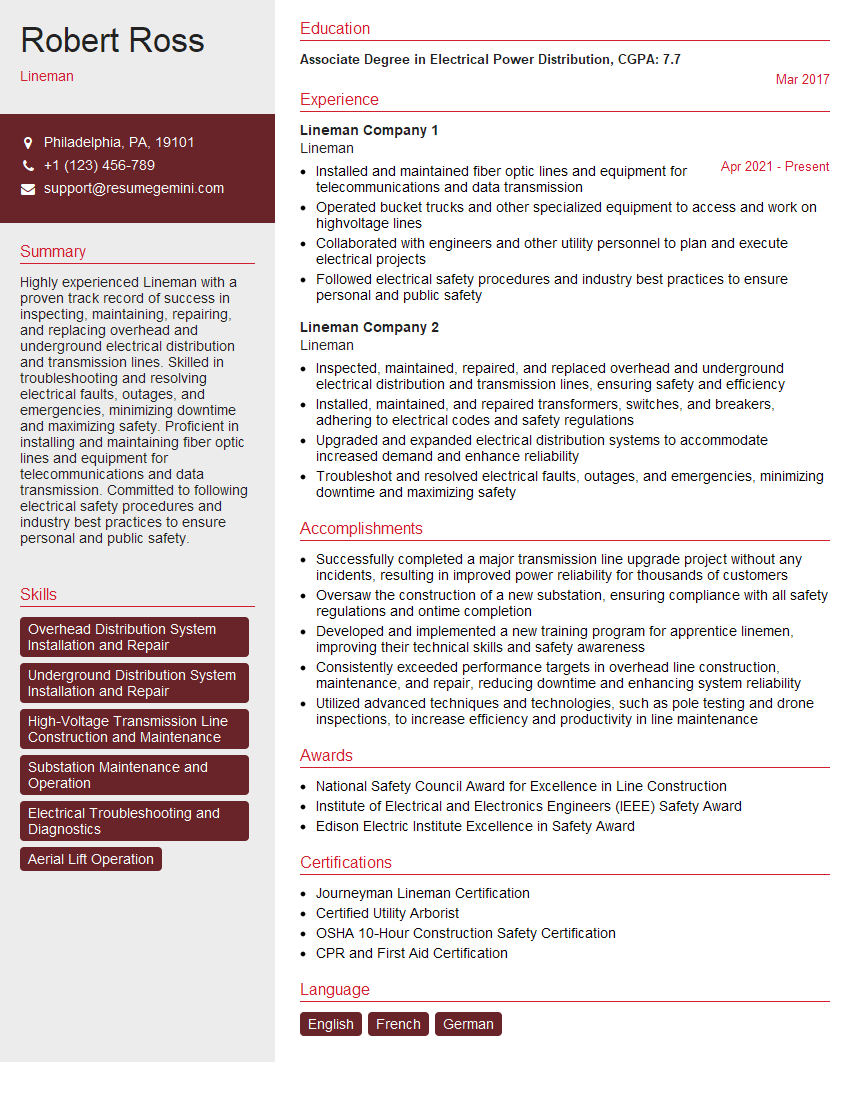

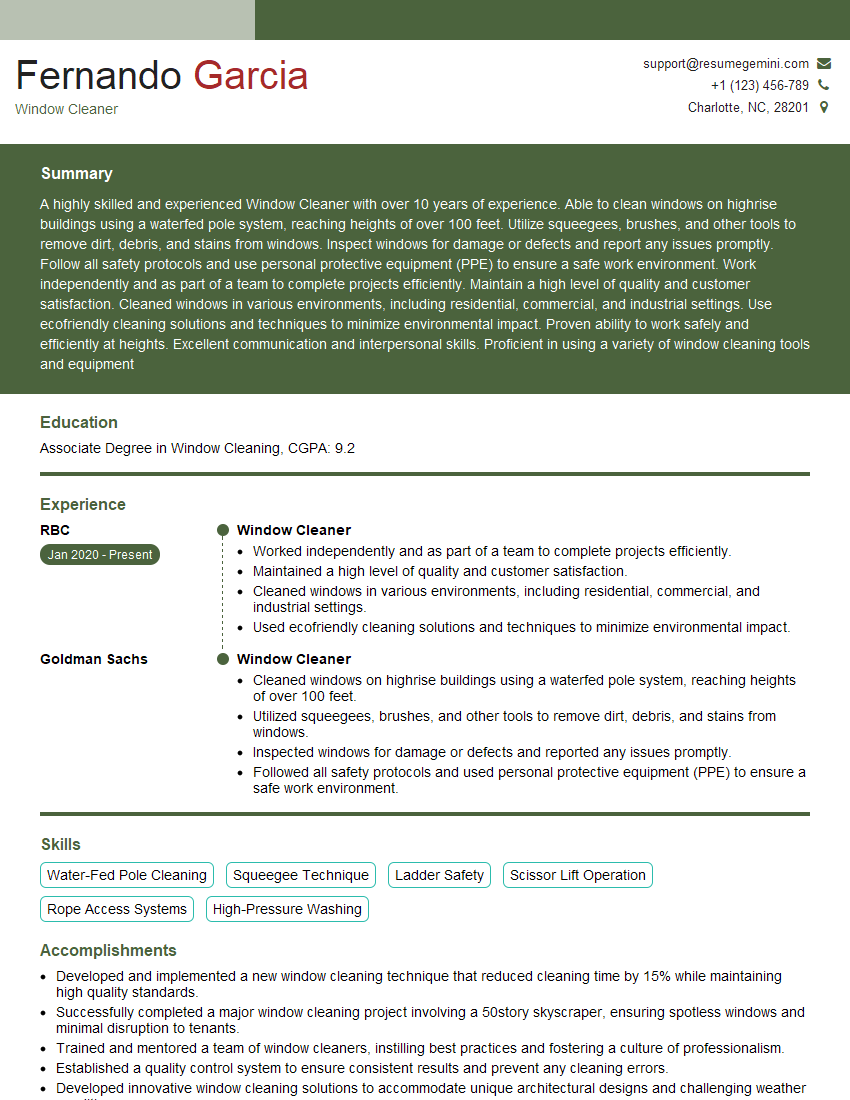

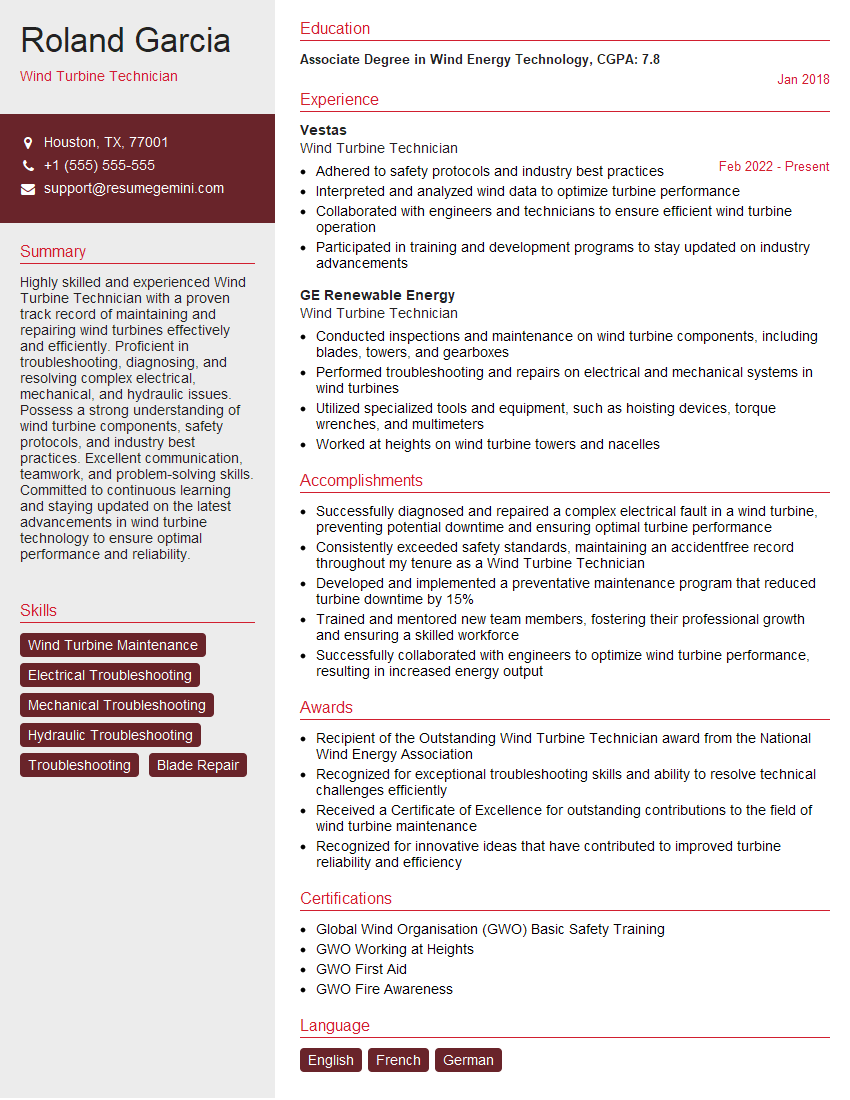

Mastering the ability to work in high places significantly expands your career opportunities across various industries, opening doors to higher-paying roles and increased job security. To enhance your job prospects, it’s crucial to have a strong, ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource to help you craft a professional resume that showcases your capabilities. We provide examples of resumes tailored to highlight experience in working at heights, helping you present your qualifications in the best possible light. Use ResumeGemini to build a resume that truly captures your potential.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.