Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Activated Sludge Process Control interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Activated Sludge Process Control Interview

Q 1. Explain the principles of the activated sludge process.

The activated sludge process is a biological wastewater treatment method that uses microorganisms to break down organic matter. Imagine a tiny city of microorganisms working together to ‘eat’ the pollutants in wastewater. It’s a fascinating, self-sustaining ecosystem! The process involves two main stages: aerobic treatment and anaerobic digestion. In the aerobic stage, wastewater is mixed with a large population of microorganisms (activated sludge) in an aeration tank. Oxygen is introduced to support the aerobic respiration of these microorganisms, which consume organic matter, converting it into carbon dioxide, water, and biomass. Then, in a secondary clarifier, the biomass (activated sludge) settles out, separating the treated water from the solids. A portion of this settled sludge is returned to the aeration tank to maintain the microbial population (return activated sludge), while the excess is removed as waste sludge.

Q 2. Describe the role of microorganisms in activated sludge treatment.

Microorganisms are the heart of the activated sludge process. These tiny heroes—bacteria, protozoa, fungi, and others—work together to break down organic pollutants. Think of them as tiny ‘recycling plants.’ Different types of microorganisms play specific roles: some break down complex organic compounds into simpler ones, while others consume the byproducts. The diversity of these microorganisms is crucial for efficient treatment. For example, aerobic bacteria consume organic matter in the presence of oxygen, while anaerobic bacteria might play a role in the digestion of sludge in the absence of oxygen. Maintaining a healthy and diverse microbial community is key to a well-functioning activated sludge plant. This is often achieved by carefully monitoring and controlling various parameters.

Q 3. What are the key parameters monitored in an activated sludge process?

Monitoring key parameters is essential for optimal activated sludge process performance. It’s like taking the vital signs of a patient. We constantly check these indicators to make sure everything is running smoothly. Key parameters include:

- Dissolved Oxygen (DO): Ensuring sufficient oxygen for aerobic microorganisms.

- Mixed Liquor Suspended Solids (MLSS): Measuring the concentration of microorganisms in the aeration tank.

- Mixed Liquor Volatile Suspended Solids (MLVSS): The concentration of living microorganisms in the MLSS.

- Sludge Volume Index (SVI): Indicates the settling characteristics of the sludge.

- pH: Maintaining a suitable pH range for microbial activity.

- Temperature: Impacts microbial growth rates.

- Influent flow and characteristics: Monitoring the wastewater entering the system.

- Effluent quality: Measuring the quality of the treated water leaving the plant, including BOD (Biological Oxygen Demand) and TSS (Total Suspended Solids).

Q 4. How do you control the dissolved oxygen (DO) levels in an activated sludge system?

Dissolved oxygen (DO) control is critical. We need to provide enough oxygen to support the microorganisms, but excessive oxygen is wasteful and increases operating costs. DO is controlled primarily through aeration systems, which typically involve diffusers or surface aerators that introduce air into the aeration tank. The amount of air is adjusted based on the DO level, which is continuously monitored using DO probes. Control strategies can be simple (on/off) or more sophisticated, employing feedback control loops to maintain the DO within a desired range, often between 1.5-2.5 mg/L. This often uses a Programmable Logic Controller (PLC) to automate the process. For instance, if the DO drops below the setpoint, the aeration system will automatically increase the airflow; if it’s above, airflow is reduced.

Q 5. Explain the concept of Mixed Liquor Suspended Solids (MLSS) and Mixed Liquor Volatile Suspended Solids (MLVSS).

Mixed Liquor Suspended Solids (MLSS) represents the total mass of solids suspended in the aeration tank, including both living and dead microorganisms, as well as inorganic matter. Think of it as the total ‘population’ in our microorganism city. Mixed Liquor Volatile Suspended Solids (MLVSS) represents only the organic fraction of the MLSS, meaning it’s essentially the mass of living microorganisms. It’s the active ‘working population’ in our city, crucial for efficient wastewater treatment. The difference between MLSS and MLVSS represents the inorganic solids, such as sand and grit. Monitoring these parameters helps us understand the microbial population density and its overall health.

Q 6. What is the significance of the Sludge Volume Index (SVI)?

The Sludge Volume Index (SVI) is a crucial indicator of sludge settleability. It’s a measure of how well the activated sludge settles in the clarifier. A high SVI indicates poor settling, which can lead to sludge carryover into the effluent, reducing treatment efficiency and potentially violating discharge permits. A low SVI indicates good settling. SVI is calculated by dividing the settled sludge volume (mL/L) after 30 minutes by the MLSS concentration (g/L). Imagine you’re making a smoothie—a low SVI is like a well-made smoothie that separates cleanly into liquid and solid components, while a high SVI is like a lumpy smoothie that doesn’t separate well. The ideal SVI range varies depending on the plant design and operational conditions, but generally, an SVI below 100 mL/g is desirable.

Q 7. How do you troubleshoot high SVI in an activated sludge system?

High SVI is a common problem in activated sludge plants. Troubleshooting involves a systematic approach. It’s like detective work to find the root cause. Here’s a possible strategy:

- Identify the cause: High SVI can stem from several factors, including filamentous bulking (excessive growth of filamentous bacteria), poor clarifier operation, toxic influent, insufficient nutrient levels, or even improper sludge wasting.

- Microscopic analysis: Conduct a thorough microscopic examination of the activated sludge to identify the presence of filamentous bacteria or other organisms that might be contributing to poor settling. This allows us to pin-point the problem, similar to a doctor identifying the type of infection.

- Process evaluation: Evaluate the operational parameters, such as DO, MLSS, MLVSS, F/M ratio (food-to-microorganism ratio), and sludge retention time (SRT). Each of these will tell us something about the plant’s health.

- Corrective actions: Based on the diagnosis, implement appropriate corrective actions. This might involve adjusting aeration, improving clarifier operation, modifying sludge wasting strategies, adding nutrients (nitrogen and phosphorus), or introducing specific chemicals to control filamentous bacteria.

- Monitoring and optimization: Continuously monitor the SVI and other key parameters to ensure the implemented measures are effective. Regular checks are essential to make sure we’ve fixed the problem and the plant is running efficiently.

Q 8. Describe the different types of aeration systems used in activated sludge processes.

Aeration systems are crucial in activated sludge processes, providing the oxygen necessary for aerobic microorganisms to break down organic matter in wastewater. Different systems offer varying levels of efficiency and cost-effectiveness.

- Surface Aeration: This uses surface aerators, like rotating surface aerators or diffused surface aerators, to introduce oxygen into the wastewater. Think of it like stirring a pot to let air in – it’s simple but may not be as efficient for large volumes.

- Fine Bubble Diffusers: These are submerged systems that release tiny air bubbles, maximizing oxygen transfer efficiency. Imagine it like a rain shower gently saturating the water; it’s highly effective but can be more complex and expensive to install and maintain.

- Coarse Bubble Diffusers: Similar to fine bubble diffusers, but with larger bubbles, leading to less efficient oxygen transfer but potentially lower operational costs.

- Membrane Aeration: This uses a membrane to separate the air and the wastewater, allowing for fine bubble aeration with increased oxygen transfer efficiency. It’s a newer technology with higher initial investment but can be highly effective.

- Kinetically Enhanced Aeration Systems: These combine surface aeration with fine bubble aeration or other techniques to provide optimized aeration based on the specific wastewater characteristics. It’s often customized for optimal results, reflecting the tailored approach needed for complex wastewater treatment.

The choice of aeration system depends on factors like wastewater characteristics, plant size, budget, and energy efficiency requirements. For instance, a small wastewater treatment plant might opt for surface aeration for its simplicity, while a large municipal plant might prefer fine bubble diffusers for superior oxygen transfer.

Q 9. Explain the function of a clarifier in an activated sludge system.

The clarifier, often a secondary clarifier in an activated sludge system, is responsible for separating the treated wastewater from the activated sludge. Think of it as the final step of cleaning – separating the clean water from the solids that did the cleaning.

It works through gravity settling. The activated sludge, which contains microorganisms that have consumed pollutants, settles to the bottom of the clarifier. The clarified effluent, or treated wastewater, overflows from the top, ready for discharge.

Efficient clarification is essential for maintaining a healthy activated sludge process. Poor clarification leads to solids carryover in the effluent, compromising treatment efficiency and potentially causing downstream problems. Regular monitoring and maintenance are critical to ensure optimal performance.

Q 10. What are the common causes of sludge bulking?

Sludge bulking is a common operational problem in activated sludge systems, characterized by the inability of the activated sludge to settle properly in the clarifier. This leads to poor clarification and effluent quality issues. Imagine trying to settle thick yogurt – if it’s too thin, it won’t separate properly.

- Filamentous Bacteria: An overgrowth of filamentous bacteria is a frequent culprit. These bacteria form long strands that interfere with sludge settling, creating a fluffy, bulky sludge.

- Nutrient Deficiencies: Imbalances in essential nutrients, such as phosphorus and nitrogen, can negatively impact microbial communities, leading to poor sludge settleability.

- Toxic Substances: The presence of toxic substances, like heavy metals or industrial chemicals, can inhibit microbial activity and cause sludge bulking.

- pH Imbalances: Significant deviations from the optimal pH range can disrupt microbial metabolism and affect sludge settling.

- Temperature Changes: Sudden changes in temperature can also stress the microbial population, leading to poor sludge settling.

- Organic Overloading: Excessively high organic loads can overwhelm the system, hindering the microbial ability to process the waste and settle effectively.

Diagnosing the cause of sludge bulking requires careful analysis of various parameters, including microscopic examination of the sludge, nutrient levels, and other operational data.

Q 11. How do you control filamentous bulking in an activated sludge system?

Controlling filamentous bulking often requires a multi-pronged approach, tailored to the specific cause. It’s like treating a disease – you need to understand the underlying cause to effectively treat it.

- Adjusting the Food-to-Microorganism (F/M) Ratio: Reducing the F/M ratio can limit the availability of readily biodegradable substrates, favoring the growth of non-filamentous bacteria.

- Selective Chlorination: Short-term chlorination can selectively eliminate filamentous bacteria while preserving the rest of the sludge’s microbial community. This is done carefully, only for a specific period.

- Improving Aeration: Ensuring adequate dissolved oxygen levels can suppress filamentous growth.

- Nutrient Augmentation: Adding nutrients, particularly phosphorus and nitrogen, if deficiencies are identified, can help restore microbial balance.

- Waste Activated Sludge (WAS) Removal: Increasing the WAS withdrawal rate helps remove excess filamentous organisms.

- Microbial Evaluation: Regular microscopic analysis of the sludge is crucial to monitor filamentous bacteria populations and assess the effectiveness of control measures. It is the cornerstone of effective filamentous bulking control.

The success of these strategies depends on a thorough understanding of the specific factors causing the bulking and ongoing monitoring of the system’s performance. It often requires a systematic approach, involving adjustments and refinements.

Q 12. What are the different types of secondary clarifiers?

Secondary clarifiers come in various designs, each with its advantages and disadvantages. The selection depends on factors like flow rate, solids concentration, and site-specific constraints.

- Conventional Clarifiers: These are the most common type, using gravity settling in a circular or rectangular tank. They are relatively simple and cost-effective.

- Lamella Clarifiers: These use inclined plates or tubes to increase the settling surface area, improving efficiency and reducing the footprint compared to conventional clarifiers. Think of them as creating many smaller settling areas within a single unit.

- High-Rate Clarifiers: These are designed for higher influent flow rates and solids concentrations, often incorporating mechanical sludge removal systems. These are very effective when treating high volumes.

- Contact Clarifiers: These combine clarification and secondary treatment within a single unit, allowing for enhanced treatment. It’s like a multi-stage approach with efficiency gains.

Choosing the right clarifier is crucial to maximize efficiency, minimize space requirements, and ensure optimal effluent quality. A good design will consider the overall treatment plant efficiency.

Q 13. Explain the role of return activated sludge (RAS) and waste activated sludge (WAS).

Return Activated Sludge (RAS) and Waste Activated Sludge (WAS) are vital components of the activated sludge process, controlling the microbial population and ensuring continuous operation. They are the heart of the process control.

Return Activated Sludge (RAS): RAS recycles a portion of the settled sludge from the clarifier back to the aeration tank. This maintains a high concentration of active microorganisms, essential for efficient wastewater treatment. Imagine this as recycling the cleaning crew back to work – they continue the cleaning cycle, ensuring continuous efficiency.

Waste Activated Sludge (WAS): WAS removes excess sludge from the system to prevent an overgrowth of microorganisms. This sludge is typically sent to a sludge treatment facility for further processing. This is like sending some of the cleaning crew home to prevent overcrowding, ensuring balanced workload.

Proper control of RAS and WAS ratios is essential for maintaining optimal system performance and preventing problems like sludge bulking or poor effluent quality.

Q 14. How is the RAS ratio determined and controlled?

The RAS ratio, expressed as a percentage, represents the amount of RAS returned to the aeration tank relative to the influent flow rate. It’s a crucial control parameter influencing the microbial concentration in the aeration tank. A well-tuned RAS ratio is essential.

The RAS ratio is determined and controlled based on several factors, including:

- Sludge Volume Index (SVI): This measures the settling characteristics of the sludge. A high SVI indicates poor settling and requires a lower RAS ratio.

- Mixed Liquor Suspended Solids (MLSS): This indicates the concentration of microorganisms in the aeration tank. The RAS ratio is adjusted to maintain the desired MLSS.

- Food-to-Microorganism (F/M) Ratio: The F/M ratio influences the microbial growth rate and needs to be optimized for effective treatment. It is directly affected by the RAS ratio.

- Effluent Quality: The RAS ratio needs to be adjusted to maintain the desired effluent quality, such as Biochemical Oxygen Demand (BOD) and Suspended Solids (SS).

Control can be manual or automated, using sensors and control systems to automatically adjust the RAS flow rate based on real-time monitoring of process parameters. Automated control leads to more stable and efficient operation.

For example, a high SVI might indicate bulking, prompting a reduction in the RAS ratio. Conversely, poor effluent quality may signal a need to increase the RAS ratio to maintain a higher concentration of active microorganisms.

Q 15. Describe the process of WAS disposal.

Waste Activated Sludge (WAS) disposal is a crucial step in the activated sludge process, focusing on managing the concentrated biomass removed from the aeration tank. The goal is to safely and effectively remove this sludge, minimizing its environmental impact. The process typically involves several stages.

- Thickening: This concentrates the sludge, reducing its volume and improving the efficiency of subsequent treatment steps. Methods include gravity thickening, dissolved air flotation (DAF), and centrifugation.

- Stabilization: This reduces the sludge’s organic content and pathogen load. Common methods include aerobic digestion, anaerobic digestion, and chemical stabilization.

- Dewatering: This further reduces the water content of the sludge, making it easier to handle and transport. Techniques include belt filter presses, centrifuge dewatering, and vacuum filtration.

- Disposal: The dewatered sludge can then be disposed of through various methods, such as land application (as fertilizer or soil amendment, requiring stringent monitoring for pathogens and heavy metals), landfilling, incineration, or used in bioenergy production.

For example, a large wastewater treatment plant might use DAF for thickening, anaerobic digestion for stabilization, and belt filter presses for dewatering before ultimately sending the dewatered sludge to a landfill. The choice of methods depends on factors like sludge characteristics, available land, regulatory requirements, and economic considerations.

Career Expert Tips:

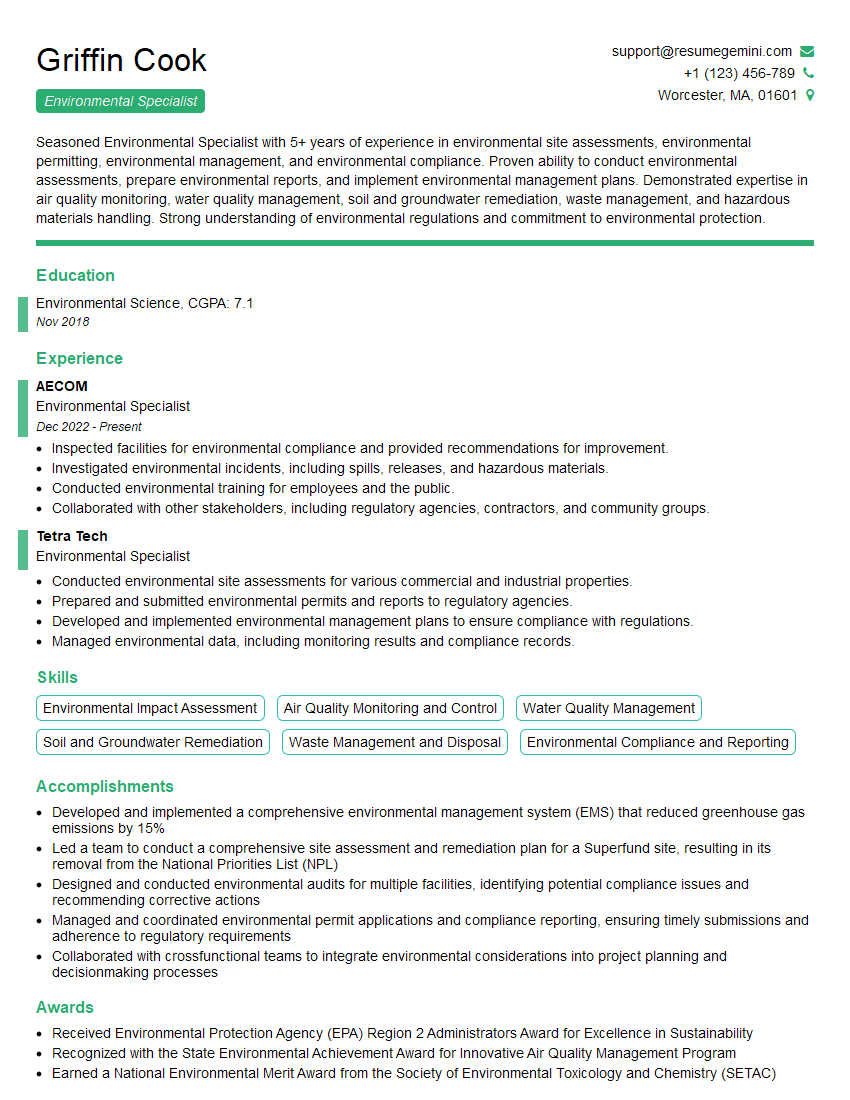

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of sludge treatment processes?

Sludge treatment processes aim to reduce the volume and pathogen load of WAS, making it safe for disposal. Several processes exist, often used in combination.

- Aerobic Digestion: Uses oxygen to break down organic matter, reducing sludge volume and stabilizing the material. This is effective but energy intensive.

- Anaerobic Digestion: Breaks down organic matter in the absence of oxygen, producing biogas (methane and carbon dioxide) which can be used for energy generation. This process is more efficient than aerobic digestion in terms of energy, but the digester needs careful control to prevent acidification.

- Chemical Conditioning: Uses chemicals like ferric chloride or lime to improve the dewaterability of the sludge, making subsequent dewatering processes more efficient.

- Thermal Drying: Uses heat to remove moisture from sludge, resulting in a lower volume and easier-to-handle material. This is energy intensive and expensive.

Imagine a smaller plant may opt for aerobic digestion due to its simplicity, while a larger facility could benefit from anaerobic digestion to generate renewable energy from the biogas produced. The best approach is always site-specific and depends on several factors.

Q 17. Explain the importance of proper sludge age control.

Proper sludge age control is vital for maintaining the health and efficiency of the activated sludge process. Sludge age (SA), or mean cell residence time (MCRT), represents the average time microorganisms remain in the system. A balanced SA ensures optimal biomass concentration and sufficient time for microorganisms to acclimate to wastewater characteristics.

Too short an SA: Leads to insufficient biomass, resulting in low treatment efficiency and poor removal of pollutants. Think of it like having too few workers for a big job – it won’t get done effectively.

Too long an SA: Can result in excessive biomass accumulation, leading to bulking, poor settling, and high sludge production. It’s like having too many workers, causing congestion and inefficiency.

Optimal SA maintains a balance, maximizing pollutant removal while minimizing sludge production. This requires regular monitoring and adjustments to the waste activated sludge (WAS) wasting rate. The optimal SA varies depending on the wastewater characteristics, the design of the plant and the type of microorganisms present.

Q 18. How do you calculate sludge retention time (SRT)?

Sludge Retention Time (SRT), also known as Mean Cell Residence Time (MCRT), is calculated as the ratio of the total mass of solids in the aeration tank to the mass of solids wasted per day. The formula is:

SRT (days) = (Total mass of MLSS in the aeration tank (kg)) / (Mass of WAS wasted per day (kg))Where MLSS is Mixed Liquor Suspended Solids. For example, if an aeration tank contains 1000 kg of MLSS and 100 kg of WAS is wasted daily, the SRT would be:

SRT = 1000 kg / 100 kg/day = 10 daysAccurate measurement of MLSS and WAS flow rate is crucial for precise SRT calculation. Regular monitoring and adjustments of the WAS wasting rate allow for control of the SRT, ensuring optimal process performance.

Q 19. What are the common operational problems encountered in activated sludge plants?

Activated sludge plants are prone to several operational problems. Some common issues include:

- Bulking: Excessive growth of filamentous bacteria impairs sludge settling, leading to poor clarification and effluent quality. This often manifests as a fluffy, stringy sludge that doesn’t settle well.

- Foaming: Excessive foaming can disrupt the process, causing operational difficulties. It is often caused by the accumulation of proteins or surfactants.

- Poor Settling: Inefficient clarification leads to high effluent suspended solids, compromising treatment efficiency.

- Toxic Shock: Introduction of toxic substances can inhibit microbial activity, causing process upset and poor performance.

- Sludge Rising: Sludge rises to the surface of the clarifier, preventing proper settling. This often related to poor dissolved oxygen levels or an imbalance in the microbial community.

Addressing these problems requires a comprehensive understanding of the process, regular monitoring, and prompt corrective actions, often involving adjustments to aeration, WAS wasting rate, and chemical addition.

Q 20. How do you prevent foaming in activated sludge systems?

Foaming in activated sludge systems is a nuisance that can lead to operational problems and even health hazards. Prevention strategies focus on identifying and addressing the root causes:

- Reduce protein and fat content: Pre-treatment of influent to remove excessive proteins and fats, common foaming precursors.

- Control dissolved oxygen levels: Maintaining sufficient dissolved oxygen helps prevent the growth of foam-producing microorganisms.

- Anti-foaming agents: Chemical anti-foaming agents can be used to control foam, but they should be used judiciously, as some can negatively impact the process.

- Adjust sludge age: Optimization of sludge age can shift the microbial community to a less foam-producing balance.

- Regular cleaning: Removing accumulated foam from the aeration tank and clarifier regularly prevents excessive foam build-up.

For instance, if foaming is linked to high protein levels, pre-treatment improvements like screening or enhanced primary sedimentation may be necessary. Each situation needs careful assessment to find the best approach.

Q 21. What are the effects of toxic shock on the activated sludge process?

Toxic shock in activated sludge plants refers to the sudden inhibition of microbial activity due to the introduction of toxic substances. These substances, often industrial discharges or accidental spills, can severely disrupt the biological processes.

Effects: Toxic shock can manifest as a sudden decrease in dissolved oxygen, poor sludge settling, increased effluent BOD and suspended solids, and even complete process failure. The microorganisms responsible for the biological treatment simply cease their activity or die.

Mitigation: Prevention is key. This involves strict monitoring of influent quality and timely detection of potential toxic events. Mitigation strategies include temporarily reducing influent flow, enhancing aeration, adding activated carbon to adsorb toxins, or even diverting the flow to an alternative treatment system. A thorough investigation is crucial after an event to identify and prevent future occurrences.

Imagine a sudden discharge of heavy metals into the plant. This could cause a rapid decline in microbial activity, necessitating quick action to reduce influent flow and potentially add a chemical treatment to bind the metals. The recovery period can be long and challenging depending on the severity and type of toxin.

Q 22. Explain the role of SCADA in activated sludge process control.

SCADA, or Supervisory Control and Data Acquisition, is the brain of a modern activated sludge plant. It acts as a central nervous system, collecting real-time data from various sensors and instruments throughout the plant and using this information to monitor and control the treatment process. Think of it as a sophisticated dashboard displaying all the vital signs of your wastewater treatment plant.

For example, SCADA systems monitor parameters like dissolved oxygen (DO), mixed liquor suspended solids (MLSS), pH, flow rate, and effluent quality. Based on these readings, the system can automatically adjust the aeration, sludge wasting, and chemical dosing to maintain optimal performance. This automated control improves efficiency, reduces operator intervention, and ensures consistent effluent quality.

In a typical scenario, a SCADA system might automatically reduce aeration if the DO level rises above a setpoint, preventing energy waste and optimizing oxygen transfer. Conversely, it will increase aeration if DO falls too low, ensuring sufficient biological activity.

Q 23. Describe your experience with different types of control strategies (e.g., PID control).

My experience encompasses various control strategies, with a strong focus on Proportional-Integral-Derivative (PID) control. PID control is the workhorse of many activated sludge processes, particularly for regulating parameters like dissolved oxygen. It’s a feedback control loop that continuously adjusts a control variable (like aeration blower speed) based on the error between the measured value (e.g., actual DO) and the desired setpoint (e.g., target DO).

The ‘P’ (proportional) term provides immediate response to changes, the ‘I’ (integral) term addresses persistent errors (offset), and the ‘D’ (derivative) term anticipates future errors based on the rate of change. Tuning a PID controller correctly is crucial; it requires understanding the process dynamics and iteratively adjusting the P, I, and D gains until optimal performance is achieved.

I’ve also worked with advanced control strategies, including model predictive control (MPC), which uses mathematical models of the system to predict future behavior and optimize control actions. MPC is particularly beneficial in complex systems where multiple interacting variables need to be managed, leading to greater energy efficiency and improved effluent quality.

Q 24. How do you troubleshoot instrumentation problems in an activated sludge system?

Troubleshooting instrumentation problems begins with systematic investigation. I follow a structured approach, starting with the simplest checks and progressing to more complex diagnostics. The process usually follows these steps:

- Visual Inspection: Checking for obvious problems like broken wires, loose connections, or damaged sensors.

- Calibration Verification: Comparing readings against known standards or secondary instruments.

- Signal Tracing: Following the signal path from the sensor to the SCADA system to identify potential breaks or interference.

- Sensor Cleaning/Replacement: Cleaning or replacing faulty sensors as needed. For example, a fouled DO probe might give inaccurate readings and require cleaning or replacement.

- Data Analysis: Reviewing historical data to identify trends or patterns that may indicate a malfunction.

For instance, if a flow meter consistently reports abnormally low flow, I would first check for blockages in the pipe, then verify its calibration against a secondary flow measurement device, and finally consider if a component within the meter itself has failed.

Q 25. Describe your experience with PLC programming in a wastewater treatment plant.

I have extensive experience in PLC programming, specifically using Allen-Bradley PLCs in wastewater treatment applications. I’ve been involved in designing, implementing, and maintaining PLC programs for various tasks, including:

- Aeration Control: Programming PLCs to manage blower speeds based on DO levels, optimizing aeration energy consumption.

- Sludge Waste Control: Developing programs to automatically control the amount of sludge wasted, maintaining optimal MLSS levels.

- Chemical Dosing: Implementing PLC programs to manage chemical addition based on influent quality and process demands.

- Alarm Management: Designing alarm systems to notify operators of critical process events, preventing potential problems.

Example: A simple ladder logic program might use a compare instruction to check if the DO level is below a setpoint; if true, the program would increase the blower speed to raise the DO level. IF DO < Setpoint THEN Increase Blower Speed

Q 26. Explain how you would optimize the energy efficiency of an activated sludge system.

Optimizing energy efficiency in an activated sludge system involves a multifaceted approach. Key strategies include:

- Dissolved Oxygen Control: Precisely controlling DO levels using advanced control strategies like PID or MPC minimizes energy consumption associated with aeration. Over-aeration is a major source of energy waste.

- Aeration System Optimization: Regularly inspecting and maintaining aeration diffusers and blowers to maximize oxygen transfer efficiency. Replacing aged diffusers and ensuring proper blower operation are crucial.

- Energy-Efficient Blowers: Utilizing variable-speed drives (VSDs) on blowers enables dynamic control of aeration based on real-time process demands.

- Wastewater Flow Optimization: Implementing strategies to minimize peak flows can reduce the energy demand during peak periods.

- Process Optimization: Fine-tuning process parameters like MLSS and sludge retention time (SRT) can optimize biological activity and reduce energy consumption.

For example, implementing a dissolved oxygen cascade control system, where the setpoint is dynamically adjusted based on the influent flow rate, can significantly reduce energy consumption without compromising treatment efficiency. This dynamically adjusts aeration to what is actually needed.

Q 27. How do you ensure compliance with environmental regulations in an activated sludge plant?

Ensuring compliance requires meticulous record-keeping, regular monitoring, and a proactive approach. My experience includes:

- Regular Monitoring: Continuously monitoring effluent quality parameters (e.g., BOD, TSS, ammonia, nutrients) to ensure they meet regulatory discharge limits. This requires rigorous calibration and maintenance of analytical instrumentation.

- Data Recording and Reporting: Maintaining accurate and complete records of all operational data, including process parameters, chemical usage, and effluent quality results. This data is essential for regulatory reporting.

- Compliance Audits: Actively participating in compliance audits to demonstrate adherence to environmental regulations.

- Permitting and Reporting: Assisting in the preparation and submission of discharge permits and compliance reports to relevant environmental agencies. This includes utilizing appropriate reporting software and following strict reporting guidelines.

- Preventative Maintenance: Implementing a robust preventative maintenance program to minimize the risk of equipment failures that could lead to non-compliance.

For instance, if effluent BOD levels approach the permitted limit, immediate corrective actions, such as adjusting the SRT or increasing aeration, are implemented, and the root cause is investigated. Documentation of these actions is critical for demonstrating compliance.

Q 28. What is your experience with data analysis and reporting in a wastewater treatment setting?

Data analysis and reporting are integral to efficient wastewater treatment plant operation and compliance. I utilize various data analysis techniques, including statistical process control (SPC), trend analysis, and regression analysis to identify process issues, optimize performance, and support decision-making. I am proficient in using software like Microsoft Excel, specialized SCADA software packages, and statistical software for data analysis and report generation.

For example, I’ve used SPC charts to monitor key parameters like DO and MLSS, identifying trends and variations that indicate process instability. This enables timely intervention and prevents potential issues. Trend analysis helps identify long-term trends in effluent quality, enabling proactive adjustments to maintain compliance and optimize the plant's overall performance.

I’m also experienced in preparing comprehensive reports summarizing plant performance, identifying areas for improvement, and communicating findings to management and regulatory agencies. These reports include graphical representations of data, statistical analyses, and recommendations for optimization.

Key Topics to Learn for Activated Sludge Process Control Interview

- Microbial Kinetics: Understanding Monod kinetics, growth rates, and their influence on process efficiency. Practical application: Analyzing and interpreting lab data to optimize aeration and biomass retention.

- Oxygen Transfer and Aeration: Mastering oxygen transfer rate (OTR), oxygen uptake rate (OUR), and their relationship to dissolved oxygen (DO) control. Practical application: Troubleshooting low DO situations and optimizing aeration systems for energy efficiency.

- Wastewater Characterization: Familiarity with key parameters like BOD, COD, TSS, MLSS, MLVSS, and their significance in process monitoring and control. Practical application: Interpreting lab results to adjust process parameters and ensure effluent quality.

- Settling Characteristics: Understanding sludge settling properties (SVI, sludge volume index), their implications for clarification and thickening. Practical application: Identifying and addressing sludge bulking issues.

- Process Control Strategies: Knowledge of various control schemes, including DO control, flow control, and nutrient control strategies (e.g., nitrogen and phosphorus removal). Practical application: Designing and implementing effective control strategies for optimal performance.

- Instrumentation and Sensors: Familiarity with common sensors used in activated sludge plants (DO probes, pH sensors, flow meters). Practical application: Troubleshooting sensor malfunctions and ensuring accurate data acquisition.

- Troubleshooting and Problem Solving: Developing a systematic approach to identifying and resolving common operational problems such as bulking, foaming, and poor effluent quality. Practical application: Analyzing process data to diagnose the root cause of operational issues and implement corrective actions.

Next Steps

Mastering Activated Sludge Process Control is crucial for career advancement in the environmental engineering field, opening doors to leadership roles and specialized projects. A strong understanding of these concepts demonstrates your technical expertise and problem-solving capabilities to potential employers. To significantly boost your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored specifically to the Activated Sludge Process Control field, ensuring your application stands out from the competition. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.