Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Advanced Biological Treatment interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Advanced Biological Treatment Interview

Q 1. Explain the principles of activated sludge treatment.

Activated sludge treatment is a widely used biological wastewater treatment process that relies on the aerobic respiration of microorganisms to break down organic matter. Imagine a miniature ecosystem within a tank: we introduce wastewater containing organic pollutants, and then add a ‘sludge’ – a mixture of bacteria, protozoa, and other microorganisms. These microorganisms consume the pollutants as their food source, converting them into less harmful substances like carbon dioxide, water, and biomass. This process happens in an aeration tank where oxygen is constantly supplied to sustain the aerobic activity. The treated water then undergoes settling, separating the clarified effluent from the activated sludge. A portion of the sludge is recycled back into the aeration tank to maintain the microbial population (return activated sludge), while the excess sludge (waste activated sludge) is removed for disposal or further processing.

The key principle lies in maintaining an optimal balance between the microbial population and the available organic matter. Too many microorganisms and they consume all the food, leaving behind clear but still potentially harmful effluent. Too little, and the treatment process will be inefficient. This balance is carefully managed through controlling parameters like dissolved oxygen, aeration rate, and sludge retention time.

Q 2. Describe different types of bioreactors and their applications.

Bioreactors are vessels designed to support biological activity. Different types cater to specific needs. For instance:

- Stirred Tank Reactors (STRs): These are widely used in the pharmaceutical and biotechnology industries for culturing cells. They employ impellers to mix the contents, ensuring uniform oxygen and nutrient distribution. Imagine a giant mixing bowl, providing a homogeneous environment for optimal cell growth.

- Airlift Bioreactors: These use air bubbles to mix the contents, providing both aeration and mixing. They’re often preferred for their simplicity and lower shear forces, making them suitable for sensitive cell cultures. Think of it like a bubbly fountain that keeps the contents gently circulating.

- Fluidized Bed Bioreactors: These contain a bed of solid particles (support media) that microbes attach to. Wastewater flows through the bed, allowing microorganisms to efficiently break down pollutants. This design is especially effective in treating high-strength wastewater or removing specific pollutants. Imagine a packed column where the microbes are efficiently arranged for maximum contact with the pollutants.

- Membrane Bioreactors (MBRs): These combine biological treatment with membrane filtration. The membrane removes solids, ensuring high-quality effluent. This system offers superior effluent quality compared to conventional activated sludge systems. Think of it as a two-stage system – the microbes do their job, and then the membrane acts as a super-fine filter.

The choice of bioreactor depends on the specific application, the type of microorganisms used, the desired productivity, and the required effluent quality.

Q 3. What are the key parameters monitored in a bioreactor?

Monitoring key parameters is crucial for efficient bioreactor operation. Critical parameters include:

- Dissolved Oxygen (DO): Ensures sufficient oxygen for aerobic processes. Low DO indicates potential problems with aeration or excessive microbial activity.

- pH: Maintains optimal conditions for microbial growth. Extreme pH values can inhibit microbial activity.

- Temperature: Affects microbial metabolism. Deviations from the optimal temperature can slow down or stop growth.

- Substrate Concentration (e.g., BOD, COD): Indicates the amount of organic matter available for microbial consumption. High concentrations may lead to oxygen depletion.

- Cell Density (Biomass): Measures the amount of microbial population. Low cell density suggests potential issues like nutrient limitation or toxicity.

- Effluent Quality (e.g., BOD, COD, TSS): Monitors the treatment efficiency and assesses the quality of the treated water.

Regular monitoring and adjustment of these parameters are crucial for maintaining optimal bioreactor performance and ensuring consistent effluent quality.

Q 4. How do you troubleshoot issues related to low cell density in a bioreactor?

Low cell density in a bioreactor can stem from several factors. Troubleshooting involves a systematic approach:

- Check nutrient levels: Insufficient nutrients (nitrogen, phosphorus, carbon sources) limit microbial growth. Analyze the influent wastewater and adjust nutrient additions if needed.

- Assess aeration: Insufficient oxygen supply inhibits microbial growth. Check aeration rates, air sparger functionality, and DO levels. Address any issues with the aeration system.

- Investigate toxic substances: The presence of toxic substances (heavy metals, organic solvents) can severely inhibit microbial growth. Test for potential toxins in the influent wastewater.

- Verify pH: Extreme pH values can inhibit microbial growth. Adjust the pH to the optimal range for the specific microorganisms being used.

- Examine temperature: Temperature deviations from the optimal range can also impact cell growth. Verify the bioreactor temperature and make adjustments if needed.

- Check for contamination: Contamination by unwanted microorganisms can compete with the desired culture, impacting growth. Microscopic examination of the culture can identify any contaminants.

- Seed with a higher concentration: Consider inoculating the bioreactor with a higher initial concentration of the target microorganisms to boost the microbial population.

A thorough investigation involving systematic analysis and process adjustments is key to addressing low cell density issues in bioreactors. This ensures optimal operational efficiency and consistently high-quality treatment.

Q 5. Explain the concept of bioaugmentation in bioremediation.

Bioaugmentation is a bioremediation technique that enhances the natural biodegradation of pollutants by introducing specific microorganisms with the desired metabolic capabilities. Imagine adding specialized cleanup crews to an already existing cleanup effort. Instead of relying solely on naturally occurring microbes, we introduce strains known to effectively degrade the target pollutant. This accelerates the remediation process and improves its effectiveness, especially in cases where natural microbial populations are insufficient or absent.

For example, in oil spill cleanup, specific bacteria capable of degrading hydrocarbons can be added to enhance the natural biodegradation of the spilled oil. Similarly, specific strains can be used to break down pesticides or other persistent organic pollutants in contaminated soil or water.

The success of bioaugmentation depends on several factors, including selecting appropriate microorganisms, optimizing environmental conditions, and ensuring the introduced microorganisms can compete effectively with the existing microbial community.

Q 6. What are the advantages and disadvantages of using microorganisms for wastewater treatment?

Microorganisms offer numerous advantages for wastewater treatment:

- Cost-effectiveness: Microorganisms are naturally occurring and readily available, making them a relatively inexpensive treatment option.

- Efficiency: They efficiently degrade a wide range of organic pollutants, significantly reducing the organic load in wastewater.

- Environmental friendliness: They produce less sludge compared to other treatment methods, minimizing disposal challenges and environmental impact.

- Flexibility: They can be adapted to treat various types of wastewater and varying pollutant concentrations.

However, there are also some disadvantages:

- Sensitivity to environmental conditions: Microbial activity is sensitive to changes in pH, temperature, and dissolved oxygen levels. Maintaining optimal conditions is crucial for consistent performance.

- Potential for bulking sludge: Certain operational issues can lead to the formation of filamentous bacteria, resulting in poor settling and excessive sludge production.

- Risk of pathogen proliferation: If not properly managed, the treatment process can potentially lead to the growth of pathogenic microorganisms.

- Difficult to control: The complex nature of microbial communities can make it challenging to precisely control the treatment process.

Careful monitoring, process optimization, and appropriate operational practices are crucial to maximize the advantages and minimize the disadvantages of using microorganisms for wastewater treatment.

Q 7. Describe different methods for cell harvesting and purification.

Cell harvesting and purification are crucial steps in various biotechnological processes. Different methods exist, depending on the type of cells and the desired purity:

- Centrifugation: A common method that utilizes centrifugal force to separate cells from the liquid medium. Different centrifugation techniques (e.g., differential centrifugation, density gradient centrifugation) offer various levels of cell separation and purification.

- Filtration: Uses filters of varying pore sizes to separate cells from the liquid. Microfiltration, ultrafiltration, and nanofiltration provide various levels of separation based on cell size and other properties.

- Sedimentation: Relies on gravity to separate cells from the liquid. It’s a simple method but may require longer processing times and is less effective for smaller cells.

- Flocculation: Uses chemicals to aggregate cells into larger clumps, facilitating their separation through sedimentation or filtration.

- Chromatography: A powerful technique to separate and purify cells based on their physical or chemical properties (e.g., size, charge, hydrophobicity). Different chromatography methods (e.g., ion exchange, affinity chromatography) offer high levels of cell purification.

The choice of method depends on several factors, including cell type, desired purity level, scale of operation, and cost considerations. Often, a combination of methods is used to achieve optimal cell harvesting and purification.

Q 8. Explain the principles of sterilization and its importance in bioprocessing.

Sterilization is the complete elimination or destruction of all forms of microbial life, including viruses, bacteria, fungi, and spores. Its importance in bioprocessing is paramount because any contamination can compromise the entire process, leading to product failure, loss of resources, and potential harm to patients (in the case of biopharmaceuticals). Think of it like this: baking a cake – if you use contaminated ingredients, the whole cake is ruined. Similarly, in bioprocessing, a single contaminant can ruin a large-scale batch of potentially life-saving medication.

Methods for sterilization include:

- Heat Sterilization: Autoclaving (using steam under pressure) is the most common method, effective for most materials. Dry heat sterilization, using ovens at high temperatures, is suitable for heat-resistant materials that can’t tolerate steam.

- Filtration: Membrane filters remove microorganisms by physical sieving. This is essential for sterilizing heat-sensitive solutions like some pharmaceuticals and media components.

- Chemical Sterilization: Using agents like ethylene oxide gas or peracetic acid eliminates microbes, suitable for materials that can’t withstand heat or filtration. However, careful attention must be paid to the complete removal of the sterilant post-treatment.

- Radiation Sterilization: Gamma irradiation is used for sterilizing certain materials, particularly those that are packaged, however there is need for careful consideration of radiation effects on product stability.

Validation of sterilization methods is crucial. This involves demonstrating that the chosen method consistently achieves sterility based on established parameters and is critical for regulatory compliance.

Q 9. How do you validate a bioprocess?

Bioprocess validation is a comprehensive process that confirms that a bioprocess consistently produces a product meeting pre-defined quality attributes and regulatory requirements. It’s not a one-time event but an ongoing process of monitoring and improvement. Imagine building a bridge – you need to ensure it’s safe and strong to support its intended weight and purpose. Similarly, in bioprocessing, validation ensures a consistent and high-quality product.

Validation typically involves these steps:

- Process Development: Thoroughly define and characterize the process.

- Process Qualification: Demonstrate that the designed process can consistently meet specifications.

- Performance Qualification: Verify that the process performs as intended under actual operating conditions.

- Continued Process Verification: Continuous monitoring of the process to maintain compliance.

Specific techniques include:

- Analytical testing: Regular sampling and assaying for product quality parameters (purity, potency, etc.).

- Statistical analysis: Evaluating process parameters to establish control and predict product quality.

- Documentation: Meticulous record-keeping of all process steps, results, and deviations.

Failing to properly validate a bioprocess can lead to product failure, regulatory non-compliance, and significant financial losses. Thorough validation is non-negotiable for commercialization of biopharmaceuticals.

Q 10. What are the regulatory requirements for biopharmaceutical manufacturing?

Regulatory requirements for biopharmaceutical manufacturing are stringent and vary depending on the specific product and geographical region. However, overarching principles involve ensuring product safety, efficacy, and quality. Key regulatory bodies include the FDA (United States) and EMA (Europe). These agencies enforce regulations based on Good Manufacturing Practices (GMP).

Key aspects of regulatory requirements:

- Compliance with GMP: Adherence to detailed guidelines covering all aspects of production, from raw materials to final product release.

- Documentation and record-keeping: Comprehensive and auditable documentation of all process steps, deviations, and investigations.

- Quality control and assurance: Rigorous testing and monitoring at various stages of the production process.

- Personnel training and qualification: Ensuring all personnel involved in manufacturing are adequately trained and qualified.

- Facility and equipment validation: Verification that facilities and equipment meet specified standards and perform consistently.

- Product release criteria: Clearly defined quality attributes and testing procedures to ensure that the final product meets standards.

- Batch release and tracking: The ability to track every batch of product throughout its lifecycle.

Non-compliance can result in significant penalties, product recalls, and even cessation of manufacturing. Therefore, thorough understanding and diligent adherence to regulatory requirements are critical for success in biopharmaceutical manufacturing.

Q 11. Explain the concept of GMP (Good Manufacturing Practices) in biotechnology.

Good Manufacturing Practices (GMP) in biotechnology are a set of guidelines that ensure the quality, safety, and efficacy of biopharmaceuticals. It’s a system designed to minimize risks of contamination, errors, and variability during manufacturing. It’s like a recipe – following it carefully ensures that the final product is of consistent quality.

Key aspects of GMP include:

- Facility design and maintenance: Maintaining clean, well-organized, and appropriately equipped facilities to prevent contamination.

- Equipment calibration and maintenance: Regular checks to ensure all equipment operates according to specification.

- Raw material control: Strict quality checks on all incoming raw materials.

- Personnel training and hygiene: Well-trained personnel following appropriate hygiene protocols to prevent contamination.

- Process validation: Documented proof that the manufacturing process consistently meets specifications.

- Quality control testing: Thorough testing at various stages of the manufacturing process to identify and prevent defects.

- Documentation and record-keeping: Clear, accurate, and auditable records of all aspects of the manufacturing process.

- Change control: A system for managing any changes to the manufacturing process.

- Deviation investigation: A structured process for investigating any deviation from established procedures.

GMP compliance is vital for regulatory approval and ensuring patient safety. Any deviation from GMP can lead to product recall, regulatory sanctions, and serious health consequences. In short, GMP is a cornerstone of quality and safety in biopharmaceutical manufacturing.

Q 12. How do you design a scale-up strategy for a bioprocess?

Scaling up a bioprocess involves increasing the production volume while maintaining product quality and consistency. It’s a complex process that requires careful planning and execution. Think of it like baking a cake – you can successfully scale up from a single cake to a hundred, but you need to carefully adjust baking time and oven temperature to achieve the same quality across all cakes.

A successful scale-up strategy typically follows these steps:

- Process characterization: Thorough understanding of the bioprocess at the small scale to identify critical parameters.

- Scale-up strategy selection: Choosing appropriate scale-up methods based on the process characteristics (e.g., geometric similarity, constant power input, constant impeller tip speed).

- Scale-down studies: Running smaller-scale experiments to predict performance at larger scales.

- Pilot plant studies: Testing the process at an intermediate scale to further refine the process parameters and to identify potential issues before full-scale production.

- Full-scale production: Implementing the validated scale-up process in the full-scale production environment.

- Process monitoring and control: Continuous monitoring and adjustments to maintain consistency.

The scale-up strategy needs to consider various factors like:

- Mixing and aeration: Ensuring adequate mixing and oxygen transfer in larger bioreactors.

- Heat transfer: Maintaining optimal temperature control in larger bioreactors.

- Mass transfer: Ensuring efficient transfer of nutrients and metabolites.

- Cell growth and product formation kinetics: Maintaining consistent cell growth and product formation rates.

Failing to properly design and execute a scale-up strategy can lead to significant production problems, compromised product quality, and substantial financial losses.

Q 13. Describe different methods for analyzing microbial populations.

Analyzing microbial populations is crucial in bioprocessing to monitor growth, assess the efficacy of sterilization, and ensure product quality. Several methods exist, each with its strengths and limitations. Imagine counting stars in the night sky – you wouldn’t count them all individually, you’d use tools and techniques to estimate the total number.

Methods for analyzing microbial populations include:

- Plate counting: Diluting a sample and plating it on an agar medium to count colony-forming units (CFU). It’s a common method, but it only counts viable cells.

- Spectrophotometry: Measuring the optical density (OD) of a culture to estimate cell density. It’s rapid but doesn’t differentiate between live and dead cells.

- Flow cytometry: Using laser-based technology to count and characterize individual cells based on size, shape, and fluorescence. It provides detailed information on cell populations.

- Microscopy: Direct visualization of cells using microscopes; provides detailed information on cell morphology but is time-consuming.

- Real-time PCR: A very sensitive technique to quantify specific microbial DNA or RNA molecules, useful in detecting low levels of contamination.

The choice of method depends on the specific application and the desired level of detail. For example, plate counting is good for determining viable cell counts in fermentation processes, while flow cytometry can provide more comprehensive information about microbial diversity in environmental samples. Each method has its advantages and limitations, and careful consideration should be given to selecting the most appropriate method for the specific application.

Q 14. Explain the concept of microbial kinetics.

Microbial kinetics describes the rate of microbial growth and its response to environmental factors. Understanding microbial kinetics is essential for optimizing bioprocesses. Imagine training for a marathon – you need to understand your body’s response to different training intensities to optimize your performance. Similarly, in bioprocessing, understanding microbial kinetics allows you to optimize the process for maximum yield and product quality.

Key aspects of microbial kinetics:

- Growth phases: Microbial growth follows distinct phases (lag, exponential, stationary, death) depending on nutrient availability and environmental conditions.

- Growth rate: The rate at which the microbial population increases, usually expressed as a specific growth rate (µ).

- Monod equation: A mathematical model describing the relationship between growth rate and substrate concentration.

µ = µmax * S / (Ks + S)where µmax is the maximum specific growth rate, S is the substrate concentration, and Ks is the half-saturation constant. - Factors influencing growth: Nutrient availability, temperature, pH, dissolved oxygen, and inhibitory compounds all affect microbial growth rates.

- Substrate utilization: The rate at which microbes consume substrates for growth and product formation.

- Product formation kinetics: The rate at which the desired product is produced during fermentation. This can be growth-associated, non-growth-associated, or mixed-growth-associated.

By understanding microbial kinetics, bioprocess engineers can optimize culture conditions to maximize product yield, minimize waste, and enhance process efficiency. Models such as the Monod equation help to predict and control microbial growth and product formation, leading to improved process design and control.

Q 15. What are the different types of bioremediation technologies?

Bioremediation technologies utilize living organisms, primarily microorganisms, to degrade or remove pollutants from contaminated environments. These technologies are broadly categorized into several types, each with its own strengths and weaknesses.

- Bioaugmentation: This involves introducing specific microorganisms with enhanced degradation capabilities into a contaminated site. For instance, adding bacteria capable of breaking down oil spills to an affected marine environment.

- Biostimulation: This focuses on enhancing the activity of naturally occurring microorganisms by providing them with optimal growth conditions, such as adding nutrients (e.g., nitrogen and phosphorus) or adjusting the pH. This is often applied to contaminated soil where indigenous microbes need a boost to effectively degrade pollutants.

- Phytoremediation: This uses plants to remove or neutralize pollutants from soil, water, or air. Plants can absorb contaminants through their roots, or they can break down pollutants through their metabolism. A classic example is the use of sunflowers to remove radioactive materials from contaminated soil.

- Bioventing: This technique involves supplying oxygen to subsurface soils to stimulate the activity of aerobic microorganisms that can degrade organic pollutants. This is commonly used in the treatment of petroleum hydrocarbon contamination.

- Composting: This is a natural process where microorganisms break down organic matter, effectively treating various types of waste and some pollutants. Municipal waste composting is a large-scale example of bioremediation.

The choice of technology depends on factors such as the type and concentration of pollutants, the environmental conditions (soil type, water table, climate), and cost-effectiveness.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you select appropriate microorganisms for a specific bioremediation application?

Selecting the right microorganisms is crucial for successful bioremediation. The process begins with identifying the target pollutant and understanding its degradation pathways. Several factors guide the selection:

- Microbial characteristics: The chosen microorganisms must be able to efficiently degrade the specific pollutant. This often involves screening microbial cultures from the contaminated site or from other environments known to harbor pollutant-degrading organisms.

- Environmental compatibility: The microorganisms should be able to thrive in the environmental conditions of the contaminated site (temperature, pH, nutrient availability, presence of inhibitors).

- Genetic stability: The selected microorganisms should maintain their degradation capabilities over time and not lose their effectiveness. Genetic engineering can be used to improve certain properties of selected species.

- Safety: The microorganisms should not pose any risk to human health or the environment. This involves careful risk assessment before application.

Techniques such as enrichment cultures, isolation, and identification using molecular methods (16S rRNA gene sequencing) are commonly used to identify and characterize suitable microorganisms. Once suitable candidates are identified, laboratory-scale experiments are conducted to assess their efficiency and optimize the bioremediation process. For example, in treating a pesticide-contaminated soil, a researcher might test various bacterial isolates for their capacity to break down the specific pesticide molecule under controlled conditions.

Q 17. Explain the role of enzymes in bioprocessing.

Enzymes are biological catalysts that significantly accelerate biochemical reactions in bioprocessing. They are crucial because they drive the conversion of substrates (starting materials) into desired products, such as pharmaceuticals, biofuels, or other valuable compounds. Without enzymes, many bioprocesses would be too slow or inefficient to be practical.

- Specificity: Enzymes exhibit high specificity, meaning they catalyze only specific reactions on specific substrates. This precise action allows for targeted transformations.

- Mild reaction conditions: Enzymatic reactions typically occur under mild conditions (ambient temperature and pressure), making them more environmentally friendly compared to chemical processes which often require harsh conditions.

- High yield and selectivity: Enzymes often achieve high yields and excellent selectivity, minimizing the formation of unwanted byproducts.

Think of enzymes as tiny, highly specialized machines inside cells that build or break down molecules with incredible precision. In industrial bioprocessing, enzymes are often extracted from microorganisms or produced using recombinant DNA technology, enabling large-scale applications like the production of high-fructose corn syrup (using glucose isomerase) or the breakdown of cellulose in biofuel production (using cellulases).

Q 18. Describe different methods for monitoring and controlling pH in a bioreactor.

Maintaining optimal pH in a bioreactor is crucial, as microbial activity and enzyme function are highly pH-dependent. Several methods are used to monitor and control pH:

- pH probes: These sensors continuously monitor the pH in the bioreactor. The signals are fed to a control system that automatically adjusts the pH.

- Acid/base addition: A common method involves adding acids (e.g., sulfuric acid, phosphoric acid) or bases (e.g., sodium hydroxide, ammonia) to the bioreactor to adjust the pH. This can be automated using pumps controlled by the pH probe readings.

- pH buffer systems: Buffers are solutions that resist changes in pH when small amounts of acid or base are added. Including a suitable buffer in the bioreactor medium helps maintain a relatively stable pH.

- Gas sparging: In some cases, controlling the CO2/O2 ratio in the gas supplied to the bioreactor can indirectly affect pH.

For example, in a bacterial fermentation process, maintaining a slightly acidic pH might be necessary to prevent unwanted microbial contamination and to optimize the production of a target compound. A computerized control system continuously monitors the pH, and automatically adds acid or base as needed to keep the pH within the optimal range.

Q 19. How do you handle contamination in a bioprocess?

Contamination in a bioprocess can have serious consequences, leading to reduced yields, product spoilage, or even safety hazards. Several strategies are used to prevent and handle contamination:

- Aseptic techniques: Strict aseptic techniques during all stages of bioprocessing are essential. This includes using sterile equipment, media, and working in sterile environments like laminar flow hoods.

- Media sterilization: Growth media must be thoroughly sterilized before use, commonly through autoclaving (high-pressure steam sterilization) or filtration.

- Equipment sterilization: Bioreactor vessels and other equipment are typically sterilized using steam, chemical disinfectants, or dry heat.

- Environmental monitoring: Regular monitoring of the environment for microbial contamination is crucial. Air samples, surface swabs, and other samples can be tested for microorganisms.

- Antimicrobial agents: In some cases, antimicrobial agents (antibiotics or disinfectants) can be added to the bioreactor to control contamination, but this needs careful consideration to avoid inhibiting the desired microorganisms.

Imagine a pharmaceutical production process: if bacterial contamination occurs, the product might be spoiled, rendering it unsafe and unusable. Therefore, strict adherence to aseptic techniques, rigorous sterilization, and comprehensive environmental monitoring are paramount.

Q 20. Explain the concept of downstream processing.

Downstream processing is the final stage of bioprocessing, encompassing all the steps involved in separating, purifying, and formulating the desired product from the fermentation broth (or other bioreactor output). It’s a critical step because the crude product often contains a mixture of cells, cell debris, other metabolites, and the desired compound.

The specific steps in downstream processing depend on the nature of the target product and the desired purity level. Generally, it involves a series of steps such as:

- Cell separation: Removing cells and cell debris using techniques like centrifugation or filtration.

- Product purification: Separating the desired product from other components in the broth. This often involves multiple purification steps to achieve the required purity.

- Formulation: Formulating the purified product into its final form for storage, use, or sale. This might include adding stabilizers, preservatives, or other excipients.

Consider the production of a therapeutic protein: the fermentation broth will contain the protein alongside many other unwanted molecules. Downstream processing aims to isolate this protein, purify it to the highest standards for safety and efficacy, and then formulate it into a stable, injectable solution ready for use by patients. The efficiency and effectiveness of this process directly affect the cost and availability of the drug.

Q 21. Describe different chromatography techniques used in downstream processing.

Chromatography techniques are widely used in downstream processing for separating and purifying biomolecules. Several chromatographic methods are employed, each with unique separation principles:

- Ion-exchange chromatography: This separates molecules based on their net charge. A stationary phase with charged groups interacts with oppositely charged molecules in the sample, allowing for separation based on charge differences.

- Size-exclusion chromatography (gel filtration): This separates molecules based on their size. Larger molecules elute faster than smaller molecules as they pass through a porous gel matrix.

- Affinity chromatography: This utilizes a specific ligand bound to a stationary phase to capture the target molecule. This offers a highly selective purification method.

- Hydrophobic interaction chromatography (HIC): This method separates molecules based on their hydrophobicity. Molecules with higher hydrophobicity bind more strongly to the hydrophobic stationary phase.

- High-performance liquid chromatography (HPLC): This is a high-resolution technique providing excellent separation and high sensitivity, suitable for purifying even very complex mixtures.

For instance, in purifying a monoclonal antibody (mAb) from a cell culture, a researcher might use protein A affinity chromatography (a specific type of affinity chromatography) as an initial step to capture the mAb, followed by size-exclusion chromatography to remove any remaining impurities. The choice of methods depends on the specific properties of the target molecule and the required purity.

Q 22. What are the challenges in scaling up bioprocesses?

Scaling up bioprocesses, moving from small-scale laboratory experiments to large-scale industrial production, presents numerous challenges. It’s like trying to bake a single perfect cupcake and then scaling up to bake thousands for a large event – the same recipe might not work!

- Maintaining consistent process parameters: Factors like temperature, pH, dissolved oxygen, and nutrient availability need precise control, which becomes exponentially more difficult at larger scales. Imagine trying to keep the temperature uniform in a small oven versus a massive industrial one.

- Mass and heat transfer limitations: Efficient mixing and oxygen transfer become critical at larger volumes. In a larger bioreactor, nutrients and oxygen may not reach all cells uniformly, leading to reduced productivity. This is similar to trying to water a large field compared to a small garden – ensuring even distribution is key.

- Increased costs: Larger bioreactors, sophisticated instrumentation, and increased operational costs are significant factors. The upfront investment for a large-scale operation can be considerable.

- Process validation and regulatory compliance: Stringent regulatory requirements for quality control and safety add complexity to scale-up. Ensuring consistent product quality across different scales is crucial and requires robust validation processes.

- Shear stress on cells: Increased mixing intensity in larger bioreactors can damage sensitive cells, affecting product yield. This is analogous to agitating a delicate mixture too vigorously, leading to damage.

Strategies for overcoming these challenges include using process models to predict scale-up behavior, employing advanced mixing and aeration strategies, and designing robust control systems.

Q 23. How do you assess the economic viability of a bioremediation project?

Assessing the economic viability of a bioremediation project involves a detailed cost-benefit analysis. It’s like evaluating the cost of cleaning a polluted lake versus the potential benefits of restoring the ecosystem and the associated economic activities.

- Project costs: This includes site characterization, bioaugmentation/biostimulation costs, equipment procurement, labor, monitoring, and regulatory compliance expenses.

- Remediation effectiveness: Estimating the reduction in pollutant levels achieved by the bioremediation process is crucial. This requires detailed modeling and field testing.

- Benefits: Quantifying the benefits can include reduced environmental liabilities, restoration of ecosystem services (e.g., improved water quality, increased property values), and potential carbon credit generation.

- Time horizon: Considering the time it takes to achieve the desired level of remediation is important. Some projects can take several years or even decades.

- Risk assessment: Evaluating potential risks and uncertainties associated with the project (e.g., unforeseen environmental impacts, technical challenges) is critical.

A Discounted Cash Flow (DCF) analysis is often used to evaluate the project’s Net Present Value (NPV) and Internal Rate of Return (IRR), factoring in the time value of money. A positive NPV and IRR above the cost of capital indicate economic viability.

Q 24. Describe different types of sensors used in bioreactors.

Bioreactors employ a variety of sensors to monitor critical process parameters in real-time. These sensors are essential for maintaining optimal growth conditions and ensuring product quality. Imagine a chef constantly checking the temperature and ingredients of a dish – the sensors do the same for the bioreactor.

- pH sensors: Measure the acidity or alkalinity of the culture medium.

- Dissolved oxygen (DO) sensors: Monitor the amount of oxygen available to the microorganisms.

- Temperature sensors: Maintain the optimal temperature for microbial growth.

- Optical sensors: These include spectrophotometers for measuring optical density (cell concentration), and fluorometers for measuring metabolic activity or product concentration.

- Conductivity sensors: Measure the total concentration of dissolved ions in the medium.

- Mass flow sensors: Monitor the flow rate of gases (e.g., air, oxygen, carbon dioxide) into and out of the bioreactor.

- Pressure sensors: Monitor the pressure inside the bioreactor.

The choice of sensors depends on the specific bioprocess and the critical parameters that need to be controlled. Advanced sensors, such as those based on microfluidics or electrochemical techniques, are increasingly being used for more precise and sensitive measurements.

Q 25. Explain the role of process analytical technology (PAT) in bioprocessing.

Process Analytical Technology (PAT) is a system for design, analysis, and control of manufacturing processes through timely measurements (i.e., during processing) of critical quality and performance attributes of raw and in-process materials and processes with the goal of assuring final product quality. It’s like having a dashboard in a car that provides real-time information about speed, fuel level, and other critical factors – PAT offers similar real-time insights into a bioprocess.

- Real-time monitoring: PAT enables continuous monitoring of key process parameters, allowing for immediate adjustments and preventing deviations from optimal conditions.

- Improved process understanding: By collecting comprehensive data, PAT helps researchers understand the complex relationships between process parameters and product quality.

- Enhanced process control: Real-time data enables the implementation of advanced control strategies, leading to more efficient and consistent processes.

- Reduced process variability: By minimizing deviations from optimal conditions, PAT contributes to reducing the variability of the final product and increased reproducibility.

- Faster process development: PAT facilitates faster process development and optimization by providing rapid feedback and enabling design of experiment (DoE) studies.

Examples of PAT tools include online spectrometers, flow cytometry, and chromatography systems. PAT implementation leads to improved product quality, reduced production costs, and faster time to market.

Q 26. How do you ensure the safety of personnel working with microorganisms?

Ensuring the safety of personnel working with microorganisms is paramount in advanced biological treatment. It’s like working in a chemistry lab – strict protocols and safety measures are essential.

- Risk assessment: A thorough risk assessment identifies potential hazards associated with specific microorganisms and procedures.

- Biosafety levels: Laboratories are classified into biosafety levels (BSLs) based on the risk posed by the microorganisms. Higher BSLs have stricter containment measures.

- Personal protective equipment (PPE): Appropriate PPE, including gloves, lab coats, eye protection, and respirators, must be used based on the risk assessment.

- Engineering controls: Engineering controls such as biological safety cabinets (BSCs) and autoclaves provide primary containment of microorganisms.

- Standard operating procedures (SOPs): Detailed SOPs outlining safe handling and disposal of microorganisms and waste materials are critical.

- Training and education: Personnel receive adequate training on safe handling practices, emergency procedures, and waste management.

- Environmental monitoring: Regular monitoring of the laboratory environment helps detect potential contamination.

Following rigorous safety protocols is crucial to prevent accidents and protect the health of personnel and the environment.

Q 27. Describe the different types of microbial growth curves.

Microbial growth curves depict the changes in the population size of microorganisms over time. They provide valuable insights into microbial physiology and are vital for optimizing bioprocesses. Think of it like charting the growth of a plant from a seed to a mature plant.

- Lag phase: Initial period where cells adapt to the new environment, and growth is slow.

- Exponential (log) phase: Rapid cell division and exponential increase in population size. This is the period of maximum growth rate.

- Stationary phase: Growth rate plateaus due to nutrient depletion or accumulation of waste products. The number of new cells equals the number of dying cells.

- Death phase: Cell death exceeds cell division, leading to a decline in the population size.

Understanding microbial growth curves is important for determining optimal harvesting times, optimizing nutrient feeding strategies, and predicting process performance.

Q 28. Explain the importance of media optimization in bioprocessing.

Media optimization is crucial in bioprocessing because it directly impacts microbial growth, product yield, and overall process efficiency. It’s like selecting the right ingredients and cooking method for a recipe – the right media is essential for optimal results.

- Nutrient composition: The type and concentration of nutrients (carbon source, nitrogen source, vitamins, minerals) significantly influence microbial growth and product formation.

- pH control: Maintaining optimal pH is essential for enzyme activity and cell growth.

- Osmotic pressure: Controlling osmotic pressure prevents cell damage and ensures optimal growth.

- Dissolved oxygen: Sufficient oxygen is often needed for aerobic microorganisms.

- Cost-effectiveness: Selecting cost-effective nutrients without compromising growth and product quality is a key consideration.

- Waste reduction: Minimizing waste generation from media components is environmentally friendly and reduces disposal costs.

Strategies for media optimization include using statistical experimental designs (e.g., Design of Experiments or DoE), and response surface methodology (RSM) to identify the optimal media composition and culture conditions.

Key Topics to Learn for Advanced Biological Treatment Interview

- Microbial Ecology and Kinetics: Understanding microbial communities, growth dynamics, and their influence on treatment efficiency. This includes exploring concepts like Monod kinetics and substrate utilization.

- Activated Sludge Process Optimization: Learn about different process configurations (e.g., conventional, extended aeration), operational parameters (e.g., F/M ratio, SRT), and their impact on effluent quality and energy consumption. Consider case studies of process upgrades and troubleshooting.

- Membrane Bioreactors (MBRs): Understand the principles of MBR technology, including membrane fouling mechanisms, cleaning strategies, and the advantages and disadvantages compared to conventional activated sludge.

- Anaerobic Digestion: Explore the various stages of anaerobic digestion, the microbial communities involved, process control strategies, and biogas production and utilization. This includes considerations of different reactor designs.

- Advanced Oxidation Processes (AOPs): Familiarize yourself with different AOPs (e.g., UV/H2O2, ozone) and their applications in treating recalcitrant compounds and improving effluent quality. Understand their limitations and costs.

- Nutrient Removal (Nitrogen and Phosphorus): Master the principles of nitrification, denitrification, and biological phosphorus removal. Explore strategies for enhanced nutrient removal and their impact on environmental regulations.

- Process Control and Instrumentation: Understand the role of sensors, online monitoring, and control strategies in optimizing biological treatment processes. Consider the practical application of automation and data analysis techniques.

- Troubleshooting and Problem Solving: Develop skills in identifying and resolving common operational challenges, such as bulking sludge, foaming, and poor effluent quality. Learn how to interpret process data and make informed decisions.

Next Steps

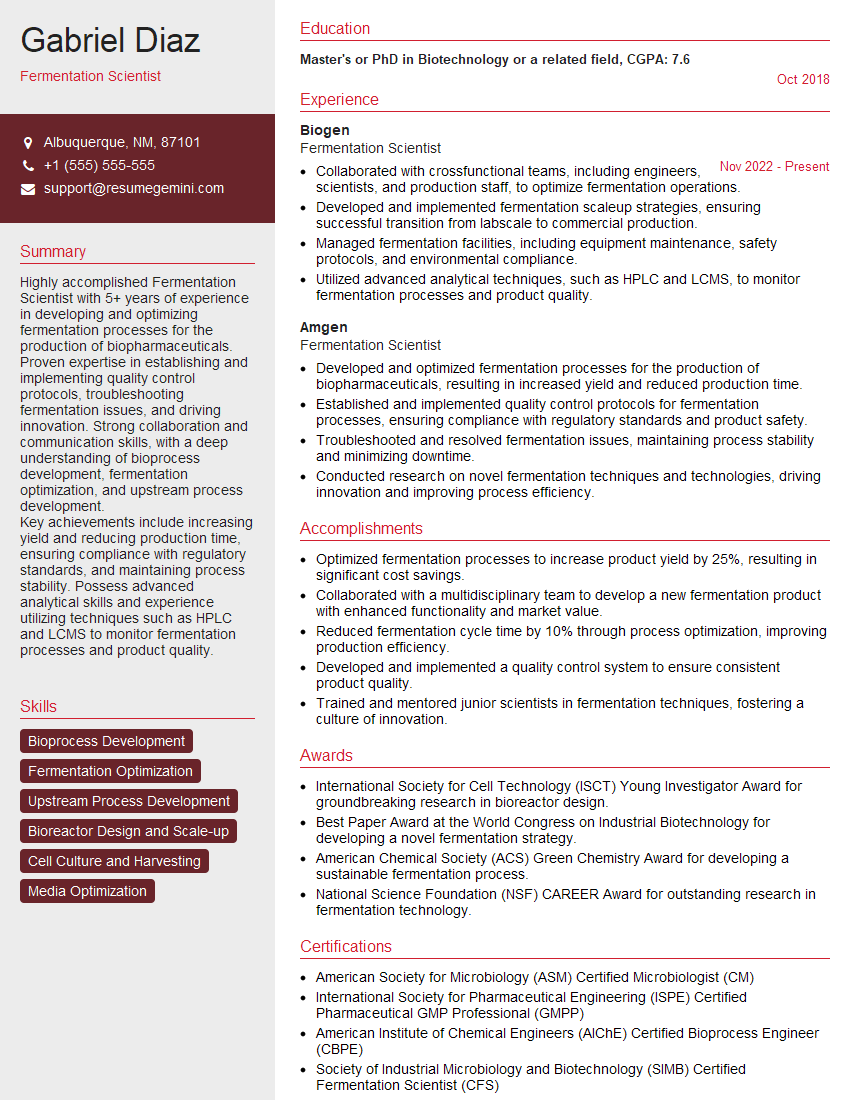

Mastering Advanced Biological Treatment opens doors to exciting career opportunities in environmental engineering and consulting, offering significant growth potential in a field crucial for sustainable development. To maximize your job prospects, create a compelling and ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume tailored to the specific demands of the Advanced Biological Treatment industry. Examples of resumes tailored to this field are available to guide you in crafting your application materials.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.