Cracking a skill-specific interview, like one for Advanced knowledge of heavy equipment operation, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Advanced knowledge of heavy equipment operation Interview

Q 1. Describe your experience operating excavators.

My experience with excavators spans over 15 years, encompassing a wide range of projects from residential site preparation to large-scale infrastructure development. I’m proficient in operating both conventional hydraulic excavators and those equipped with advanced GPS technology. I’ve worked with various sizes of excavators, from compact machines for tight urban spaces to massive units for heavy earthmoving. My expertise includes trenching, excavation, loading trucks, demolition, and precise grading work, all performed with a strong focus on safety and efficiency. For instance, on one project involving a congested city center, I used a compact excavator to carefully excavate around existing utilities, demonstrating precise control and minimizing disruption. Another project involved using a larger excavator to create the foundations for a new bridge, requiring coordination with other heavy equipment and precise depth control.

Q 2. Explain the different types of excavator attachments and their applications.

Excavator attachments significantly broaden the machine’s versatility. Think of them as specialized tools for different jobs. Common attachments include:

- Buckets: These are the most common, used for digging, loading, and moving materials. Different bucket types exist – narrow for trenching, wide for bulk excavation, and even specialized buckets for handling specific materials.

- Hydraulic Breakers (or Hammers): These powerful tools are used for demolition, rock breaking, and concrete removal. They’re essential for tasks that require considerable force.

- Rippers: These are heavy-duty teeth attached to the arm, ideal for breaking up hard ground and compacted soil. They are particularly effective in challenging soil conditions.

- Grapples: Used for handling scrap metal, logs, or other bulky materials. They offer a way to efficiently move irregularly shaped objects.

- Augers: These are drilling attachments used to bore holes for various purposes, such as installing pilings or utility lines.

- Thumbs: These are added to the bucket to provide greater control over material handling, allowing for improved precision and manipulation of objects.

The choice of attachment depends entirely on the specific task. For example, a ripper would be crucial for breaking up rocky soil before excavation, while a grapple would be perfect for clearing debris from a construction site. Using the right attachment improves efficiency and safety by matching the tool to the job.

Q 3. How do you ensure the safety of yourself and others while operating heavy equipment?

Safety is paramount in heavy equipment operation. My approach is multi-faceted and proactive. It begins with:

- Pre-operational checks: Thoroughly inspecting the machine for any mechanical issues or fluid leaks before starting any work.

- Site awareness: Conducting a site assessment to identify potential hazards, such as underground utilities, overhead power lines, or unstable ground conditions. This includes marking out safe zones and establishing clear communication procedures.

- Proper signaling and communication: Utilizing hand signals, two-way radios, and spotters as needed, to ensure clear communication with other workers and equipment operators.

- Personal Protective Equipment (PPE): Always wearing appropriate PPE, including hard hats, safety glasses, hearing protection, and high-visibility clothing.

- Safe operating procedures: Strictly adhering to all safety regulations and operating the equipment within its designed capabilities. This includes never exceeding the rated lifting capacity and maintaining appropriate speed for the conditions.

- Environmental awareness: Being mindful of the surrounding environment, ensuring safe distances from the public and preventing damage to property or the ecosystem.

I’ve personally intervened to stop unsafe practices and have always prioritized the safety of myself and others above all else. A single lapse in judgment can have devastating consequences.

Q 4. What are the daily pre-operational checks you perform on a bulldozer?

My daily pre-operational checks on a bulldozer are meticulous and follow a standardized procedure. They include:

- Visual inspection: Checking for any damage to the tracks, blade, and other components. Looking for leaks or unusual wear.

- Fluid levels: Verifying the levels of engine oil, hydraulic fluid, coolant, and fuel. Low levels are addressed immediately.

- Tire pressure (if applicable): Ensuring adequate tire pressure for optimal performance and stability.

- Operational systems: Testing the functionality of the steering, blade control, and other systems. This includes checking the responsiveness of the controls and the absence of unusual noises.

- Brakes: Testing the effectiveness of the brakes to confirm they are fully functional.

- Lights and signals: Verifying the operation of lights and warning signals to ensure visibility.

- Safety features: Inspecting the condition and functionality of safety devices like the emergency shut-off.

I document all checks and any issues found in a pre-start checklist, which provides a record of the machine’s condition before operation. This preventative maintenance minimizes the risk of breakdowns and accidents.

Q 5. Explain the process of grading a site using a motor grader.

Grading a site with a motor grader involves skillfully manipulating the blade to achieve the desired elevation and slope. The process generally follows these steps:

- Site preparation: Clearing the area of any obstacles and ensuring the ground is suitable for grading.

- Establishing benchmarks: Setting reference points to guide the grading process, usually using survey equipment or GPS technology.

- Rough grading: Using the grader’s blade to initially level the site, removing high spots and filling low areas. This involves adjusting the blade angle and position to achieve the desired result.

- Fine grading: Refining the grade to achieve a precise and smooth surface. This often involves multiple passes and careful blade adjustments to ensure accuracy.

- Slope control: Using the blade to create slopes that meet specifications, ensuring proper drainage and stability.

- Compaction: After grading, compaction may be necessary to ensure the stability of the surface.

Think of it like sculpting with earth. The motor grader is your tool, and precision and patience are crucial for achieving the desired outcome. Effective grading significantly reduces the need for extra earthmoving and ensures that the site is properly prepared for the next stage of construction.

Q 6. How do you handle equipment malfunctions in the field?

When equipment malfunctions in the field, my response is systematic and prioritizes safety. The steps I take are:

- Immediate shutdown: Immediately shutting down the equipment and securing the area to prevent accidents.

- Safety assessment: Evaluating the situation for any immediate safety concerns, ensuring the area is safe for myself and other personnel.

- Troubleshooting: Attempting to diagnose the problem based on my knowledge and experience. This may involve checking fluid levels, fuses, or obvious mechanical issues.

- Communication: Contacting the supervisor or maintenance team to report the problem and request assistance. Providing detailed information about the malfunction is crucial for efficient repairs.

- Temporary repairs (if safe and possible): If a minor repair can be safely performed in the field, I may attempt it, always prioritizing safety.

- Documentation: Carefully documenting the malfunction, repair attempts, and any resulting downtime.

One time, I experienced a hydraulic leak on a backhoe in the middle of a crucial project. Following these steps, I quickly shut down the machine, assessed the situation, communicated with the team, and then a mobile repair team was dispatched, resulting in minimal downtime.

Q 7. Describe your experience with GPS-guided heavy equipment.

I have extensive experience operating GPS-guided heavy equipment, specifically excavators and bulldozers. This technology significantly enhances precision and efficiency. GPS guidance systems provide real-time positioning data, allowing for accurate grading, trenching, and other tasks. The system superimposes a digital model of the project onto the machine’s display, guiding the operator to achieve the precise design specifications. This reduces rework, saves materials, and minimizes human error.

For example, on a recent project involving the creation of precisely graded foundations for a large building, the GPS guidance system enabled me to work significantly faster and to a higher degree of accuracy than would have been possible using traditional methods. The resulting savings in time and materials were substantial. My experience with different GPS systems and their integration with machine controls gives me a comprehensive understanding of their capabilities and limitations.

Q 8. How do you maintain a safe working distance from other equipment and personnel?

Maintaining a safe working distance is paramount in heavy equipment operation. It’s not just about avoiding collisions; it’s about preventing injuries from moving parts, falling objects, or unexpected equipment movements. My approach is multifaceted:

- Visual Awareness: Before starting any operation, I conduct a thorough site survey, identifying potential hazards and establishing clear sightlines. This includes checking for personnel, other equipment, overhead power lines, and unstable ground conditions.

- Communication: Clear and consistent communication is key. I use hand signals, radios, or designated spotters to coordinate movements with other operators and workers. This includes establishing a ‘blind spot’ communication protocol, ensuring everyone knows each other’s limitations and potential blind spots.

- Safe Operating Distances: I adhere strictly to manufacturer-recommended safe operating distances, and where these are not clearly defined, I exercise additional caution. This often means maintaining a larger buffer zone than strictly necessary. For example, when operating a bulldozer near a trench, I’d maintain a considerable distance to prevent ground instability from affecting the dozer’s stability.

- Warning Systems: I ensure all equipment warning systems (lights, horns, backup alarms) are functioning properly and used appropriately. In noisy environments, I rely on visual cues as much as possible.

For instance, on a recent highway construction project, a spotter was crucial for operating a large excavator near a busy lane. His constant communication prevented a near-miss with a passing truck.

Q 9. What are your experience levels with various types of loaders (wheel, skid steer)?

I have extensive experience with both wheel loaders and skid steer loaders. My experience with wheel loaders spans over ten years, encompassing various models and applications from material handling in quarries to site preparation in construction. I am proficient in operating machines ranging from small, compact models to large articulated loaders with capacities exceeding 10 cubic yards. I am well-versed in their operational characteristics, including the use of different attachments (buckets, forks, etc.).

My skid steer experience is equally robust. I’m comfortable operating a wide range of models, from compact units for tight spaces to larger machines with various attachments for tasks ranging from landscaping to demolition work. I understand the nuances of their design, including their articulation and zero-turn capabilities. I’m particularly skilled in using skid steers for precise tasks requiring dexterity, such as landscaping, snow removal, and grading.

I always prioritize safe operation regardless of the loader type, focusing on proper load weight distribution and avoiding exceeding the machine’s rated capacity. For example, I always check the weight of the material before loading and ensure the load is evenly distributed in the bucket to prevent tipping.

Q 10. How do you adapt your operating techniques to different soil conditions?

Adapting to different soil conditions is essential for efficient and safe heavy equipment operation. My approach involves understanding the soil’s properties and adjusting operating techniques accordingly:

- Soil Type Identification: I first identify the soil type (clay, sand, gravel, etc.) to assess its bearing capacity and potential for compaction or instability. This is crucial for selecting the appropriate equipment and operating techniques.

- Speed and Traction: On loose or unstable soils (like sand or mud), I reduce speed to prevent wheel slippage or getting stuck. I may use lower gears and differential locks for improved traction.

- Equipment Selection: I choose the appropriate equipment for the soil conditions. For example, I would use a tracked machine for soft or muddy terrains to minimize ground pressure and improve traction. On firm ground, a wheeled loader might be more efficient.

- Loading Techniques: I adjust loading techniques to prevent soil compaction or damage. In loose soils, I might use smaller loads to prevent instability. In hard-packed soils, I might use rippers or other attachments to loosen the soil before loading.

For example, during a recent earthmoving project, we encountered both soft clay and hard rocky soil. I adjusted my operating techniques on a backhoe loader—using a lighter touch on the clay to avoid excessive digging and employing a more aggressive approach with the ripper attachment on the rocky sections.

Q 11. Explain your understanding of load capacity and stability.

Understanding load capacity and stability is critical for preventing accidents. Load capacity refers to the maximum weight a machine can safely lift or carry, while stability refers to the machine’s ability to remain upright and balanced. Both are intertwined:

- Load Capacity Limits: I always adhere to the manufacturer’s stated load capacity limits for any equipment I operate. Exceeding these limits significantly increases the risk of tipping or structural damage. I regularly check the load charts provided with the equipment and verify the load weight before lifting.

- Center of Gravity: I understand the importance of maintaining a low center of gravity. Improperly distributing the load can shift the center of gravity, making the machine unstable. For example, when loading a truck, I always ensure the load is evenly distributed to prevent tipping.

- Ground Conditions: I assess the ground conditions before operating the machine, ensuring it’s stable and capable of supporting the load. Soft or uneven ground significantly reduces stability.

- Safe Operating Practices: I follow safe operating practices, such as avoiding sudden movements, keeping the boom and bucket as close to the machine as possible when working, and never exceeding the safe operating angles.

A real-world example: I once witnessed an operator exceed the load limit on a crane, resulting in the crane tipping. This highlights the importance of always adhering to manufacturer specifications and maintaining awareness of the machine’s limitations.

Q 12. Describe your experience with preventative maintenance on heavy equipment.

Preventative maintenance is essential for keeping heavy equipment functioning reliably and safely. My experience includes comprehensive daily, weekly, and monthly inspection and maintenance routines:

- Daily Inspections: I perform thorough daily inspections, checking fluid levels (engine oil, hydraulic fluid, coolant), tire pressure, belts, hoses, and other critical components. I also check for any leaks, unusual noises, or other signs of potential problems.

- Weekly Inspections: In addition to daily checks, weekly inspections include more detailed checks of components such as filters (air, fuel, hydraulic), lubrication points, and safety mechanisms.

- Monthly Maintenance: Monthly maintenance often includes tasks such as changing filters, lubricating components, and inspecting brake systems and electrical systems. I meticulously document all maintenance activities.

- Scheduled Maintenance: I follow manufacturer-recommended scheduled maintenance procedures, which may involve more extensive tasks such as engine overhauls or component replacements.

I believe in proactive maintenance. Early detection and addressing minor issues prevents larger, more costly repairs later. For example, a small hydraulic leak detected early can prevent catastrophic hydraulic failure later, saving both time and money.

Q 13. How do you interpret blueprints and construction plans?

Interpreting blueprints and construction plans is crucial for efficient and accurate equipment operation. My approach involves understanding the drawing’s key elements:

- Scales and Dimensions: I carefully examine the scale and understand the dimensions indicated on the plan to determine the exact size and location of features. This helps me plan my movements and avoid potential collisions.

- Elevation and Grading: I interpret elevation and grading information to ensure the work is done to the correct specifications. This is particularly important for excavation and grading work.

- Utility Locations: I identify and carefully avoid underground utilities marked on the plans (water, gas, electricity). Safety is paramount, and hitting a utility line could have serious consequences.

- Construction Sequencing: I understand the construction sequence and plan my work accordingly. This ensures a smooth and efficient workflow, minimizing conflicts with other trades.

For example, recently, a blueprint indicated the precise location of underground pipes. Understanding this allowed me to avoid damaging the lines during excavation, preventing a major disruption and potential safety hazard.

Q 14. Explain your proficiency with different types of cranes (tower, mobile, etc.)

My experience with cranes encompasses various types, including tower cranes, mobile cranes, and overhead cranes. I understand the specific characteristics and limitations of each type:

- Tower Cranes: I’m experienced in the operation and safety procedures associated with tower cranes, including understanding their lifting capacity, reach, and limitations imposed by wind speed. I understand the importance of proper rigging and load securing.

- Mobile Cranes: I’m proficient in operating various mobile cranes, understanding their maneuverability, lifting capacity, and the importance of proper counterweight and outrigger setup. I’m familiar with different types of booms and lifting attachments.

- Overhead Cranes: I’ve worked with overhead cranes in industrial settings, understanding their operation and the importance of safety procedures, particularly in coordinating movements with other personnel working in the area.

My experience includes working with different crane models and capacities, always prioritizing safety and adherence to regulations and manufacturer specifications. For instance, on a high-rise construction project, my experience with tower cranes ensured the safe and efficient lifting of large structural components to their designated positions.

Q 15. What are the safety regulations you adhere to when operating heavy equipment?

Safety is paramount in heavy equipment operation. My adherence to safety regulations is unwavering and begins before I even start the engine. This includes a thorough pre-operational inspection, checking all fluids, tire pressure, and ensuring all safety devices – seatbelts, lights, horns, and emergency shut-offs – are functioning correctly. I always wear appropriate Personal Protective Equipment (PPE), including a hard hat, safety glasses, high-visibility clothing, and steel-toed boots. Before commencing any task, I assess the work area for hazards, including overhead power lines, underground utilities, and unstable ground conditions. I establish clear communication protocols with spotters or other personnel on-site, using hand signals or radios to ensure everyone is aware of the equipment’s movements. Throughout operation, I maintain a safe speed, avoid sharp turns, and remain alert to my surroundings. Following all company-specific safety protocols, such as daily equipment checks and reporting procedures, is equally critical.

For example, on a recent project involving excavation near a busy road, I implemented a traffic management plan which included flaggers, signage, and reduced speed limits to ensure the safety of both the crew and the public.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage fuel efficiency while operating heavy equipment?

Fuel efficiency is crucial for both economic and environmental reasons. My approach involves several strategies. Firstly, I prioritize proper machine maintenance. Regular servicing, including filter changes and lubrication, ensures optimal engine performance and reduces fuel consumption. Secondly, I avoid unnecessary idling. If the machine will be stationary for more than a minute, I shut it off. Thirdly, I operate the equipment smoothly, avoiding sudden acceleration and braking. Fourthly, I select the appropriate gear for the task at hand, matching the machine’s power output to the resistance. Finally, I pay attention to terrain conditions and avoid unnecessary work in challenging situations. For example, if working on a steep incline, I’ll plan the movement carefully to avoid excessive engine strain. In one instance, by meticulously planning the movement of materials and optimizing the machine settings, I was able to reduce fuel consumption on a large earthmoving project by 15%.

Q 17. What is your experience with different types of backhoes and their applications?

I have extensive experience with various backhoe types, including standard backhoes, mini-excavators, and specialized backhoes equipped with features like hydraulic breakers or thumbs. Standard backhoes are versatile for general digging and trenching tasks and are common in construction sites, utility work, and landscaping. Mini-excavators excel in confined spaces and tight working areas like urban settings and interior demolition. Specialized backhoes with attachments provide more specific capabilities, for example, a hydraulic breaker for demolition or a thumb for material handling. The choice depends entirely on the specific application. For instance, when working in a residential area with limited space, a mini-excavator was the ideal choice to avoid damaging surrounding property. Conversely, a larger backhoe with a breaker was the solution for a demolition job involving the removal of a significant concrete structure.

Q 18. Describe your experience with operating equipment in confined spaces.

Operating equipment in confined spaces demands extra caution and precision. Before beginning any work in a confined area, I thoroughly assess the space, identifying any potential obstacles or hazards such as low ceilings, restricted visibility, or unstable structures. I plan the movement of the equipment meticulously, taking into consideration dimensions and turning radii. I use spotters strategically to guide the machine and to monitor its surroundings. I always prioritize slow, controlled movements and use additional safety measures, such as implementing shoring and bracing if necessary. During a recent project which involved working in a basement, the careful use of a mini-excavator and a detailed plan was paramount to preventing damage to nearby walls and infrastructure.

Q 19. How do you handle unexpected equipment failures or emergencies?

Unexpected equipment failures or emergencies require immediate and decisive action. My first response is to ensure the safety of myself and others around me, immediately shutting down the equipment and clearing the area if necessary. Following that, I assess the situation to determine the nature of the problem. If it’s a minor issue I can address myself, I’ll do so, but I’ll always prioritize safety. If it’s a more significant malfunction, I immediately report it to the supervisor, providing a detailed description of the issue and the circumstances surrounding it. In one instance, a hydraulic line on a bulldozer failed, causing a sudden loss of steering control. I immediately applied the emergency brake, brought the machine to a safe stop, reported the incident, and waited for the repair team to address the situation, ensuring everyone was safe in the process.

Q 20. Explain your understanding of different types of hydraulic systems used in heavy equipment.

Heavy equipment relies heavily on hydraulic systems to generate power for various functions such as lifting, digging, and moving. I understand the basics of open-center and closed-center systems. Open-center systems use a pump that constantly delivers hydraulic fluid, while closed-center systems regulate fluid flow more precisely. Understanding the different types of hydraulic valves – directional control valves, pressure control valves, and flow control valves – is also crucial for operating the equipment effectively and safely. I am familiar with various components such as hydraulic cylinders, pumps, motors, and filters. A firm understanding of these systems is essential for troubleshooting issues, such as leaks or low pressure, which can directly impact equipment efficiency and safety. For example, recognizing the symptoms of a failing hydraulic pump – reduced lifting capacity, unusual noises, or overheating – allows for timely maintenance and prevents major breakdowns.

Q 21. Describe your knowledge of heavy equipment regulations and permits.

Knowledge of heavy equipment regulations and permits is essential for legal and safe operation. I am familiar with local, state, and federal regulations governing equipment operation, including licensing requirements, safety standards, and environmental protection guidelines. I understand the permit processes needed for operating specific types of equipment in various settings, such as operating permits for road construction or specialized permits for working near power lines. I consistently adhere to these regulations and ensure that all necessary paperwork is in order before commencing any task. For example, when working near power lines, I am aware that specific clearances must be maintained and permits obtained from the relevant power company, which safeguards both personnel and equipment.

Q 22. How do you perform routine maintenance on heavy equipment?

Routine maintenance on heavy equipment is crucial for preventing breakdowns, ensuring safety, and maximizing operational lifespan. It’s a systematic process that combines preventative measures with regular checks and adjustments.

- Daily Inspections: This involves a visual check of all fluid levels (engine oil, hydraulic fluid, coolant, transmission fluid), tire pressure, belts, hoses for cracks or leaks, and checking for any unusual noises or vibrations. I always document my findings in a logbook. For example, I might note a slight oil leak on a hydraulic line and plan for repair during a scheduled maintenance period.

- Scheduled Maintenance: This is more in-depth and follows the manufacturer’s recommendations. It often includes things like oil changes, filter replacements (air, fuel, hydraulic), lubrication of moving parts, and inspections of critical components like brakes and steering systems. The frequency of scheduled maintenance depends on operating hours or calendar time, typically measured in hours or months.

- Component-Specific Maintenance: This involves tasks that aren’t done every day or even every week, but are needed at set intervals, or when problems are observed during daily or scheduled maintenance. This could include things like replacing worn-out brake pads, repairing or replacing damaged tracks on a bulldozer, or servicing a particular attachment.

Think of it like maintaining your car – regular oil changes, tire rotations, and fluid checks keep it running smoothly. Ignoring these leads to major issues down the road. With heavy equipment, those issues can be costly and dangerous.

Q 23. How do you troubleshoot common heavy equipment problems?

Troubleshooting heavy equipment problems requires a systematic approach combining observation, diagnostic tools, and experience. My approach typically involves these steps:

- Identify the Problem: What exactly is malfunctioning? Is it a loss of power, unusual noise, fluid leak, or something else? Accurate observation is key. For example, if the engine is overheating, it could be due to a failing thermostat, a coolant leak, or a clogged radiator.

- Gather Information: When did the problem start? What were the operating conditions? Was there any unusual event before the issue occurred? This information can provide valuable clues.

- Visual Inspection: Carefully examine the affected area for obvious problems – loose connections, leaks, damaged components.

- Utilize Diagnostic Tools: Depending on the equipment, diagnostic tools, such as computer diagnostic systems or pressure gauges, may be necessary to pinpoint the root cause. For example, a code reader can help diagnose electrical issues in modern excavators.

- Consult Manuals and Resources: Refer to the operator’s manual and any relevant troubleshooting guides. These provide invaluable information and potential solutions.

- Test and Verify: After making a repair, test the system to ensure the problem is fixed before returning the equipment to service.

I’ve often used this process to troubleshoot issues ranging from simple hydraulic leaks (requiring a hose replacement) to more complex problems involving electrical systems or engine performance. The key is patience, attention to detail, and a willingness to consult resources when necessary.

Q 24. Explain your experience with working on challenging terrains or difficult weather conditions.

Operating heavy equipment in challenging terrains and weather conditions requires extra skill, caution, and adaptability. I’ve worked on steep slopes, muddy terrain, and in extreme temperatures. For example, working on a mountain road construction project required careful planning and execution to avoid slippage and ensure the safety of both myself and the equipment.

- Terrain Adaptation: Operating on slopes or uneven ground necessitates slow speeds, careful maneuvering, and the use of appropriate safety measures, like locking differential systems, to prevent rollovers or slides.

- Weather Considerations: Extreme temperatures (both hot and cold) impact engine performance and the efficiency of hydraulic systems. For instance, during extreme cold, engine warm-up time increases significantly. In rainy conditions, traction is a major concern and careful control is essential.

- Safety Procedures: In challenging conditions, adherence to safety protocols is paramount. This includes wearing appropriate protective gear, having a spotter if necessary, and being constantly aware of surroundings.

My experience has taught me the importance of pre-planning, adapting to the conditions, and consistently prioritizing safety to successfully complete projects even under challenging circumstances.

Q 25. Describe your experience with different types of heavy equipment attachments.

Heavy equipment attachments vastly expand the versatility of the machines. My experience includes working with a variety of attachments on excavators, loaders, and backhoes. Here are a few examples:

- Buckets: Different buckets are designed for specific tasks, such as digging, trenching, material handling (for example, a clamshell bucket for lifting and dumping materials). The selection of the right bucket is crucial for efficiency and safety.

- Hydraulic Hammers: These attachments break up rock, concrete, or other hard materials. Operating a breaker requires specific techniques to avoid damaging the equipment.

- Grapples: Used for lifting and moving logs, scrap metal, or other irregularly shaped materials. Understanding the weight capacity and proper operating techniques is vital to prevent accidents.

- Rippers: These are particularly useful for breaking up hard soil or rocky ground, significantly assisting in earthmoving tasks.

- Augers: These are used for drilling holes for foundations, posts, or utility lines. Different diameter augers are used depending on the requirements.

Proper attachment selection and safe operation are critical for effective and safe work. Understanding the capabilities and limitations of each attachment is essential for efficient task completion.

Q 26. Explain your understanding of the different types of earthmoving equipment.

Earthmoving equipment is categorized based on its function and capabilities. I have extensive experience with various types:

- Excavators: Used for digging, lifting, and moving earth. They come in various sizes and configurations, from small mini-excavators to massive hydraulic excavators.

- Bulldozers: Push large quantities of earth, primarily used for land clearing, grading, and site preparation.

- Loaders (Wheel Loaders and Backhoes): Wheel loaders scoop up and move materials, backhoes dig and load materials. They are used for various tasks, including loading trucks and digging foundations.

- Scrapers: Efficiently move large volumes of earth over longer distances. They are commonly used in large-scale earthmoving projects.

- Graders: Used for smoothing and grading surfaces, creating level roads and creating fine grades.

Choosing the right equipment for a specific task is crucial for efficient project completion. Understanding the capabilities and limitations of each type of earthmoving equipment is essential for any project manager or heavy equipment operator.

Q 27. How do you ensure the accurate and efficient completion of assigned tasks?

Accurate and efficient task completion relies on several key factors:

- Thorough Planning: Before starting any task, I carefully review plans and specifications, identifying potential challenges and developing a detailed work plan. This often includes site assessment to account for terrain and access.

- Effective Equipment Selection: Choosing the right equipment for the job is crucial. I’ll consider factors like the material to be moved, the distance, the terrain, and other relevant considerations.

- Skillful Operation: My experience allows me to operate equipment efficiently and safely, minimizing downtime and waste.

- Safety Procedures: Following all safety protocols is paramount to avoid injuries and equipment damage.

- Regular Communication: Maintaining open communication with supervisors and other team members is crucial for coordinating efforts and resolving any issues promptly.

- Quality Control: I regularly inspect my work to ensure that it meets the required specifications and standards.

For example, on a recent project involving trenching, effective planning ensured that the trench was dug to the correct depth and width, and the proper equipment selection minimized both time spent and fuel usage. Through consistent attention to these aspects, I strive to consistently deliver high-quality work efficiently and safely.

Key Topics to Learn for Advanced Heavy Equipment Operation Interviews

- Advanced Machine Operation & Maintenance: Understanding preventative maintenance schedules, troubleshooting malfunctions, and performing minor repairs on various heavy equipment types (e.g., excavators, bulldozers, loaders).

- Safety Procedures & Regulations: Demonstrating in-depth knowledge of OSHA regulations, site-specific safety protocols, and emergency procedures related to heavy equipment operation.

- Advanced Operation Techniques: Discussing efficient operating techniques for maximizing productivity, minimizing wear and tear, and adapting to diverse terrain and project requirements. This includes proficiency in various attachments and their applications.

- GPS & Technology Integration: Understanding and explaining your experience with GPS-guided systems, machine control technology, and data logging systems used in modern heavy equipment.

- Project Management & Coordination: Demonstrating your ability to collaborate with other crew members, manage tasks effectively, understand project timelines, and contribute to overall project success.

- Environmental Awareness: Articulating your understanding of environmental considerations, such as soil erosion control, minimizing fuel consumption, and adhering to environmental regulations.

- Problem-Solving & Decision-Making: Providing examples of how you’ve overcome operational challenges, solved equipment malfunctions, and made critical decisions in high-pressure situations.

Next Steps

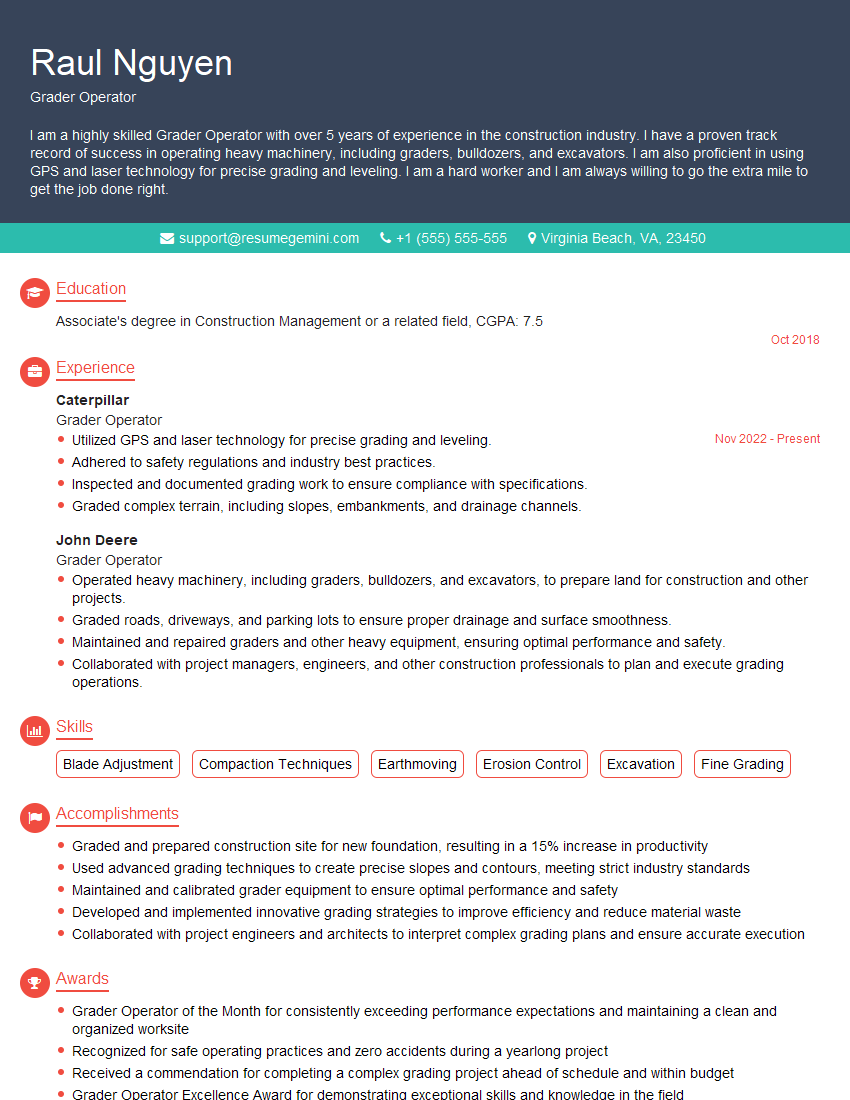

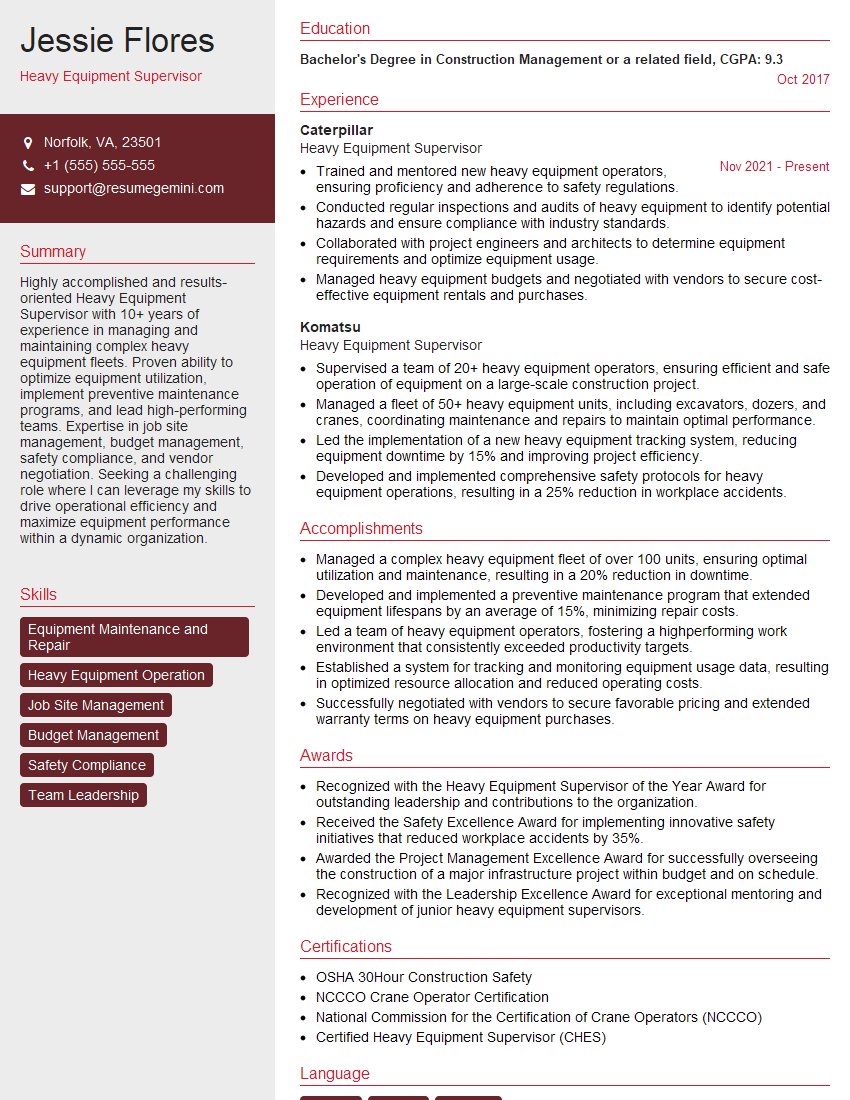

Mastering advanced heavy equipment operation opens doors to high-demand, well-compensated roles within the construction, mining, and infrastructure sectors. To stand out in a competitive job market, a strong, ATS-friendly resume is crucial. This is where ResumeGemini can help. ResumeGemini provides the tools and resources to craft a compelling resume that highlights your skills and experience effectively, maximizing your chances of landing an interview. Examples of resumes tailored to advanced heavy equipment operation are available within the ResumeGemini platform, providing you with valuable templates and guidance. Invest in your future; invest in a professional resume with ResumeGemini.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.