Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Aerial Utility Installation interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Aerial Utility Installation Interview

Q 1. Describe your experience with different types of aerial utility equipment.

My experience encompasses a wide range of aerial utility equipment, from bucket trucks and digger derricks to specialized tools for cable splicing and tensioning. Bucket trucks are our workhorses, providing elevated access to lines. Digger derricks are crucial for setting poles and handling heavy loads. I’m proficient with various tensioning devices, ensuring proper cable sag and minimizing stress on the infrastructure. I’ve also worked extensively with hand tools like cable cutters, come-alongs, and various types of splicing equipment, adapted to the specific type of cable being handled. For instance, working with fiber optic cables requires specialized fusion splicing equipment, requiring a different skill set than working with copper conductors.

- Bucket Trucks: Used for accessing and working on overhead lines safely.

- Digger Derricks: Essential for placing utility poles and handling heavy materials.

- Tensioning Devices: Used to ensure proper cable sag and prevent damage.

- Specialized Splicing Equipment: Used for connecting different cable types, like copper or fiber optic.

Q 2. Explain the safety procedures you follow when working at heights.

Safety is paramount in aerial utility work. We adhere strictly to a comprehensive safety program, beginning with thorough pre-job planning. This involves risk assessments, identifying potential hazards like power lines, falling objects, and weather conditions. Every team member uses appropriate personal protective equipment (PPE), including hard hats, safety glasses, harnesses, and fall protection equipment. Before commencing any work at height, we conduct a thorough inspection of all equipment, ensuring proper functionality and securing all necessary permits. We utilize various fall protection systems, including anchor points, lifelines, and self-retracting lifelines (SRLs) to prevent falls. Regular training and safety briefings are integral to maintaining a high level of awareness and minimizing risks. We use the buddy system, meaning there is always a second worker present to assist and maintain constant vigilance. Think of it like climbing a mountain – you wouldn’t go alone without proper gear and a plan.

Q 3. How do you identify and resolve common issues with aerial utility lines?

Identifying and resolving issues in aerial utility lines requires systematic troubleshooting. We start with visual inspections, checking for signs of damage, wear, or unusual sagging. Specialized testing equipment, such as ohmmeters and cable fault locators, helps pinpoint the exact location and nature of problems. For example, a sudden drop in voltage might indicate a break or short circuit in a conductor. Using a cable fault locator helps us narrow down the problem area, improving our efficiency when we’re performing repairs hundreds of feet in the air. Common issues include broken conductors, faulty insulators, and tree interference. Repairs range from simple replacements to complex splicing procedures, depending on the extent of damage. We always prioritize safe working procedures, often requiring de-energizing lines before working on them. Thorough documentation of all repairs and maintenance is critical for record-keeping and future reference.

Q 4. What are the different types of aerial cable and their applications?

Aerial cables come in various types, each suited to specific applications. Copper conductors, for instance, are commonly used for power distribution and telephone lines. Their high conductivity makes them ideal for carrying electrical currents. Aluminum conductors, lighter than copper, are also used for power transmission, often reinforced with steel for added strength. Fiber optic cables, composed of thin strands of glass, transmit data through light pulses. They’re essential for high-speed internet and telecommunications. Coaxial cables are designed to carry high-frequency signals and are often used in cable television networks. The choice of cable depends on the application – carrying high voltage electricity needs a different cable than transmitting high-speed data.

- Copper Conductors: High conductivity for power and telecommunications.

- Aluminum Conductors: Lightweight, often steel-reinforced for power transmission.

- Fiber Optic Cables: Data transmission using light pulses.

- Coaxial Cables: High-frequency signal transmission for cable TV.

Q 5. Describe your experience with installing and maintaining aerial fiber optic cables.

My experience with aerial fiber optic cable installation and maintenance is extensive. This involves careful planning, route surveying, and meticulous installation techniques. We use specialized fusion splicers to create seamless connections between fiber strands, minimizing signal loss. Testing equipment verifies the quality of the connections and the overall integrity of the cable. Maintenance includes regular inspections to identify potential issues such as fiber cuts, connector damage, or environmental factors affecting the cable’s performance. Protecting fiber optic cables from damage is crucial, and requires careful handling during installation and routine checks to make sure there is no rodent damage or external stress on the line. Working with fiber optics demands precision and attention to detail; even a small imperfection can significantly impact signal quality.

Q 6. How do you ensure the structural integrity of utility poles and structures?

Ensuring the structural integrity of utility poles and structures is crucial for safety and reliability. Regular inspections are conducted to identify signs of decay, cracking, or other damage. We assess the condition of the ground around the poles, looking for signs of erosion or settling. Techniques such as ground penetration radar (GPR) can be used to assess soil conditions and identify potential underground issues affecting pole stability. When necessary, poles are replaced or reinforced, often using specialized techniques like adding guy wires or installing new cross arms to redistribute weight and increase stability. Proper grounding is also essential to prevent electrical hazards. Think of these poles as the backbone of the system; their strength directly impacts the reliability and safety of the entire network.

Q 7. What are the common hazards associated with aerial utility installation?

Aerial utility installation presents several inherent hazards. Working at heights is inherently risky, with the potential for falls. Contact with energized power lines poses a severe electrical shock hazard. Exposure to weather conditions, such as extreme heat, cold, rain, or wind, can be dangerous and impact work efficiency. Working around heavy equipment also creates risks, necessitating constant awareness and adherence to safety protocols. Improper handling of materials can lead to injuries, and potential interactions with wildlife or insects may also need to be considered. The risk of falling objects also needs to be evaluated before work starts.

Q 8. Explain your experience with various splicing techniques for aerial cables.

My experience encompasses a wide range of splicing techniques for aerial cables, tailored to the specific cable type and application. This includes mechanical splicing, using various connectors and compression tools for efficient and reliable joints. For example, I’m proficient with compression connectors for coaxial cables, ensuring signal integrity is maintained. I also have extensive experience with various types of heat-shrink splices, vital for ensuring watertight seals in different weather conditions. For fiber optic cables, I utilize fusion splicing, a precise technique that minimizes signal loss. The choice of technique depends heavily on factors such as cable type (coaxial, fiber optic, copper), the environmental conditions, and the required load capacity of the splice. Choosing the wrong technique can lead to signal degradation, weakening of the cable, or even catastrophic failure. I always prioritize safety and adhere to manufacturer specifications for every splice I make. I’ve successfully completed hundreds of splices across a variety of projects, consistently exceeding performance expectations.

- Mechanical Splicing: Utilizing various compression tools and connectors for quick and reliable joins, especially suited for copper cables.

- Heat-Shrink Splicing: Employing heat-shrink tubing and sealant to create watertight and durable connections, ideal for diverse environmental conditions.

- Fusion Splicing: Precisely fusing fiber optic cables together for minimal signal loss, critical for high-bandwidth applications.

Q 9. How do you handle emergencies during aerial utility installation?

Emergency handling during aerial utility installation requires immediate action and a calm, methodical approach. My training emphasizes safety protocols above all else. The first step is always to ensure the safety of myself and my team, evacuating the immediate area if necessary and contacting emergency services. Then, I would assess the situation: Is there a downed power line? Cable damage? An injury? The type of emergency dictates the response. A downed power line necessitates immediate isolation and notification of the power company before any intervention. Cable damage might require temporary repairs or securing the damaged section to prevent further harm. Injuries require first aid and potentially calling emergency medical services. Beyond immediate action, a thorough post-incident investigation is crucial to prevent similar events in the future. This includes reviewing the safety procedures followed, identifying any equipment malfunction, and implementing corrective measures to prevent recurrence. I’ve handled several emergencies in the field, always prioritizing safety and efficient problem solving. For example, once, a sudden high wind event threatened to cause damage to a partially installed cable, and I had to quickly secure it with additional support, preventing any harm or delay to the project.

Q 10. What are your skills in using aerial lifts and bucket trucks?

I’m highly proficient in operating aerial lifts and bucket trucks, possessing extensive experience and all necessary certifications. My skills include pre-operational checks (ensuring the equipment is in safe working order, checking hydraulics, inspecting safety mechanisms), safe operation (smooth maneuvers, adherence to weight limits), and maintenance (basic troubleshooting, reporting issues for professional servicing). I am equally comfortable working at significant heights and navigating confined spaces, utilizing the aerial equipment with precision and safety. I understand the limitations of the equipment and always prioritize safe operating procedures. This includes ensuring proper grounding techniques are followed when working near energized lines. Moreover, I’m adept at using the various controls to position the bucket accurately for efficient and safe work. My ability to operate aerial lifts and bucket trucks safely and efficiently ensures project completion with minimal risk and maximum productivity. For instance, during a recent project, I utilized the aerial lift’s precise controls to install a new cable in a densely populated area, minimizing disruption to public traffic and ensuring the safety of pedestrians and traffic.

Q 11. Describe your understanding of relevant safety regulations and standards (e.g., OSHA).

My understanding of safety regulations and standards, particularly OSHA (Occupational Safety and Health Administration) regulations, is comprehensive. I’m familiar with all relevant standards concerning working at heights, electrical safety, fall protection, and lockout/tagout procedures. These regulations are paramount in preventing accidents and injuries. I’m also knowledgeable about the specific safety standards relating to the use of aerial lifts, bucket trucks, and the handling of various cable types. I regularly attend safety training sessions to update my knowledge and remain compliant with all regulations. For instance, I am well versed in OSHA’s requirements regarding fall protection and regularly inspect harnesses, lanyards, and other equipment to ensure they are in perfect working condition before commencing work at heights. Before any project, I conduct a thorough job safety analysis (JSA) to identify potential hazards and implement the appropriate safety measures. My adherence to safety regulations is unwavering, ensuring the safety of my team and the public.

Q 12. How do you plan and execute a complex aerial utility installation project?

Planning and executing a complex aerial utility installation project involves a multi-stage process. It starts with a thorough review of the project specifications, blueprints, and site surveys. This helps identify potential challenges and develop a detailed plan outlining the various stages, timelines, and resources required. This includes scheduling, material procurement, equipment selection, risk assessment, and safety planning. Next, I coordinate with relevant stakeholders, including utility companies, engineers, and local authorities. This ensures seamless collaboration and adherence to all necessary regulations and permits. During execution, I closely supervise the installation, ensuring adherence to the plan, addressing any unforeseen issues promptly, and maintaining open communication with the project team. I utilize project management tools to track progress, manage resources, and ensure the project remains on schedule and within budget. A recent project involved installing a high-capacity fiber optic cable across a challenging terrain, requiring meticulous planning to navigate environmental obstacles and ensure minimal disruption to the surrounding ecosystem. I successfully completed this project ahead of schedule, demonstrating effective planning and execution.

Q 13. How do you troubleshoot problems with aerial utility lines using diagnostic tools?

Troubleshooting problems with aerial utility lines utilizes a range of diagnostic tools and techniques. This could involve using cable testers to assess the electrical continuity and identify breaks or shorts in copper cables. For fiber optic lines, Optical Time-Domain Reflectometers (OTDRs) are employed to pinpoint faults along the cable length. I also utilize other diagnostic tools, like thermal imagers, to identify overheating, a common cause of cable failures. In some cases, visual inspection might reveal physical damage to the cables or supporting structures. Once the problem is identified, the appropriate repair or replacement procedure is carried out, ensuring the integrity of the system. Each diagnostic method is carefully chosen based on the type of cable and the nature of the suspected problem. For example, using an OTDR for a copper cable wouldn’t provide useful information. My expertise enables me to quickly diagnose and resolve problems, ensuring minimal service disruption.

Q 14. What is your experience with grounding and bonding procedures?

Grounding and bonding are critical safety procedures in aerial utility installation, minimizing the risk of electrical shock and damage. Grounding involves connecting the aerial equipment and metallic structures to the earth, providing a path for electrical current to safely dissipate. Bonding connects various metallic parts of the equipment, preventing voltage differences that could cause electric shocks or damage. I strictly adhere to grounding and bonding protocols, using appropriate grounding rods, clamps, and conductors. The specific techniques vary depending on the environment and the type of equipment. For example, working near high-voltage lines demands meticulous attention to grounding procedures. My experience ensures that all grounding and bonding procedures are performed correctly, ensuring both worker and equipment safety. Neglecting these crucial procedures can have severe consequences, leading to injuries or costly equipment damage.

Q 15. Explain your knowledge of different types of aerial cable terminations.

Aerial cable terminations are crucial for ensuring the safety and reliability of utility lines. They secure the cable to structures, providing a robust and weather-resistant connection. Different termination types are chosen based on factors such as cable type, voltage level, and environmental conditions.

- Compression terminations: These use a compression fitting to firmly grip the cable conductor. They are common for lower voltage applications and are relatively easy to install. Think of it like a really strong clamp squeezing the cable tightly.

- Pothead terminations: These are used for higher voltage cables and provide insulation and protection against environmental factors. They are more complex and often involve sealing compounds and specialized components. Imagine a protective housing that safeguards the cable connection from the elements.

- Dead-end terminations: These are used to terminate a cable at the end of a run, preventing the cable from moving. They provide extra support and are particularly important in areas prone to strong winds or vibrations. These are like anchors for your cable, securing it firmly in place.

- Splice terminations: These are used to join two cables together. Careful splicing ensures a seamless electrical connection and minimizes energy loss. It’s like creating a strong, electrically sound joint between two cable segments.

The selection of the appropriate termination type is critical to the long-term performance and safety of the aerial network. Incorrect termination can lead to failures, power outages, and safety hazards.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain accurate records and documentation of your work?

Maintaining accurate records is paramount in aerial utility installation. This is crucial for safety, regulatory compliance, and future maintenance. We utilize a combination of digital and physical methods to ensure comprehensive documentation.

- Digital Records: We use specialized software to log installation details including location coordinates (using GPS), cable type and specifications, termination type, date of installation, crew members involved, and any relevant photos or videos. This creates a centralized, searchable database.

- Physical Records: We also maintain hard copies of as-built drawings, inspection reports, and maintenance logs. These serve as backups and are readily accessible even during technological failures. These are typically stored in organized, waterproof files for protection.

- As-built drawings: These are essential to show the final placement of cables, poles and related equipment. They may be compared against the original plans to confirm the accurate implementation of the project. These serve as important records for future maintenance and troubleshooting.

Regular audits of our records ensure accuracy and completeness. A robust record-keeping system protects both the company and the public by providing clear documentation of our work.

Q 17. How do you collaborate effectively with other members of a crew?

Effective teamwork is critical in our line of work. Safety and efficiency depend on seamless collaboration. Our crew uses several strategies to work as a cohesive unit.

- Pre-job briefings: Before commencing any task, we have a thorough briefing. This involves reviewing the work plan, safety procedures, and assigning roles and responsibilities to each member.

- Clear communication: We utilize hand signals, radio communication, and verbal cues to maintain constant communication, particularly during potentially hazardous tasks. Open communication helps ensure that everyone is informed and on the same page.

- Mutual respect: We foster an environment of mutual respect and trust where everyone feels comfortable voicing concerns or suggesting safer or more efficient work methods.

- Regular check-ins: We check in frequently to monitor progress, address challenges, and ensure everyone’s safety and well-being.

This collaborative approach not only increases efficiency but also significantly reduces the risk of accidents. Everyone’s expertise is valued, and open communication ensures a smooth and safe work environment.

Q 18. Describe your experience with working in various weather conditions.

Working in varying weather conditions is an inherent part of aerial utility installation. We’re prepared to work safely and efficiently in different circumstances.

- Extreme heat: In hot weather, we take frequent breaks, hydrate adequately, and use cooling vests or other protective gear to prevent heatstroke.

- Cold weather: In freezing temperatures, we use appropriate layers of insulated clothing, hand and foot warmers, and take frequent breaks to avoid hypothermia. Safety also requires using ice grips and working at a slower pace.

- Rain and wind: In inclement weather, we use specialized equipment, such as waterproof gear and harnesses, and may delay certain tasks for safety reasons. We monitor weather forecasts closely and adjust our schedules accordingly.

- Snow and ice: Snow and ice pose significant safety risks. We employ additional safety measures like using ice cleats and ensuring stable footing before starting any task. In extreme conditions, we might postpone operations entirely.

Weather preparedness and safety procedures are essential to avoid accidents and ensure that work is performed without compromising safety.

Q 19. What are your skills in using hand tools and power tools related to aerial utility work?

Proficiency with both hand and power tools is essential for efficient and safe aerial utility installation. My skills encompass a wide range of tools.

- Hand tools: I am proficient in using various hand tools, such as wire cutters, crimpers, lineman’s pliers, screwdrivers, wrenches, and measuring tapes. These tools are crucial for precision work and often used for finer details or in situations where power tools are impractical.

- Power tools: I have extensive experience with power tools, including drills, saws, grinders, and tensioning tools. These tools enhance efficiency, particularly during large-scale projects.

- Specialized tools: I’m also familiar with specialized tools specific to aerial utility work, such as come-alongs, block and tackle systems, and hydraulic tensioners. These are vital for safely handling heavy cables and equipment.

Regular maintenance and safe operation of all tools are prioritized to ensure both efficiency and safety. I understand the importance of using the right tool for the job and following all safety regulations.

Q 20. Explain your understanding of load calculations and line sag.

Understanding load calculations and line sag is fundamental to ensuring the structural integrity and safety of aerial utility lines. Incorrect calculations can lead to line failures.

- Load Calculations: These involve determining the total weight a line must support, including the weight of the cable itself, ice loading (in cold climates), wind loading, and any attached equipment. Factors like the cable’s material and diameter are also critical components of the calculation.

- Line Sag: Sag refers to the vertical drop of a cable between two support points. Excessive sag can result in ground clearance issues or contact with obstacles. Insufficient sag can lead to excessive tension, potentially causing cable failure. The amount of sag is calculated using formulas that incorporate factors like cable tension, cable weight, span length, and temperature.

- Software and Calculations: We use specialized software to assist with these calculations, ensuring accuracy and reducing the risk of errors. Accurate calculation helps prevent failures and ensure safety.

Accurate load calculations and understanding line sag ensure that the cable is installed with the appropriate tension to withstand environmental loads while maintaining safe ground clearances.

Q 21. How do you ensure compliance with environmental regulations during installation?

Environmental compliance is a top priority in our work. We adhere strictly to all relevant regulations to minimize environmental impact.

- Minimizing disturbance: We plan our work to minimize disturbance to natural habitats. We identify and protect sensitive areas during installation.

- Waste management: We follow strict protocols for waste disposal, ensuring proper handling of materials such as cable scraps and packaging. We recycle or dispose of waste responsibly.

- Erosion control: In areas prone to erosion, we use appropriate methods to prevent soil erosion during the installation process. This involves taking preventative measures to avoid land disturbances.

- Permitting and compliance: We obtain all necessary permits before beginning work and adhere to all local, state, and federal regulations. This ensures compliance and reduces environmental risks.

Our commitment to environmental responsibility contributes to the long-term sustainability of our projects and helps protect the environment. We understand our responsibility to minimize the impact of our work.

Q 22. What is your experience with working on energized lines?

Working on energized lines demands the highest level of safety awareness and adherence to strict protocols. My experience encompasses years of working with voltages ranging from low-voltage distribution lines to high-voltage transmission lines. This involves meticulous planning, using specialized equipment like insulated tools and hot sticks, and employing techniques such as grounding and tagging procedures to mitigate risks. For instance, before commencing any work on an energized line, I always conduct a thorough risk assessment, verifying the voltage level, and ensuring the proper safety measures are in place. I’m proficient in various live-line techniques, including using insulating blankets, rubber gloves, and specialized tools for working on energized conductors. Safety is paramount, and I’ve always prioritized safe work practices to avoid accidents and injuries.

One particular incident involved working on a live line during a storm. The increased risk of lightning and wind required us to adjust our safety protocols in real-time and work more cautiously. By calmly assessing the situation and working as a team, we completed the task safely and efficiently.

Q 23. How do you manage your time effectively when working on multiple projects?

Managing multiple projects effectively requires a structured approach. I use a project management methodology that combines prioritization, scheduling, and effective communication. I start by identifying critical path activities and setting realistic deadlines for each project. I then leverage project management software to track progress, assign tasks, and manage resources. This enables me to quickly assess bottlenecks and adjust schedules accordingly. Regular communication with team members and stakeholders is crucial, ensuring everyone is aware of deadlines and potential challenges. The key is to remain flexible and adapt to changing priorities while maintaining focus on the overall goals.

For example, I recently managed three simultaneous projects involving different aspects of aerial utility installation – a new substation connection, preventative maintenance on a transmission line, and a rural electrification project. By using a Gantt chart to visualize the schedule and employing daily stand-up meetings to address challenges and re-prioritize tasks, I successfully completed all three projects on time and within budget.

Q 24. Describe your approach to problem-solving in challenging aerial situations.

My problem-solving approach in challenging aerial situations involves a systematic, multi-step process. It begins with a thorough assessment of the situation, identifying the root cause of the problem. This often requires careful observation, data analysis, and sometimes, the use of specialized diagnostic tools. Next, I develop multiple potential solutions, evaluating each for feasibility, cost-effectiveness, and safety. This includes consulting relevant codes, standards, and best practices. I carefully select the optimal solution, considering all factors and ensuring it aligns with safety regulations. Finally, I implement the solution, monitor its effectiveness, and document the entire process for future reference. This ensures continuous improvement and learning from past experiences.

For instance, I once encountered a complex situation involving a damaged conductor on a high-voltage transmission line during a heavy rainstorm. By using a drone to inspect the damage, we were able to pinpoint the exact location and type of damage, thus selecting the most appropriate repair strategy. Following strict safety protocols, we successfully repaired the line minimizing downtime.

Q 25. What is your understanding of different types of aerial insulators?

Aerial insulators are crucial for preventing current leakage and ensuring the safety of electrical transmission and distribution systems. I’m familiar with several types, including:

- Pin-type insulators: These are commonly used for lower-voltage applications and consist of a porcelain or glass insulator with a pin at the top to support the conductor.

- Suspension insulators: These are used for high-voltage lines and consist of a string of individual disc insulators connected in series to increase the overall insulation strength.

- Strain insulators: Used at points of high mechanical stress, such as angles in transmission lines. They are designed to withstand significant tensile loads.

- Post insulators: Used in substations and other high-voltage equipment. They are typically made of porcelain or composite materials and provide high dielectric strength.

The selection of the appropriate insulator type depends on factors like voltage level, mechanical strength requirements, and environmental conditions. Understanding the properties and limitations of each type is essential for ensuring the long-term reliability and safety of the electrical system.

Q 26. How do you perform preventative maintenance on aerial utility equipment?

Preventative maintenance on aerial utility equipment is crucial for ensuring system reliability and preventing costly outages. My approach involves a comprehensive program that includes regular inspections, cleaning, and testing. Inspections involve visual checks for signs of wear and tear, corrosion, or damage. Cleaning helps remove dirt, debris, and contaminants that can compromise the insulation. Testing involves using specialized equipment to measure insulation resistance and verify the integrity of the system. A preventative maintenance schedule is developed that takes into account the type of equipment, environmental conditions, and operational history. This schedule may include tasks like tightening connections, replacing damaged components, and applying protective coatings.

For example, our company uses a computerized maintenance management system (CMMS) to track and schedule preventative maintenance tasks. This ensures that all critical equipment receives the necessary attention and helps us predict and avoid potential problems before they escalate.

Q 27. What is your familiarity with GIS mapping and its use in aerial utility installation?

Geographic Information System (GIS) mapping is an indispensable tool in aerial utility installation. I have extensive experience using GIS software to plan projects, manage assets, and improve operational efficiency. GIS data helps us to visualize the location of existing infrastructure, identify potential obstacles, and optimize the placement of new lines. It allows for accurate measurements and the creation of detailed maps that assist in planning construction routes and determining material requirements. Additionally, GIS data can be used to create as-built drawings and update asset management databases, which greatly improves coordination and collaboration between different teams and stakeholders.

In a recent project, we used GIS to identify the optimal route for a new transmission line, minimizing environmental impact and land acquisition costs. The GIS data also helped us avoid conflicts with existing underground utilities, reducing the risk of damage and delays.

Q 28. Describe your experience with trenching and backfilling for underground cable connections.

My experience with trenching and backfilling for underground cable connections includes all aspects of the process, from planning and design to completion and restoration. I’m proficient in the use of various trenching equipment, including excavators and trenchers, ensuring safe and efficient excavation. I understand the importance of proper depth and width of trenches to accommodate cables and provide adequate protection. I also know how to utilize different backfilling techniques, employing appropriate materials and compaction methods to prevent cable damage and ensure long-term stability. Compliance with local codes and regulations is always a top priority. Safety is paramount throughout the entire process, with emphasis on minimizing the risk of damage to underground utilities, preventing cave-ins, and protecting workers from hazards.

One project involved the installation of a new fiber optic cable network in a densely populated area. By carefully planning the trenching route using GIS data and employing directional drilling techniques where necessary, we minimized disruption to traffic and existing underground infrastructure. Following appropriate compaction techniques during backfilling ensured the long-term integrity of the cable installation.

Key Topics to Learn for Aerial Utility Installation Interview

- Safety Regulations and Procedures: Understanding and applying OSHA regulations, fall protection techniques, and safe work practices in aerial environments.

- Pole Climbing and Line Work: Mastering various climbing techniques, proper use of equipment (e.g., climbing spurs, safety belts), and efficient line handling procedures.

- Electrical Theory and Practices: Demonstrating knowledge of voltage, current, and resistance; understanding safe handling of energized lines and equipment; familiarity with grounding techniques.

- Aerial Equipment Operation and Maintenance: Practical experience with bucket trucks, aerial lifts, and other specialized equipment; knowledge of preventative maintenance and troubleshooting.

- Materials and Installation Techniques: Familiarity with different types of conductors, insulators, and hardware; understanding installation methods for various aerial utility components.

- Troubleshooting and Repair: Ability to diagnose and resolve common issues with aerial lines and equipment; experience with fault location and repair procedures.

- Permitting and Documentation: Understanding the process of obtaining permits and maintaining accurate records of work performed.

- Teamwork and Communication: Highlighting experience in collaborative environments, effective communication skills, and adherence to safety protocols as part of a crew.

- Problem-solving and Critical Thinking: Demonstrating the ability to analyze situations, identify potential hazards, and develop effective solutions in challenging aerial work environments.

Next Steps

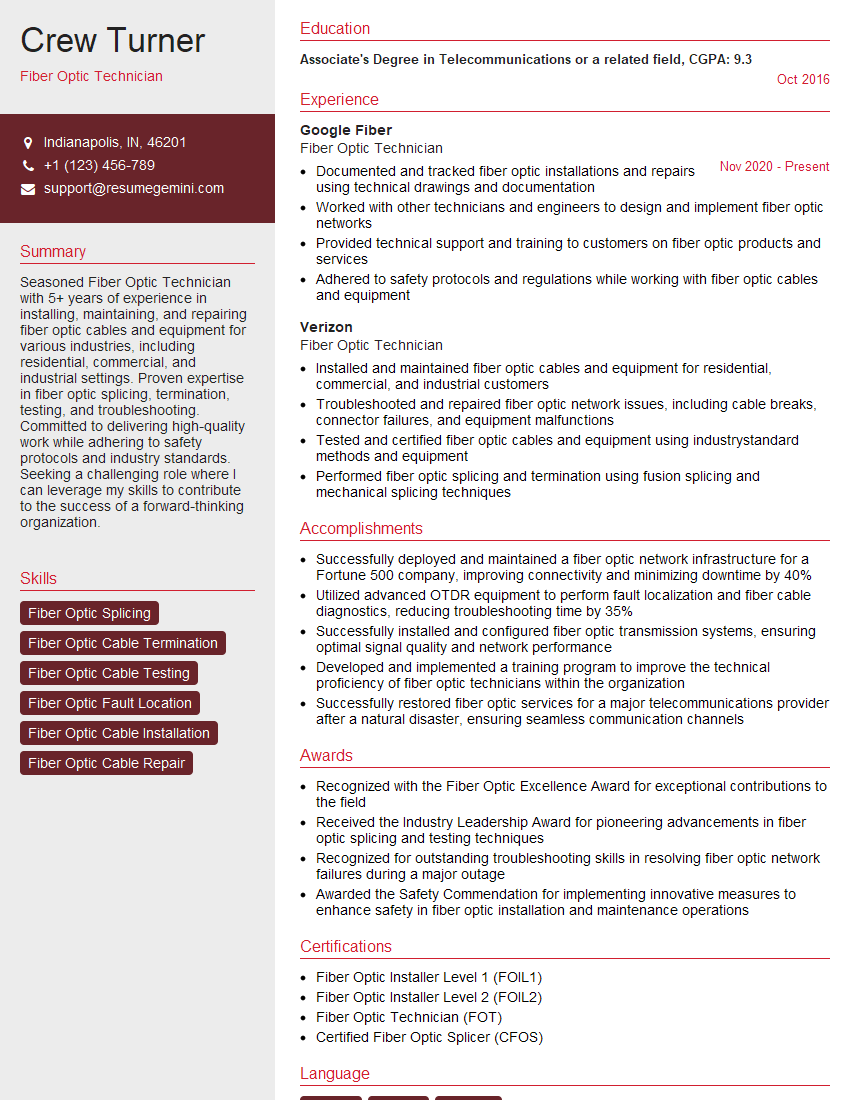

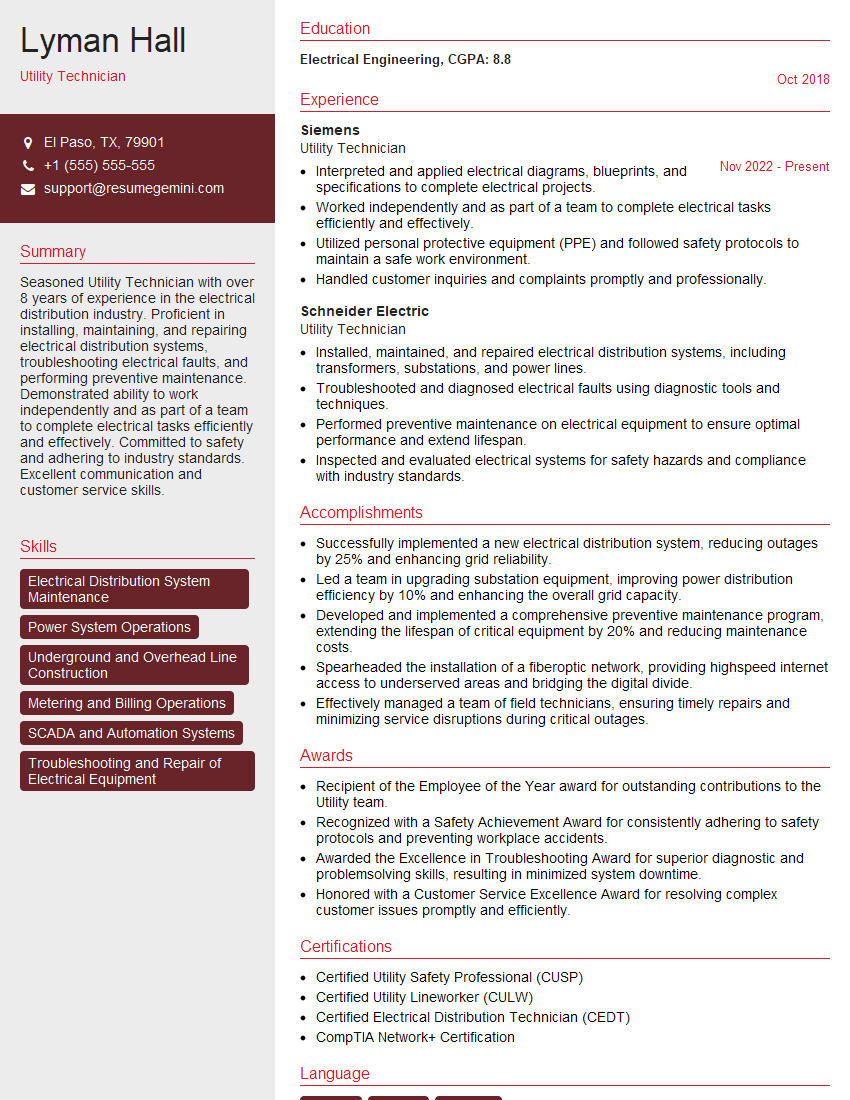

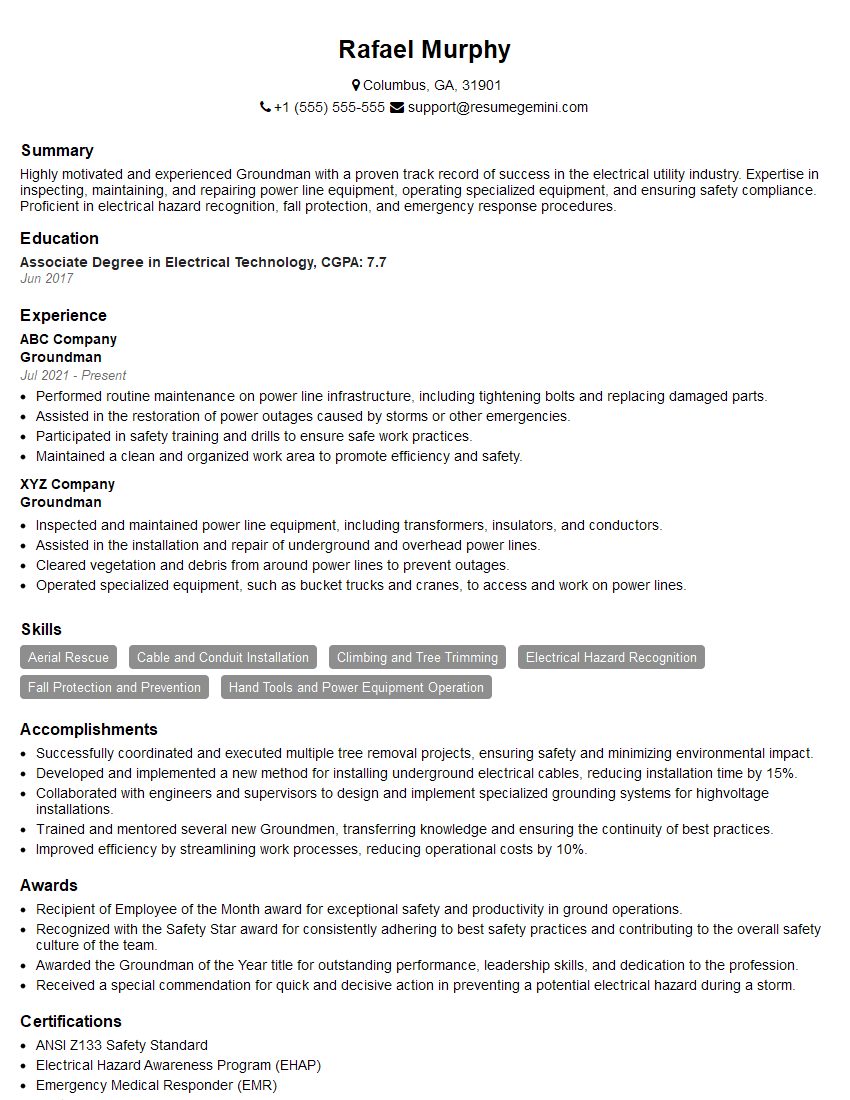

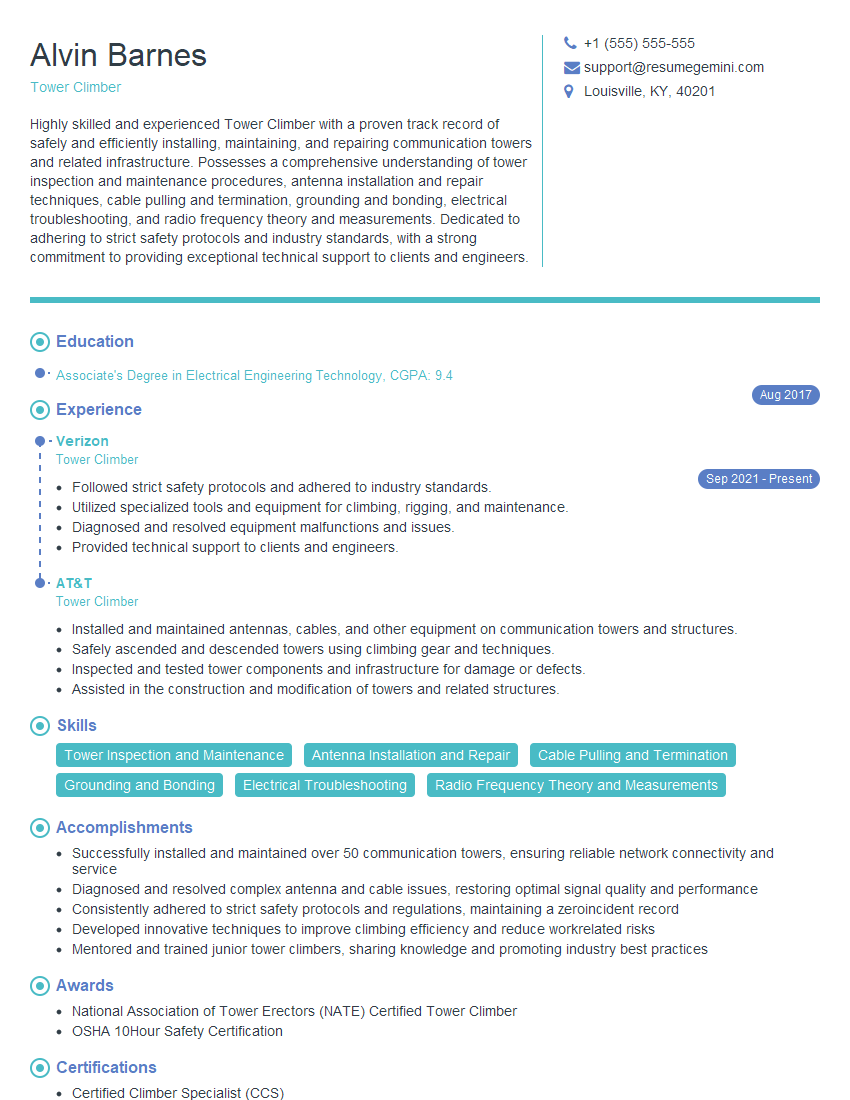

Mastering Aerial Utility Installation opens doors to a rewarding career with excellent growth potential, offering opportunities for specialization and advancement within the industry. A strong resume is crucial for showcasing your skills and experience to potential employers. Building an ATS-friendly resume significantly increases your chances of getting noticed. We recommend using ResumeGemini to craft a compelling and effective resume that highlights your qualifications. ResumeGemini provides examples of resumes tailored to Aerial Utility Installation to guide you in creating a professional document that stands out.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.