Are you ready to stand out in your next interview? Understanding and preparing for Air Compressor Filtration interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Air Compressor Filtration Interview

Q 1. What are the different types of air compressor filters and their applications?

Air compressor filters are crucial for removing contaminants from compressed air, ensuring clean air for various applications. They come in several types, each designed for specific needs:

- Intake Filters: These are the first line of defense, located at the compressor’s intake. They protect the compressor’s internal components from large particles like dust, dirt, and debris. Think of them as the ‘pre-cleaner’ for your system. They typically use coarse media like woven fabric or metal mesh.

- Aftercoolers: After the air is compressed, it’s hot and carries moisture. Aftercoolers cool the air, causing water to condense. They often include a filter to separate this water and prevent it from contaminating the downstream system.

- Particulate Filters: These remove finer particles from the compressed air stream after cooling. They use increasingly fine media, often paper or synthetic materials, to trap particles down to micron sizes. The efficiency of these filters is rated in microns (µm), indicating the smallest particle size they can effectively remove.

- Coalescing Filters: These specialized filters target oil and water aerosols – tiny droplets suspended in the air. They’re particularly important in applications where oil-free air is critical, such as medical equipment or precision manufacturing. The coalescing element brings the droplets together to form larger drops that are easily separated and drained.

- Activated Carbon Filters: These filters adsorb (not absorb) oil vapors, odors, and other gaseous contaminants. They’re often used as a final stage of filtration for applications requiring exceptionally clean air. Imagine them as a sponge for gaseous contaminants.

Applications: The choice of filter depends on the application. A paint sprayer needs very clean air to avoid imperfections, requiring high-efficiency particulate and coalescing filters. A general-purpose pneumatic tool might only need basic intake and particulate filtration. Medical applications demand the highest level of filtration, often combining several filter types.

Q 2. Explain the importance of regular air compressor filter maintenance.

Regular maintenance of air compressor filters is paramount for several reasons:

- Preventing Compressor Damage: Contaminants entering the compressor can cause wear and tear on internal components, leading to costly repairs or premature failure. Think of it like sand in the engine of your car – it will grind everything down.

- Ensuring Air Quality: A clogged filter reduces airflow and delivers contaminated air, compromising the quality of the end product or damaging downstream equipment. This is particularly crucial in sensitive applications like food processing or pharmaceuticals.

- Improving Efficiency: A clean filter allows for optimal airflow, improving the compressor’s efficiency and reducing energy consumption. A clogged filter forces the compressor to work harder, using more energy and potentially shortening its lifespan.

- Safety: In some applications, contaminated air can pose safety risks. For example, oil aerosols in breathing air can be hazardous to health. Regular filter changes are crucial for safety and health.

The frequency of maintenance depends on the application, the environment, and the filter’s specifications. A dirty filter dramatically impacts air quality and system efficiency.

Q 3. How do you determine the appropriate filter element for a specific application?

Selecting the correct filter element is critical for optimal performance and system lifespan. Several factors need to be considered:

- Airflow Requirements: The filter must be able to handle the compressor’s airflow capacity without excessive pressure drop. Choosing a filter with too low a capacity will restrict airflow and damage the compressor.

- Contaminant Type and Size: The filter’s media should be appropriate for the type and size of contaminants present in the intake air. A particulate filter won’t remove oil vapors, and vice-versa.

- Operating Pressure: The filter must withstand the operating pressure of the compressor. Using a filter with inadequate pressure rating can lead to catastrophic failure.

- Filter Efficiency: Efficiency is usually expressed as a percentage or by the smallest particle size it removes (in microns). The required efficiency depends on the downstream application’s sensitivity to contaminants. A high-efficiency filter is crucial for applications requiring extremely clean air.

- Filter Media Material: Various materials are used for filter media (e.g., paper, synthetic fibers, metal mesh). Each has its strengths and weaknesses in terms of efficiency, durability, and cost.

Consult the compressor manufacturer’s specifications and the filter manufacturer’s data sheets to ensure compatibility. Consider performing a particle size analysis of your intake air to accurately determine the necessary filter rating.

Q 4. Describe the process of replacing an air compressor filter.

Replacing an air compressor filter involves a few straightforward steps, but safety precautions are paramount. Always disconnect the power to the compressor before starting any maintenance.

- Locate the Filter: Identify the filter element’s location. It’s often easily accessible, often with a clear cover or housing.

- Drain any accumulated liquids: If there are any drain valves on the filter housing, open them to discharge accumulated water or oil.

- Remove the Filter Housing: Carefully remove the filter housing cover or access panel, taking note of how it’s assembled to ensure correct reassembly.

- Remove the Old Filter Element: Carefully remove the old filter element, paying attention to the orientation. Dispose of it properly.

- Install the New Filter Element: Carefully install the new filter element, ensuring correct orientation as per the manufacturer’s instructions. Avoid damaging the filter media during installation.

- Reassemble the Filter Housing: Carefully reassemble the filter housing and cover, ensuring a tight seal to prevent leaks.

- Inspect for Leaks: Before restarting the compressor, inspect the filter housing and connections for leaks.

- Restart the Compressor: Once you’ve ensured everything is correctly assembled and there are no leaks, restart the compressor and monitor its operation.

Always refer to the compressor’s manual for detailed instructions on filter replacement. Improper installation can lead to filter failure and compressor damage.

Q 5. What are the common causes of filter element failure?

Filter element failure can stem from several causes:

- Clogging: Excessive accumulation of contaminants exceeding the filter’s capacity is the most common reason. This restricts airflow and increases pressure drop.

- Mechanical Damage: Physical damage to the filter element during installation or operation, like tears or punctures, can compromise its integrity.

- Media Degradation: The filter media can degrade over time due to chemical reactions, high temperatures, or exposure to aggressive contaminants.

- Improper Installation: Incorrect installation can lead to leaks or inefficient filtration.

- High Pressure Drop: Operating the compressor at a higher pressure than the filter is designed for can damage the filter element.

- Moisture Ingress: Excessive moisture can damage the filter media, especially in paper-based filters.

Regular filter inspections and timely replacements are vital to prevent premature filter failure and protect the compressor system.

Q 6. How do you troubleshoot a problem with an air compressor’s filtration system?

Troubleshooting a filtration system problem requires a systematic approach:

- Check Filter Pressure Drop: Use a pressure gauge to measure the pressure drop across the filter. A significantly higher-than-normal pressure drop indicates a clogged filter.

- Inspect the Filter Element: Visually inspect the filter element for signs of damage, clogging, or degradation.

- Check for Leaks: Inspect the filter housing and connections for any leaks, which can reduce filtration efficiency.

- Examine the Intake Air: Assess the quality of the intake air. Excessive dust or moisture can overload the filter.

- Verify Airflow: Ensure the compressor is delivering the expected airflow. Restricted airflow can indicate a problem beyond the filter.

- Check for Proper Installation: Verify that the filter element is correctly installed.

If the problem persists after these steps, consult the compressor manufacturer’s documentation or a qualified technician.

Q 7. What are the consequences of using a contaminated air supply?

Using a contaminated air supply can have severe consequences:

- Damage to Downstream Equipment: Abrasive particles can wear out pneumatic tools, damage precision instruments, and contaminate products.

- Reduced Product Quality: Contaminated air can lead to defects in finished products, requiring rework or scrapping.

- Health Risks: Oil aerosols or other contaminants in the air can pose health hazards to workers.

- Increased Maintenance Costs: Contaminated air accelerates the wear and tear on equipment, leading to increased maintenance and repair costs.

- System Inefficiencies: Contamination can reduce system efficiency, leading to increased energy consumption.

Maintaining a clean air supply is paramount for protecting equipment, ensuring product quality, and safeguarding worker health and safety. The cost of neglecting filtration far outweighs the cost of regular filter maintenance.

Q 8. Explain the concept of differential pressure and its relevance to air filtration.

Differential pressure, in the context of air filtration, is the difference in pressure between the inlet and outlet of an air compressor filter. Think of it like this: the cleaner air on the outlet side has less resistance to flow than the dirty, particle-laden air on the inlet side. This pressure difference is directly proportional to the filter’s level of contamination. A higher differential pressure indicates a clogged filter, restricting airflow and potentially damaging the compressor.

Its relevance is crucial for maintenance. By regularly monitoring differential pressure using a pressure gauge, we can determine when a filter needs changing. This prevents reduced air compressor efficiency, increased energy consumption, and potential damage to downstream equipment that rely on clean, dry air. For instance, a spray painting operation needs consistent, contaminant-free air; a clogged filter would lead to uneven spray patterns and potentially damage the paint job.

Q 9. How often should air compressor filters be changed?

There’s no single answer to how often air compressor filters should be changed. It depends heavily on several factors: the type of compressor, the application, the environment, and the filter’s micron rating. A compressor operating in a dusty environment will require more frequent filter changes than one in a clean room. Similarly, a filter with a lower micron rating (meaning it traps smaller particles) will clog faster.

However, a good rule of thumb is to monitor the differential pressure gauge. When the pressure differential exceeds the manufacturer’s recommended limit (usually indicated on the filter or compressor), it’s time for a replacement. Additionally, regular visual inspections can reveal excessive dirt buildup, even before the pressure differential significantly increases. As a best practice, creating a scheduled maintenance plan with regular filter checks (e.g., monthly or quarterly, depending on the factors above) is essential. Ignoring filter maintenance can lead to costly repairs or complete system failure.

Q 10. What are the safety precautions involved in handling air compressor filters?

Safety is paramount when handling air compressor filters. Always ensure the compressor is completely shut off and depressurized before attempting any filter maintenance. Compressed air can be incredibly dangerous. Wear appropriate personal protective equipment (PPE), including safety glasses or goggles to protect your eyes from dust and debris, and gloves to prevent cuts or skin irritation from sharp filter media.

When removing a used filter, be mindful of the trapped contaminants – some might be hazardous or irritating. Dispose of used filters responsibly according to local regulations. Never force a filter into place; ensure proper alignment and a secure seal to avoid leaks. If you encounter any unusual resistance during installation or removal, seek assistance from trained personnel. Following these precautions prevents injuries and ensures the safe operation of your equipment.

Q 11. Describe the various filter ratings (e.g., micron rating).

Filter ratings, typically expressed in microns (µm), represent the size of the particles the filter can effectively remove. One micron is one-millionth of a meter. A lower micron rating indicates a finer filter capable of trapping smaller particles. For instance, a 5-micron filter removes particles larger than 5 microns, while a 0.3-micron filter removes even the finest dust and oil aerosols.

Different applications require different ratings. For general-purpose applications, a 5-10 micron filter might suffice. However, precision applications like painting, food processing, or medical equipment require much finer filtration, perhaps in the sub-micron range. Choosing the right rating ensures the appropriate level of air purity for your specific needs. Selecting an unnecessarily fine filter can increase pressure drop and shorten filter life; too coarse a filter might not adequately protect downstream equipment.

Q 12. Explain the difference between pre-filters, coalescing filters, and after-filters.

Air compressor filter systems often employ a combination of filters to achieve optimal purification. Let’s break down the differences:

- Pre-filters: These are the first line of defense, acting as a coarse filter to remove large particles such as dust, debris, and larger liquid droplets. They protect the subsequent finer filters from rapid clogging and extend their lifespan. Think of it like a sieve removing large pebbles before finer filtration.

- Coalescing filters: These filters are specifically designed to remove liquid aerosols (water and oil) from the compressed air stream. They use a hydrophobic media that causes the tiny liquid droplets to coalesce (combine) into larger drops that are then separated from the air stream by gravity or centrifugal force.

- After-filters: These are the final stage of filtration, providing the highest level of purification. They remove remaining fine particles and ensure the air quality meets the application’s requirements. Their micron rating will be determined by the downstream requirements.

Imagine a water treatment plant: pre-filters remove large debris, coalescing filters remove oil and suspended solids, and after-filters polish the water to drinking quality. The same principle applies to air compressor filtration.

Q 13. How do you select the right filter housing for a given application?

Selecting the right filter housing depends on several factors: the size and flow rate of the compressor, the type of filters being used, the pressure rating, and the mounting requirements. The housing must be compatible with the filter elements and should be able to withstand the operating pressure of the compressor.

Consider these steps:

- Determine flow rate and pressure: The housing must handle the compressor’s output without restricting airflow or exceeding its pressure rating.

- Choose the correct filter type: The housing must be suitable for the specific filter element (spin-on, cartridge, etc.)

- Check material compatibility: The housing material should be compatible with the compressed air and any contaminants present. Some materials may corrode or degrade with specific substances.

- Assess mounting options: Ensure the housing can be mounted securely in the available space.

Improper housing selection can lead to leaks, filter damage, and inefficient filtration. Always consult the compressor manufacturer’s recommendations and filter supplier specifications to ensure proper selection.

Q 14. What are the potential environmental impacts of improper air filtration?

Improper air filtration has significant environmental impacts. Unfiltered compressed air can release various pollutants into the atmosphere. If the compressed air is used in a painting or spraying operation, unfiltered air can release volatile organic compounds (VOCs) into the environment contributing to air pollution and smog formation. If oil aerosols are not adequately removed, they can contaminate soil and water sources, potentially harming wildlife and ecosystems. Improper disposal of used filters also contributes to landfill waste.

Furthermore, inefficient filtration increases energy consumption by the compressor, thereby increasing the carbon footprint. By implementing proper filtration practices, including regular filter maintenance and responsible disposal, industries can minimize their environmental impact and contribute to a cleaner and healthier environment.

Q 15. What are the economic benefits of effective air compressor filtration?

Effective air compressor filtration translates to significant economic benefits across several areas. Primarily, it drastically reduces the risk of costly equipment damage. Contaminants like dust, moisture, and oil can wreak havoc on pneumatic tools and machinery, leading to premature wear, breakdowns, and expensive repairs. Imagine a manufacturing plant; a single compressor failure can halt production, resulting in lost revenue and potential penalties for missed deadlines.

Secondly, filtration improves the quality and consistency of the compressed air itself. This is crucial in industries like pharmaceuticals and food processing where even minute particles can compromise product quality and safety. Consistent, clean air minimizes production rejects and reduces waste, leading to direct cost savings. Finally, cleaner air extends the lifespan of the compressor itself, delaying the need for expensive replacements or major overhauls. Think of it as regular car maintenance – preventative measures save money in the long run.

Career Expert Tips:

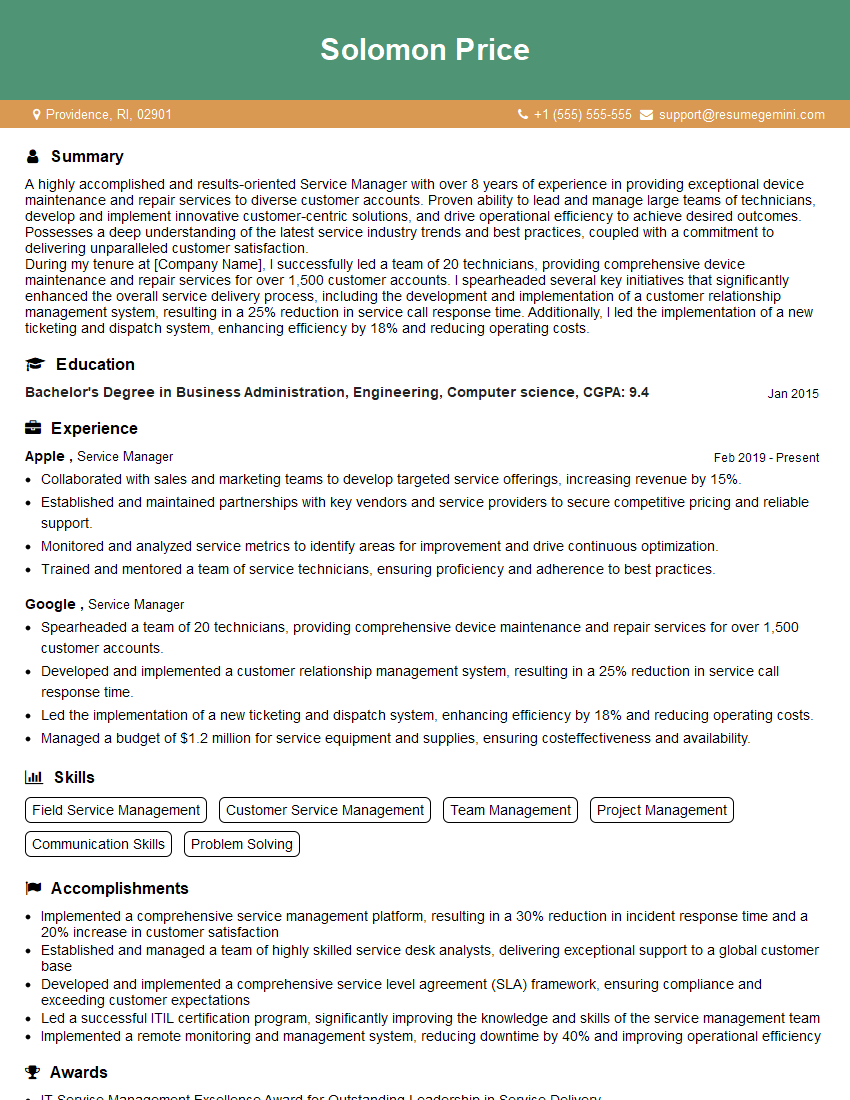

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you monitor the performance of an air compressor filtration system?

Monitoring an air compressor filtration system involves a multi-pronged approach. Regular visual inspections are paramount. Look for signs of excessive dust buildup on the filter housing or pressure drop indicators. A significant pressure drop across the filter element suggests it’s becoming clogged and needs replacing.

Pressure gauges are essential for tracking pressure before and after the filter. A significant difference indicates a restriction. Differential pressure gauges are specifically designed for this purpose and provide a more precise reading. Additionally, regular testing of the air quality downstream of the filter using a particle counter or oil content analyzer ensures the system’s effectiveness. These tests provide quantifiable data to confirm the filter’s performance and guide replacement schedules.

Finally, maintaining a detailed logbook recording pressure readings, filter change dates, and test results provides valuable historical data. This allows you to predict future maintenance needs and identify any trends or anomalies in the system’s performance.

Q 17. What are some common problems associated with automatic drain valves on filter housings?

Automatic drain valves, while designed to remove accumulated condensate from filter housings, can suffer from several problems. The most common is malfunctioning due to clogging. This can be caused by the buildup of solids, scale, or even corrosion within the valve itself, preventing it from opening and draining the water. This leads to water buildup which can support microbial growth and eventually lead to filter damage.

Another issue is leakage. A faulty valve seal can result in air leaks, reducing system efficiency and potentially causing safety hazards. Regular malfunction can be due to frozen condensate during cold weather operations, and finally, improper sizing can cause incomplete drainage leading to water accumulation. Proper maintenance which includes regular cleaning and lubrication as indicated by the manufacturer, as well as checking the valve and its response, are crucial to ensuring the valve functions efficiently.

Q 18. Describe different types of filter media (e.g., cellulose, sintered metal).

Air compressor filter media come in a variety of types, each with its own characteristics. Cellulose filters are a common and cost-effective option. They’re made from compressed cellulose fibers and offer good filtration for larger particles. However, they are susceptible to moisture damage, making them unsuitable for applications with high humidity.

Sintered metal filters are more durable and can withstand high temperatures and pressures. They’re constructed from tightly packed metal particles, creating a highly porous structure. They’re excellent for removing smaller particles but are often more expensive than cellulose alternatives. Other types include coalescing filters, designed to remove oil and water aerosols, and activated carbon filters which are excellent for removing odors and certain gases.

Q 19. What are the advantages and disadvantages of different filter media?

The choice of filter media depends largely on the application. Cellulose filters offer a good balance between cost and performance for applications with low humidity and minimal fine particulate contamination. Their main disadvantage is susceptibility to moisture and their relatively low particle retention capacity.

Sintered metal filters, while more expensive, provide superior durability and efficiency in demanding applications. Their resistance to high temperatures and pressures makes them ideal for use in harsh environments. However, they may not be as effective at removing certain types of aerosols as coalescing filters. The advantages and disadvantages are also influenced by their respective efficiencies, service life, and pressure drop characteristics.

Q 20. How do you ensure the proper installation of an air compressor filter?

Proper installation of an air compressor filter is critical for optimal performance and safety. Begin by following the manufacturer’s instructions meticulously. Ensure that the filter is installed in the correct orientation – often indicated by arrows on the housing. Before installation, inspect the filter housing and seals for any damage. Tighten all connections securely using the correct torque wrench to avoid over-tightening and damage, while ensuring a leak-free seal.

Cleanliness is paramount. Before installing a new filter, ensure that the connecting pipework is free of debris and contaminants. This prevents contaminants from entering the new filter and immediately compromising its performance. Always consult a professional technician if there is any doubt or difficulty during the installation process.

Q 21. Explain the importance of filter integrity testing.

Filter integrity testing is crucial to ensure that the filter is functioning as intended and preventing contaminants from reaching the downstream equipment. This is especially important in applications where compressed air is used for sensitive processes like pharmaceutical manufacturing or medical equipment operation.

Several methods are used including bubble point testing which involves applying pressure to the filter element and monitoring for bubbles to detect holes or leaks. Alternatively, a pressure decay test measures the rate of pressure drop in the filter after initial pressurization. A rapid drop suggests a leak or breach. Regular testing enables proactive maintenance, preventing potential equipment failures and ensures consistent air quality. Remember to always follow the specific test procedures outlined by the filter manufacturer.

Q 22. How do you interpret a filter pressure drop reading?

A filter pressure drop reading indicates the resistance to airflow through the filter element. A small pressure drop signifies a clean filter with minimal restriction, while a large pressure drop suggests the filter is becoming clogged with contaminants. Think of it like a straw – a clean straw allows easy sipping, while a clogged straw requires more effort. We interpret the reading in relation to the filter’s specifications; exceeding the manufacturer’s recommended differential pressure indicates the filter needs replacement. For example, if a filter’s manual specifies a maximum pressure drop of 10 PSI, and we measure 12 PSI, it’s time for a change. Regular monitoring of pressure drop helps prevent downstream equipment damage and ensures consistent air quality.

Q 23. How do you deal with filter element disposal?

Filter element disposal depends heavily on the contaminants they’ve trapped. Oil-contaminated filters require special handling as hazardous waste, usually requiring disposal through certified waste management companies that specialize in industrial waste. These companies will follow all relevant local, state, and federal regulations, ensuring safe and environmentally sound disposal. For filters with less hazardous contaminants, proper disposal might involve simply placing them in a designated waste bin for non-hazardous materials. However, always refer to the filter manufacturer’s guidelines and relevant safety data sheets (SDS) for specific disposal instructions. Improper disposal can lead to significant environmental and legal repercussions.

Q 24. Describe your experience with various types of compressed air dryers.

My experience encompasses various compressed air dryer types, including refrigerated dryers, desiccant dryers, and membrane dryers. Refrigerated dryers are cost-effective for removing large amounts of water vapor, but they leave some moisture behind. Desiccant dryers, either heat-regenerated or pressure swing, provide significantly drier air, vital for applications sensitive to moisture. Membrane dryers offer a lower-energy solution than desiccant dryers but generally don’t produce as dry air. I’ve worked on selecting the appropriate dryer type based on the application’s requirements, such as dew point specifications and the desired level of dryness. For instance, in a precision instrument manufacturing facility, the extremely low dew point required necessitated installing desiccant dryers to prevent corrosion.

Q 25. How do you identify the root cause of recurring filter failures?

Recurring filter failures are rarely due to simple coincidence. To pinpoint the root cause, I follow a structured approach: First, I examine the frequency and nature of failures. Are filters clogging prematurely or suffering mechanical damage? Then, I inspect the upstream components – is there excessive contamination entering the system (e.g., due to leaks or inadequate pre-filtration)? I also analyze the operating conditions – are temperatures or pressures outside the filter’s operating range? For instance, if filters consistently fail due to excessive pressure, I’d investigate possible blockages or restrictions in the compressed air system. If the failure is due to physical damage, there might be vibrations, inadequate support, or improper installation. The systematic investigation helps prevent future issues.

Q 26. What are your strategies for optimizing filter life and minimizing maintenance costs?

Optimizing filter life and minimizing maintenance costs involves a multi-pronged strategy. First, selecting the correct filter element for the specific application is crucial. Using high-quality filters with appropriate capacity and contaminant removal efficiency significantly impacts their lifespan. Second, regular maintenance, including scheduled pressure drop monitoring and timely filter replacements, prevents premature failure and costly emergency repairs. Third, implementing upstream air treatment solutions like pre-filters significantly extends the life of downstream filters by capturing large particulate matter. Finally, using a computerized maintenance management system (CMMS) helps track filter performance, optimize replacement schedules and provide accurate cost analysis, leading to significant savings in the long run.

Q 27. Describe your experience with different brands of air compressor filters.

I’ve worked with a variety of brands, including Atlas Copco, Ingersoll Rand, Sullair, and Donaldson. My experience spans across different filter technologies and applications. Each brand offers its unique features and performance characteristics. For example, Donaldson is known for its extensive filter media options and its robust design. Atlas Copco emphasizes energy efficiency and integration with their compressor systems. My selection depends on specific project requirements, considering factors like performance, cost, availability, and technical support offered by each vendor. The key is not brand loyalty but rather choosing the best solution for the job.

Q 28. How familiar are you with relevant industry standards and regulations regarding air quality?

I’m very familiar with relevant industry standards and regulations regarding compressed air quality. This includes ISO 8573-1, which specifies the classes of purity for compressed air, covering particulate matter, water, and oil content. I also understand OSHA regulations regarding workplace safety and the handling of hazardous materials, especially relevant for oil-contaminated filters. My experience allows me to ensure our processes comply with all legal and industry best practices, safeguarding the environment and worker health. Understanding these standards is crucial for designing, installing, and maintaining a safe and efficient compressed air system.

Key Topics to Learn for Air Compressor Filtration Interview

- Compressor Types and Their Filtration Needs: Understanding the differences in filtration requirements for various compressor types (e.g., reciprocating, rotary screw, centrifugal) and their impact on system efficiency and longevity.

- Filtration Media and Selection: Knowing the properties of different filter media (e.g., coalescing, particulate, activated carbon) and how to choose the appropriate media based on contaminant types and application requirements. Practical application: Analyzing a system’s contaminant profile to recommend the best filter.

- Filter Element Design and Performance: Familiarizing yourself with filter element construction, pressure drop characteristics, and their impact on overall system performance. This includes understanding filter ratings and testing methodologies.

- Differential Pressure and Monitoring: Understanding the significance of differential pressure across filters as an indicator of filter performance and the need for replacement. Practical application: Troubleshooting a system experiencing high pressure drop.

- Air Compressor System Design and Integration: Knowledge of how filtration systems are integrated into overall air compressor systems and the importance of proper placement and sizing for optimal performance.

- Maintenance and Replacement Strategies: Understanding best practices for filter maintenance, including scheduled replacement, proper disposal, and the impact of inadequate maintenance on system reliability and efficiency.

- Troubleshooting Common Filtration Problems: Developing problem-solving skills to diagnose and address common issues such as filter clogging, bypass, and contamination-related system failures.

- Safety Regulations and Standards: Familiarity with relevant safety regulations and industry standards related to air compressor filtration and compressed air quality.

- Advanced Filtration Technologies: Exploring advanced filtration technologies such as membrane filtration or specialized adsorbents for specific contaminant removal.

Next Steps

Mastering air compressor filtration demonstrates a crucial understanding of system optimization, cost-effectiveness, and safety. This expertise is highly valued in many industries, leading to increased career opportunities and higher earning potential. To maximize your job prospects, create an ATS-friendly resume that showcases your skills and experience effectively. We recommend using ResumeGemini, a trusted resource for building professional resumes. ResumeGemini offers examples of resumes tailored to the Air Compressor Filtration field to help you present yourself in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.