Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Ammonia Safety Procedures interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Ammonia Safety Procedures Interview

Q 1. Describe the hazards associated with ammonia leaks.

Ammonia leaks pose significant hazards due to ammonia’s properties. It’s a colorless gas with a pungent, suffocating odor at low concentrations. However, at higher concentrations, the olfactory nerves can become desensitized, masking the warning sign. The primary hazards include:

- Toxicity: Ammonia is highly toxic, causing respiratory irritation, burns, and even death at high concentrations. Inhalation can lead to pulmonary edema (fluid build-up in the lungs). Even short-term exposure can result in serious health problems.

- Flammability: While not inherently flammable under normal conditions, ammonia can form explosive mixtures with air at certain concentrations. This is particularly risky in confined spaces where a leak can accumulate.

- Corrosiveness: Anhydrous ammonia (pure ammonia) is not corrosive to most metals, but aqueous ammonia (ammonia dissolved in water) is corrosive and can damage equipment and infrastructure.

- Environmental impact: Ammonia leaks can harm the environment, affecting soil, water, and plant life. It can lead to eutrophication in water bodies, causing algal blooms and depleting oxygen levels, harming aquatic life.

Imagine a scenario where a refrigeration system malfunctions, releasing a significant amount of ammonia into a processing plant. The immediate consequences would likely include employee injuries from inhalation, potential explosions, and significant environmental damage if it reaches surrounding areas. Effective safety measures and emergency response plans are critical to mitigate such risks.

Q 2. Explain the different types of ammonia detection systems.

Ammonia detection systems are crucial for early warning and prevention of leaks. Several types exist, each with its strengths and weaknesses:

- Fixed gas detectors: These are permanently installed sensors strategically positioned throughout ammonia handling areas. They continuously monitor ammonia levels and trigger alarms if a predetermined threshold is exceeded. They are often networked for centralized monitoring.

- Portable gas detectors: These handheld devices allow for spot checks and emergency response. They provide immediate readings and are invaluable for assessing the extent of a leak during an emergency.

- Optical gas imaging (OGI): This technology uses infrared cameras to visualize ammonia plumes, making it useful for detecting leaks in hard-to-reach areas or large-scale releases. Think of it like seeing heat signatures, but for ammonia.

- Ammonia-specific sensors: Some sensors utilize electrochemical or semiconductor technologies that are highly selective to ammonia, minimizing false positives from other gases present in the environment.

For example, a large industrial refrigeration plant would likely use a combination of fixed detectors for continuous monitoring, portable detectors for regular inspections and emergency response, and potentially OGI for identifying the source of a leak during an incident.

Q 3. What are the personal protective equipment (PPE) requirements for working with ammonia?

Personal Protective Equipment (PPE) is paramount when working with ammonia. The specific PPE depends on the task and the potential exposure level, but generally includes:

- Respiratory protection: This is critical. Self-contained breathing apparatus (SCBA) is typically required for high-concentration leaks or entry into contaminated areas. Air-purifying respirators may be suitable for low-concentration environments, but only with proper fit testing and atmospheric monitoring.

- Eye protection: Chemical splash goggles or a full-face shield are needed to protect against ammonia’s corrosive effects on eyes.

- Skin protection: Protective clothing, such as chemical-resistant suits, gloves, and boots, are essential to prevent skin contact and burns. The material needs to be impervious to ammonia.

- Other PPE: Depending on the situation, additional PPE might include hard hats, safety shoes, and hearing protection.

Think of it like this: handling ammonia requires the same level of precaution as handling a highly corrosive chemical, and respiratory protection is arguably even more critical due to ammonia’s toxicity. Proper training on PPE selection and use is essential.

Q 4. Outline the emergency response procedures for an ammonia release.

Emergency response procedures for an ammonia release are critical and must be well-rehearsed. A typical procedure involves:

- Immediate evacuation: Evacuate personnel from the affected area immediately. This is the highest priority.

- Alarm activation: Trigger site alarms to alert others and emergency services.

- Emergency services contact: Contact local emergency services and follow their instructions.

- Leak isolation: If safe to do so, attempt to isolate the leak source to prevent further release, but prioritize personal safety.

- Decontamination: Decontaminate personnel who may have been exposed to ammonia. This might involve showering and changing clothing.

- Ventilation: Improve ventilation in the affected area to disperse the ammonia.

- Leak repair: Repair the leak as soon as it’s safe to do so, potentially engaging specialized contractors.

- Post-incident investigation: Conduct a thorough investigation to determine the cause of the leak and prevent future occurrences.

Regular drills and training are vital to ensure everyone knows their roles and responsibilities in the event of an ammonia release. A well-defined emergency response plan, readily accessible to all personnel, is a cornerstone of ammonia safety.

Q 5. Explain the process of ammonia refrigeration system shutdown.

Shutting down an ammonia refrigeration system requires a carefully controlled process to prevent leaks and ensure safety. The steps typically involve:

- Isolate the system: Close the valves that isolate the ammonia system from the rest of the process, preventing further flow of ammonia.

- Purge the system: Slowly purge the system with an inert gas (like nitrogen) to displace the ammonia. This reduces the pressure and minimizes the risk of leaks during the shutdown.

- Pressure reduction: Slowly reduce the pressure in the system to a safe level, as recommended by the equipment manufacturer.

- Recovery of ammonia: Recover the ammonia from the system into storage tanks for later use. This is crucial for environmental protection and resource conservation.

- System inspection: Once the system is depressurized, visually inspect for any leaks or damage.

- Documentation: Thoroughly document all steps taken during the shutdown process.

The specific procedure might vary depending on the system’s design and size. Following manufacturer’s instructions and employing lockout/tagout procedures to prevent accidental restarts is absolutely crucial. A failure to follow these steps can lead to significant ammonia releases.

Q 6. What are the key components of an ammonia safety management system?

A comprehensive ammonia safety management system (SMS) consists of several key components working together:

- Risk assessment and management: Regularly assess potential hazards and implement controls to mitigate risks. This includes identifying potential leak points and developing procedures to address them.

- Engineering controls: Design and maintain the ammonia system to minimize leaks and prevent uncontrolled releases. This includes using high-quality equipment, proper piping and insulation, and regular inspections.

- Administrative controls: Develop and implement safe work practices, operating procedures, and emergency response plans. This also covers training programs for employees.

- Personal protective equipment (PPE): Ensure that appropriate PPE is available and used correctly by all personnel handling ammonia.

- Monitoring and detection: Implement a system of ammonia detection and monitoring to provide early warning of leaks.

- Emergency response plan: Establish and regularly rehearse an emergency response plan to deal with ammonia releases.

- Training and competency assurance: Provide comprehensive training to all personnel handling ammonia, ensuring they are competent to work safely.

- Record keeping and documentation: Maintain detailed records of all aspects of ammonia safety management, including risk assessments, training, and incident reports.

Think of an SMS as a layered security system, each component contributing to overall safety. Its effectiveness depends on consistent implementation, regular review, and ongoing improvements based on lessons learned.

Q 7. How do you conduct a risk assessment for an ammonia handling process?

Conducting a risk assessment for ammonia handling involves a systematic process:

- Hazard identification: Identify all potential hazards associated with ammonia handling, including leaks, exposure, fire, and explosions.

- Vulnerability assessment: Evaluate the vulnerability of the system and personnel to these hazards. Consider factors like the amount of ammonia handled, the location of equipment, and the effectiveness of existing controls.

- Risk analysis: Analyze the likelihood and severity of each hazard, determining the level of risk. This might involve using a risk matrix or other quantitative methods.

- Risk control measures: Develop and implement appropriate control measures to reduce the risks. These controls can be hierarchical, starting with elimination, substitution, engineering controls, administrative controls, and finally, PPE.

- Risk monitoring and review: Regularly monitor and review the effectiveness of the control measures, making adjustments as needed.

For example, in a meat processing plant using ammonia refrigeration, a risk assessment might focus on the potential for leaks in the refrigeration system, the proximity of workers to the system, and the effectiveness of the emergency response plan. The assessment would lead to specific safety measures like leak detection, regular maintenance, and appropriate employee training. The process is iterative; the assessment should be updated regularly to reflect any changes in the process or equipment.

Q 8. Describe the regulatory requirements for ammonia storage and handling.

Regulatory requirements for ammonia storage and handling are stringent and vary slightly depending on location (e.g., OSHA in the US, similar agencies in other countries). However, common threads include detailed regulations concerning the design, construction, and operation of ammonia storage facilities. These regulations aim to minimize the risk of leaks and ensure worker safety.

- Storage Tank Requirements: Regulations typically specify material compatibility, pressure ratings, safety relief valves, and secondary containment systems to prevent spills in case of leaks. For example, tanks might need double-walled construction or be situated within a bunded area to capture spills.

- Piping and Valves: Regulations address material selection, leak detection systems, and the use of appropriate fittings and valves designed for ammonia service. Regular inspections and leak testing of piping are crucial.

- Ventilation and Monitoring: Adequate ventilation is mandated to prevent ammonia buildup in hazardous concentrations. Continuous ammonia monitoring systems with alarms are required to detect leaks promptly. These systems might include sensors placed strategically around the storage and processing areas.

- Emergency Response Plans: Comprehensive emergency response plans, including procedures for leak mitigation, evacuation, and first aid, are mandatory. These plans must detail roles and responsibilities of personnel, emergency equipment locations, and communication protocols.

- Employee Training: Regulations dictate that employees working with ammonia receive appropriate training on safe handling procedures, emergency response protocols, and the health hazards associated with ammonia exposure. Regular refresher training is also usually required.

Non-compliance can lead to hefty fines, operational shutdowns, and even criminal charges in cases of serious accidents.

Q 9. Explain the principles of ammonia leak detection and repair.

Ammonia leak detection and repair relies on a multi-pronged approach combining preventative measures with rapid response capabilities. Think of it like a layered security system for your ammonia system.

- Leak Detection Methods: This involves using a combination of technologies. Fixed gas detectors continuously monitor ammonia levels in critical areas, triggering alarms upon exceeding pre-set thresholds. Portable gas detectors are crucial for spot checks and investigating suspected leaks. Visual inspections, regularly scheduled, can identify signs of leaks such as frost formation or ammonia odors. Advanced techniques such as acoustic leak detection utilize sound waves to pinpoint leak locations.

- Leak Repair Procedures: Repair procedures must be carefully planned and executed to ensure safety. Areas around the leak must be isolated and properly ventilated to limit exposure. Qualified personnel, wearing appropriate personal protective equipment (PPE), should handle the repairs. Small leaks might be repaired with specialized clamps or sealant. Larger leaks may require complete section replacement, necessitating a shutdown of the relevant system part.

- Emergency Response: In case of a significant leak, the emergency response plan should be activated immediately. This includes evacuating personnel from the affected area, contacting emergency services, and implementing leak mitigation strategies such as vapor suppression systems or diverting ammonia flow.

Regular maintenance, thorough inspections, and well-trained personnel are essential for effective leak detection and repair, minimizing risks and preventing major incidents.

Q 10. What are the common causes of ammonia leaks in industrial settings?

Ammonia leaks in industrial settings stem from a variety of causes, often stemming from equipment failure, human error, or insufficient maintenance.

- Corrosion: Ammonia can be corrosive to certain materials, leading to weakened pipe sections or fittings, causing leaks. Regular inspections and material selection are key preventative measures.

- Mechanical Damage: Impacts, vibrations, or improper handling of equipment can cause damage to pipes, valves, and fittings, leading to leaks. Protecting equipment and ensuring careful handling are crucial.

- Improper Installation: Faulty installation of ammonia systems, including inadequate welding or improper sealing, can create weaknesses that eventually lead to leaks.

- Seal Failure: Leaks can arise from damaged or deteriorated gaskets, seals, or flanges. Regular inspection and timely replacement of worn seals are crucial.

- Human Error: Improper operation of valves, insufficient tightening of connections, and inadequate training can lead to human error causing leaks.

- Freezing: In certain conditions, ammonia can freeze, leading to cracking of pipes and equipment components. This is often overlooked but is a contributing factor.

A proactive approach combining regular inspections, preventative maintenance, and employee training is critical for minimizing the frequency of ammonia leaks.

Q 11. Describe the health effects of ammonia exposure.

Ammonia exposure poses significant health risks, ranging from mild irritation to life-threatening consequences, depending on the concentration and duration of exposure. The severity depends on the concentration and duration.

- Eye and Respiratory Irritation: Low concentrations can cause burning sensations in the eyes, nose, and throat. Higher concentrations can lead to severe respiratory distress, including pulmonary edema (fluid buildup in the lungs).

- Skin Burns: Direct contact with liquid ammonia can cause severe burns and tissue damage.

- Central Nervous System Effects: High ammonia concentrations can affect the central nervous system, causing dizziness, disorientation, headaches, nausea, and even coma or death.

Immediate medical attention is crucial for any significant ammonia exposure. Removal from the affected area, ensuring fresh air, and seeking medical help are critical steps. The effects of exposure can be long lasting and may involve respiratory complications.

Q 12. What are the different methods for ammonia neutralization?

Ammonia neutralization involves converting the ammonia into a less hazardous substance. The specific method chosen depends on the scale of the spill or leak and the environment. Safety is paramount in all cases.

- Water Dilution: For small spills, water dilution can help reduce the concentration of ammonia, converting some to ammonium hydroxide. This is effective only for small amounts.

- Acid Neutralization: This is a common method for larger spills, involving reacting ammonia with an acid such as sulfuric acid or nitric acid. This reaction produces ammonium sulfate or ammonium nitrate, which are less hazardous. This requires careful control of the process to avoid runaway reactions and must be done by trained professionals.

- Specialized Absorbents: Absorbent materials such as activated carbon or diatomaceous earth can be used to soak up spilled ammonia. These methods are helpful for containing spills and prevent spread.

Neutralization processes should always be conducted following strict safety protocols and under the supervision of qualified personnel. Protective equipment is crucial to prevent exposure.

Q 13. Explain the importance of regular ammonia system inspections.

Regular ammonia system inspections are vital for preventing leaks, ensuring safe operation, and maintaining compliance with regulations. These inspections are much like a regular health check-up for your system.

- Early Leak Detection: Regular inspections help to identify small leaks early on, before they escalate into major incidents. This prevents larger environmental damage and avoids costly repairs.

- Preventative Maintenance: Inspections allow for timely maintenance of equipment, replacing worn components, and addressing potential problems before they cause failures.

- Compliance with Regulations: Regular inspections are a legal requirement for many facilities and demonstrate a commitment to safe operation. This protects the company and employees.

- System Integrity: Thorough inspections ensure that the ammonia system remains in optimal working condition, minimizing the risk of leaks and ensuring safe and efficient operation.

A comprehensive inspection program should include visual inspections, pressure testing, and leak detection using various methods. A schedule based on risk assessment should be employed.

Q 14. How do you ensure compliance with OSHA regulations for ammonia handling?

Ensuring compliance with OSHA regulations for ammonia handling requires a multi-faceted approach.

- Develop and Implement a Written Program: This program must document all aspects of ammonia handling, including storage, handling, emergency response, and employee training. This is the foundation of your safety system.

- Employee Training: All employees involved in ammonia handling must receive comprehensive training on safe practices, emergency procedures, and the health hazards associated with ammonia exposure. Regular refresher courses are vital.

- Regular Inspections and Maintenance: A detailed inspection and maintenance schedule must be developed and strictly followed. This ensures equipment is in good repair.

- Personal Protective Equipment (PPE): Ensure appropriate PPE, including respirators, gloves, eye protection, and protective clothing, is available and used correctly. This protects personnel.

- Emergency Response Plan: A well-defined emergency response plan should be in place, including procedures for leak detection, mitigation, evacuation, and communication. This is crucial in case of an emergency.

- Record Keeping: Maintain meticulous records of all inspections, maintenance activities, employee training, and emergency response drills. Documentation is key for demonstrating compliance.

OSHA compliance is not just about avoiding penalties; it is about ensuring a safe working environment for everyone. A commitment to safety should drive all your decisions.

Q 15. Describe the process for safely transferring ammonia.

Safe ammonia transfer hinges on meticulous planning and execution, prioritizing prevention of leaks and exposure. It involves understanding the properties of ammonia – its volatility, reactivity, and toxicity – and using appropriate equipment and procedures.

- Pre-transfer checks: Before initiating the transfer, inspect all equipment for damage or leaks. This includes hoses, valves, pumps, and storage tanks. Ensure all connections are secure and leak-tight.

- Proper equipment: Use only equipment designed for ammonia service, including pressure relief valves, and leak detection systems. Consider using double-walled piping for added safety.

- Ventilation: Adequate ventilation is crucial during the transfer process to prevent ammonia buildup. This is especially important in enclosed areas.

- Personal Protective Equipment (PPE): All personnel involved must wear appropriate PPE, including respirators with ammonia cartridges, safety glasses, gloves, and protective clothing.

- Emergency response plan: Before the transfer, ensure a comprehensive emergency response plan is in place, including procedures for leaks, spills, and exposure incidents. This should include identifying emergency exits, locations of safety showers and eyewash stations, and designated communication channels.

- Slow and controlled transfer: The transfer should be conducted slowly and under controlled conditions to minimize pressure fluctuations and the risk of leaks. Monitor the pressure and flow rate throughout the process.

- Post-transfer inspection: After the transfer is complete, inspect all equipment again for leaks or damage. Ensure all valves are properly closed and secured. Clean up any spills immediately.

Example: Imagine transferring anhydrous ammonia from a tanker truck to a storage tank. Failure to properly secure the connection could lead to a significant release, posing a serious threat to personnel and the environment. A slow and controlled transfer, coupled with constant monitoring, is essential for safety.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the role of ventilation in ammonia safety.

Ventilation plays a critical role in ammonia safety by preventing the build-up of ammonia gas to hazardous concentrations. Ammonia is lighter than air, so adequate ventilation helps dissipate it quickly. Poor ventilation can lead to a range of problems, from mild irritation to fatalities.

- Dilution: Effective ventilation dilutes the ammonia concentration in the air, reducing the risk of exposure to harmful levels.

- Prevention of asphyxiation: High concentrations of ammonia can displace oxygen, leading to asphyxiation. Ventilation prevents this by maintaining sufficient oxygen levels.

- Reducing the risk of ignition: Ammonia is not flammable under normal conditions, but high concentrations can create a fire or explosion hazard in the presence of certain oxidizers. Adequate ventilation minimizes this risk.

Example: In a refrigeration plant, proper ventilation ensures that any ammonia leaks are quickly diluted and vented to the outside atmosphere. Without proper ventilation, a small leak could quickly escalate into a serious incident.

The type of ventilation required depends on the specific application, but it’s crucial to consider factors such as the amount of ammonia present, the size and layout of the area, and the potential for ammonia leaks. Local and national regulations should always be followed in this area.

Q 17. What are the different types of ammonia sensors and their limitations?

Several types of ammonia sensors exist, each with its own strengths and weaknesses:

- Electrochemical sensors: These sensors use an electrochemical reaction to detect ammonia. They are relatively inexpensive and provide continuous monitoring, but they are susceptible to interference from other gases and have a limited lifespan.

- Photoionization detectors (PIDs): PIDs use ultraviolet light to ionize ammonia molecules, creating a current that is proportional to the concentration. They are sensitive but can be affected by humidity and temperature variations.

- Infrared (IR) sensors: IR sensors measure the absorption of infrared light by ammonia molecules. These sensors are highly specific to ammonia but can be more expensive than other types of sensors.

- Colorimetric tubes: These are simple, inexpensive devices that use a chemical reaction to change color in the presence of ammonia. However, they are not continuous monitoring systems and only provide a single point-in-time measurement.

Limitations: All sensors have limitations. They may have a limited range of detection, may require regular calibration, and can be affected by environmental conditions such as temperature, humidity, and the presence of other gases. Sensor failure can occur, therefore redundancy and regular maintenance are crucial.

It is vital to choose a sensor that is appropriate for the specific application and to understand its limitations.

Q 18. How do you interpret and respond to ammonia sensor alarms?

Responding to ammonia sensor alarms requires a prompt and coordinated effort. The specific response will depend on the concentration level indicated and the location of the alarm.

- Evacuation: If the alarm indicates a high concentration of ammonia, immediate evacuation of the area is necessary. This is the highest priority to protect personnel.

- Isolate the source: If possible and safe to do so, attempt to isolate the source of the leak to prevent further release of ammonia.

- Ventilation: Increase ventilation in the affected area to dilute the ammonia concentration.

- Emergency response team: Notify the emergency response team, or appropriate personnel, according to your established procedures.

- Leak repair: Once the area is safe, and the source is isolated, trained personnel can begin leak repair, if possible. This should only be undertaken by appropriately qualified and equipped personnel.

- Documentation: Thoroughly document the incident, including the alarm time, concentration levels, actions taken, and any injuries or damages.

Example: If a sensor in a refrigeration room triggers an alarm indicating a high ammonia concentration, immediate evacuation of the room is mandatory. Then, isolation of the suspected leak would be the next priority while calling emergency services.

Q 19. Describe the process for cleaning up an ammonia spill.

Cleaning up an ammonia spill requires a cautious and methodical approach, prioritizing the safety of personnel. Never attempt to clean up a significant spill without proper training and equipment.

- Evacuation and isolation: Evacuate the area and isolate the spill to prevent further exposure.

- PPE: Personnel involved in the cleanup must wear appropriate PPE, including self-contained breathing apparatus (SCBA), protective clothing, gloves, and eye protection.

- Contain the spill: Use absorbent materials, such as spill pads or sand, to contain the spill and prevent its spread.

- Neutralization (if appropriate): In some cases, a neutralizing agent may be used, but this must be done carefully, using the correct material and following manufacturer instructions. Boric acid is sometimes used but needs careful handling. Using water might react with ammonia to create a dangerous caustic solution, thus should only be done under the supervision of an experienced technician.

- Proper disposal: Dispose of the contaminated absorbent materials and neutralized ammonia according to local regulations. This often involves specialized waste disposal companies.

- Decontamination: After the cleanup, decontaminate the area and equipment properly.

Example: A small ammonia spill in a laboratory might be cleaned up using absorbent pads and then disposed of as hazardous waste. A larger spill would require more extensive containment measures and potentially the involvement of specialized cleanup crews.

Q 20. Explain the importance of employee training in ammonia safety.

Employee training is paramount in ammonia safety. A well-trained workforce is essential to minimizing the risk of accidents and ensuring a safe working environment. Training should cover all aspects of ammonia handling and emergency response, building a safety-first culture.

- Reduced risk of accidents: Proper training equips employees with the knowledge and skills to handle ammonia safely, thereby reducing the likelihood of leaks, spills, and other incidents.

- Improved emergency response: Trained employees can effectively respond to ammonia emergencies, minimizing the impact of any incident and protecting personnel.

- Compliance with regulations: Adequate training ensures compliance with relevant safety regulations and industry best practices.

- Increased awareness: Training raises employee awareness of the hazards associated with ammonia and instills a safety-conscious attitude.

Example: A worker who understands the importance of proper ventilation and leak detection procedures is less likely to create or overlook hazardous conditions, creating a safer atmosphere for all.

Q 21. What are the key elements of an ammonia safety training program?

A comprehensive ammonia safety training program should encompass several key elements:

- Hazard identification and risk assessment: Training should begin with a thorough explanation of the physical and chemical properties of ammonia and the associated hazards.

- Safe handling procedures: Employees should be trained on proper procedures for handling, transferring, storing, and using ammonia.

- Emergency response procedures: Training should cover emergency response procedures, including how to recognize and respond to leaks, spills, and exposures. This should include practical exercises and drills.

- Personal protective equipment (PPE): Employees should be trained on the proper selection, use, and maintenance of PPE for ammonia handling.

- Ventilation and monitoring: Training should cover ventilation systems and the use and interpretation of ammonia sensors.

- First aid and medical response: Employees should receive training on first aid and medical response procedures for ammonia exposure.

- Regulatory compliance: Training should include information on relevant safety regulations and industry best practices.

- Regular refresher training: Regular refresher training is essential to reinforce learning and keep employees up-to-date on best practices.

The program should be tailored to the specific tasks and responsibilities of the employees. It should include both theoretical instruction and practical exercises, including mock emergency scenarios to test employee responses and preparedness.

Q 22. Describe your experience with ammonia refrigeration system maintenance.

My experience with ammonia refrigeration system maintenance spans over 15 years, encompassing a wide range of tasks from preventative maintenance to troubleshooting complex issues. I’ve worked on systems varying in size from small commercial units to large-scale industrial plants. My routine maintenance includes checking oil levels and quality in compressors, inspecting for leaks using electronic leak detectors, monitoring pressure gauges and temperature sensors, cleaning condenser coils and evaporators, and ensuring proper functioning of safety devices like pressure relief valves. For example, I once identified a significant decrease in compressor efficiency, which, upon investigation, was traced to a buildup of ice on the evaporator. Addressing this improved system performance substantially, highlighting the importance of regular cleaning.

Troubleshooting complex issues requires a systematic approach. I utilize diagnostic tools such as pressure-temperature charts, and specialized instruments to pinpoint the root cause. I’ve successfully diagnosed and repaired compressor failures, refrigerant leaks (locating the leak point using specialized equipment), and control system malfunctions. A particularly challenging case involved a sudden pressure drop in a large industrial system. Through meticulous investigation, I discovered a faulty pressure relief valve, preventing a potentially catastrophic ammonia release.

Q 23. Explain your understanding of ammonia toxicity and its impact on human health.

Ammonia (NH3) is a highly toxic gas. Exposure can cause severe health effects, depending on the concentration and duration. Low concentrations can cause irritation of the eyes, nose, and throat, while higher concentrations can lead to pulmonary edema (fluid buildup in the lungs), potentially fatal. The effects are immediate and potentially devastating; imagine inhaling something that burns your lungs from the inside. Symptoms can manifest quickly, ranging from coughing and shortness of breath to severe respiratory distress.

Chronic exposure to lower levels of ammonia can also have health consequences, leading to respiratory problems, eye damage, and skin irritation. Understanding the potential impact is crucial for preventing accidents. For example, I once witnessed a minor leak, initially unnoticed, causing several workers to experience eye irritation and respiratory distress. This highlighted the importance of immediately reporting any ammonia-related occurrences and implementing robust safety measures.

Q 24. How would you identify and mitigate potential ammonia hazards in a new facility?

Identifying and mitigating potential ammonia hazards in a new facility requires a proactive and multi-faceted approach, starting even before construction begins. This begins with a thorough risk assessment, considering the location, the quantity of ammonia used, and the potential for leaks or releases. The assessment should include the identification of potential failure points in the system, such as piping, valves, and fittings. Furthermore, it should incorporate the surroundings, considering the presence of nearby populations and sensitive ecosystems.

Mitigation strategies would involve implementing robust engineering controls, such as double-walled piping, automatic leak detection systems, and adequate ventilation. Safety systems like pressure relief valves, properly sized and regularly tested, are critical. A comprehensive emergency response plan, including staff training and procedures for evacuation and emergency response should be put into place. I would also ensure that suitable personal protective equipment (PPE) is provided and workers receive comprehensive training on its use, along with emergency procedures and first aid for ammonia exposure. Regular inspections and maintenance will prevent potential accidents. Think of it like building a house – you wouldn’t start without blueprints, and you definitely wouldn’t skip the inspection stage.

Q 25. Describe your experience working with ammonia-related safety regulations.

My experience with ammonia-related safety regulations is extensive. I am familiar with OSHA (Occupational Safety and Health Administration) regulations in the US, and equivalent regulations in other jurisdictions, which dictate the safe handling, storage, and use of ammonia. I have direct experience in ensuring compliance with these regulations, including maintaining detailed records, conducting regular inspections, and implementing corrective actions where necessary. I’m proficient in interpreting and applying these regulations to real-world scenarios, which is crucial for ensuring the safety of workers and the environment.

For example, I have been involved in developing and implementing safety programs that meet or exceed these regulatory requirements. This includes designing and implementing safety procedures for routine operations, maintenance, and emergency response. I understand the importance of documentation and record-keeping, ensuring that all safety procedures are documented, and that all incidents are thoroughly investigated and reported. I also have expertise in providing training to employees on ammonia safety procedures and emergency response.

Q 26. What is your experience with ammonia safety audits and inspections?

I have extensive experience in conducting ammonia safety audits and inspections, following established checklists and industry best practices. These audits typically involve a thorough review of the refrigeration system, safety equipment, emergency response plans, and employee training programs. I’m skilled in identifying potential hazards, assessing risks, and recommending corrective actions to improve safety. I use a combination of visual inspections, functional testing of equipment, and review of documentation to ensure compliance with regulations and best practices.

During an audit, I might discover a malfunctioning pressure relief valve or a poorly maintained leak detection system. Identifying these issues early allows for timely repairs, preventing potential accidents. My reports clearly outline findings, including observations, potential hazards, and prioritized recommendations for improvements. The goal is not just to identify problems but to provide actionable insights that facility managers can use to enhance their safety programs.

Q 27. Explain your familiarity with different types of ammonia relief valves and their function.

Ammonia refrigeration systems employ various types of relief valves to protect against overpressure. Common types include spring-loaded relief valves, rupture discs, and pilot-operated relief valves. Spring-loaded valves are the most common, opening when the system pressure exceeds a predetermined setpoint. Rupture discs are designed to burst at a specific pressure, providing a one-time release. Pilot-operated valves are more sophisticated, often used in larger systems, providing more precise pressure control and often linked to alarm systems.

The function of each valve is to prevent catastrophic failure by releasing excess pressure, preventing equipment damage and potential ammonia releases. Regular inspection and testing are critical. For example, a failure to regularly inspect a spring-loaded valve might lead to it becoming stuck, rendering it ineffective in the event of an overpressure situation. Testing of these valves ensures their proper functionality and provides assurance that they will operate correctly when needed. Understanding the different types and their operating principles is essential for maintaining safe ammonia systems.

Q 28. Describe your experience with incident investigation related to ammonia releases.

Investigating ammonia releases requires a systematic and thorough approach. I follow a structured methodology, often using the ‘5 Whys’ technique to identify the root cause of the incident. This involves documenting the sequence of events leading to the release, identifying contributing factors such as equipment failure, human error, or process deviations. Gathering evidence through witness statements, reviewing maintenance records, and analyzing system data is crucial.

For example, I once investigated a release caused by a corroded pipe. The initial investigation identified the pipe failure, but further investigation using the ‘5 Whys’ revealed that inadequate corrosion prevention measures were in place. My recommendations included implementing enhanced corrosion control procedures and improved inspection protocols. The goal of an investigation isn’t just to assign blame but to understand the root causes to prevent future incidents, thereby improving the safety of the system.

Key Topics to Learn for Ammonia Safety Procedures Interview

- Ammonia Properties and Hazards: Understand the physical and chemical properties of ammonia, including its toxicity, flammability, and reactivity. Explore the potential health effects of exposure (acute and chronic) and the environmental impact of ammonia releases.

- Leak Detection and Response: Learn various methods for detecting ammonia leaks (e.g., gas detectors, visual inspection). Practice outlining emergency response procedures, including evacuation plans, personal protective equipment (PPE) use, and leak containment strategies.

- Personal Protective Equipment (PPE): Familiarize yourself with the appropriate PPE for handling ammonia, including respirators, gloves, and eye protection. Understand the selection criteria for PPE based on the specific risk level and the limitations of each type of equipment.

- Emergency Procedures and Drills: Study emergency shutdown procedures for ammonia systems. Understand the role of emergency response teams and the importance of regular drills and training exercises to ensure preparedness.

- Regulatory Compliance and Standards: Become familiar with relevant safety regulations and industry standards related to ammonia handling and storage. This includes understanding permit requirements, reporting procedures, and best practices for compliance.

- Risk Assessment and Mitigation: Learn how to conduct thorough risk assessments for ammonia-related operations. Develop strategies for mitigating identified risks through engineering controls, administrative controls, and personal protective measures.

- Ammonia Refrigeration Systems: If applicable to the role, understand the principles of ammonia refrigeration systems, including their operation, maintenance, and potential hazards. Focus on safe handling practices for refrigerants.

- Incident Investigation and Reporting: Understand the process for investigating ammonia-related incidents, including data collection, root cause analysis, and reporting to regulatory agencies. This includes identifying contributing factors and implementing corrective actions to prevent future incidents.

Next Steps

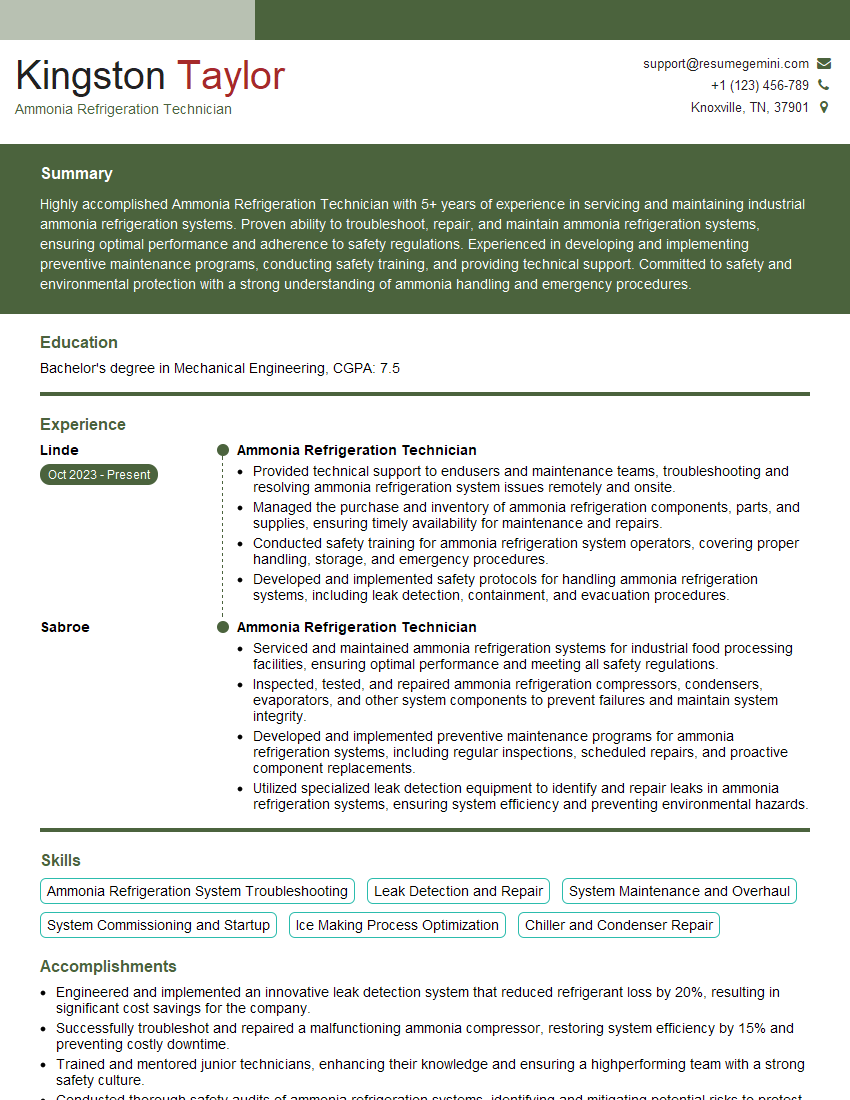

Mastering Ammonia Safety Procedures is crucial for career advancement in industries that utilize ammonia. A strong understanding of these procedures demonstrates your commitment to safety and your ability to contribute effectively to a safe and productive work environment. To significantly increase your chances of landing your dream job, focus on creating an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of the Ammonia Safety Procedures field. Examples of resumes tailored to Ammonia Safety Procedures are available to help guide your resume creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.