Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Arc Flash Hazard Assessment and Mitigation interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Arc Flash Hazard Assessment and Mitigation Interview

Q 1. Define arc flash and its potential hazards.

Arc flash is a dangerous electrical hazard resulting from a short circuit or fault in electrical equipment. Imagine a sudden, explosive release of energy – that’s essentially what an arc flash is. This powerful arc generates intense heat, light, and pressure, capable of causing severe burns, hearing damage, eye injuries, and even fatalities. The potential hazards are significant, ranging from minor skin burns to life-threatening injuries depending on the energy released and proximity to the arc. For instance, a worker servicing a switchboard could be exposed to an arc flash if a tool slips and causes a short circuit. The resulting arc could deliver a fatal amount of energy.

Q 2. Explain the process of conducting an arc flash hazard assessment.

Conducting an arc flash hazard assessment involves a systematic process to identify and mitigate potential hazards. It begins with a thorough review of electrical system one-line diagrams and equipment details. Then, a qualified electrical engineer or technician uses specialized software to perform calculations, determining the available fault current and the resulting incident energy at various points in the electrical system. This involves inputting parameters like voltage, short circuit current, and working distances. The study then defines arc flash boundary distances and associated hazard risk categories based on calculated incident energy levels. Finally, a report is generated detailing the findings, including risk categorizations, recommended PPE, and other mitigation measures. This whole process ensures that workplaces are safe and comply with relevant safety regulations.

Q 3. What are the key components of an arc flash study?

A comprehensive arc flash study includes several key components:

- One-line diagrams: Showing the electrical system layout.

- Equipment data: Including device ratings, fault current contributions, and impedance values.

- Calculations: Determining short circuit current, arc flash boundary, and incident energy at various points.

- Incident energy calculations: Determining the amount of energy released during an arc flash event.

- Arc flash boundary: Defining the distance from equipment where the risk of severe injury exists.

- Risk categorization: Assigning risk categories (e.g., based on NFPA 70E) to equipment.

- Recommended PPE: Specifying the appropriate personal protective equipment required based on the risk category.

- Mitigation recommendations: Suggesting actions to reduce the likelihood or severity of an arc flash.

Q 4. How is incident energy calculated?

Incident energy is calculated using specialized software and industry-accepted formulas. These formulas consider several factors, including the available short circuit current, the arc duration (often assumed to be 0.2 seconds for worst-case scenarios), and the distance from the arc. A simplified representation often used is based on the arc’s current and time. The software takes these factors and more into account to predict the amount of energy that could be transferred to a person within a given distance from the arc. The resulting incident energy is expressed in calories per square centimeter (cal/cm²). This value directly informs the selection of appropriate Personal Protective Equipment (PPE). The more sophisticated software packages also take into account factors like the equipment’s enclosure and other mitigating factors.

Q 5. What are the different types of arc flash PPE?

Arc flash PPE is designed to protect workers from the thermal hazards of an arc flash. Key types include:

- Arc-rated clothing: This includes jackets, pants, and other garments specifically tested and rated to withstand a certain level of incident energy.

- Arc-rated face shields: Providing protection for the face and eyes from intense heat, light, and flying debris.

- Arc-rated gloves: Insulated gloves designed to prevent electrical shock and thermal burns.

- Arc-rated hoods: Covering the head and neck to protect against burns.

- Arc-rated footwear: Protecting the feet from heat and electrical hazards.

Q 6. Describe the hierarchy of hazard controls for arc flash.

The hierarchy of hazard controls for arc flash follows a well-defined order, prioritizing the most effective methods:

- Elimination: This is the most effective but often the most difficult. It involves removing the hazard altogether, such as replacing high-voltage equipment with lower voltage alternatives.

- Substitution: Replacing hazardous equipment or processes with safer alternatives. For example, using low-voltage control circuits.

- Engineering controls: Implementing engineering solutions to reduce exposure to hazards, such as installing arc flash relays or improved safety devices.

- Administrative controls: Establishing safe work procedures, training programs, lockout/tagout procedures, and permits to work.

- Personal Protective Equipment (PPE): Using appropriate arc-rated PPE to mitigate the hazard when other controls are insufficient. This is the last line of defense.

Q 7. What is the significance of NFPA 70E in arc flash mitigation?

NFPA 70E, the standard for Electrical Safety in the Workplace, is paramount in arc flash mitigation. It provides guidance on evaluating arc flash hazards, selecting appropriate PPE, implementing safe work practices, and training employees. Compliance with NFPA 70E is critical for ensuring a safe workplace. The standard mandates conducting arc flash risk assessments, labeling electrical equipment with hazard warnings (including arc flash boundaries and incident energy levels), and training employees on arc flash hazards and mitigation strategies. Failure to comply can result in significant legal and safety ramifications, including severe injuries and fatalities.

Q 8. Explain the concept of arc flash boundary.

The arc flash boundary is the distance from an electrical equipment enclosure within which the incident energy level from an arc flash exceeds 1.2 cal/cm². This energy level is considered the threshold for potential second-degree burns. Think of it like this: imagine throwing a snowball. The closer you are to the point of impact, the more intense the impact, and the more likely you are to get hurt. Similarly, the closer you are to an electrical panel during an arc flash, the more intense the energy you’ll be exposed to. The arc flash boundary is the ‘safe’ distance to ensure your safety from severe burns.

Determining the boundary involves conducting an arc flash hazard assessment. This assessment typically utilizes specialized software that considers factors such as system voltage, fault current, and equipment type. The software then calculates the incident energy at various distances from the equipment to define the boundary.

Q 9. How do you determine the appropriate arc flash PPE category?

Determining the appropriate arc flash PPE (Personal Protective Equipment) category depends entirely on the incident energy level calculated for a specific piece of equipment at a particular working distance. The incident energy value is measured in calories per square centimeter (cal/cm²). This is then cross-referenced with industry standards (such as IEEE 1584) to determine the appropriate PPE category. This standard categorizes PPE based on the level of protection offered against incident energy levels.

For example, a low incident energy level might necessitate Category 1 PPE (which might just be a flame resistant shirt), while a very high incident energy level would demand Category 4 PPE (requiring a high-quality arc-rated suit, face shield, and other protective gear). There’s no ‘one-size-fits-all’ answer; the category is always driven by the results of the arc flash study.

Q 10. What are the limitations of arc flash studies?

Arc flash studies, while crucial for safety, have limitations. The primary limitation is that they are based on modeling and calculations, not real-world events. The accuracy of the study depends heavily on the accuracy of the input data, like the system impedance and available fault current. Any inaccuracies in this data will directly impact the calculated results and the calculated arc flash boundary. The study also doesn’t predict when an arc flash will occur, only its potential severity at different distances.

Furthermore, the study assumes certain conditions, such as specific fault types and locations. Unforeseen circumstances, such as equipment degradation or unusual system events, can alter the actual arc flash behavior and potentially render the study’s conclusions less reliable. Finally, the studies are inherently conservative in their estimations; underestimating the hazard is far more dangerous than overestimating it, so safety margins are often built into the calculations.

Q 11. How often should arc flash studies be updated?

The frequency of arc flash study updates depends on several factors, including the age of the electrical system, the frequency of modifications or upgrades, and any changes in the system’s configuration. However, a reasonable guideline is to update the studies at least every 5 years. More frequent updates are necessary if there have been significant changes to the electrical system, such as additions of new equipment or major renovations. Think of it like a car inspection; regular checks ensure continued safety and identify potential problems before they escalate. In a similar manner, periodic arc flash studies maintain a current understanding of the risks to personnel.

Changes in equipment, such as replacing a circuit breaker with a different model or a change in system fault current, require immediate reassessment of the affected area. Regular maintenance and inspections of the electrical system should also contribute to a better understanding of potential hazard evolution and prompt updates to the study when necessary.

Q 12. Describe the role of a lockout/tagout procedure in arc flash prevention.

Lockout/Tagout (LOTO) procedures are fundamental to arc flash prevention. LOTO involves completely isolating electrical equipment from the power source before any work is performed. This involves physically disconnecting the power and using a lockout device (like a padlock) and a tag to prevent accidental re-energization. The lock and tag serve as a visual and physical barrier, indicating that the equipment is out of service and should not be energized.

LOTO prevents human error, the biggest cause of arc flash incidents. It ensures that a worker cannot accidentally energize equipment while it’s being worked on. A LOTO program should be established and strictly followed, including detailed procedures for each piece of equipment. It is a crucial layer of safety in addition to PPE, and is considered an absolute requirement before any work is done on electrical equipment.

Q 13. What are the common causes of arc flash incidents?

Common causes of arc flash incidents often stem from human error and equipment failure. Some key causes include:

- Improper work practices: Failing to follow established safety procedures like LOTO.

- Equipment malfunction: Faulty components, insulation breakdown, or worn-out equipment.

- Unintended contact: Accidental contact with energized conductors or components.

- Inadequate maintenance: Lack of regular inspection and maintenance of electrical systems.

- Incorrect wiring or connections: Faulty installations or modifications.

- Improper use of tools: Using tools that can create conductive paths or unintended shorts.

Essentially, arc flashes often occur when there’s a failure in safety protocols or equipment integrity which creates a conductive path leading to a short circuit and a massive release of electrical energy.

Q 14. Explain the difference between arc flash and shock hazards.

While both arc flash and shock hazards involve electrical energy, they differ significantly in their nature and effects. An electric shock occurs when a person comes into direct contact with an energized conductor, resulting in a current passing through the body. The severity depends on the current’s magnitude and the path it takes through the body. Think of it as a relatively small, concentrated energy release.

An arc flash, however, is a much more violent event. It’s a sudden, high-energy release that occurs when a fault in the electrical system creates an arc, a high-temperature, high-current plasma that vaporizes metal and generates intense heat, light, and pressure. This is like a massive, explosive release of energy, leading to much more severe injuries from thermal burns. An arc flash can also lead to an electric shock as secondary effect.

In short: Shock is a direct current pathway through the body; arc flash is an explosive release of energy from an arc, and can cause extensive thermal injuries, blast injuries, and also may lead to an electric shock.

Q 15. How do you interpret an arc flash label?

Arc flash labels are crucial safety warnings indicating the potential arc flash hazard at a specific electrical panel or equipment. They provide critical information to workers, allowing them to select the appropriate Personal Protective Equipment (PPE) and work safely. A typical label includes:

- Arc Flash Boundary: This defines the safe working distance. Stepping beyond this boundary increases the risk of severe injury.

- Incident Energy (I2t): This value, expressed in cal/cm2, represents the amount of energy released during an arc flash. The higher the number, the more severe the potential burn.

- Arc Flash PPE Category: This indicates the minimum PPE category required to protect against the calculated incident energy. Categories range from 1 (lowest hazard) to 4 (highest hazard). This dictates the required arc rating of protective clothing.

- Voltage: The voltage of the equipment is clearly displayed.

- Date of Study: The date the arc flash hazard assessment was conducted; studies should be reviewed and updated periodically (often every 5 years or when significant changes occur to the electrical system).

Example: An arc flash label might show “Incident Energy: 4.0 cal/cm2, Arc Flash PPE Category 2, Voltage: 480V.” This tells workers that they need at least Category 2 arc-rated clothing when working near this equipment and that the risk of burns is significant.

Career Expert Tips:

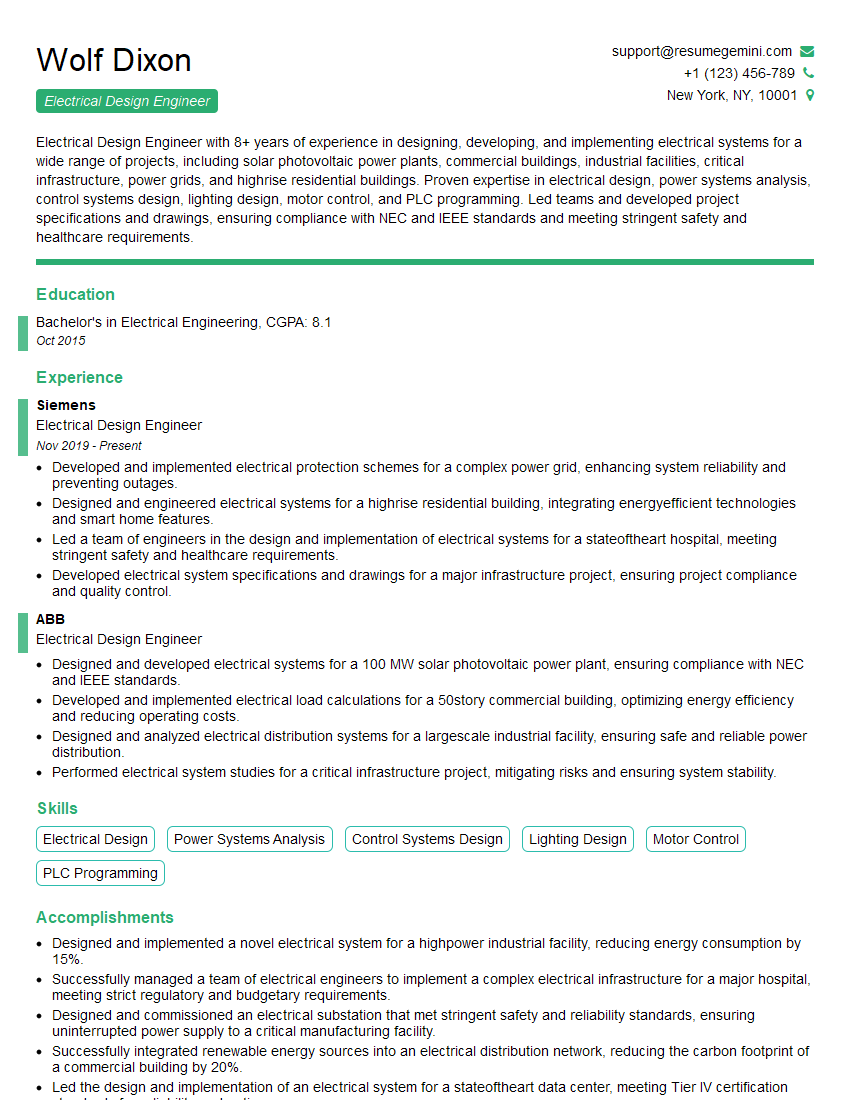

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are some best practices for working on energized electrical equipment?

Working on energized electrical equipment is inherently dangerous. Best practices prioritize safety and involve strict adherence to lockout/tagout (LOTO) procedures, rigorous risk assessments, and the use of appropriate PPE. Key practices include:

- Lockout/Tagout (LOTO): This is paramount. Energy sources must be completely isolated and locked out before any work begins. Multiple authorized workers may need to participate in the LOTO process.

- Arc Flash Hazard Analysis: A comprehensive arc flash risk assessment must be performed to determine the potential hazards and necessary safety precautions. This assessment will dictate the required PPE.

- Proper PPE Selection: Based on the arc flash hazard analysis, workers must wear appropriate arc-rated clothing, including flame-resistant (FR) garments, arc flash face shields, and insulated gloves. PPE should be inspected regularly to ensure it’s in good condition and properly rated for the task.

- Qualified Personnel: Only trained and qualified individuals should work on energized equipment. They must understand the hazards and safety procedures.

- Work Permits and Procedures: A detailed work permit should be developed and followed, outlining every step of the process. This ensures a safe and methodical approach.

- Grounding and Bonding: To further reduce risk, appropriate grounding and bonding techniques should be used wherever possible.

Failing to follow these best practices can lead to severe injuries or fatalities.

Q 17. What are the different methods for arc flash mitigation?

Arc flash mitigation strategies aim to reduce the incident energy and the likelihood of an arc flash event. They fall into several categories:

- Engineering Controls: These are the most effective methods, modifying the electrical system to reduce the potential for arc flashes. Examples include installing arc flash relays, using improved equipment designs, and employing reduced voltage systems.

- Administrative Controls: These focus on safe work practices, training, and procedures. This includes implementing robust LOTO programs, developing and enforcing safe work practices, and providing comprehensive arc flash training for all personnel.

- Personal Protective Equipment (PPE): As a last line of defense, arc-rated PPE protects workers from the thermal effects of an arc flash. The level of protection is directly linked to the calculated incident energy and will be specific to the equipment being worked on.

A comprehensive approach often combines all three categories for optimal protection. Engineering controls are prioritized whenever feasible, followed by administrative controls, with PPE serving as the final layer of defense.

Q 18. Discuss the role of engineering controls in arc flash reduction.

Engineering controls are the most effective way to reduce arc flash hazards. They focus on modifying the electrical system itself to minimize the risk. Examples include:

- Arc Flash Relays: These devices detect arcing faults and quickly interrupt the power, limiting the duration and severity of the event.

- Improved Equipment Design: Modern equipment incorporates features that reduce the likelihood of arc flashes, such as better insulation and improved contact design.

- Reduced Voltage Systems: Lower voltage systems inherently produce lower incident energy levels during arc flashes. Switching to a lower voltage may be cost-effective in reducing risk.

- Isolation Devices: Properly installed and maintained isolation devices help separate the energy source from the equipment being worked on.

- Proper Grounding and Bonding: These techniques are vital to prevent hazardous voltages from appearing where they are not expected. This is an especially important consideration when working on multiple pieces of equipment in an area.

Implementing engineering controls often requires a significant upfront investment, but the long-term benefits in terms of safety and reduced incident costs are substantial.

Q 19. What are the responsibilities of an employer regarding arc flash safety?

Employers have a legal and ethical responsibility to provide a safe working environment for their employees. Regarding arc flash safety, this includes:

- Performing Arc Flash Hazard Assessments: Regularly conducting comprehensive arc flash risk assessments to identify potential hazards.

- Implementing Safety Programs: Developing and implementing a comprehensive arc flash safety program that includes training, procedures, and emergency response plans.

- Providing Proper PPE: Ensuring employees have access to and are trained on the use of appropriate arc-rated PPE.

- Training Employees: Providing thorough training to all employees who may work near energized electrical equipment.

- Enforcing Safety Rules: Strict enforcement of safety rules and procedures is vital. This includes regular inspections and audits.

- Maintaining Equipment: Regularly inspecting and maintaining electrical equipment to prevent equipment failures.

- Following OSHA Standards: Compliance with all applicable OSHA standards relating to electrical safety.

Failure to meet these responsibilities can result in serious penalties, including fines, lawsuits, and damage to the company’s reputation.

Q 20. How do you ensure the accuracy of an arc flash study?

Ensuring the accuracy of an arc flash study is crucial for worker safety. Several steps contribute to accuracy:

- Accurate One-Line Diagrams: The study must be based on an accurate one-line diagram of the electrical system. This diagram should include all relevant equipment, including breakers, transformers, and protective devices.

- Thorough Data Collection: Accurate data on equipment ratings, protective device settings, and cable sizes is essential for calculations. Any missing or incorrect data can significantly impact the results.

- Qualified Software and Expertise: The study should be conducted using industry-recognized software and by qualified engineers with expertise in arc flash calculations. Regular software updates are crucial to ensure that the program is using the latest and most accurate algorithms.

- Verification and Validation: After the study is completed, the results should be reviewed and validated. Any anomalies or inconsistencies should be investigated and resolved.

- Regular Updates: The study should be regularly reviewed and updated to reflect any changes in the electrical system or equipment. Changes in equipment or the electrical system will require recalculation of incident energy values.

A poorly conducted study can lead to inaccurate incident energy values and PPE selection, jeopardizing worker safety.

Q 21. Describe the process of verifying arc flash PPE.

Verification of arc flash PPE is a critical step to ensure it provides the necessary level of protection. This process involves:

- Manufacturer’s Certification: The PPE must come with a manufacturer’s certificate indicating its arc rating (expressed in cal/cm2). This certification confirms the PPE meets the required industry standards.

- Visual Inspection: Before each use, the PPE should be visually inspected for any damage, such as tears, holes, or wear and tear. Damaged PPE should be immediately removed from service.

- Regular Testing and Maintenance: Depending on usage, the PPE may need regular testing and maintenance to ensure it continues to meet the required performance standards. This will involve periodic laboratory testing by qualified testing agencies.

- Proper Cleaning and Storage: PPE needs to be properly cleaned and stored according to the manufacturer’s instructions. This helps to prolong its useful life.

- Training: Workers must be trained in the proper use and care of arc flash PPE. This includes proper donning and doffing procedures, inspection protocols and recognition of damage.

Regular verification and maintenance of arc flash PPE ensure it consistently provides the required protection against arc flash hazards.

Q 22. Explain the importance of training in arc flash safety.

Arc flash safety training is paramount because it directly impacts the well-being of electrical workers. A comprehensive training program isn’t just about ticking boxes; it’s about fostering a safety culture. It equips individuals with the knowledge and skills to identify, assess, and mitigate arc flash hazards effectively. Without proper training, workers are significantly more vulnerable to severe injuries or fatalities.

- Theoretical Knowledge: Training should cover the physics of arc flash, the factors that influence its severity (system voltage, available fault current, etc.), and the interpretation of arc flash labels and studies.

- Practical Skills: Hands-on training on the use of personal protective equipment (PPE), including arc flash suits, face shields, and hearing protection, is crucial. This also includes practicing safe work procedures and lockout/tagout (LOTO) techniques.

- Emergency Response: Training should also include procedures for responding to arc flash incidents, such as first aid and emergency evacuation protocols.

Imagine a scenario where an electrician, lacking proper training, attempts to work on energized equipment without appropriate PPE. The consequences could be catastrophic – severe burns, blindness, or even death. Training significantly reduces the likelihood of such incidents.

Q 23. How do you handle an arc flash incident?

Handling an arc flash incident requires a swift and coordinated response, prioritizing the safety of everyone involved. The immediate steps involve:

- Ensure Scene Safety: Immediately de-energize the equipment if possible and safe to do so. If de-energizing isn’t immediately feasible, establish a safety perimeter to prevent further exposure.

- First Aid and Emergency Services: Attend to the injured person(s) providing first aid as necessary while calling emergency medical services. Arc flash burns are often severe and require specialized medical attention.

- Investigation and Reporting: Once the immediate danger is mitigated, conduct a thorough investigation to determine the root cause of the incident. This involves documenting the event, collecting evidence, and reviewing the safety procedures that were in place. Detailed reports are essential for improving safety protocols and preventing future occurrences.

- Equipment Inspection: After the incident, a qualified electrician must thoroughly inspect the affected equipment to assess the extent of the damage and ensure its safe operation before re-energizing it.

One crucial element is proper training in emergency response procedures. This might involve simulated scenarios to prepare workers for the stress of a real arc flash incident.

Q 24. What are the regulatory requirements for arc flash hazard assessment?

Regulatory requirements for arc flash hazard assessments vary depending on location, but generally align with internationally recognized standards such as IEEE 1584 and NFPA 70E. These standards provide guidelines for performing arc flash risk assessments, determining incident energy levels, and selecting appropriate PPE. Key regulatory aspects include:

- Regular Assessments: Facilities must conduct periodic arc flash hazard assessments, typically every 2-5 years or whenever significant changes are made to the electrical system.

- Documentation: Detailed documentation of the assessment process, including calculations, assumptions, and results, is essential. This documentation serves as evidence of compliance with regulatory requirements.

- Labeling: Equipment must be clearly labeled with arc flash hazard information, including incident energy levels, required PPE categories, and other relevant data. This ensures that workers are aware of the hazards before commencing work.

- Training Requirements: Regulations often mandate specific training requirements for electrical workers, covering arc flash hazards, PPE, and safe work procedures.

Non-compliance with these regulations can lead to significant penalties, including fines, operational shutdowns, and even criminal charges in cases of severe incidents.

Q 25. How do you communicate arc flash risks to non-technical personnel?

Communicating arc flash risks to non-technical personnel requires simplifying complex technical concepts without sacrificing accuracy. Using clear, concise language and visuals is key.

- Analogies and Visual Aids: Instead of using technical jargon, explain the concept of arc flash using relatable analogies, like comparing the intense heat and light to a miniature sun. Visual aids, such as diagrams and short videos, can greatly enhance understanding.

- Focus on Consequences: Highlight the potential consequences of arc flash incidents – severe burns, blindness, and even death – to emphasize the severity of the risks. This approach generates a better understanding of the need for safety precautions.

- Simplified Information: Provide information in a simplified format, avoiding complex technical details. Focus on the key messages, such as the importance of staying clear of energized equipment and adhering to safety protocols.

- Interactive Sessions: Interactive sessions, such as question-and-answer periods, can be helpful to address concerns and clarify any misunderstandings.

For instance, you might explain that an arc flash is like a powerful explosion of electricity and that specialized protective clothing is necessary to prevent serious injuries. Using simple language and real-world examples makes the information more relatable and memorable.

Q 26. What are the potential consequences of inadequate arc flash protection?

Inadequate arc flash protection can lead to a range of severe consequences, extending far beyond immediate injuries to workers. The potential repercussions include:

- Catastrophic Injuries: Arc flash incidents can cause devastating burns, blindness, hearing loss, and other life-altering injuries.

- Fatalities: In severe cases, arc flash incidents can be fatal.

- Financial Losses: The costs associated with arc flash incidents can be substantial, including medical expenses, worker’s compensation claims, equipment damage, production downtime, and legal liabilities.

- Reputational Damage: Serious accidents can severely damage a company’s reputation and erode public trust.

- Regulatory Penalties: Non-compliance with safety regulations can result in significant fines and penalties.

- Insurance Issues: Inadequate safety measures can impact insurance premiums and potentially lead to coverage denials.

The human cost of inadequate arc flash protection is immeasurable, but the financial and legal consequences are also substantial. A proactive approach to safety is not just a moral imperative, but also a sound business decision.

Q 27. Describe your experience with different arc flash software and tools.

Throughout my career, I’ve worked with several arc flash software and tools, each with its strengths and weaknesses. My experience encompasses:

- ETAP: A robust software package used for power system analysis, including arc flash hazard calculations. It provides detailed reports, including incident energy levels and required PPE categories.

- EasyPower: Another comprehensive software solution used for electrical system modeling and analysis, with capabilities for arc flash studies and report generation.

- SKM PowerTools: Similar to ETAP and EasyPower, this software offers advanced analysis features, including short-circuit, coordination, and arc flash studies.

- Specialized Mobile Apps: Several mobile applications are available that allow on-site technicians to quickly assess basic arc flash hazards and verify PPE compliance.

The choice of software often depends on the specific needs of the project and the client’s existing infrastructure. My expertise lies not just in using these tools, but in interpreting their outputs, understanding their limitations, and ensuring the results are practically applicable.

Q 28. Discuss a challenging arc flash project and how you overcame the difficulties.

One particularly challenging project involved assessing the arc flash hazards in a large, aging industrial facility with poorly documented electrical systems. The initial challenge was the lack of comprehensive system documentation – outdated schematics, missing information, and undocumented modifications.

To overcome this, we employed a multi-pronged approach:

- On-Site Inspection: We began with a detailed on-site inspection of the entire facility to document the existing electrical system, including equipment types, ratings, and wiring configurations. This involved extensive fieldwork, including using infrared thermography to identify potential hot spots and areas of concern.

- Data Acquisition: We used specialized test equipment to gather data on fault currents, system impedances, and other critical parameters necessary for accurate arc flash calculations. This step was crucial for verifying the accuracy of existing documentation and identifying discrepancies.

- Software Modeling: We developed a detailed electrical system model using ETAP software, incorporating the data gathered during the on-site inspection and testing. This model allowed us to conduct accurate arc flash calculations and simulations, identifying the most hazardous areas.

- Iterative Process: The process was iterative. After each phase, we reviewed and refined our models, incorporating new information and addressing inconsistencies. This meticulous approach ensured that our final arc flash assessment was both accurate and comprehensive.

This project highlighted the importance of thorough documentation and the value of using a combination of field measurements, software analysis, and iterative refinement to address uncertainties in an aging electrical system.

Key Topics to Learn for Arc Flash Hazard Assessment and Mitigation Interview

- Arc Flash Hazard Analysis: Understanding incident energy calculations, including the impact of system voltage, short-circuit current, and working distance.

- Risk Assessment Methodology: Applying industry standards (IEEE 1584, NFPA 70E) to determine appropriate personal protective equipment (PPE) and safe work practices.

- Arc Flash Boundary Determination: Calculating and defining the arc flash boundary to establish safe working distances and zones.

- Mitigation Strategies: Exploring various methods for reducing arc flash hazards, such as equipment modifications, improved grounding techniques, and the use of arc flash relays.

- Protective Equipment Selection: Choosing appropriate PPE based on calculated incident energy levels and risk assessment findings. Understanding the limitations and maintenance requirements of PPE.

- Lockout/Tagout Procedures: Implementing and verifying effective lockout/tagout procedures to prevent accidental energization during maintenance activities.

- Electrical Safety Training Programs: Developing and implementing comprehensive training programs to ensure workers understand arc flash hazards and mitigation techniques.

- Regulatory Compliance: Staying up-to-date with relevant safety regulations and standards, ensuring compliance within your work environment.

- Practical Application: Demonstrate your ability to apply theoretical knowledge to real-world scenarios, such as interpreting arc flash study reports and developing practical mitigation plans.

- Problem-Solving Approaches: Explain your ability to identify, analyze, and solve complex electrical safety problems effectively and efficiently, including troubleshooting and root cause analysis.

Next Steps

Mastering Arc Flash Hazard Assessment and Mitigation is crucial for career advancement in the electrical industry, demonstrating your commitment to safety and technical expertise. A strong resume is essential to showcase your skills and experience to potential employers. Creating an ATS-friendly resume significantly increases your chances of getting noticed by recruiters. ResumeGemini is a trusted resource to help you build a professional and effective resume. Examples of resumes tailored to Arc Flash Hazard Assessment and Mitigation roles are available to help guide you in creating a compelling application. Invest in your future – craft a resume that reflects your expertise and secures your next opportunity.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.