Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Biodiesel and Renewable Fuel Management interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Biodiesel and Renewable Fuel Management Interview

Q 1. Explain the transesterification process in biodiesel production.

Transesterification is the chemical process at the heart of biodiesel production. It’s essentially a reaction where triglycerides (the main component of vegetable oils and animal fats) are converted into fatty acid methyl esters (FAME), which is biodiesel, and glycerol. This reaction requires a catalyst, typically methanol (a type of alcohol) and a strong base like sodium hydroxide (NaOH) or potassium hydroxide (KOH).

Imagine it like this: you have a long chain of molecules (the triglyceride) and you want to break it into smaller, more useful chains (FAME). The methanol acts like a pair of molecular scissors, and the base helps to speed up this ‘cutting’ process. The glycerol is the byproduct, a valuable commodity in its own right.

The process typically involves three main steps: mixing the oil with methanol and the catalyst, reaction (esterification), and separation of the biodiesel from the glycerol. Proper temperature and mixing are crucial for optimal yield. The resulting biodiesel is then washed to remove any remaining catalyst and glycerol before it’s ready for use.

Q 2. Describe the different feedstocks used in biodiesel production and their advantages/disadvantages.

A wide range of feedstocks can be used for biodiesel production, each with its own set of advantages and disadvantages.

- Soybean Oil: Widely available, high yield, but its production can impact deforestation and biodiversity.

- Rapeseed Oil (Canola): High yield, relatively low saturated fat content, but cultivation requires significant land and resources.

- Palm Oil: High yield, but its production is a major driver of deforestation and habitat loss, leading to significant environmental concerns.

- Used Cooking Oil (UCO): Sustainable option as it diverts waste from landfills, but requires careful processing to remove impurities and contaminants.

- Algae: High potential for sustainable biodiesel production due to its high oil content and fast growth rate, but currently expensive and requires further research to optimize cultivation and extraction.

- Animal Fats (Tallow): Readily available byproduct from the meat industry, but concerns around saturated fat content and potential for disease transmission.

Choosing the right feedstock involves a careful consideration of economic viability, environmental impact, and the availability of suitable resources. It’s often a balancing act between yield, sustainability, and cost-effectiveness.

Q 3. What are the key quality parameters for biodiesel, and how are they determined?

Biodiesel quality is defined by several key parameters, ensuring it meets safety and performance standards. These parameters are typically tested using standardized methods according to ASTM (American Society for Testing and Materials) or EN (European Norm) standards.

- Fatty Acid Methyl Ester (FAME) Content: Specifies the percentage of FAMEs in the biodiesel, ideally above 96.5%. Determined by Gas Chromatography.

- Viscosity: Measures the resistance of the biodiesel to flow. Important for proper engine operation. Measured using a viscometer.

- Cetane Number: Indicates how readily the fuel ignites. A higher cetane number is preferable for better combustion and reduced emissions. Determined using a cetane number tester.

- Water Content: Excess water can lead to corrosion and microbial growth. Measured using Karl Fischer titration.

- Free Glycerin Content: Unreacted glycerin indicates incomplete transesterification. Measured through titration methods.

- Acid Number: Indicates the presence of free fatty acids, affecting biodiesel stability and engine performance. Measured through titration.

These parameters are critical for ensuring the biodiesel meets the required specifications for different engine applications and for safeguarding the environment and engine performance.

Q 4. How do you ensure the environmental compliance of a biodiesel production facility?

Environmental compliance for a biodiesel production facility involves adhering to strict regulations concerning air emissions, wastewater discharge, and waste management. This requires a multi-pronged approach.

- Air Emissions Control: Implementing technologies to reduce emissions of particulate matter, volatile organic compounds (VOCs), and other pollutants. This could involve the use of scrubbers, filters, and proper ventilation systems.

- Wastewater Treatment: Treating wastewater to remove glycerol, catalyst residues, and other contaminants before discharge. This often involves biological treatment processes followed by advanced treatment techniques.

- Waste Management: Implementing proper procedures for handling and disposal of solid waste, including spent catalysts and filter materials. This might involve recycling, incineration, or disposal at licensed facilities.

- Permitting and Reporting: Obtaining all necessary permits and licenses from environmental regulatory agencies and ensuring accurate and timely reporting of emissions and waste data.

- Regular Monitoring: Regularly monitoring emissions and wastewater discharge to ensure compliance with established limits. This requires the use of monitoring equipment and qualified personnel.

Regular audits and inspections by regulatory agencies are a crucial part of maintaining compliance and minimizing environmental impact.

Q 5. Discuss the challenges associated with the storage and transportation of biodiesel.

Storage and transportation of biodiesel pose unique challenges due to its susceptibility to oxidation and degradation. Several factors need consideration.

- Oxidation Stability: Biodiesel is more prone to oxidation than petroleum diesel, leading to the formation of gums and sediments that can clog fuel filters and damage engine components. Proper storage in inert atmosphere or the use of antioxidants can mitigate this.

- Cold Flow Properties: At low temperatures, biodiesel can solidify, hindering flow and engine starting. Additives or blending with petroleum diesel can improve cold flow properties.

- Water Contamination: Biodiesel readily absorbs water, promoting microbial growth and degradation. Proper storage in sealed containers and the use of water-absorbing filters are essential.

- Tank Compatibility: Ensuring compatibility of storage tanks and pipelines with biodiesel is crucial. Some materials can be degraded or react with biodiesel.

- Transportation Infrastructure: The existing infrastructure for fuel transportation might not be completely compatible with biodiesel, requiring modifications or adaptations in some cases.

Proper handling and storage protocols are vital to ensure biodiesel quality and prevent degradation during transportation and use.

Q 6. Explain the different types of renewable fuel blends and their applications.

Renewable fuel blends combine biodiesel with petroleum diesel to leverage the benefits of both fuels. The blend ratio is typically expressed as a percentage (e.g., B20 for 20% biodiesel, 80% petroleum diesel).

- B5, B10, B20: Common blends used in various transportation sectors. B20 is increasingly used in heavy-duty vehicles. These blends offer reduced emissions and improved lubricity while maintaining engine compatibility.

- B100: Pure biodiesel, typically used in vehicles specifically designed for biodiesel or in certain applications where higher biofuel content is required.

- Bioethanol Blends: Bioethanol, produced from fermented biomass, is commonly blended with gasoline (e.g., E10, E85). Bioethanol blends reduce emissions and improve octane ratings.

The choice of fuel blend depends on factors like engine type, environmental regulations, and fuel availability. Blending helps to gradually integrate renewable fuels into the existing infrastructure.

Q 7. What are the economic factors influencing the biodiesel market?

Several economic factors influence the biodiesel market, making it a dynamic and complex sector.

- Feedstock Prices: Fluctuations in the prices of feedstocks, such as soybean oil, rapeseed oil, or used cooking oil, significantly impact biodiesel production costs and overall market price.

- Crude Oil Prices: Crude oil prices directly influence petroleum diesel prices, affecting the competitiveness of biodiesel. When crude oil prices are low, biodiesel becomes less competitive.

- Government Policies and Incentives: Government subsidies, tax credits, and mandates for renewable fuel use can substantially influence biodiesel demand and production. These policies create economic incentives for adoption.

- Technological Advancements: Improvements in biodiesel production technologies can reduce costs and enhance efficiency, improving market competitiveness.

- Consumer Demand and Awareness: Growing consumer awareness of environmental benefits and the increasing demand for sustainable fuels drive the adoption of biodiesel.

- Transportation and Distribution Costs: The costs associated with transporting and distributing biodiesel across geographical regions play a vital role in the overall market pricing.

Understanding these factors is crucial for effective market analysis, strategic planning, and investment decisions within the biodiesel industry.

Q 8. Describe the role of catalysts in biodiesel production.

Catalysts are crucial in biodiesel production because they significantly speed up the transesterification reaction. This reaction converts triglycerides (fats and oils) into fatty acid methyl esters (FAME), which is what constitutes biodiesel. Without a catalyst, the reaction would be incredibly slow, impractical for commercial production.

The most common catalyst used is sodium hydroxide (NaOH) or potassium hydroxide (KOH), which are strong bases. These bases initiate a nucleophilic attack on the triglyceride molecule, breaking the ester bonds and forming glycerol and FAME. Other catalysts, such as solid acid catalysts (e.g., zeolites), are also being explored to improve the process and reduce waste.

Think of the catalyst like a matchmaker; it brings the reactants together, facilitating a faster and more efficient reaction without being consumed itself. The choice of catalyst affects factors such as reaction time, yield, and purity of the final biodiesel product. For instance, using a higher concentration of base catalyst can speed up the reaction but may also lead to increased soap formation, which needs to be addressed in post-processing.

Q 9. How do you troubleshoot common issues in biodiesel production, such as high free fatty acid content?

High free fatty acid (FFA) content is a common issue in biodiesel production, hindering the transesterification process and reducing the quality of the final product. High FFA levels lead to soap formation, which reduces the yield of biodiesel and increases purification costs.

Troubleshooting involves a multi-step approach:

- Analyze the feedstock: The first step is determining the FFA content of the oil or fat. High FFA levels indicate the need for pre-treatment before transesterification.

- Pre-esterification: For feedstocks with high FFA, a pre-esterification step is necessary. This involves reacting the FFA with methanol in the presence of an acid catalyst (like sulfuric acid) to convert them into esters before the main transesterification process.

- Optimize reaction conditions: This includes adjusting the methanol-to-oil ratio, catalyst concentration, reaction temperature, and reaction time. Careful monitoring and control of these parameters are vital for efficient transesterification.

- Washing and purification: After the reaction, thorough washing is crucial to remove glycerol, soap, and unreacted methanol. Centrifugation can separate out the biodiesel from the by-products.

- Analyze the final product: Quality control is essential to ensure the biodiesel meets the required standards, which includes testing for FFA content, water content, viscosity, and other relevant parameters.

For example, if you find soap formation, you might need to optimize the washing steps. If your yield is low, you may need to review the catalyst concentration or the reaction time. Each step should be monitored using analytical techniques to understand the process parameters, identify issues, and implement corrective actions.

Q 10. What are the lifecycle assessments of biodiesel compared to traditional diesel fuel?

Lifecycle assessments (LCAs) compare the environmental impacts of biodiesel and traditional diesel across their entire lifecycle, from feedstock production to end-of-life disposal. LCAs consider factors like greenhouse gas emissions, energy consumption, water usage, and land use.

Biodiesel generally demonstrates a significantly lower carbon footprint compared to petroleum diesel. This is primarily because biodiesel production utilizes renewable resources, such as vegetable oils or animal fats, which sequester carbon dioxide during their growth. Furthermore, the combustion of biodiesel releases less particulate matter and other harmful pollutants.

However, the environmental impact of biodiesel is influenced by several factors including the type of feedstock used (e.g., palm oil has significant deforestation concerns), the processing method (energy intensive processes negate some environmental benefits), and the transportation distance of the feedstock and fuel. Sustainable practices throughout the biodiesel production chain are crucial to ensure its overall environmental benefits.

A comprehensive LCA incorporates a detailed analysis of all life cycle stages of both biodiesel and petroleum diesel, enabling a fair comparison and evaluation of their environmental impacts. It’s important to consider the specific feedstock and production methods when comparing these LCAs, as the environmental impacts can vary significantly.

Q 11. Explain the different methods for analyzing the fatty acid composition of biodiesel.

Analyzing the fatty acid composition of biodiesel is essential for quality control and ensuring it meets the required specifications. Several methods are used:

- Gas chromatography (GC): This is the most common method. A sample of biodiesel is injected into a gas chromatograph, which separates the different fatty acid methyl esters based on their boiling points. A detector then measures the amount of each ester, providing a detailed fatty acid profile.

- Gas chromatography-mass spectrometry (GC-MS): This technique combines gas chromatography with mass spectrometry to identify and quantify each fatty acid methyl ester with high accuracy. This method is particularly useful for identifying less common or unusual fatty acids.

- Nuclear magnetic resonance (NMR) spectroscopy: NMR spectroscopy can also be used to determine the fatty acid composition, although it’s generally less precise than GC or GC-MS.

These methods provide valuable information on the quality and properties of biodiesel. For example, the proportion of saturated and unsaturated fatty acids influences the fuel’s cold flow properties (ability to flow at low temperatures). The fatty acid profile helps in determining the suitability of the biodiesel for different applications and engines. Accurate analysis is crucial for ensuring the biodiesel conforms to industry standards and regulations.

Q 12. Discuss the regulations and standards related to biodiesel production and use.

Regulations and standards for biodiesel production and use vary across countries and regions, but generally aim to ensure quality, safety, and environmental protection.

Key aspects include:

- Quality standards: Organizations like ASTM International and EN (European Norm) publish standards that define the physical and chemical properties of biodiesel, such as cetane number, viscosity, and free fatty acid content. These standards ensure consistent quality and performance.

- Feedstock regulations: Some regulations govern the types of feedstocks that can be used for biodiesel production, potentially restricting the use of certain crops or waste streams due to environmental or sustainability concerns.

- Emission standards: Biodiesel must meet emission standards similar to or better than those of petroleum diesel. Regulations often focus on reducing particulate matter, nitrogen oxides, and greenhouse gas emissions.

- Blending requirements: Many countries mandate or incentivize the blending of biodiesel with petroleum diesel, with varying percentages of blending allowed or required.

- Transportation and storage: Regulations address the safe transportation, handling, and storage of biodiesel to prevent spills and other hazards.

Adherence to these regulations and standards is vital for ensuring the safe and responsible production and use of biodiesel, promoting sustainable fuel practices, and protecting the environment.

Q 13. How do you manage the supply chain for renewable fuels?

Managing the supply chain for renewable fuels requires a robust and integrated approach. It starts with securing reliable sources of feedstock, ensuring their sustainability and traceability. This involves working closely with farmers, processors, and other stakeholders to ensure a consistent supply.

Key aspects of supply chain management include:

- Feedstock sourcing: Identifying sustainable and cost-effective sources of feedstock, considering factors such as geographical location, transportation costs, and environmental impact.

- Quality control: Implementing rigorous quality control measures throughout the supply chain, from feedstock procurement to biodiesel production and distribution.

- Logistics and transportation: Efficiently managing the transportation and storage of feedstock and biodiesel to minimize costs and environmental impacts.

- Inventory management: Optimizing inventory levels to ensure sufficient supply while avoiding waste or spoilage.

- Risk management: Identifying and mitigating risks throughout the supply chain, such as feedstock price volatility, weather events, and geopolitical factors.

- Technology integration: Leveraging technologies such as blockchain to improve transparency and traceability in the supply chain, enabling better monitoring and accountability.

Effective supply chain management ensures the availability of sustainable and high-quality renewable fuels, contributing to the success of the biofuel industry and achieving environmental goals. Collaboration across the supply chain is critical for efficiency, sustainability, and cost-effectiveness.

Q 14. Describe the different types of renewable fuel technologies.

Renewable fuel technologies encompass a wide range of methods for producing fuels from renewable sources. These technologies can be broadly categorized into:

- Biodiesel: Produced through transesterification of vegetable oils or animal fats, as discussed earlier.

- Bioethanol: Fermented from sugar-rich feedstocks such as corn, sugarcane, or cellulosic biomass (e.g., agricultural residues).

- Biobutanol: Produced through fermentation, offering some advantages over bioethanol, such as higher energy density and lower corrosiveness.

- Biogas: Generated through anaerobic digestion of organic waste materials, producing methane which can be used as a fuel or upgraded to biomethane for injection into natural gas pipelines.

- Green diesel: Hydrotreated vegetable oil (HTVO) or hydroprocessed esters and fatty acids (HEFA), produced through a catalytic process that upgrades vegetable oils or fats to a diesel-like fuel.

- Advanced biofuels: These include fuels derived from algae, municipal solid waste, or other non-food sources, aiming to reduce competition with food production and minimize environmental impact.

The choice of renewable fuel technology depends on factors such as feedstock availability, infrastructure, cost-effectiveness, and environmental impact. Technological advancements continue to improve the efficiency and sustainability of these technologies.

Q 15. What are the sustainability considerations in renewable fuel production?

Sustainability in renewable fuel production hinges on minimizing environmental impact throughout the entire lifecycle, from feedstock cultivation to fuel distribution. It’s not just about using renewable resources; it’s about responsible resource management.

Feedstock Selection: Choosing sustainable feedstocks is crucial. For biodiesel, this means prioritizing non-food crops like algae or waste oils, reducing competition with the food supply. Using waste products minimizes land use and reduces the carbon footprint.

Land Use and Water Consumption: Renewable fuel production shouldn’t lead to deforestation or excessive water depletion. Careful planning and efficient irrigation techniques are essential, particularly for crops like Jatropha or algae.

Greenhouse Gas Emissions: The primary benefit of renewable fuels is their lower greenhouse gas emissions compared to fossil fuels. This requires analyzing the entire production process, from fertilizer use to transportation, to ensure a net reduction in emissions. Life cycle assessment (LCA) studies are vital in quantifying this.

Waste Management: Effective waste management strategies are critical. Biodiesel production generates byproducts like glycerin; responsible processing and utilization of these byproducts prevent environmental contamination.

Social Impact: Sustainability also involves considering the social aspects. This encompasses fair labor practices, community engagement, and ensuring the production doesn’t negatively impact local livelihoods.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the quality and safety of renewable fuels?

Ensuring the quality and safety of renewable fuels involves rigorous testing and adherence to industry standards. This is crucial for both environmental protection and engine performance.

ASTM Standards: We adhere strictly to standards set by organizations like ASTM International. These standards define specifications for fuel properties like viscosity, cetane number (for ignition quality), and the presence of contaminants. Regular testing against these standards is non-negotiable.

Quality Control at Each Stage: Quality control checks are implemented at every stage of the production process—from feedstock analysis to the final product. This includes monitoring parameters like free fatty acid content, water content, and sediment levels in biodiesel.

Contaminant Removal: Effective filtration and purification steps are vital to remove impurities that could damage engines or compromise fuel performance. For example, removing water is critical to prevent microbial growth and corrosion.

Regular Inspections and Audits: Regular plant inspections and external audits ensure adherence to safety protocols and quality standards. This includes assessing storage facilities, handling procedures, and emergency response plans.

Traceability: Maintaining a clear chain of custody and traceability ensures that the fuel’s origin and quality can be easily verified throughout the supply chain.

Q 17. Explain the role of government policies in promoting the use of renewable fuels.

Government policies play a vital role in driving the adoption of renewable fuels. They incentivize production and consumption through a variety of mechanisms.

Tax Credits and Subsidies: Tax credits and subsidies directly reduce the cost of producing and using renewable fuels, making them more competitive with fossil fuels. This is often crucial in the early stages of market development.

Renewable Portfolio Standards (RPS): RPS mandates require electricity providers or fuel suppliers to generate a certain percentage of their energy from renewable sources. This creates a guaranteed market for renewable fuels.

Blending Mandates: These mandates require a certain percentage of renewable fuels to be blended with conventional fuels, increasing their market penetration.

Carbon Pricing Mechanisms: Carbon taxes or cap-and-trade systems make fossil fuels more expensive, increasing the relative competitiveness of renewable fuels.

Research and Development Funding: Government funding supports research into new technologies and feedstocks, leading to cost reductions and performance improvements in renewable fuel production.

For instance, the US has the Renewable Fuel Standard (RFS), while the EU has its Renewable Energy Directive, both aiming to increase renewable fuel usage through policy mechanisms.

Q 18. Describe the potential environmental impacts of using renewable fuels.

While renewable fuels offer significant environmental advantages, it’s crucial to acknowledge their potential impacts. A holistic approach is necessary, focusing on minimizing any negative effects.

Land Use Change: Large-scale cultivation of certain feedstocks can lead to deforestation or habitat loss if not managed sustainably. Careful planning and responsible land management practices are crucial.

Water Consumption: Some feedstocks require significant water resources for cultivation, particularly in arid regions. Efficient irrigation techniques and water-saving strategies are vital.

Fertilizer Use: Excessive fertilizer use can cause water pollution and harm biodiversity. Sustainable farming practices are essential to minimize these impacts.

Greenhouse Gas Emissions from Production: Although the overall emissions are lower than fossil fuels, some greenhouse gases are emitted during the production process. Optimizing processes and using energy-efficient technologies can minimize this.

Air Quality Impacts: While generally cleaner than fossil fuels, emissions from renewable fuel combustion might still contribute to air pollution depending on the specific fuel and combustion efficiency.

It’s important to note that the environmental impact varies significantly depending on the specific feedstock and production methods. Life cycle assessments are crucial in evaluating the net environmental benefit.

Q 19. What are the economic incentives for using renewable fuels?

Economic incentives for using renewable fuels are multifaceted and significant, impacting both producers and consumers.

Reduced Fuel Costs (Long-Term): Although initial investments might be higher, the long-term cost of renewable fuels can be lower than fossil fuels, particularly with increasing fossil fuel prices and government support.

Energy Independence and Security: Renewable fuels reduce reliance on foreign oil imports, improving energy security and reducing vulnerability to global price fluctuations.

Economic Growth and Job Creation: The renewable fuel industry creates jobs in rural areas, supporting local economies and diversifying employment opportunities.

Improved Balance of Payments: Reduced reliance on imported fossil fuels improves a nation’s balance of payments, freeing up resources for other investments.

Environmental Compliance and Market Access: Stricter environmental regulations increasingly make renewable fuels a necessity for compliance, opening new market opportunities.

For example, biodiesel producers often benefit from government incentives, reducing production costs and increasing their competitiveness. For consumers, long-term fuel cost savings can be substantial, offsetting initial higher investments.

Q 20. How do you optimize the efficiency of biodiesel production processes?

Optimizing biodiesel production efficiency focuses on maximizing yield, minimizing waste, and reducing energy consumption.

Process Optimization: This includes fine-tuning reaction parameters like temperature, pressure, and reaction time to achieve high conversion rates of feedstock to biodiesel.

Catalyst Selection: Choosing the right catalyst is crucial for efficient transesterification, the chemical process that converts oils and fats to biodiesel. Homogenous and heterogeneous catalysts are used with distinct advantages and disadvantages.

Feedstock Pretreatment: Proper pretreatment of feedstocks (e.g., removing impurities, adjusting free fatty acid content) improves reaction efficiency and reduces byproduct formation.

Waste Minimization: Efficient byproduct recovery and utilization (e.g., recovering glycerin) minimizes waste and can create additional revenue streams.

Energy Integration: Integrating renewable energy sources, like solar or wind power, into the production process reduces reliance on fossil fuels and minimizes the carbon footprint.

For instance, employing advanced process control systems can monitor and adjust reaction parameters in real time, maximizing efficiency and minimizing waste. The use of supercritical methanol can significantly increase reaction rates.

Q 21. What are the safety procedures for handling and storing biodiesel?

Safety in handling and storing biodiesel is paramount, given its flammability and potential health effects.

Proper Storage Tanks: Biodiesel should be stored in approved tanks designed for flammable liquids. These tanks need to be properly grounded to prevent static electricity buildup.

Ventilation: Adequate ventilation is critical in storage areas and processing facilities to prevent the buildup of flammable vapors.

Spill Containment: Spill containment measures, such as berms or secondary containment systems, should be in place to prevent environmental contamination in case of a spill.

Personal Protective Equipment (PPE): Workers handling biodiesel should always wear appropriate PPE, including gloves, eye protection, and respiratory protection. Skin contact should be avoided.

Fire Safety Measures: Fire extinguishers and other fire suppression systems appropriate for flammable liquids should be readily available.

Proper Labeling and Handling Procedures: All containers must be clearly labeled with hazard warnings. Detailed handling procedures should be established and followed by all personnel.

Regular inspections and maintenance of storage facilities and equipment are essential for preventing accidents. Proper training for all personnel is also vital to ensuring safe handling and storage.

Q 22. Discuss the various technologies for renewable energy integration.

Integrating renewable energy sources into our energy infrastructure requires a multifaceted approach. Several key technologies play crucial roles.

- Photovoltaic (PV) Solar Power: Sunlight is converted directly into electricity using solar panels. This is a widely adopted technology, constantly improving in efficiency and cost-effectiveness. For example, large-scale solar farms are becoming increasingly common, providing renewable power to grids.

- Concentrated Solar Power (CSP): This technology uses mirrors or lenses to focus sunlight onto a receiver, generating heat that drives a turbine to produce electricity. CSP plants can incorporate thermal energy storage, allowing for power generation even at night.

- Wind Energy: Wind turbines capture kinetic energy from wind and convert it into electricity. Offshore wind farms are particularly promising due to higher and more consistent wind speeds.

- Biomass Energy: Organic matter, including agricultural residues and dedicated energy crops, is converted into biofuels or biogas, which can be used for heat, electricity, or transportation.

- Hydropower: The energy of flowing water is harnessed to generate electricity. While a mature technology, improvements in dam design and turbine efficiency are continually improving output and minimizing environmental impacts.

- Geothermal Energy: This harnesses heat from the Earth’s interior to generate electricity or provide direct heating. Geothermal power plants are particularly suitable for regions with high geothermal activity.

These technologies often work in synergy. For example, a biorefinery might use solar power to supplement its energy needs while producing biofuels.

Q 23. Explain the concept of carbon footprint reduction through renewable fuels.

Renewable fuels, such as biodiesel, offer a significant pathway to reduce carbon footprints compared to fossil fuels. This reduction stems from the carbon cycle. Plants used to produce biodiesel absorb CO2 during their growth through photosynthesis. When this biodiesel is combusted, the CO2 released is largely offset by the CO2 absorbed during the plant’s growth.

Unlike fossil fuels, which release carbon that has been sequestered for millions of years, the net carbon emissions from renewable fuels are significantly lower. This reduction is further enhanced by using sustainable feedstocks and efficient production methods. For instance, using waste cooking oil instead of virgin vegetable oils reduces the land and resource use associated with biodiesel production, decreasing the overall environmental impact.

Quantifying the carbon footprint reduction requires a Life Cycle Assessment (LCA), which evaluates the environmental impacts of a product throughout its entire life cycle, from raw material extraction to end-of-life disposal. LCAs help identify areas for further improvements in sustainability.

Q 24. What are the future trends and advancements in biodiesel production?

The future of biodiesel production is bright, driven by technological advancements and a growing demand for sustainable transportation fuels.

- Advanced Feedstocks: Research is focused on utilizing non-food feedstocks like algae, microalgae, and agricultural waste to reduce competition with food production. Algae, in particular, holds immense potential due to its high oil content and rapid growth rate.

- Improved Catalysts and Processes: Developing more efficient and cost-effective catalysts for transesterification (the process of converting vegetable oils into biodiesel) is a major area of focus. This includes exploring heterogeneous catalysts, which are easier to separate from the biodiesel product, simplifying downstream processing.

- Process Intensification: Techniques like supercritical fluid extraction and microwave-assisted transesterification are being investigated to enhance reaction rates and reduce energy consumption.

- Integration with Biorefineries: Biorefineries are increasingly designed to produce multiple products from a single feedstock, creating a more sustainable and economically viable system. This can include biodiesel, biogas, and other bio-based chemicals.

- Automation and AI: Automation and artificial intelligence are being implemented to optimize biodiesel production processes, improve efficiency, and enhance quality control.

These advancements promise a more sustainable, efficient, and economically competitive biodiesel industry.

Q 25. How do you manage the waste generated during biodiesel production?

Waste management in biodiesel production is critical for environmental protection and economic viability. The primary waste streams include glycerin (a byproduct of transesterification), spent catalyst, and wash water.

- Glycerin: Glycerin is a valuable byproduct that can be purified and used in various industries, such as cosmetics, pharmaceuticals, and food processing. Finding efficient and cost-effective purification methods is crucial for maximizing its value.

- Spent Catalyst: Depending on the catalyst used, spent catalysts can be regenerated or disposed of responsibly according to environmental regulations. Regeneration reduces waste and saves costs, while responsible disposal minimizes environmental risks.

- Wash Water: Wash water contains residual soapstock and other impurities. Proper treatment, such as settling, filtration, and possibly biological treatment, is necessary before discharge to protect water quality.

Implementing a robust waste management plan is essential for a successful and environmentally friendly biodiesel operation. This includes investing in appropriate treatment technologies, adhering to environmental regulations, and exploring opportunities to valorize waste streams as valuable products.

Q 26. Explain the role of different fuel additives in enhancing biodiesel performance.

Fuel additives play a vital role in enhancing biodiesel performance and addressing some of its limitations. These additives can improve properties like cold flow, oxidation stability, and lubricity.

- Cold Flow Improvers: Biodiesel’s high cloud point (the temperature at which it starts to cloud) can hinder its use in cold climates. Additives like methyl esters of fatty acids or synthetic polymers can reduce the cloud point, ensuring better cold flow performance.

- Antioxidants: Biodiesel is susceptible to oxidation, which can lead to gum formation and engine deposits. Antioxidants, such as tertiary butylhydroquinone (TBHQ) or vitamin E, delay oxidation and improve the storage stability of biodiesel.

- Lubricity Improvers: Biodiesel’s lubricity can be lower than that of petroleum diesel, potentially causing increased wear on fuel injectors and other engine components. Additives like fatty acid methyl esters (FAMEs) or synthetic esters can improve lubricity.

- Cetane Improvers: Cetane number is a measure of ignition quality. While biodiesel typically has a good cetane number, additives can further enhance it, particularly for blends with petroleum diesel.

The selection of appropriate additives depends on the specific biodiesel feedstock, the desired performance characteristics, and the engine type. Careful consideration and testing are necessary to ensure compatibility and optimal performance.

Q 27. Describe the different types of biorefineries and their functionalities.

Biorefineries are facilities that process biomass into a range of bio-based products. Different types of biorefineries exist, depending on the feedstock and the desired products.

- First-Generation Biorefineries: These primarily use food crops (like corn, sugarcane, or soybeans) to produce biofuels (like ethanol or biodiesel). While established, they face challenges related to food security and land use.

- Second-Generation Biorefineries: These utilize lignocellulosic biomass (non-food biomass like agricultural residues, wood chips, or dedicated energy crops) to produce biofuels and other bio-based chemicals. This approach aims to reduce competition with food production and maximize resource utilization.

- Third-Generation Biorefineries: These use microalgae or other advanced feedstocks to produce biofuels and other high-value products. While still under development, they hold the potential for very high yields and reduced environmental impact.

- Integrated Biorefineries: These are designed to produce multiple products from a single feedstock, maximizing resource utilization and reducing waste. For example, an integrated biorefinery could produce biodiesel, biogas, bio-based chemicals, and even electricity.

The choice of biorefinery type depends on various factors including feedstock availability, economic viability, environmental considerations, and technological advancements.

Q 28. How do you address the challenges of scaling up biodiesel production?

Scaling up biodiesel production presents numerous challenges, including ensuring consistent feedstock supply, managing waste, and meeting stringent quality standards.

- Feedstock Supply: Securing a reliable and sustainable supply of high-quality feedstock is crucial. This may require developing strategic partnerships with farmers and exploring diverse feedstock sources to mitigate risks associated with relying on a single source.

- Process Optimization: Scaling up requires optimizing the production process to maintain efficiency and consistency at larger scales. This includes designing efficient reactors, optimizing reaction parameters, and implementing advanced process control systems.

- Waste Management: Proper waste management becomes increasingly critical at larger scales. This requires investing in appropriate treatment technologies and exploring opportunities to valorize waste streams to reduce environmental impact and potentially generate additional revenue.

- Quality Control: Maintaining consistent product quality is essential for meeting market demands and regulatory requirements. Implementing rigorous quality control measures, including standardized testing procedures, is critical throughout the production process.

- Economic Viability: Scaling up requires careful financial planning and risk assessment. This involves evaluating production costs, market demand, and pricing strategies to ensure economic viability and profitability.

Addressing these challenges requires a holistic approach involving technological advancements, efficient management practices, and strong collaborations across the biodiesel value chain.

Key Topics to Learn for Biodiesel and Renewable Fuel Management Interview

- Biodiesel Production Processes: Understand the different methods of biodiesel production (e.g., transesterification), including feedstock selection, reaction parameters, and product purification.

- Feedstock Analysis and Quality Control: Learn about analyzing the quality of various feedstocks (e.g., vegetable oils, animal fats) and ensuring they meet the required specifications for biodiesel production. This includes understanding relevant standards and testing procedures.

- Renewable Fuel Properties and Specifications: Familiarize yourself with the physical and chemical properties of biodiesel and other renewable fuels, and how these properties impact their performance and compatibility with existing infrastructure.

- Engine Performance and Emissions: Understand the impact of using biodiesel blends on engine performance, emissions (including greenhouse gas emissions), and fuel efficiency.

- Sustainability and Life Cycle Assessment: Grasp the environmental implications of biodiesel production and utilization, including carbon footprint analysis and the overall sustainability of the process.

- Storage and Handling: Learn about the safe storage and handling practices for biodiesel and other renewable fuels, addressing potential safety concerns.

- Economic Aspects of Biodiesel Production: Understand the economic factors influencing biodiesel production, including feedstock costs, production costs, and market dynamics.

- Regulatory Compliance and Standards: Become familiar with relevant regulations and standards related to biodiesel production, distribution, and use.

- Problem-Solving in Biodiesel Production: Prepare to discuss troubleshooting common problems encountered during biodiesel production, such as catalyst deactivation or byproduct removal.

- Future Trends in Renewable Fuels: Research emerging technologies and future trends in renewable fuel production and utilization, showing your forward-thinking approach.

Next Steps

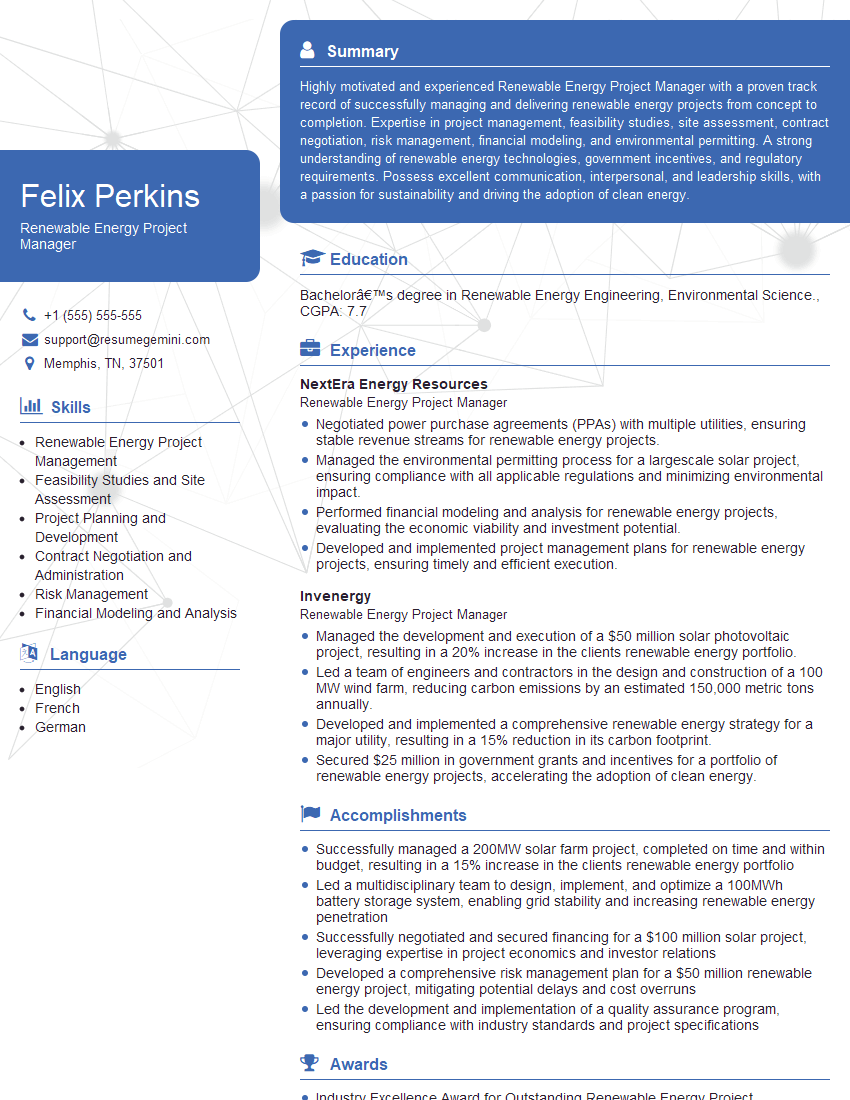

Mastering Biodiesel and Renewable Fuel Management opens doors to exciting career opportunities in a rapidly growing industry focused on sustainability and energy security. A strong understanding of these concepts significantly enhances your employability and positions you for leadership roles. To maximize your job prospects, it’s crucial to create an ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini is a trusted resource that can help you build a professional, impactful resume tailored to the specific requirements of the Biodiesel and Renewable Fuel Management sector. Examples of resumes tailored to this field are available to help guide you. Take the next step in your career journey and craft a resume that makes a lasting impression.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.