Are you ready to stand out in your next interview? Understanding and preparing for Brazing Machine Operation interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Brazing Machine Operation Interview

Q 1. What types of brazing processes are you familiar with?

Brazing is a joining process that uses a filler metal with a lower melting point than the base metals being joined. I’m familiar with several brazing processes, each offering advantages depending on the application. These include:

- Torch Brazing: A manual process where a filler metal is melted using a torch. This is versatile but relies heavily on the operator’s skill for consistent results. I’ve used this extensively for smaller, intricate parts where automation isn’t feasible.

- Furnace Brazing: Parts are placed in a furnace where they’re heated to the brazing temperature. This allows for high-volume, consistent brazing. I’ve worked with large batch furnace brazing for automotive components and heat exchangers.

- Induction Brazing: Uses electromagnetic induction to heat the parts locally, providing precise heat control. This is ideal for joining dissimilar metals or for intricate geometries. My experience includes working with induction brazing machines for high-precision electronic components.

- Dip Brazing: Parts are submerged in a molten bath of brazing filler metal. This is very efficient for high-volume, simple geometries. I’ve supervised this process for the mass production of small metal parts.

Q 2. Describe your experience with different brazing filler metals.

The choice of filler metal is critical to a successful braze joint. The filler metal must be compatible with the base metals, have the correct melting point, and possess the desired mechanical properties. I have extensive experience with various filler metal compositions, including:

- Silver-based alloys: Offer high strength and corrosion resistance. These are commonly used in high-performance applications like aerospace and electronics. I’ve specifically worked with Ag-Cu alloys in aerospace component brazing.

- Copper-based alloys: More cost-effective than silver-based alloys but offer slightly lower strength. I’ve used these for applications where cost is a major factor, such as plumbing fittings.

- Nickel-based alloys: Excellent for high-temperature applications and offer great corrosion resistance. These are frequently used in industrial settings like power generation. I’ve successfully used Nickel-based alloys for brazing components in high-stress environments.

- Aluminum-based alloys: Used for brazing aluminum and its alloys. I’ve worked with these extensively in aerospace and automotive applications where lightweight materials are desired.

Selecting the right filler metal involves considering factors like the base metals, required strength, corrosion resistance, and cost.

Q 3. Explain the importance of pre-cleaning parts before brazing.

Pre-cleaning is paramount for a successful braze joint. Oxides and other contaminants on the surface of the parts prevent proper wetting and capillary flow of the filler metal, leading to weak or incomplete joints. This is like trying to glue two pieces of wood together without first cleaning off dust and grime – it simply won’t stick properly.

My cleaning procedures typically include:

- Solvent cleaning: Using appropriate solvents to remove grease, oil, and other organic contaminants.

- Mechanical cleaning: Using abrasive blasting, wire brushing, or other methods to remove loose oxides and scale.

- Chemical cleaning: Employing pickling or etching processes to remove stubborn oxides or other contaminants. This step is often critical for achieving a properly prepared surface.

Thorough cleaning ensures that the filler metal wets the base metal surfaces effectively, resulting in a strong and reliable braze joint.

Q 4. How do you ensure consistent braze joint quality?

Consistent braze joint quality is crucial for product reliability. I achieve this by carefully controlling several key parameters:

- Precise temperature control: Using calibrated equipment to ensure that the parts reach the correct brazing temperature. This includes monitoring the temperature profile of the furnace or induction coil closely.

- Proper fixturing: Ensuring parts are correctly positioned and held together during the brazing process. This prevents warping and ensures consistent joint geometry.

- Controlled atmosphere: Minimizing oxidation by using a protective atmosphere (e.g., inert gas) during the brazing process. This is especially important for reactive metals.

- Careful filler metal application: Ensuring the correct amount of filler metal is placed in the joint and spread evenly. I employ techniques like preplacing filler metal or using controlled dispensing systems.

- Regular quality checks: Conducting thorough inspections of the brazed joints to ensure they meet specified standards. This involves visual inspection, dimensional checking, and sometimes destructive testing.

Through a meticulous approach to these factors, I maintain consistent braze joint quality which directly translates to enhanced product performance and longevity.

Q 5. What safety precautions do you follow when operating a brazing machine?

Safety is paramount when operating brazing equipment. My safety procedures are stringent and include:

- Eye protection: Wearing appropriate safety glasses or face shields to protect against ultraviolet radiation, sparks, and molten metal splashes.

- Respiratory protection: Utilizing respirators or ventilation systems to avoid inhaling fumes from the brazing process, especially when using flux or filler metals with volatile constituents.

- Heat protection: Using heat-resistant gloves and clothing to prevent burns from hot parts or equipment.

- Proper ventilation: Ensuring adequate ventilation in the work area to remove fumes and gases.

- Fire prevention: Keeping fire extinguishers nearby and ensuring flammable materials are stored safely away from the brazing area.

- Personal Protective Equipment (PPE): Always wearing the appropriate PPE for the specific task including safety shoes.

I strictly adhere to all safety regulations and company policies to ensure a safe working environment for myself and my colleagues.

Q 6. How do you troubleshoot common brazing machine malfunctions?

Troubleshooting brazing machine malfunctions requires a systematic approach. I typically follow these steps:

- Identify the problem: Determine the specific issue by observing the machine’s behavior and analyzing any error messages.

- Check the basics: Verify power supply, gas supply, and coolant flow, as many issues stem from simple causes. For example, a faulty gas regulator could lead to inconsistent heating.

- Inspect components: Visually inspect the heating elements, electrodes (in induction brazing), and other critical components for damage or wear. Worn heating elements could result in uneven heating and weak braze joints.

- Check the controls: Ensure the machine’s control system is functioning properly. This might involve checking settings, calibrations, and sensor readings. If the controller displays an error, I consult the manufacturer’s documentation.

- Consult documentation: Refer to the machine’s manual or contact the manufacturer’s technical support for assistance with more complex problems.

By systematically checking these points, I can usually identify and rectify the issue quickly, minimizing downtime and ensuring the machine operates effectively.

Q 7. What are the signs of a faulty braze joint?

Identifying a faulty braze joint requires careful inspection. Signs of a poor braze joint include:

- Porosity: Presence of voids or pores in the braze joint, indicating incomplete filling or gas entrapment. This will often result in reduced joint strength and corrosion.

- Incomplete penetration: The filler metal hasn’t fully penetrated the joint, leaving gaps between the base metals. This weakness is a major cause of failure.

- Lack of fusion: The filler metal hasn’t properly bonded with the base metals, resulting in a weak joint. This manifests as a lack of continuity across the joint.

- Excessive filler metal: Too much filler metal can indicate problems with pre-cleaning or assembly, potentially leading to cracking.

- Discoloration or cracking: Unusual discoloration or cracks in the braze joint indicate potential metallurgical issues or defects.

I employ a combination of visual inspection, dimensional checks, and sometimes destructive testing (like tensile testing or cross-sectional analysis) to thoroughly assess braze joint quality and identify any defects.

Q 8. Describe your experience with different brazing machine types (e.g., induction, torch).

My experience encompasses a wide range of brazing machine types, primarily focusing on induction and torch brazing. Induction brazing, which I’ve used extensively in high-volume manufacturing settings, offers precise temperature control and rapid heating, ideal for consistent braze joints. Think of it like a microwave for metal—it heats the workpiece directly and efficiently. I’ve worked with both automated and manual induction brazing systems, mastering setup, programming, and troubleshooting. Torch brazing, on the other hand, is more versatile for smaller-scale operations and unique geometries where localized heating is needed. It’s like wielding a precise flamethrower, requiring skill and experience to achieve uniform heating and prevent overheating.

For example, in one project, we used induction brazing to join thousands of copper heat sinks to electronic components. The speed and consistency of the induction process significantly increased our output. In another project, we employed torch brazing to repair a complex stainless steel assembly that wasn’t suitable for induction due to its intricate design and varying metal thicknesses. This required a delicate touch and precise flame manipulation.

Q 9. How do you maintain and clean a brazing machine?

Maintaining a brazing machine is crucial for its longevity and safety. It’s a multi-step process starting with daily cleaning. This involves removing excess brazing filler metal, flux residues, and any splatter from the machine’s components. I always use appropriate safety equipment, such as gloves and eye protection, during cleaning. Regularly inspect the machine for wear and tear, paying close attention to critical components such as heating elements (for induction brazing), gas lines (for torch brazing), and the control panel. Any signs of damage or malfunction should be addressed immediately to prevent further issues. A preventative maintenance schedule is essential. This might involve periodic replacement of worn parts, calibration of sensors, and thorough inspections by qualified technicians.

Think of it like maintaining a car: regular oil changes and inspections prevent major breakdowns. Similarly, consistent cleaning and preventative maintenance of a brazing machine ensure optimal performance and reduce downtime.

Q 10. What are the key parameters to monitor during brazing (temperature, time, pressure)?

Monitoring key parameters is crucial for consistent and high-quality brazing. Temperature is the most critical parameter, ensuring the brazing filler metal melts and flows properly without overheating the base materials. We monitor this using thermocouples or infrared temperature sensors, ensuring the temperature is within the specified range for the chosen brazing alloy and base materials. Time is also important, as insufficient dwell time can result in weak joints, while excessive time can lead to material degradation. Pressure, especially in vacuum or pressurized brazing, needs careful monitoring to ensure proper filler metal flow and prevent voids or porosity in the braze joint. All these parameters are interlinked, requiring a balance for successful brazing. For example, inadequate pressure in a vacuum brazing system could lead to incomplete filler metal flow, resulting in a weak joint.

Q 11. How do you interpret brazing machine control panel readings?

Interpreting brazing machine control panel readings is a fundamental skill. Different machines have varying displays, but common elements include temperature readings, pressure gauges (if applicable), timers, and error codes. Understanding the machine’s normal operating range is essential for identifying deviations. For example, a sudden drop in temperature during induction brazing might indicate a problem with the power supply or heating element, while an error code might signal a malfunctioning sensor or safety system. My experience allows me to quickly diagnose potential issues from control panel readings and take appropriate corrective actions.

Imagine the control panel as a car’s dashboard—it provides vital information about the machine’s health and performance. Being able to interpret this information accurately is essential for effective operation and troubleshooting.

Q 12. What experience do you have with different brazing alloys and their applications?

My experience covers a broad spectrum of brazing alloys, including silver-based, copper-based, and nickel-based alloys. The choice of alloy depends on the base materials being joined, the desired joint strength, and the operating temperature. Silver-based alloys, for instance, are known for their high strength and excellent corrosion resistance, making them suitable for joining precious metals or applications requiring high reliability. Copper-based alloys are often preferred for their good thermal and electrical conductivity, while nickel-based alloys can withstand high temperatures and harsh environments. I’ve used various alloys in diverse applications, including joining stainless steel in automotive exhaust systems, brazing copper tubing in HVAC systems, and creating intricate assemblies in the electronics industry. Selecting the correct alloy is critical for achieving the desired joint properties.

Q 13. Explain your understanding of braze joint design and its effect on strength.

Braze joint design is critical for achieving the desired strength and reliability. Factors such as joint clearance, surface preparation, and the geometry of the joint significantly impact the final strength. A properly designed joint ensures that the filler metal flows smoothly and completely fills the gap between the base materials, creating a strong metallurgical bond. Insufficient clearance can lead to incomplete filler metal flow and weak joints, while excessive clearance can result in porosity and reduced strength. Surface preparation, including cleaning and degreasing, is also vital for ensuring proper wetting and adhesion of the filler metal. Joint geometry, such as the shape and size of the joint, should be optimized for even heat distribution and stress relief, improving the overall joint strength. For example, a lap joint usually provides better strength compared to a butt joint.

Q 14. How do you ensure proper joint fit-up before brazing?

Ensuring proper joint fit-up before brazing is crucial for a strong and reliable joint. This involves accurately aligning and clamping the parts to be joined, ensuring consistent joint clearance throughout. Techniques like using jigs and fixtures, ensuring proper surface cleanliness and removal of any burrs or imperfections, and careful alignment are crucial steps. I often use precision measuring tools, such as calipers and micrometers, to check the joint clearance and ensure it’s consistent with the requirements of the chosen brazing alloy and joint design. Proper fit-up minimizes the risk of incomplete filler metal flow, voids, and porosity, leading to a stronger and more reliable braze joint. Imagine trying to glue two pieces of wood together—precise alignment is crucial for a strong bond. The same principle applies to brazing.

Q 15. What are the limitations of brazing?

Brazing, while a versatile joining process, does have limitations. One key limitation is the temperature requirement; the base materials must withstand the brazing temperature without melting or degrading. This restricts its use with certain heat-sensitive materials like some plastics or low-melting-point metals.

Another limitation is the need for precise joint design and cleanliness. Oxides and contaminants on the joint surfaces can prevent proper wetting and bonding, resulting in weak or failed brazes. This requires careful surface preparation.

Finally, brazing may not be suitable for joining dissimilar materials with significantly different coefficients of thermal expansion. Differential expansion and contraction during heating and cooling can cause stress and cracking in the braze joint. For instance, brazing aluminum to steel requires careful consideration of this issue.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with quality control procedures in brazing.

My experience with quality control in brazing involves a multi-faceted approach. It starts with meticulously inspecting the base materials for defects like cracks, porosity, or contamination before the brazing process begins. This is crucial because imperfections in the base material will likely lead to weak joints.

During the brazing process, I monitor parameters like temperature, time, and pressure to ensure they remain within the specified process window. Deviations from these parameters can significantly impact the quality of the braze joint. For example, insufficient time at brazing temperature can result in incomplete bonding, while overheating can damage the base material. I regularly calibrate equipment to guarantee the accuracy of readings.

Post-brazing inspection is equally important. I use visual inspection to assess joint appearance and then use techniques like dye penetrant testing to detect surface cracks and radiographic inspection (X-ray) to detect internal flaws. Dimensions are also checked to ensure they meet specifications. Documentation of all these checks is mandatory.

Q 17. What documentation do you maintain during brazing operations?

Comprehensive documentation is critical for traceability and quality control in brazing. The documents I maintain include:

- Material Certificates: Verification of the base materials’ chemical composition and properties.

- Process Parameters Logs: Detailed records of temperature, time, pressure, and gas flow rates during each brazing cycle.

- Inspection Reports: Documentation of all visual and non-destructive testing (NDT) methods employed, along with results and images.

- Operator Logs: Records of the operator’s name, date, time, and any observations or unusual occurrences during the process.

- Calibration Records: Proof that all equipment used (temperature controllers, timers, etc.) is calibrated and functioning correctly.

- Non-Conformance Reports: Documentation of any defects found during inspection, the corrective actions taken, and the disposition of the affected parts.

Q 18. How do you handle non-conforming braze joints?

Handling non-conforming braze joints requires a systematic approach. First, the nature and extent of the defect are carefully documented in a Non-Conformance Report (NCR). This NCR becomes a critical piece of documentation explaining the failure of the part.

Then, a root cause analysis is conducted to determine the underlying cause of the defect. Was it due to incorrect process parameters, faulty materials, or operator error? This step is important for preventing future occurrences.

Depending on the severity of the defect and the application, the non-conforming joint may be scrapped, repaired (if feasible), or subjected to further testing. All decisions are documented and authorized by appropriate personnel, and the NCR is updated to reflect the final disposition.

Q 19. How familiar are you with different types of brazing fluxes?

I’m familiar with various brazing fluxes, each tailored to specific applications and base materials. These include:

- Organic fluxes: Typically resin-based, they’re widely used for general-purpose brazing and offer good cleaning action.

- Inorganic fluxes: Often borax-based or mixtures of borates, chlorides, and fluorides, these are effective for higher temperatures and different metal combinations.

- Activated fluxes: Contain additives that enhance their cleaning and wetting properties, particularly useful for difficult-to-braze materials.

- No-clean fluxes: Designed to leave minimal residue after brazing, eliminating the need for post-brazing cleaning—a benefit in some applications.

The choice of flux depends on several factors, including the base metals being joined, the brazing temperature, and the desired post-brazing cleanliness.

Q 20. Explain the role of flux in the brazing process.

Flux plays a crucial role in brazing by acting as a cleaning agent and a wetting aid. Its primary function is to remove oxide layers from the base metal surfaces. These oxide layers prevent the braze filler metal from properly wetting and flowing, leading to poor bonding. Flux dissolves or breaks down these oxides, creating a clean surface for the braze filler metal to adhere to.

Furthermore, flux reduces the surface tension of the molten braze filler metal, promoting better flow and penetration into the joint. This leads to stronger, more reliable braze joints. Think of it like this: the flux prepares the surface, making it receptive to the ‘glue’ (braze filler metal). Without flux, the ‘glue’ wouldn’t adhere well.

Q 21. What is your experience with automated brazing systems?

I have significant experience with automated brazing systems, having worked extensively with both induction brazing and furnace brazing systems. Automated systems offer advantages like increased production rates, improved consistency, and reduced labor costs compared to manual brazing.

In induction brazing, for instance, I’ve worked with systems that use precisely controlled electromagnetic fields to heat the workpiece locally, which leads to very efficient and accurate heating. We use programmable logic controllers (PLCs) to manage the power and time cycles for each part.

With automated furnace brazing, I’ve managed systems where parts are loaded onto conveyor systems, then moved through controlled temperature zones within the furnace. The automation here focuses on precisely controlling the heating cycle and atmosphere inside the furnace. The systems use sensors to monitor temperature profiles, ensuring consistent braze quality.

My experience includes troubleshooting automated systems, optimizing parameters for various parts, and maintaining a high level of quality control within these high-output environments.

Q 22. How do you perform preventative maintenance on a brazing machine?

Preventative maintenance on a brazing machine is crucial for ensuring its longevity, efficiency, and safety. It’s like regularly servicing your car – you catch small problems before they become major breakdowns. My preventative maintenance routine typically involves several key steps:

Visual Inspection: A thorough daily check for any loose connections, leaks, damage to the torch, or unusual wear and tear on components. I pay close attention to the heating element, ensuring there’s no cracking or discoloration indicating potential failure.

Cleaning: Regularly cleaning the brazing chamber and torch nozzles is vital to prevent build-up of flux and brazing material which can affect the quality of future brazing operations and lead to malfunctions. I use appropriate cleaning solvents and tools, following all safety procedures.

Gas Pressure Checks: Consistent monitoring of gas pressures (fuel and shielding gas) is essential. Inaccurate pressures can impact the brazing process, leading to inconsistent results or even hazards. Regular calibration of pressure gauges is also critical.

Lubrication: Moving parts, such as the torch mechanism or any automated feed systems, require regular lubrication with appropriate lubricants to prevent friction and premature wear. This ensures smooth operation and prevents potential damage.

Scheduled Maintenance: Beyond daily checks, I follow a scheduled maintenance plan according to the manufacturer’s recommendations, which may include replacing worn parts, performing more in-depth cleaning, or calibrating the temperature control systems.

By following this regimen, I ensure the machine operates consistently, produces high-quality brazed joints, and minimizes the risk of downtime or safety incidents.

Q 23. Describe a time you had to troubleshoot a complex brazing issue.

Once, we experienced inconsistent braze joint strength on a batch of stainless steel components. Initially, we suspected problems with the brazing filler metal, but after checking the lot numbers and verifying its quality, we moved to the next step.

We systematically examined other potential causes: gas flow rates, temperature profiles, and joint design. We carefully analyzed the brazing parameters using our data logging system and discovered that the temperature was fluctuating slightly beyond the acceptable range. This fluctuation was subtle and initially missed during the daily checks.

After tracing the issue back to a faulty thermocouple, we replaced it. This immediately resolved the problem, and subsequent batches displayed consistent and strong braze joints. The experience highlighted the importance of detailed record-keeping and a systematic approach to troubleshooting complex issues. It also underscored that even seemingly small inconsistencies can significantly impact the final product quality.

Q 24. What is your experience with different joint configurations?

My experience encompasses a wide range of joint configurations, including lap joints, butt joints, T-joints, and corner joints. The specific configuration selection depends on the application and the materials being brazed. Each joint design presents unique challenges and requires careful consideration of factors like surface preparation, fixturing, and brazing parameters. For example:

Lap Joints: These are relatively simple to assemble and braze, offering good strength and are commonly used in many applications.

Butt Joints: These require precise alignment and are often more challenging, needing specific fixturing to maintain alignment during the brazing process. They provide a strong, visually appealing joint.

T-Joints and Corner Joints: These more complex joints necessitate careful consideration of heat distribution and flux application to ensure complete penetration and uniform brazing. They often require specialized fixturing for proper alignment.

My expertise extends to selecting the optimal joint design for various applications, considering factors such as required strength, aesthetics, and ease of assembly. I also understand how variations in the joint design can affect the brazing process itself.

Q 25. How do you ensure the safety of yourself and your coworkers while operating a brazing machine?

Safety is paramount in brazing operations. My safety procedures begin with a thorough understanding and adherence to the company’s safety protocols and the manufacturer’s guidelines for the specific brazing machine. This includes:

Personal Protective Equipment (PPE): Always wearing appropriate PPE is non-negotiable. This includes safety glasses, heat-resistant gloves, and a protective apron to shield from heat and sparks. I also ensure proper ventilation to prevent inhalation of fumes.

Machine Operation Procedures: I strictly follow the established operating procedures for the brazing machine, paying close attention to all safety warnings and instructions. Never operating the machine if fatigued or under the influence of any substances.

Emergency Procedures: Knowing the location and proper use of fire extinguishers and other safety equipment is crucial. Regular safety training ensures that my team and I can quickly and effectively respond to any emergency situations.

Workplace Organization: Maintaining a clean and organized workspace is essential to prevent accidents. Properly storing materials and tools ensures easy access without causing potential hazards.

Teamwork: Constant communication with coworkers ensures that everyone is aware of ongoing operations and potential hazards. This is vital, especially during complex brazing tasks.

Regular safety briefings and training sessions help maintain our high safety standards and reinforce safe work practices.

Q 26. What are the environmental concerns associated with brazing?

Brazing, while a highly efficient joining process, does present some environmental concerns. Primarily, these are related to:

Fume Emissions: Brazing fluxes and filler metals can release fumes containing potentially harmful substances. Adequate ventilation is therefore absolutely critical to keep concentrations below permissible exposure limits. I utilize local exhaust ventilation systems to capture these fumes directly at the source.

Waste Disposal: Spent fluxes and cleaning solvents need to be disposed of properly according to local regulations. We follow strict waste management practices to ensure environmentally responsible disposal.

Energy Consumption: Brazing machines require energy to operate. We continuously strive to optimize our brazing processes to minimize energy consumption and reduce our carbon footprint. This includes using energy-efficient equipment and practices.

We actively participate in efforts to minimize the environmental impact of our brazing operations by employing environmentally friendly fluxes and utilizing energy-efficient equipment wherever possible.

Q 27. How do you ensure traceability of materials and processes in brazing?

Traceability is crucial in ensuring the quality and consistency of our brazed components. We meticulously track all materials and processes involved, starting with the raw materials:

Material Identification: Every batch of filler metal, base material, and flux is clearly labeled with its unique identification number, including its chemical composition and supplier information. This information is recorded in our database.

Process Parameters: We document all brazing parameters for each batch, including temperature profiles, gas flow rates, and brazing time. This data is meticulously recorded and archived, making it easily retrievable for future reference or audits.

Quality Control Inspections: Each completed batch undergoes rigorous quality control inspections, including visual inspection, dimensional checks, and strength testing. Results from these inspections are documented and linked to the specific batch’s identification number.

Database Management: We use a sophisticated database management system to store and manage all traceability data. This database allows easy retrieval of information for any specific lot number, providing a complete audit trail for all operations.

This comprehensive traceability system allows us to quickly identify and rectify any issues if a problem arises, ensuring consistent product quality and adherence to industry standards.

Q 28. What are your strengths and weaknesses as a brazing machine operator?

My strengths as a brazing machine operator include my meticulous attention to detail, proficiency in troubleshooting complex issues, and commitment to safety. I’m adept at operating a variety of brazing machines and possess a strong understanding of the various brazing techniques. I’m also a team player and enjoy collaborating with others to achieve optimal results.

A potential area for improvement is my experience with newer, automated brazing systems. While I have a strong foundation in traditional brazing techniques, expanding my expertise in automated systems would enhance my efficiency and allow me to contribute even more effectively to advanced brazing projects. I’m actively seeking opportunities to further develop my skills in this area through training and hands-on experience.

Key Topics to Learn for Brazing Machine Operation Interview

- Machine Operation & Safety Procedures: Understanding the specific machine you’ll be operating, including its controls, safety mechanisms, and emergency procedures. This includes pre-operational checks and routine maintenance.

- Brazing Processes & Techniques: Thorough knowledge of different brazing methods (e.g., torch brazing, furnace brazing), filler metal selection, and joint design for optimal strength and quality. Practical experience with various brazing alloys and their applications is crucial.

- Quality Control & Inspection: Understanding quality control methods used to ensure brazed joints meet required specifications. This involves visual inspection, dimensional checks, and potentially destructive or non-destructive testing techniques.

- Troubleshooting & Problem Solving: Ability to identify and resolve common issues such as improper joint formation, porosity, or leaks. This requires a systematic approach to diagnosing problems and implementing corrective actions.

- Material Science & Metallurgy: Basic understanding of the materials being brazed, their properties, and how those properties affect the brazing process. Knowledge of thermal expansion and contraction is beneficial.

- Production Efficiency & Optimization: Understanding the importance of efficient operation, minimizing downtime, and maximizing output while maintaining quality. This might include understanding cycle times and production targets.

- Health & Safety Regulations: Familiarity with relevant health and safety regulations pertaining to brazing operations, including the handling of hazardous materials and personal protective equipment (PPE).

Next Steps

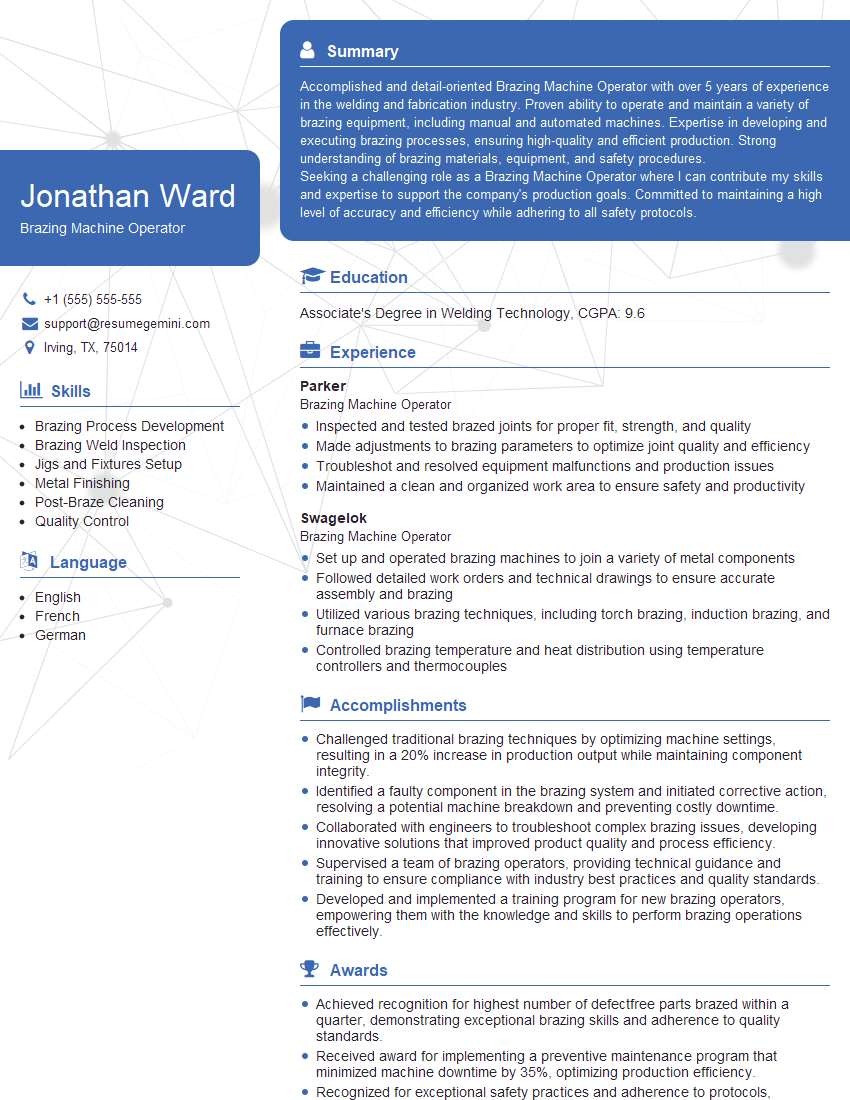

Mastering Brazing Machine Operation opens doors to a rewarding career with excellent growth potential, offering opportunities for specialization and advancement within manufacturing and related industries. To significantly increase your chances of landing your dream job, it’s essential to create a compelling, ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume that gets noticed. Examples of resumes tailored to Brazing Machine Operation are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.