The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Buffer Robotics interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Buffer Robotics Interview

Q 1. Explain the principles of robotic motion planning.

Robotic motion planning is the process of finding a collision-free path for a robot to move from a starting point to a goal point while satisfying various constraints like joint limits, obstacle avoidance, and time optimization. It’s like planning a road trip – you need to find the best route, avoid traffic (obstacles), and arrive on time (within time constraints).

This involves several key steps:

- Path Planning: Finding a collision-free path. Algorithms like A*, RRT (Rapidly-exploring Random Tree), and Dijkstra’s algorithm are commonly used. A* is like using a map app to find the shortest route. RRT is good for complex, unknown environments.

- Trajectory Generation: Creating a smooth and dynamically feasible trajectory along the planned path. This ensures the robot’s movements are smooth and physically possible, avoiding jerky motions. Think of this as fine-tuning your road trip to avoid sudden stops and starts.

- Motion Control: Implementing the trajectory using control algorithms that make the robot accurately follow the planned trajectory. This is like using the car’s steering wheel and accelerator to follow the route on your map.

Different planning approaches exist, including kinodynamic planning (considering dynamics), and multi-robot planning (coordinating multiple robots).

Q 2. Describe different types of robotic sensors and their applications.

Robotic sensors are crucial for robots to perceive their environment and interact with it. Here are some key types:

- Proximity Sensors: Detect the presence of objects without specifying their distance precisely. Ultrasonic sensors (like those in some cars’ parking assistance) and infrared sensors are examples. They’re useful for obstacle avoidance in basic navigation.

- Range Sensors: Measure the distance to objects. LIDAR (Light Detection and Ranging) and radar are prominent examples. LIDAR creates detailed 3D maps of the surroundings and is commonly used in autonomous vehicles and robots for mapping and navigation. Radar works well in poor visibility conditions.

- Vision Sensors (Cameras): Provide rich visual information about the environment. These range from simple cameras to sophisticated stereo vision systems capable of depth perception. They are used for object recognition, scene understanding, and visual servoing.

- Force/Torque Sensors: Measure forces and torques applied to the robot’s end-effector (gripper, tool). These sensors are important for tasks requiring precise interaction with objects, such as delicate assembly or grasping.

- IMU (Inertial Measurement Unit): Measures acceleration and angular velocity, providing information about the robot’s own motion. They are critical for balance and orientation in mobile robots.

The choice of sensor depends on the application. For example, a simple cleaning robot might only need proximity sensors, while a surgical robot requires highly precise force/torque and vision sensors.

Q 3. What are the advantages and disadvantages of different robot manipulators?

Robot manipulators, or robot arms, come in various designs, each with its own advantages and disadvantages:

- Revolute Manipulators (Articulated Robots): Use rotating joints. They are highly flexible and can reach a wide range of configurations, but their kinematics can be complex. Think of a human arm.

- Prismatic Manipulators: Use sliding joints. They are simpler in terms of kinematics but less flexible in terms of reachable workspace. Think of a drawer sliding in and out.

- SCARA (Selective Compliance Assembly Robot Arm): Combine both revolute and prismatic joints. These are highly precise and efficient for assembly tasks.

- Parallel Manipulators: Have multiple arms connected to a common platform. They offer high stiffness and precision but have a limited workspace. Examples include Stewart platforms.

Advantages & Disadvantages Summary:

- Revolute: High dexterity, complex kinematics

- Prismatic: Simple kinematics, limited dexterity

- SCARA: High speed and accuracy in a plane, limited dexterity

- Parallel: High stiffness and precision, limited workspace

The choice depends heavily on the specific task. A welding robot might prefer a revolute arm for its reach, whereas a pick-and-place robot might opt for a SCARA for its speed and accuracy in a 2D plane.

Q 4. How do you handle robot calibration and error compensation?

Robot calibration involves accurately determining the robot’s physical parameters (like link lengths and joint offsets) and its relationship to the workspace. Error compensation addresses inaccuracies in the robot’s motion due to various factors such as wear and tear, thermal expansion, and manufacturing tolerances.

Calibration Procedures:

- Geometric Calibration: Identifies errors in the robot’s kinematic model. This often involves using external measurement systems like laser trackers to precisely measure the robot’s position and orientation at various points.

- Kinematic Calibration: Focuses on compensating for the inaccuracies in the kinematic model. It involves adjusting the robot’s parameters to reduce the errors between the commanded positions and actual positions.

Error Compensation Techniques:

- Feedforward Compensation: Predicts and compensates for known errors based on the robot’s current state. This is like proactively adjusting your driving based on expected road conditions.

- Feedback Compensation: Uses sensor data to measure the actual robot position and orientation and adjust accordingly. This is like using a GPS and adjusting your route in real-time.

- Adaptive Control: Continuously adjusts the control parameters based on the changing environment and robot condition. This is like self-adjusting your driving style based on the ever-changing road conditions.

Regular calibration and effective error compensation are crucial for ensuring robot accuracy and repeatability, especially in precision applications like manufacturing and surgery.

Q 5. Explain the concept of inverse kinematics in robotics.

Inverse kinematics is the process of determining the joint angles of a robot manipulator required to achieve a desired end-effector pose (position and orientation) in the workspace. It’s like figuring out how to move your arm and hand to touch a specific spot on a table – you instinctively know the joint angles needed, but a robot needs to calculate them.

Forward kinematics, the opposite, calculates the end-effector pose given the joint angles. Inverse kinematics is more challenging because it involves solving a system of non-linear equations, and multiple solutions are often possible. Numerical methods like Newton-Raphson or iterative methods are commonly used to solve for the joint angles. Analytical solutions are also possible for simpler robot manipulators.

Example: Imagine a robot arm with two joints. You want the end-effector to reach a specific (x, y) coordinate. Inverse kinematics would calculate the angles of each joint needed to achieve that position. This is vital for robot control as it translates desired positions into commands that the robot can understand.

Q 6. Discuss different robot programming languages and their suitability for specific tasks.

Various robot programming languages exist, each with strengths and weaknesses:

- RAPID (ABB robots): Proprietary language for ABB robots, known for its robust features and suitability for complex industrial applications.

- KRL (KUKA robots): Similar to RAPID, a proprietary language for KUKA robots, widely used in manufacturing.

- VAL (Fanuc robots): Another proprietary language for Fanuc robots, also commonly used in industrial automation.

- ROS (Robot Operating System): Not a programming language itself, but a framework that provides libraries and tools for robot software development. It supports various languages like C++, Python, and others, and is popular for research and development due to its flexibility and extensive libraries.

- Python: A versatile language used for robot control, especially in research and prototyping. It offers ease of use and a rich ecosystem of libraries for various tasks.

Suitability for Tasks:

- Industrial tasks: Proprietary languages like RAPID and KRL excel due to their integration with the robot hardware and support for advanced features.

- Research and prototyping: ROS and Python are preferred for flexibility, ease of use, and the availability of libraries.

The choice of language often depends on the specific robot platform and the complexity of the application. Using the right programming language is crucial for efficiency and error prevention.

Q 7. Describe your experience with robotic vision systems and image processing techniques.

My experience with robotic vision systems involves designing, implementing, and integrating vision-based solutions for various robotic applications. This encompasses several stages:

- Image Acquisition: Selecting appropriate cameras (mono, stereo, RGB-D) based on the specific task requirements.

- Image Processing: Utilizing various techniques for image enhancement (noise reduction, filtering), feature extraction (edge detection, corner detection), and object recognition (using machine learning algorithms like convolutional neural networks).

- 3D Reconstruction: Employing stereo vision or RGB-D data to create 3D point clouds and meshes of the environment for robot navigation and manipulation.

- Object Recognition and Pose Estimation: Employing computer vision algorithms to identify objects within the scene and determine their location and orientation relative to the robot. This is critical for tasks such as bin picking or assembly.

- Visual Servoing: Using visual feedback to control robot movements, closing the loop between perception and action. For example, a robot may use a camera to track an object and adjust its movements to keep it centered in its view.

I’ve used various libraries and toolkits, including OpenCV, ROS’s image processing libraries, and deep learning frameworks like TensorFlow and PyTorch, depending on the project’s needs. For example, in one project, I implemented a vision system that allowed a robotic arm to pick and place randomly oriented objects from a bin, utilizing deep learning for object detection and pose estimation. This required careful calibration of the camera and robot, robust image processing techniques to handle variations in lighting and object appearances, and efficient algorithms for pose estimation and motion planning.

Q 8. How do you ensure the safety of robotic systems in industrial environments?

Ensuring the safety of robotic systems in industrial environments is paramount. It’s not just about preventing accidents; it’s about building trust and ensuring efficient, reliable operation. My approach is multifaceted and involves several key strategies:

- Safety-Rated Hardware and Software: We utilize components certified to relevant safety standards (e.g., ISO 13849, IEC 61508). This includes safety PLCs, emergency stop systems, and sensors with built-in redundancy. Software is designed with fail-safe mechanisms and rigorous testing to minimize the risk of unexpected behavior.

- Risk Assessment and Mitigation: Before deploying any robot, we conduct a thorough risk assessment to identify potential hazards. This helps determine appropriate safety measures, such as light curtains, safety scanners, and interlocks, tailored to the specific application and environment. For example, in a collaborative robot (cobot) application, we would prioritize force limiting and speed monitoring to prevent harm to human workers.

- Emergency Stop Systems and Fail-Safe Mechanisms: Multiple, independently activated emergency stop buttons are strategically placed. We also implement software and hardware fail-safes. If a sensor fails or a critical component malfunctions, the robot will safely shut down or enter a safe state, minimizing the potential for injury or damage.

- Regular Maintenance and Inspections: Preventative maintenance is crucial. Regular inspections, calibrations, and software updates ensure the system remains in optimal condition and safety features are functioning correctly. We document all maintenance activities to track performance and identify potential issues early.

- Operator Training: Comprehensive training for operators is essential. They need to understand the robot’s capabilities, limitations, and safety procedures. This includes how to operate the system correctly and respond effectively to emergencies.

In essence, a layered safety approach—combining robust hardware, sophisticated software, careful planning, and diligent maintenance—is crucial for ensuring a safe working environment with industrial robots.

Q 9. Explain your experience with ROS (Robot Operating System).

I have extensive experience with ROS (Robot Operating System), using it across multiple robotic projects. ROS provides a flexible framework for building complex robotic systems by modularizing functionalities.

My experience includes:

- Node development: I’ve created numerous ROS nodes for various tasks, such as sensor data processing, motor control, path planning, and computer vision. For example, I developed a node in C++ to process point cloud data from a LiDAR sensor, filtering noise and identifying obstacles.

- ROS packages and libraries: I’m proficient in leveraging existing ROS packages and libraries to accelerate development. This includes packages for navigation, control, and visualization. I’ve integrated navigation stacks like

move_baseandgmappingfor autonomous navigation tasks. - ROS communication mechanisms: I’m familiar with ROS’s various communication paradigms, including topics, services, and actions, selecting the appropriate method based on the specific application requirements. For instance, I’ve used ROS actions for complex tasks needing feedback and preemption, such as grasping objects with a robotic arm.

- ROS visualization tools: I utilize tools like

rvizto visualize robot state, sensor data, and planned paths, making debugging and system monitoring much easier. For instance, I debugged a path planning issue by visualizing the robot’s pose and planned trajectory inrviz, revealing a discrepancy in the robot’s odometry data.

My ROS expertise has enabled me to rapidly prototype and deploy robust robotic solutions in diverse applications.

Q 10. Describe your experience with path planning algorithms (e.g., A*, RRT).

Path planning is fundamental to autonomous robotic systems. I have significant experience with various algorithms, including A* and Rapidly-exploring Random Trees (RRT).

A* is a best-first search algorithm ideal for finding optimal paths in known environments. Its efficiency comes from using a heuristic function to estimate the cost to reach the goal. I’ve used A* in applications such as warehouse navigation, where a precise, shortest-path solution is crucial. In one project, we used A* to plan the optimal route for a robot to navigate a cluttered warehouse, avoiding obstacles and optimizing travel time.

RRT, on the other hand, is a probabilistic algorithm well-suited for high-dimensional spaces and unknown environments. It excels at finding feasible paths even with complex obstacles. I’ve applied RRT in applications involving robotics manipulation where the robot’s workspace is complex and not fully known a priori. For example, I utilized RRT to plan a collision-free trajectory for a robotic arm to reach a target point in a cluttered workspace, accounting for joint limits and self-collisions.

Choosing the appropriate algorithm depends heavily on the application’s specific constraints and the characteristics of the environment. Factors like the complexity of the environment, the availability of a map, computational constraints, and the need for optimality play significant roles in algorithm selection.

Q 11. How do you troubleshoot robotic system malfunctions?

Troubleshooting robotic malfunctions requires a systematic approach. My process typically involves:

- Identify the Symptom: Precisely define the problem. Is the robot not moving? Are sensors providing incorrect data? Is there a communication error? This requires careful observation and logging of error messages.

- Gather Data: Collect relevant information such as error logs, sensor readings, and robot states. Review the robot’s recent operational history and any changes made to its software or hardware.

- Isolate the Problem: Use the gathered data to pinpoint the source of the issue. Is it a hardware problem (e.g., faulty motor, broken sensor), a software bug, or a communication issue? This might involve testing individual components or modules systematically.

- Develop and Test a Solution: Once the root cause is identified, develop and implement a solution. This could involve replacing a faulty component, modifying software code, or adjusting system parameters. Thorough testing is critical to ensure the fix is effective and doesn’t introduce new problems.

- Document the Fix: Document the entire troubleshooting process, including the problem, the steps taken to diagnose the issue, and the solution implemented. This helps prevent similar problems in the future and aids in collaboration with other engineers.

For example, in one instance, a robot’s movement was jerky and inaccurate. By carefully examining sensor data and logs, we discovered a communication issue between the robot’s controller and its motor drivers. Replacing the faulty cable solved the problem.

Q 12. Discuss your experience with robotic simulation software.

Robotic simulation software is indispensable for robot design, testing, and development. It allows for virtual prototyping and testing before deploying physical robots, saving significant time and resources. I’m experienced with several simulation platforms including Gazebo and CoppeliaSim.

My experience involves:

- Environment Modeling: Creating realistic virtual environments to test robot behavior in various scenarios. This often includes importing CAD models, adding obstacles, and simulating sensor data.

- Robot Modeling and Control: Developing and simulating robot models, including kinematics and dynamics. I also use simulation to test different control algorithms and tune parameters before deploying them on real hardware.

- Sensor Simulation: Simulating various sensors (e.g., LiDAR, cameras, IMUs) to generate realistic sensor data for algorithm testing. This is crucial for developing and testing perception algorithms in a controlled environment.

- Path Planning and Navigation Simulation: Testing path planning algorithms in simulated environments before deploying them on real robots. This allows for extensive testing in various environments with different obstacle configurations without risking damage to the physical robot.

Using simulation significantly reduced development time and costs by allowing me to thoroughly test and debug algorithms and control systems in a virtual setting before deploying them to real-world applications.

Q 13. Explain the different types of robot end-effectors and their applications.

Robot end-effectors are the tools at the end of a robotic arm, enabling it to interact with the environment. Their choice significantly impacts the robot’s capabilities. Different applications require different end-effectors:

- Grippers: These are used for grasping and manipulating objects. There are various types:

- Parallel grippers: Simple, robust, and suitable for objects with regular shapes.

- Angled grippers: Allow access to confined spaces.

- Three-fingered grippers: Provide better dexterity and adaptability to a wider range of shapes.

- Vacuum grippers: Ideal for smooth, flat surfaces.

- Welding Torches: Used for robotic welding processes. These are designed for specific welding techniques and materials.

- Spray Painting Tools: Precisely apply paint or other coatings.

- Cutting Tools: Include tools like saws, drills, or laser cutters, depending on the materials being processed.

- Specialized End-Effectors: Many specialized end-effectors cater to specific tasks, like those used in surgery, assembly, or material handling.

Selecting the appropriate end-effector is crucial for the success of any robotic application. Factors like payload capacity, dexterity, required precision, and the types of objects being manipulated all influence this decision.

Q 14. How do you design a robust and reliable robotic system?

Designing a robust and reliable robotic system necessitates a holistic approach, focusing on several key aspects:

- Modular Design: Breaking down the system into smaller, independent modules simplifies design, testing, and maintenance. This modularity makes it easier to replace or upgrade individual components without affecting the entire system.

- Redundancy and Fail-Safes: Incorporating redundancy in critical components and implementing fail-safe mechanisms significantly enhances reliability. For instance, using dual sensors or backup power supplies minimizes the impact of component failures.

- Robust Control Algorithms: Utilizing robust control algorithms that are resistant to noise and disturbances ensures consistent performance even in unpredictable conditions. This might involve using techniques like Kalman filtering to improve sensor accuracy or using adaptive control to adjust to changing environments.

- Thorough Testing: Rigorous testing is critical. This includes unit testing of individual modules, integration testing of the entire system, and environmental testing in real-world conditions. Simulation plays a key role in this process.

- Careful Selection of Components: Choosing high-quality, reliable components from reputable manufacturers is paramount. This helps prevent premature failures and downtime.

- Maintenance Plan: Establishing a regular maintenance schedule with preventative measures helps detect and address potential problems before they lead to system failures. This also ensures the system operates at peak performance.

By emphasizing these principles, you build a robotic system that is not only functional but also resilient, dependable, and easy to maintain, crucial for long-term success in industrial settings.

Q 15. Describe your experience with different robotic control architectures.

My experience encompasses a wide range of robotic control architectures, from simple open-loop systems to sophisticated closed-loop and hierarchical control strategies. I’ve worked extensively with:

- Open-loop control: This is the simplest type, where the robot’s actions are pre-programmed without feedback from the environment. Think of a simple pick-and-place operation where the robot’s movements are predetermined based on known positions. While simple to implement, it’s highly susceptible to errors and uncertainties in the environment.

- Closed-loop control (feedback control): This involves incorporating sensor data to continuously adjust the robot’s actions, ensuring accuracy. For example, using a vision system to track an object and adjust the robot’s grasp accordingly. PID (Proportional-Integral-Derivative) controllers are commonly used in this context.

- Hierarchical control: This approach involves dividing the control problem into different levels of abstraction. A higher-level controller might plan the overall task, while lower-level controllers handle individual joint movements. This is particularly useful for complex tasks requiring coordination between multiple robots or subsystems. I have extensive experience implementing hierarchical control using ROS (Robot Operating System).

- Hybrid control: Often combines elements of both open-loop and closed-loop control. For example, a robot might use open-loop control for initial positioning and then switch to closed-loop control for fine adjustments based on sensor feedback.

In one project, we implemented a hybrid control system for a collaborative robot (cobot) that assisted human workers in an assembly line. The cobot used open-loop control for large movements to pre-position parts, then switched to force-controlled closed-loop control for precise insertion, ensuring safe interaction with the human operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of force/torque sensing in robotics.

Force/torque sensing is crucial for robots that need to interact physically with their environment. Force/torque sensors, typically mounted on the robot’s end-effector or joints, measure the forces and torques applied to the robot. This information provides valuable feedback for controlling the robot’s interaction. Imagine a robot delicately assembling a circuit board – force sensing is vital to prevent damage to components.

These sensors provide crucial information for:

- Compliance control: Allows the robot to adapt to unexpected forces or disturbances. For instance, if the robot encounters unexpected resistance while inserting a peg into a hole, the force sensor feedback can adjust the insertion force to prevent damage.

- Force-based manipulation: Enables robots to perform tasks requiring precise force control, such as polishing, sanding, or surgery. In surgical applications, force sensing helps prevent tissue damage.

- Collision detection and avoidance: Detecting collisions with objects in the environment to ensure safety.

The data from force/torque sensors are often incorporated into closed-loop control systems. For example, a simple implementation might use a PID controller where the force sensor reading serves as the feedback signal to regulate the robot’s applied force. More advanced techniques use impedance control or admittance control, which allow the robot to react dynamically to external forces.

Q 17. How do you handle robot coordinate systems and transformations?

Handling robot coordinate systems and transformations is fundamental in robotics. Robots operate in multiple coordinate systems – base frame, tool frame, and world frame, to name a few. Transformations describe how to map points and orientations from one coordinate system to another. This is often done using homogeneous transformations, which are 4×4 matrices.

I am proficient in using tools like ROS’s tf (transform library) to manage these transformations. This library allows us to define and track the relationships between different coordinate frames in a dynamic environment. For example, if a robot’s end-effector moves, the tf library updates the transformation between the end-effector frame and the base frame accordingly. Knowing these transformations allows us to accurately calculate the robot’s pose and plan trajectories in the correct coordinate system.

Example (Conceptual): Imagine a robot arm trying to pick up an object. The robot needs to know the object’s position in the world frame. It also knows its own position (base frame) and the transformation between its end-effector (tool frame) and its base frame. By applying the appropriate transformations, we can calculate the desired position and orientation of the end-effector in its own frame to accurately grasp the object.

Q 18. Discuss your experience with real-time operating systems (RTOS) in robotics.

Real-Time Operating Systems (RTOS) are essential for robotics due to their ability to guarantee predictable timing for critical control tasks. I’ve worked extensively with several RTOS, including VxWorks and FreeRTOS. They’re crucial for tasks requiring precise timing, such as motor control and sensor data acquisition. An RTOS allows us to schedule tasks with priorities, ensuring that time-sensitive actions are completed within their deadlines.

Here are some key aspects of my experience with RTOS in robotics:

- Task scheduling: Allocating computational resources to different tasks based on their priorities. This is vital for coordinating multiple control loops and sensor processing.

- Interrupt handling: Handling external events (e.g., sensor data arriving) in a timely manner without disrupting other tasks.

- Synchronization mechanisms: Using semaphores, mutexes, and other mechanisms to coordinate access to shared resources among different tasks.

In one project, we used FreeRTOS to develop a control system for a multi-legged robot. The RTOS guaranteed that the leg control loops received sufficient processing time, ensuring coordinated locomotion and stability even on uneven terrain.

Q 19. Explain the concept of robotic redundancy and its benefits.

Robotic redundancy refers to having more degrees of freedom (DOFs) than strictly necessary to perform a task. For example, a robot arm might have seven joints instead of the six needed for reaching any point in 3D space. This redundancy offers several benefits:

- Obstacle avoidance: The extra DOFs allow the robot to avoid obstacles by choosing alternative paths.

- Singularity avoidance: Redundancy helps circumvent singularities, which are configurations where the robot loses some of its maneuverability. Think of a robot arm fully extending its joints – it’s difficult to move at that point.

- Optimization of secondary criteria: While the primary goal might be reaching a target point, redundancy allows optimizing for secondary goals, such as minimizing energy consumption or maximizing workspace coverage.

- Improved dexterity and manipulability: More DOFs provide greater flexibility and precision, allowing for complex manipulation tasks.

Imagine a robot arm navigating a cluttered workspace. With redundancy, the robot can avoid collisions by choosing a different joint configuration even if its primary path is blocked. Algorithms such as the pseudoinverse method are used to resolve redundancy and determine optimal joint configurations. This is particularly relevant in human-robot interaction where safety and flexibility are paramount.

Q 20. Describe your experience with different types of actuators (e.g., hydraulic, pneumatic, electric).

My experience encompasses a variety of actuators, each with its own strengths and weaknesses:

- Electric actuators: These are widely used due to their precision, controllability, and relative ease of integration. Examples include servo motors, stepper motors, and brushless DC motors. They are ideal for applications demanding precise positioning and repeatability.

- Hydraulic actuators: Offer high power density and force output, making them suitable for heavy-duty applications. However, they are generally less precise and more complex to control than electric actuators. They are commonly used in industrial robots for heavy lifting and manipulation.

- Pneumatic actuators: Relatively inexpensive and simple to use, providing fast movements but limited precision. They’re often found in simpler robotic systems or applications requiring fast, powerful but less precise movements, such as clamping or gripping.

The choice of actuator depends heavily on the specific application. For example, in a delicate assembly task, electric actuators would be preferred for their precision; however, for a heavy lifting robot, hydraulic actuators might be the better choice due to their high force capabilities. I’ve had experience selecting and implementing all three types, considering factors such as payload capacity, speed requirements, precision needs, cost, and overall system complexity.

Q 21. How do you design a robot cell layout for optimal efficiency?

Designing a robot cell layout for optimal efficiency involves careful consideration of several factors to maximize throughput, minimize cycle times, and ensure safety. A systematic approach is crucial:

- Process analysis: Begin by thoroughly analyzing the manufacturing process, defining all necessary steps, and their sequence.

- Robot selection: Choose a robot with the appropriate payload capacity, reach, and degrees of freedom to meet the task requirements. Consider factors such as speed, accuracy, and repeatability.

- Workcell layout: Arrange the workcell components (robot, fixtures, conveyors, sensors) in a way that minimizes movement distances and maximizes efficiency. Simulations often play a vital role here. Tools like Delmia or RobotStudio are incredibly helpful.

- Safety considerations: Implement safety measures such as light curtains, emergency stops, and interlocks to prevent accidents. This is a non-negotiable aspect.

- Material handling: Plan for efficient material handling to and from the workcell. This often involves integrating conveyors, AGVs (Automated Guided Vehicles), or other material handling systems.

- Programming and testing: Develop efficient robot programs and thoroughly test the entire system to identify and resolve any bottlenecks or issues before deployment.

For example, when designing a robot cell for palletizing, we’d optimize the layout to minimize the distance the robot travels between the input conveyor, the pallet, and the output conveyor. This is often accomplished by using efficient picking strategies and a well-designed pallet layout.

Q 22. Explain your experience with PLC programming in robotics.

My experience with PLC programming in robotics is extensive. PLCs (Programmable Logic Controllers) are the brains behind many robotic systems, responsible for coordinating movements, sensor inputs, and overall automation. I’ve worked extensively with various PLC platforms, including Allen-Bradley, Siemens, and Mitsubishi, using languages like Ladder Logic and Structured Text. For example, in a recent project involving a palletizing robot, I programmed the PLC to manage the robot’s pick-and-place cycle, coordinating it with conveyor belt sensors to ensure efficient and error-free operation. This involved using timers, counters, and complex logic to handle various scenarios, such as empty pallets or product jams. I also implemented safety features within the PLC program, monitoring emergency stops and sensor signals to prevent accidents. My expertise extends to troubleshooting PLC programs and optimizing their performance for maximum efficiency and throughput.

One specific challenge involved integrating a vision system with the PLC and robot. The vision system provided coordinates for the robot to pick objects, and I used structured text to interpret the data received, perform error checking, and ensure the robot accurately retrieved each item. This highlighted the importance of seamless data communication between different elements of the robotic cell.

Q 23. How do you integrate robotic systems with other manufacturing equipment?

Integrating robotic systems with other manufacturing equipment is crucial for creating a fully automated production line. This typically involves understanding communication protocols, such as EtherCAT, Profinet, or Profibus, and utilizing industrial network architectures. I’ve successfully integrated robots with conveyors, vision systems, CNC machines, and other automated guided vehicles (AGVs). For instance, in a project involving a robotic welding cell, I integrated the robot controller with a laser scanner to accurately position the workpieces. The communication protocol was Profibus, and I used the PLC as a central hub to manage communication and data exchange. This involved careful calibration and precise timing to ensure the robot received the correct data precisely when needed.

The key to seamless integration is proper planning. This begins with a thorough understanding of the functionalities of each piece of equipment and establishing a clear communication strategy. This often includes creating detailed I/O diagrams, specifying communication protocols, and thoroughly testing the integration process before full-scale implementation. One common approach is using a supervisory control and data acquisition (SCADA) system to oversee the entire production line, coordinating all the individual components.

Q 24. Describe your experience with different types of robot grippers.

My experience with robot grippers encompasses a wide range of types, each tailored to specific application requirements. I’ve worked with:

- Vacuum grippers: Ideal for handling smooth, flat objects, these use suction to hold parts. I’ve used them extensively in applications involving printed circuit boards (PCBs) and fragile items.

- Mechanical grippers: Using jaws to clamp onto objects, these are versatile and suitable for a variety of parts. I’ve employed these in palletizing, assembly, and machine tending applications. The selection of jaws is crucial here to avoid damaging the workpieces.

- Magnetic grippers: Used for handling ferrous materials, these are very efficient and quick. I’ve used these in metal handling and processing applications.

- Adaptive grippers: Offering flexibility in handling parts of varying shapes and sizes, these are often more expensive but provide greater adaptability. Examples include soft robotic grippers which use compliant materials to better handle oddly shaped items.

Choosing the right gripper is crucial for successful automation. Factors to consider include part geometry, material properties, required gripping force, and cycle time. For example, using a vacuum gripper for a porous object would be inefficient, while a mechanical gripper might damage a delicate item. Proper selection ensures efficiency and safety. My work frequently requires a thorough assessment of these parameters to select the optimal gripper for each project.

Q 25. Explain the concept of robot dynamics and control.

Robot dynamics and control are fundamental to robotics. Robot dynamics describe the relationship between forces, torques, and the robot’s resulting motion. This involves understanding inertia, gravity, and friction effects on each joint. Control systems use this information to accurately position and move the robot. This is achieved through feedback control loops, using sensors (such as encoders and accelerometers) to measure the actual robot’s position and velocity, and comparing it to the desired values. Control algorithms then adjust the motor torques to minimize the difference.

Common control algorithms include PID (Proportional-Integral-Derivative) control, which provides robust and stable performance. Advanced techniques such as adaptive control and model predictive control are also used to handle uncertainties and improve performance. In practice, this often involves tuning the control parameters to optimize the robot’s trajectory tracking and responsiveness. For instance, in a high-speed assembly task, precise control is crucial to avoid collisions and achieve high accuracy. I have significant experience using different control algorithms and implementing advanced control schemes on industrial robots.

Q 26. How do you validate the performance of a robotic system?

Validating the performance of a robotic system is a critical step to ensure safety and efficiency. This involves a multi-stage process. First, we conduct simulations to verify the robot’s motion planning and control algorithms in a virtual environment. Then we move on to rigorous testing, involving a range of tests such as:

- Accuracy and repeatability tests: Measuring the robot’s ability to reach target positions consistently.

- Cycle time tests: Measuring the time taken to complete a specific task.

- Payload tests: Verifying the robot’s capacity to handle the required weight.

- Safety tests: Ensuring the system meets safety standards and prevents accidents.

Data logging and statistical analysis are essential for quantifying the system’s performance. For example, repeatability is often expressed as the standard deviation of multiple measurements of the same position. Any deviations outside of pre-defined tolerances require investigation and adjustment. Ultimately, the validation process continues after deployment, monitoring performance over time and identifying potential areas for improvement. The entire process is carefully documented and traceability is maintained throughout the lifecycle.

Q 27. Discuss your experience with robotic safety standards (e.g., ISO 10218).

Robotic safety standards, such as ISO 10218, are paramount in my work. ISO 10218 defines safety requirements for industrial robots, covering aspects such as risk assessment, safeguarding, and emergency stops. My experience includes risk assessments to identify potential hazards and implementing appropriate safety measures. This includes using safety-rated sensors, light curtains, and emergency stop buttons. Compliance with these standards is vital to ensure the safety of personnel working around robots.

For example, in a project involving a collaborative robot (cobot) working alongside human operators, we implemented safety features like speed and force limiting to prevent injuries. The robot’s software was programmed to react appropriately to unexpected events, such as a human entering the robot’s workspace. Documentation of these safety features and risk assessments is crucial, forming a significant part of the project’s overall documentation. Furthermore, regular safety inspections and maintenance are performed to maintain compliance and ensure continuous safety. A deep understanding of these regulations is essential for designing, implementing, and operating robots safely. I’m always up to date on the latest safety standards and best practices.

Key Topics to Learn for Buffer Robotics Interview

- Robotics Fundamentals: Understand core concepts like kinematics, dynamics, control systems, and sensor integration. Consider exploring different robotic architectures and their applications.

- Buffering Strategies in Robotics: Explore the practical applications of buffering techniques in robotic systems, focusing on data management, motion planning, and error handling. Analyze the trade-offs between different buffering approaches.

- Programming for Robotics: Develop proficiency in relevant programming languages (e.g., Python, C++, ROS) commonly used in robotics development. Practice implementing algorithms and control strategies.

- Computer Vision and Perception: Understand how robots perceive their environment. Explore image processing, object recognition, and scene understanding techniques crucial for autonomous navigation and manipulation.

- AI and Machine Learning in Robotics: Familiarize yourself with the application of AI and machine learning for tasks like path planning, object manipulation, and adaptive control. Consider reinforcement learning and its role in robotics.

- System Integration and Testing: Gain experience in integrating different robotic components and thoroughly testing the system for robustness and reliability. Understand debugging and troubleshooting methodologies.

- Ethical Considerations in Robotics: Be prepared to discuss the ethical implications of robotics and autonomous systems, including safety, privacy, and societal impact.

Next Steps

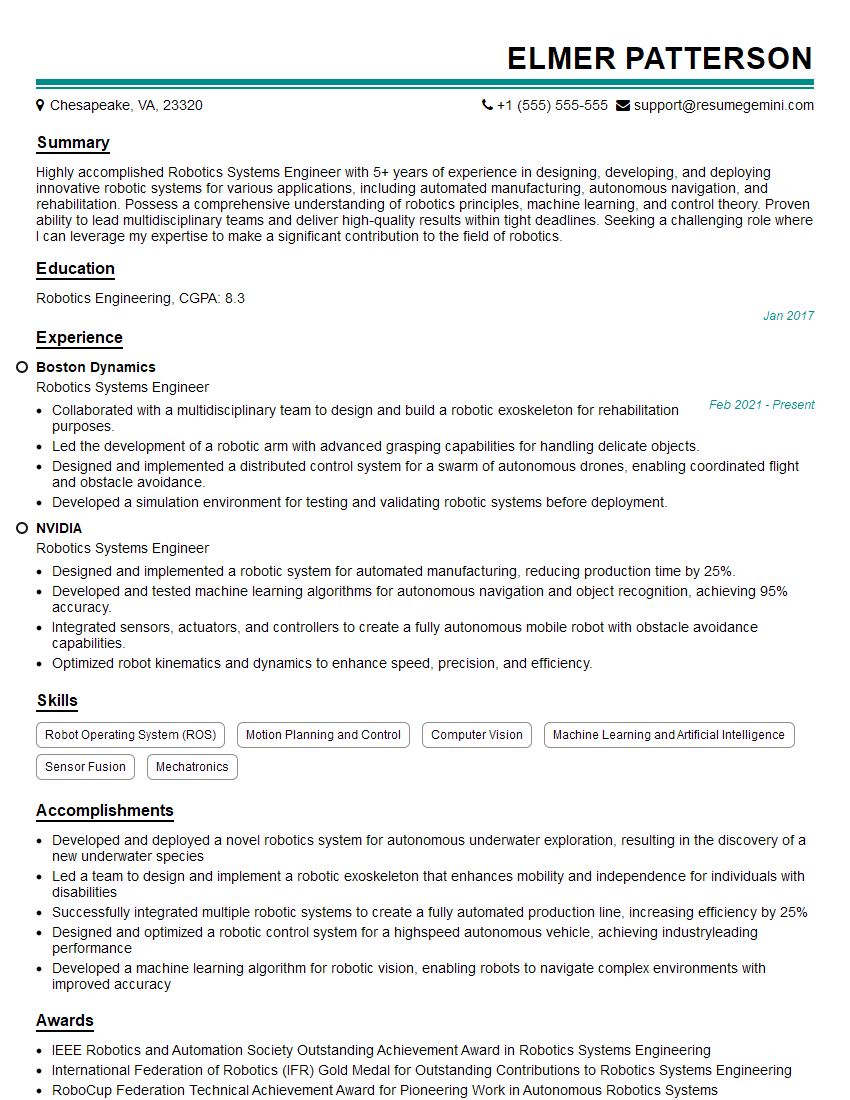

Mastering Buffer Robotics-related skills significantly enhances your career prospects in the rapidly growing field of robotics and automation. A strong foundation in these areas positions you for exciting opportunities and higher earning potential. To maximize your chances of landing your dream job, create an ATS-friendly resume that effectively highlights your skills and experience. We strongly encourage you to leverage ResumeGemini, a trusted resource for building professional and impactful resumes. Examples of resumes tailored to Buffer Robotics are available below to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.