The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Built-up Roofing Installation interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Built-up Roofing Installation Interview

Q 1. Describe the different types of built-up roofing (BUR) systems.

Built-up roofing (BUR) systems are characterized by their multiple layers of roofing materials, typically asphalt-based, applied to a roof deck. There isn’t a single definitive ‘type’, but rather variations based on the specific components and their arrangement. We can categorize them based on the type of waterproofing membrane used:

- Asphalt-saturated felt: This is the most traditional type, using layers of felt saturated with asphalt. It’s cost-effective but may require more layers for adequate protection.

- Modified bitumen: This uses a polymer-modified asphalt, offering improved flexibility, durability, and resistance to cracking compared to traditional asphalt-saturated felt. It’s a popular choice for many applications.

- Cold-applied systems: These utilize cold-process adhesives, eliminating the need for hot asphalt, thus reducing safety hazards and potential for fire. This is often used in smaller-scale or specialized roofing applications.

The choice of BUR system depends on factors like budget, roof slope, climate, and the building’s specific needs. For example, a building in a harsh, cold climate might benefit from a modified bitumen system to withstand temperature fluctuations, while a smaller, simpler structure could effectively use a cold-applied system.

Q 2. Explain the process of installing a BUR system, from base sheet to top coat.

BUR system installation is a meticulous process requiring skilled labor. Here’s a step-by-step overview:

- Preparation: Thoroughly clean and dry the roof deck. Repair any existing damage, ensuring a smooth and level surface. This is crucial for proper adhesion.

- Base Sheet Installation: The first layer, often a layer of roofing felt, is applied to provide a base for subsequent layers. It’s typically adhered using hot asphalt or a cold-process adhesive, depending on the system.

- Ply Application: Multiple layers of felt or membrane are applied, overlapping each layer by a specified amount (typically 2-4 inches) to ensure complete coverage and prevent water penetration. Each layer is adhered using hot asphalt or adhesive.

- Flashing Installation: Critical around penetrations (pipes, vents, etc.) and at edges of the roof. Flashing prevents water from entering these vulnerable points. This requires precise fitting and sealing.

- Surfacing: The final layer, often a granular surfacing material like gravel or slag, protects the underlying layers from UV degradation and weathering. It also provides ballast and helps prevent wind uplift.

Throughout the process, careful attention must be paid to detail. Proper overlaps, consistent adhesion, and accurate flashing are essential to a long-lasting, leak-free roof.

Q 3. What are the key components of a BUR system and their functions?

A BUR system comprises several key components:

- Base Sheet: Provides a foundation for the rest of the system and helps in moisture protection.

- Plies (Membrane): Multiple layers of felt or modified bitumen providing the primary waterproofing barrier. The number of plies depends on the roof’s requirements and local codes.

- Asphalt/Adhesive: Binds the layers together, creating a cohesive and waterproof membrane. Hot asphalt requires specialized equipment and expertise.

- Flashing: Waterproof sealant used around penetrations and roof edges to prevent leaks.

- Surfacing: Protects the underlying layers from UV degradation, weathering, and wind uplift. Common materials include gravel, slag, or cap sheets.

Each component plays a vital role in the overall performance and longevity of the roof. For instance, a weak adhesive could lead to delamination and leaks, while insufficient flashing around a pipe could allow water ingress. Proper selection and installation of every component are critical.

Q 4. How do you ensure proper adhesion between layers in a BUR system?

Proper adhesion is paramount in a BUR system. Several techniques ensure strong bonds between layers:

- Clean Surfaces: Thoroughly cleaning the roof deck and each ply before applying asphalt or adhesive ensures optimal bonding. Dust, debris, and moisture will compromise adhesion.

- Appropriate Adhesives: Selecting the right type and amount of adhesive (hot asphalt or cold-process) based on the materials being joined and environmental conditions is crucial.

- Proper Application: Even and consistent application of the adhesive prevents voids and weak spots. Hot asphalt requires careful temperature control for optimal viscosity.

- Sufficient Roll-Out Time: Allowing sufficient time for the adhesive to tack before the next layer is applied. The tack time will vary depending on the adhesive and weather conditions.

- Weight and Pressure: Using rollers to compact the layers and ensure proper contact between the adhesive and the plies improves adhesion.

Think of it like building a brick wall – if the mortar (adhesive) isn’t properly applied, the wall will be weak and prone to collapse. The same is true for a BUR roof; proper adhesion is critical for its structural integrity and leak prevention.

Q 5. What are the common problems encountered during BUR installation, and how are they addressed?

Common problems during BUR installation include:

- Poor Adhesion: Caused by unclean surfaces, insufficient adhesive, or improper application. This leads to delamination and leaks.

- Improper Flashing: Inadequate flashing at penetrations or edges allows water ingress. Careful attention to detail and quality materials are essential here.

- Uneven Surfaces: High and low spots on the roof deck prevent proper adhesion and create stress points in the membrane.

- Poor Weather Conditions: Excessive heat, cold, or rain during installation can negatively impact adhesion and overall quality.

Addressing these issues: Prevention is key; proper surface preparation, thorough quality control during each step, and selecting materials appropriate to the environment are crucial. If problems are encountered, repairing them promptly, often involving removing and reinstalling the affected area, is critical. The best approach is always to follow the manufacturer’s instructions and utilize experienced roofing crews.

Q 6. What safety precautions are essential during BUR installation?

Safety is paramount during BUR installation. Key precautions include:

- Fall Protection: Working at heights requires appropriate fall protection equipment, including harnesses, lifelines, and anchor points. The roof should be properly assessed for potential fall hazards.

- Hot Asphalt Safety: When using hot asphalt, workers need proper protective equipment, including heat-resistant gloves, boots, and clothing, and appropriate eye protection. They should also be aware of potential fire hazards.

- Proper Ventilation: Ensuring adequate ventilation prevents the buildup of harmful fumes from adhesives or asphalt.

- Use of Proper Tools: Only use tools appropriate to the job and in good working condition, properly maintained, and safety checks before starting the task.

- Training and Supervision: Workers should receive proper training in handling roofing materials, using safety equipment, and following safety procedures. Experienced supervision is also crucial.

Remember: Safety isn’t just a guideline; it’s a non-negotiable requirement. Neglecting safety can lead to serious injury or even fatality.

Q 7. How do you determine the slope requirements for a BUR roof?

The slope requirement for a BUR roof depends on several factors, including the type of BUR system used, the climate, and local building codes. Generally, BUR systems are designed for low-slope applications (0-3%). Steeper slopes might require modifications or alternative roofing systems.

Determining Slope: The roof slope is usually measured as the ratio of vertical rise to horizontal run (rise/run). For instance, a 1:12 slope means a 1-inch rise for every 12 inches of horizontal run. This slope is usually determined from the architectural plans or through a site survey. A proper assessment should be made to ensure the slope can adequately shed water, preventing ponding. In some cases, additional drainage features might be needed to accommodate inadequate slope.

Manufacturers provide specific slope recommendations for their BUR systems. Exceeding the recommended slope could compromise the system’s performance, while a slope that is too flat can lead to ponding and potential leaks.

Q 8. Explain the importance of flashing in a BUR system.

Flashing in a built-up roofing (BUR) system is crucial for preventing water penetration. Think of it as the roof’s raincoat seams – sealing critical areas where the roof meets other building components to ensure a watertight barrier. Without proper flashing, water can easily seep into the building, leading to significant damage and costly repairs.

Flashing is typically installed at vulnerable points such as:

- Around chimneys and vents

- At roof valleys and intersections

- Along parapet walls and edges

- Where the roof meets dormers or skylights

The material used for flashing varies, but common choices include metal (copper, aluminum, galvanized steel), and modified bitumen. Proper installation involves meticulous detailing, ensuring a complete seal and overlaps that direct water away from the vulnerable areas. A poorly installed flashing is a recipe for leaks, so quality materials and skilled labor are essential.

Q 9. Describe different methods for repairing damaged BUR roofs.

Repairing damaged BUR roofs depends heavily on the extent and type of damage. Small punctures or blisters can often be addressed with a spot repair, involving cleaning the area, applying hot asphalt, and embedding a patch of new roofing felt. This is a relatively simple, quick fix for minor issues.

For more significant damage, such as large tears or extensive deterioration, a more involved repair might be necessary. This may involve removing the damaged sections of the roofing membrane, preparing the underlying deck, and then applying new layers of felt and hot asphalt to restore the roof’s integrity. A complete section replacement could be required in severe cases.

Another common repair involves addressing ponding water. This often involves creating a slight slope through additional insulation and/or modifying the roof’s drainage system. Never underestimate the importance of proper drainage in preventing further damage. The choice of repair method will greatly depend on the nature and extent of damage, along with the overall condition of the roof.

Q 10. How do you inspect a BUR roof for potential problems?

Inspecting a BUR roof requires a systematic approach to identify potential problems. The inspection should ideally be done by a trained professional who can detect subtle signs of damage.

The process usually includes:

- Visual inspection: Examining the entire roof surface for signs of blistering, cracking, ponding water, punctures, or missing or damaged gravel.

- Detail inspection: Closely examining flashings around penetrations (chimneys, pipes), valleys, and edges for signs of leaks or deterioration. This often requires carefully checking seams and edges.

- Checking drainage systems: Inspecting gutters, downspouts, and drains to ensure they’re functioning properly and are free of blockages.

- Checking the insulation: If possible, verifying the condition of the insulation to ensure it is in place and providing adequate thermal protection.

- Documentation: Taking photos and detailed notes of any observed issues.

A drone inspection can be a valuable tool for efficient overview and identification of large-scale issues. Remember, prevention is always cheaper than cure; regular inspections can help to catch minor problems before they escalate into major headaches and expensive repairs.

Q 11. What are the advantages and disadvantages of BUR systems compared to other roofing systems?

BUR systems, while traditional, offer certain advantages and disadvantages when compared to other roofing systems like single-ply membranes (TPO, EPDM) or metal roofing.

Advantages:

- Durability: With proper installation and maintenance, BUR roofs can last for many decades.

- Cost-effective (sometimes): Can be more affordable upfront than some other systems, particularly for larger areas.

- Adaptability: Can be applied over various substrates.

- Excellent water resistance: When properly installed, they form an exceptionally good barrier against water penetration.

Disadvantages:

- Labor-intensive installation: Requires skilled labor and specialized equipment (like hot asphalt kettles), making installation time-consuming.

- Temperature-sensitive: Installation is highly dependent on weather conditions.

- Less aesthetically pleasing: Often a less attractive option compared to sleek metal or single-ply systems.

- Potential for ponding: Improper installation or drainage can lead to water ponding.

The best choice for a roofing system depends on various factors including budget, aesthetic preferences, climate, and the building’s specific needs. A professional assessment is essential for determining the most suitable option.

Q 12. How do you manage different weather conditions during BUR installation?

Weather conditions significantly impact BUR installation. Hot, dry weather is ideal for proper asphalt adhesion, while rain or extreme cold can compromise the entire process. Detailed weather forecasts are essential before initiating any work.

Here are some key management strategies:

- Postponement: The installation should be postponed if rain, extreme heat, or freezing temperatures are predicted.

- Protection: Newly laid layers of felt should be protected from rain using tarps or other coverings.

- Rapid work in suitable conditions: When suitable conditions arise, the team must work efficiently to complete as much as possible before the weather changes. Having adequate manpower and equipment can be crucial to quickly complete work.

- Temperature control: The asphalt needs to be at the correct temperature for optimal application. This might involve heating or cooling techniques depending on the weather.

Careful planning, monitoring, and flexibility are crucial for successful BUR installation in varying weather conditions. Safety for the installation crew is paramount during harsh weather; the project may need to be halted if severe conditions pose a safety risk.

Q 13. Explain the role of insulation in a BUR system.

Insulation plays a vital role in a BUR system, providing several key benefits beyond simply keeping the building warm in winter and cool in summer. It acts as a thermal barrier, reducing energy consumption and improving comfort inside the building. Furthermore, it serves as a crucial component in preventing moisture issues. Proper insulation helps to regulate temperature differences between the interior and exterior of the roof, limiting the build-up of condensation which is a major cause of roofing failure.

Common insulation materials for BUR systems include:

- Polyisocyanurate (Polyiso): A rigid foam known for its high R-value (thermal resistance).

- Extruded polystyrene (XPS): Another rigid foam with good insulating properties and moisture resistance.

- Mineral wool: Offers both thermal and fire resistance.

The thickness of the insulation layer is determined based on factors like the local climate, desired energy efficiency, and building codes. Proper installation, which often requires securing the insulation boards to ensure they remain in place, is just as crucial as the choice of the insulation material itself.

Q 14. What are the proper disposal methods for BUR materials?

Proper disposal of BUR materials is crucial for environmental protection and compliance with local regulations. The materials used in a BUR system, particularly the asphalt and felt, are not readily biodegradable. Improper disposal can lead to environmental contamination and landfill issues.

The proper disposal methods often include:

- Recycling: Some regions have facilities that can recycle certain BUR components, such as some types of felt. This is a preferable method, reducing the environmental impact.

- Specialized disposal facilities: Many areas have designated facilities specifically equipped to handle hazardous waste, including asphalt roofing materials. This ensures that materials are disposed of safely and appropriately.

- Compliance with local regulations: Before disposal, it is important to check and comply with local and state regulations for hazardous waste disposal, to prevent potential fines and penalties.

It’s highly recommended to contract a licensed and insured waste removal company experienced in handling BUR materials. They can take care of proper removal, transportation and disposal, ensuring compliance with all environmental regulations. Never attempt to dispose of these materials improperly. Doing so can have serious repercussions.

Q 15. What are the different types of bitumen used in BUR systems?

Bitumen, the key ingredient in built-up roofing (BUR) systems, comes in several types, each with unique properties affecting performance and cost. The most common are:

- Asphalt: This is the most widely used bitumen type. It’s relatively inexpensive, readily available, and easy to work with. Different grades exist, with variations in viscosity and temperature sensitivity, impacting its suitability for different climates and applications. For instance, a higher-viscosity asphalt might be preferred in hotter climates to prevent sagging.

- Coal Tar Pitch: Coal tar pitch offers excellent water resistance and durability, making it a good choice for projects demanding high longevity. However, it’s less commonly used now due to environmental concerns and its strong odor. It’s also less flexible than asphalt, making it more prone to cracking under stress.

- Modified Bitumen: This category encompasses bitumens enhanced with polymers like SBS (styrene-butadiene-styrene) or APP (Atactic Polypropylene). These modifications improve the bitumen’s flexibility, durability, and resistance to temperature extremes, leading to longer-lasting roofs. SBS modified bitumen, for example, excels in low-temperature flexibility, making it ideal for colder climates.

Choosing the right bitumen type depends on factors like budget, climate, roof design, and project requirements. A thorough analysis of these factors is crucial for successful BUR installation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you calculate the amount of materials needed for a BUR roofing project?

Calculating material quantities for a BUR project requires careful planning and accurate measurements. Here’s a step-by-step approach:

- Measure the roof area: Precisely measure the roof’s surface area, accounting for all slopes, valleys, and projections. Use appropriate measuring tools and break down complex shapes into simpler ones for easier calculation.

- Determine the number of plies: The number of layers (plies) of roofing felt depends on the desired durability and local building codes. A typical BUR system may consist of two or three plies.

- Calculate felt requirements: Each ply requires a specific amount of roofing felt, typically expressed in squares (100 square feet). Consider overlap (usually 2-4 inches) to ensure complete coverage and watertightness. For example, if you have a 1000 square foot roof and need two plies with a 3-inch overlap, the actual felt required will be slightly more than 2000 square feet to account for the waste.

- Calculate bitumen requirements: Bitumen is typically applied in liquid form. The amount needed depends on the type of bitumen, the number of plies, and the desired coverage. Manufacturers often provide application rates in gallons per square.

- Account for accessories: Remember to include quantities for other materials like base sheets, insulation, flashing, fasteners, and primers.

Using spreadsheets or specialized roofing software can simplify calculations and ensure accuracy. Always add a contingency of 5-10% to account for unforeseen circumstances or material waste.

Q 17. Describe your experience with different types of roofing felts.

My experience encompasses various roofing felts used in BUR systems, each with its characteristics and applications. These include:

- Organic Felt: Made from recycled paper saturated with bitumen, organic felt is relatively inexpensive and easy to work with. However, it’s more susceptible to moisture absorption and deterioration compared to other types. I’ve found it suitable for simpler projects with lower longevity requirements.

- Glass Fiber Felt: Made from fiberglass mats saturated with bitumen, glass fiber felt is stronger, more dimensionally stable, and less prone to moisture damage than organic felt. It offers superior performance, especially in hot climates, and is my preferred choice for most projects due to its balance of cost and performance.

- Modified Bitumen Felts: These incorporate polymer modifications for enhanced performance. They often have higher initial costs but their improved flexibility, UV resistance, and overall durability translate to longer lifespan and reduced maintenance, making them a cost-effective choice in the long run. I’ve worked extensively with SBS-modified felts, noticing their excellent low-temperature flexibility.

Selecting the appropriate felt requires understanding the project’s specific needs and environmental conditions. The right choice ensures the overall success and longevity of the BUR system.

Q 18. What are the common causes of BUR system failures?

BUR system failures can stem from various causes, often interconnected. Some of the most common include:

- Poor Installation: Improper preparation of the substrate, insufficient adhesion between plies, inadequate sealing of seams and flashings, and incorrect application of bitumen are frequent culprits. I’ve seen projects fail because of shortcuts taken during installation.

- Substrate Issues: Underlying defects in the roof deck, such as moisture, cracks, or uneven surfaces, can compromise the system’s integrity, causing premature failure. Thorough substrate preparation is essential.

- Material Defects: Using low-quality materials or materials unsuitable for the climate can lead to premature degradation. Careful material selection and verification are crucial.

- Environmental Factors: Exposure to extreme temperatures, UV radiation, and ponding water can accelerate deterioration. Designing the system to withstand these conditions is vital.

- Lack of Maintenance: Regular inspections and prompt repairs of minor issues are critical for extending the roof’s lifespan. Neglecting maintenance often leads to larger, more costly repairs later.

Careful attention to detail during design, material selection, and installation is crucial in preventing these issues and ensuring a long-lasting BUR system.

Q 19. How do you ensure the longevity of a BUR roofing system?

Ensuring the longevity of a BUR roofing system involves a multi-faceted approach starting from the initial design phase and extending throughout the system’s lifespan:

- Proper Design and Planning: Careful consideration of the building’s design, local climate, and anticipated loads is critical. This includes selecting appropriate materials and detailing the system to withstand anticipated stresses.

- Meticulous Installation: Precise adherence to manufacturer’s specifications and best practices is essential. This includes proper substrate preparation, accurate application of bitumen, careful sealing of all seams and flashings, and quality control throughout the installation process. I always emphasize the importance of a well-trained crew.

- High-Quality Materials: Selecting durable, high-performance materials, including bitumen, felts, and accessories, is crucial for long-term performance. Using certified and reputable suppliers is key.

- Regular Maintenance: Regular inspections and prompt repairs of any observed damage are critical. Addressing minor issues before they escalate prevents larger, more costly repairs later. This could include inspecting for ponding water, checking for cracks and blisters, and ensuring proper drainage.

- Protection from Environmental Factors: Minimizing exposure to UV radiation and extreme temperatures through proper design and using UV-resistant materials is crucial. Proper drainage to prevent ponding water is also critical.

A well-designed, properly installed, and regularly maintained BUR system can easily last for two decades or more.

Q 20. What are your skills in using roofing equipment?

My skills in using roofing equipment are comprehensive and encompass a wide range of tools and machinery used in BUR installations. This includes proficiency in:

- Torch Application of Bitumen: I am experienced in safely and effectively using propane torches to melt and apply bitumen, ensuring even coverage and avoiding fire hazards.

- Roller Application of Bitumen: I am skilled in using rollers of varying sizes to achieve uniform bitumen distribution and proper adhesion between plies.

- Power Tools: I am proficient in using various power tools, including pneumatic nailers for securing flashings and other accessories, and cutting tools for precise trimming of roofing materials.

- Safety Equipment: I am thoroughly trained and experienced in using safety equipment, including personal protective equipment (PPE), fall protection systems, and fire safety equipment, ensuring a safe work environment for myself and my team.

- Specialized Equipment: I’m familiar with the operation and maintenance of more specialized equipment like hot air welders for certain types of modified bitumen membranes.

Safety is paramount, and my expertise extends to ensuring the safe and efficient operation of all equipment used in BUR installation.

Q 21. How do you handle conflicts or disagreements within a roofing crew?

Conflict resolution is a crucial skill for any team leader in the construction industry. When disagreements arise within my roofing crew, I address them proactively and professionally using a structured approach:

- Active Listening: I make sure to listen to everyone involved without interruption, fully understanding their perspectives and concerns.

- Neutral Facilitation: I act as a neutral facilitator, encouraging open communication and respectful dialogue between the conflicting parties.

- Identifying the Root Cause: I work to identify the underlying cause of the disagreement. Is it a misunderstanding, a difference in approach, or something more systemic?

- Finding Common Ground: I guide the team towards finding common ground and a mutually acceptable solution, emphasizing collaborative problem-solving.

- Clear Communication: I ensure clear and concise communication of the agreed-upon solution to all parties involved.

- Follow-up and Prevention: I follow up to ensure the solution is effective and implement measures to prevent similar conflicts in the future. This might involve additional training or improved communication strategies.

My goal is always to resolve conflicts constructively, fostering a positive and productive work environment. I believe in building a team where open communication and mutual respect are the norm.

Q 22. Explain your understanding of roofing industry codes and standards.

Understanding roofing industry codes and standards is paramount for safe and compliant installations. These codes, such as those published by organizations like the International Code Council (ICC) and the American Society for Testing and Materials (ASTM), dictate everything from material specifications and installation methods to safety protocols and fire resistance requirements. For Built-Up Roofing (BUR), specific standards address the types of felts, asphalt, and surfacing materials used, as well as the minimum number of plies and the application techniques. For example, ASTM D3161 covers asphalt-saturated roofing felts, specifying their weight, dimensions, and performance characteristics. Ignoring these standards can lead to project failure, costly repairs, and legal liability.

My experience encompasses a thorough understanding of these standards and their practical application. I’m familiar with regional variations and modifications to the codes and routinely consult the latest editions to ensure compliance. I also stay updated on any changes or new interpretations through industry publications and continuing education.

Q 23. Describe your experience with different types of roofing substrates.

Different roofing substrates form the base layer of a BUR system and significantly impact its longevity and performance. My experience includes working with various substrates, each requiring specific preparation and installation techniques. These include:

- Concrete Decks: These require thorough cleaning and patching of cracks or imperfections before applying the BUR system. Moisture content must be carefully monitored to prevent blistering.

- Wood Decks: Wood decks necessitate the use of a suitable vapor barrier to prevent moisture damage. They also require proper treatment for rot and insect infestation.

- Metal Decks: These need to be cleaned and primed to ensure proper adhesion of the BUR system. Careful consideration needs to be given to thermal expansion and contraction.

- Insulated Metal Panels (IMPs): These present unique challenges due to their composition and fastening systems. Appropriate sealant and attachment methods are crucial.

Understanding the characteristics of each substrate is crucial for choosing the correct materials and installation methods. For example, a concrete deck with high moisture content might necessitate the use of a specialized primer to achieve optimal adhesion, while a wood deck needs a vapor barrier to mitigate the risk of moisture penetration.

Q 24. How do you manage a roofing project schedule effectively?

Effective project scheduling is critical for on-time and within-budget completion. I utilize a combination of techniques, including:

- Detailed Project Planning: This involves breaking down the project into smaller, manageable tasks with clearly defined timelines and dependencies.

- Resource Allocation: Efficiently assigning labor and materials ensures timely progress. This includes considering weather conditions and potential delays.

- Regular Monitoring & Progress Tracking: Daily or weekly progress reports allow for proactive identification and resolution of any issues or delays.

- Communication & Coordination: Maintaining clear communication with clients, subcontractors, and suppliers ensures everyone is on the same page.

- Contingency Planning: Building in buffer time for unexpected delays due to weather or material shortages is vital.

For instance, in a recent project, I used project management software to track progress, manage resources, and communicate with the team. This allowed us to complete the project ahead of schedule despite a few unexpected weather delays.

Q 25. How do you ensure quality control throughout the BUR installation process?

Quality control is built into every step of the BUR installation process. My approach includes:

- Material Inspection: Thoroughly checking all materials upon delivery for any damage or defects ensures that only high-quality materials are used.

- Substrate Preparation Verification: Careful inspection of the substrate for proper cleaning, patching, and priming is crucial for optimal adhesion.

- Application Quality Assurance: Regular monitoring of the installation process to ensure proper ply placement, overlap, and adherence to manufacturer’s instructions.

- Adherence Testing: Performing pull-off tests or other relevant tests to assess the adhesion strength of the installed BUR system.

- Final Inspection: A thorough final inspection after completion to check for any imperfections or areas needing attention. This also includes checking for proper drainage and flashing details.

By implementing these quality control measures, we ensure the longevity and performance of the BUR roofing system, minimizing the risk of future leaks or damage.

Q 26. Describe a time you had to solve a challenging roofing problem.

On one project, we encountered unexpected subsurface voids in the concrete deck during installation. This presented a significant challenge as it risked compromising the integrity of the entire BUR system. My team and I worked together to develop a solution. We carefully mapped the voids using ground-penetrating radar, then filled them using a lightweight, high-strength expanding foam. After the foam cured, we proceeded with the BUR installation. This required careful planning and coordination with the subcontractors but ultimately prevented potential future issues and ensured the longevity of the roof.

Q 27. What are the latest trends and advancements in BUR roofing technology?

The BUR roofing industry is constantly evolving. Recent trends and advancements include:

- Improved Asphalt Technology: Development of modified bitumens with enhanced durability and resistance to weathering and UV degradation.

- Advanced Reinforcing Materials: Use of stronger and more durable synthetic felts, offering improved tear resistance and overall system strength.

- Sustainable Materials: Increased adoption of recycled materials in BUR systems, promoting environmental sustainability.

- Improved Installation Techniques: The use of specialized equipment and techniques enhances efficiency and reduces waste. For example, hot air welding of seams reduces the potential for leaks.

- Integration with Building Information Modeling (BIM): Using BIM technology to plan and coordinate the BUR installation, improving efficiency and accuracy.

Staying abreast of these advancements is crucial for maintaining a competitive edge and delivering high-quality, sustainable roofing solutions.

Q 28. How do you maintain professional relationships with clients and colleagues?

Maintaining professional relationships with clients and colleagues is essential. I strive to build strong relationships based on:

- Open Communication: Regularly communicating project updates, addressing concerns promptly, and actively listening to feedback.

- Respect & Professionalism: Treating everyone with respect, regardless of their role, and maintaining a professional demeanor at all times.

- Collaboration & Teamwork: Working collaboratively with colleagues and subcontractors to achieve shared goals.

- Problem-Solving & Conflict Resolution: Approaching problems constructively and resolving conflicts fairly and effectively.

- Building Trust & Rapport: Establishing trust through consistent performance, reliability, and commitment to excellence.

By fostering these relationships, I create a positive and productive work environment, leading to successful projects and repeat business.

Key Topics to Learn for Built-up Roofing Installation Interview

- Roofing System Components: Understanding the function and interaction of various components like base sheets, plies, asphalt, and gravel.

- Installation Techniques: Mastering the practical skills of applying base sheets, mopping asphalt, installing plies, and finishing with gravel or other surfacing materials. This includes understanding different application methods and their suitability for varying conditions.

- Safety Procedures and Regulations: Demonstrating knowledge of OSHA standards, fall protection, and safe handling of materials like hot asphalt.

- Material Selection and Properties: Understanding the characteristics of different roofing materials and their appropriate applications based on factors like climate, building type, and budget.

- Troubleshooting and Problem-Solving: Ability to identify and address common issues such as blisters, leaks, and uneven surfaces during and after installation.

- Quality Control and Inspection: Understanding the importance of adhering to specifications and performing thorough inspections to ensure a long-lasting and leak-free roof.

- Estimating and Project Management: Familiarity with basic estimating procedures, material calculations, and project scheduling.

- Environmental Considerations: Understanding the environmental impact of roofing materials and disposal methods.

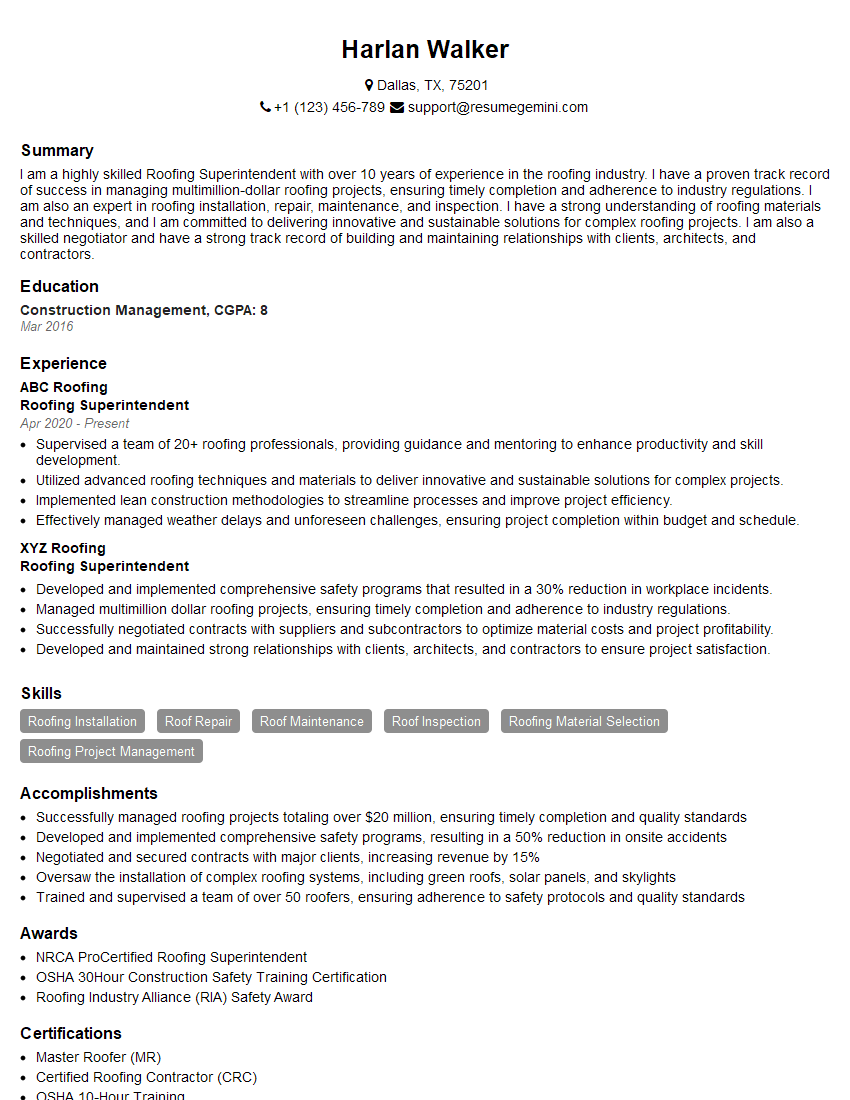

Next Steps

Mastering Built-up roofing installation opens doors to a rewarding career with excellent growth potential. This specialized skill is highly sought after, offering opportunities for advancement and higher earning potential. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is essential for getting your application noticed by recruiters. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, highlighting your expertise in Built-up Roofing Installation. Examples of resumes tailored to this field are provided to help guide your resume creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.