Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Case Hardening interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Case Hardening Interview

Q 1. Explain the different types of case hardening processes.

Case hardening is a heat treatment process that increases the hardness and wear resistance of the surface of a metal component while maintaining a softer, more ductile core. This is achieved by introducing a higher concentration of carbon or nitrogen to the surface layer. Several methods exist, each with its own advantages and disadvantages. The most common types include:

- Carburizing: This process increases the carbon content of the surface, typically using a carbon-rich atmosphere like gas or solid carburizers.

- Nitriding: This process introduces nitrogen into the surface, resulting in a hard, wear-resistant layer. Various methods, such as gas nitriding and plasma nitriding, are employed.

- Carbonitriding: A combination of carburizing and nitriding, offering benefits of both increased carbon and nitrogen at the surface.

- Induction Hardening: This method uses electromagnetic induction to heat the surface layer, rapidly followed by quenching. It’s suitable for specific geometries and doesn’t involve changing the material composition.

- Flame Hardening: This involves heating the surface with a high-temperature flame, followed by quenching, useful for larger components.

The choice of method depends on the specific requirements of the component, such as the desired case depth, hardness, and the material itself.

Q 2. Describe the advantages and disadvantages of carburizing.

Carburizing offers several advantages, making it a popular choice for many applications. It provides a deep and uniform case hardening layer, significantly enhancing wear resistance and fatigue strength. This is crucial for components subjected to high stress and friction, such as gears and crankshafts. The core remains ductile, preventing brittle fracture under load. For instance, imagine a gear in a heavy-duty truck transmission – carburizing ensures the teeth withstand immense forces without breaking.

However, carburizing also has limitations. It’s a relatively time-consuming process, requiring carefully controlled temperature and time cycles. The process can also distort the component, requiring subsequent straightening operations. Additionally, the high carbon content in the case layer can make it susceptible to oxidation at high temperatures if not properly protected.

Q 3. What are the critical parameters to control during a carburizing cycle?

Controlling the carburizing cycle is crucial for achieving the desired case depth and hardness. Critical parameters include:

- Temperature: Precise control is needed to ensure the correct diffusion rate of carbon into the steel. Too low, and the process is slow; too high, and grain growth can negatively impact properties.

- Time: The duration of the carburizing process directly dictates the case depth. Longer times lead to deeper cases.

- Carbon Potential: This refers to the activity of carbon in the carburizing atmosphere. It dictates the amount of carbon absorbed by the steel, directly impacting the case hardness.

- Atmosphere Composition: The gas composition must be carefully controlled to ensure uniform carburization and prevent unwanted reactions, such as oxidation or decarburization.

- Part Geometry: The shape of the component can affect the uniformity of the carburized layer. Complex geometries might require specific techniques or multiple stages to ensure even penetration of carbon.

Monitoring these parameters using sensors and sophisticated control systems is essential for consistent and reliable results.

Q 4. How do you determine the optimal case depth for a specific application?

Determining the optimal case depth depends heavily on the application. A thorough understanding of the intended use and loading conditions is essential. For example:

- High-stress applications (gears, axles): These often require a deeper case depth to ensure sufficient wear and fatigue resistance.

- Low-stress applications (small fasteners): These might need only a thin case for surface protection.

The process often involves a balance between wear resistance (deeper case) and core toughness (shallower case). Finite element analysis (FEA) and experimentation can be used to determine the optimal case depth that satisfies both requirements. Industry standards and historical data for similar applications can also guide the decision-making process.

Q 5. Explain the role of quench media in case hardening.

The quench media plays a vital role in case hardening by rapidly cooling the heated surface layer, transforming the austenite (high-temperature form of steel) into martensite (a hard, brittle phase). The rate of cooling significantly influences the final hardness of the case. A faster quench rate leads to a harder case, while a slower quench rate results in a softer case. The selection of quench media is crucial, as improper quenching can lead to cracking or distortion of the component. The choice involves balancing the required cooling rate with the risks of cracking.

Q 6. What are the different types of quench media used in case hardening?

Several quench media are used in case hardening, each offering a different cooling rate and suitability for various applications:

- Oil: Offers a moderate cooling rate, making it suitable for many applications where the risk of cracking is high. Different types of oil provide variations in cooling rate.

- Water: Provides a very fast cooling rate, resulting in a harder case but with an increased risk of cracking. Often used with specific additives to control the cooling rate.

- Polymer Quenchants: These offer better control over the cooling rate compared to water or oil, and also tend to have better environmental profiles.

- Air: Provides a slow cooling rate, generally used when a slower cooling is desired to minimize distortions and stress. Useful for some components such as those that have thin cross-sections.

The choice of quench media is based on the material, component geometry, and the desired final hardness.

Q 7. Describe the process of nitriding and its applications.

Nitriding is a case hardening process that introduces nitrogen into the surface of a metal component, usually steel, forming hard nitrides. Unlike carburizing, which changes the carbon content, nitriding creates a thin but exceptionally hard and wear-resistant layer. The process is typically carried out at lower temperatures (500-570°C) than carburizing, making it suitable for components with complex geometries or those requiring precise dimensional control, minimizing distortion.

There are different nitriding methods, including gas nitriding (using ammonia gas), plasma nitriding (using a plasma discharge), and salt bath nitriding. The choice depends on factors like cost, required case depth, and equipment availability.

Nitriding finds applications in various industries. It’s particularly valuable for components requiring high wear resistance, such as:

- Engine components: Camshafts, gears, and other engine parts benefit from the increased durability and resistance to scuffing provided by nitriding.

- Molding tools: Nitriding improves the surface hardness and wear resistance of molds, leading to longer tool life and better surface finish of the molded product.

- Medical implants: Nitriding can enhance the biocompatibility and wear resistance of some implant materials.

The relatively thin case depth and the absence of significant dimensional changes post-nitriding make it a preferred choice for many precision components.

Q 8. What are the common defects found in case hardened components and how are they prevented?

Case hardening, while strengthening the surface of a component, can unfortunately lead to several defects. These defects can compromise the integrity and performance of the final product. Common issues include:

- Incomplete Case: This occurs when the carbon diffusion isn’t complete throughout the designated depth, resulting in inconsistent hardness. Imagine trying to bake a cake – if the heat doesn’t penetrate fully, you’ll have an undercooked center. Prevention involves careful control of carburizing time and temperature, ensuring adequate carbon potential, and using appropriate furnace design.

- Soft Spots or Decarburization: These occur when the surface layer loses carbon, leading to reduced hardness. This often happens due to oxidation at high temperatures. Prevention requires controlling the furnace atmosphere (using protective gases), preventing prolonged exposure to air, and careful cleaning of parts before heat treatment.

- Distortion and Cracking: Uneven heating or cooling rates during the process can create internal stresses, leading to warping or cracking. Preventing this requires careful part design, controlled heating and cooling cycles (e.g., using furnaces with optimized temperature control and quenching systems), and potentially using fixtures to minimize distortion.

- Surface Defects: Surface imperfections such as scratches or scale before case hardening can exacerbate existing problems or create new ones after. Prevention involves careful handling and cleaning of parts prior to heat treatment, and potentially pre-treatment processes to improve surface condition.

In summary, preventing defects requires meticulous control over every stage of the case hardening process, from part preparation to final quenching and tempering.

Q 9. Explain the importance of post-heat treatment processes after case hardening.

Post-heat treatment processes are crucial for optimizing the properties of case-hardened components. They primarily address residual stresses and refine the microstructure for optimal performance. These processes typically include:

- Tempering: This involves reheating the component to a lower temperature (below the critical temperature) to relieve internal stresses generated during quenching. This helps to improve toughness and reduce brittleness, making the component less prone to cracking or fracturing under load. Think of it as allowing the metal to relax after the rapid cooling of quenching.

- Stress Relieving: Similar to tempering, stress relieving aims to reduce residual stresses, but it’s often applied at a lower temperature and for a longer duration, focusing on relieving stresses without significantly altering the hardness. This is important for larger or more complex parts where warping or cracking is a greater concern.

- Shot Peening or other surface treatments: These can be applied to further improve fatigue resistance by inducing compressive residual stresses on the surface. This is especially useful in applications involving cyclic loading.

Neglecting post-heat treatment can lead to premature failure of components, especially in demanding applications.

Q 10. How do you verify the case depth and hardness of a case hardened component?

Verifying case depth and hardness is essential for quality control. We use several methods:

- Hardness Testing: Various techniques like Rockwell, Brinell, and Vickers hardness testing are used to measure the hardness at different depths. A microhardness tester allows for precise measurements at incremental depths, creating a hardness profile that clearly indicates case depth and the hardness gradient.

- Sectioning and Metallography: This involves cutting and polishing a cross-section of the component, etching it with a reagent, and then examining it under a microscope. This provides a visual representation of the case depth, microstructure changes, and the presence of any defects.

- Magnetic methods: Certain methods utilize magnetic properties to indirectly measure case depth, providing a rapid assessment though generally less precise than sectioning and metallography.

Choosing the right method depends on the component’s size, shape, and the required level of precision. Often, a combination of methods is employed to ensure comprehensive verification.

Q 11. What are the different hardness testing methods used for case hardened parts?

Several hardness testing methods are suitable for case-hardened parts, each offering specific advantages:

- Rockwell Hardness Test: A widely used method that employs a penetrator to measure the depth of indentation under a specific load. The Rockwell C scale (using a diamond cone penetrator) is often used for case-hardened steels due to the high hardness of the case.

- Brinell Hardness Test: This uses a hardened steel or carbide ball indenter to create an indentation. It’s suitable for measuring the hardness of thicker case depths or softer cores.

- Vickers Hardness Test: Employing a diamond pyramidal indenter, this method is precise and suitable for both hard and soft materials, allowing for measurements at various depths within the case-hardened layer.

- Microhardness Testing: Uses a small indenter and lower loads, enabling highly localized measurements at extremely shallow depths to create a detailed hardness profile.

The choice depends on factors such as the required accuracy, the depth of the case, and the size and shape of the component. A metallurgical lab will have the necessary equipment to provide comprehensive analysis.

Q 12. Describe the principles of carbon potential control in carburizing furnaces.

Carbon potential control in carburizing furnaces is critical for achieving the desired case depth and hardness. Carbon potential refers to the activity or concentration of carbon in the furnace atmosphere. It’s essentially a measure of how readily carbon can diffuse into the workpiece. This control is typically achieved by:

- Precise Gas Mixture Control: The atmosphere within the furnace is carefully controlled using a precise mix of gases like methane, carbon monoxide, and hydrogen. The ratios of these gases determine the carbon potential. Sophisticated sensors monitor and maintain this delicate balance, preventing fluctuations that could lead to inconsistencies in case depth.

- Temperature Control: Temperature significantly influences carbon diffusion. Maintaining a stable and uniform temperature throughout the furnace is vital for consistent carbon potential and uniform case depth. Temperature gradients can lead to uneven carburization.

- Material Selection: The carburizing medium itself impacts carbon potential. Different carburizing materials (e.g., solid carburizers, liquid carburizers, or gaseous carburizers) have different carbon potentials and are selected based on specific requirements.

- Monitoring and Adjustment: Continuous monitoring of both carbon potential and temperature is crucial. Modern furnaces employ sophisticated control systems that automatically adjust gas flow rates and heating elements to maintain the target carbon potential.

Imagine it like baking a cake again: if you don’t control the oven temperature or the ingredients, you won’t get a consistent bake. The same applies to carbon potential; getting it right is key to successful case hardening.

Q 13. Explain how different alloying elements affect the case hardening process.

Alloying elements significantly influence the case hardening process, affecting both the case depth and the microstructure. Different elements have different effects:

- Nickel (Ni): Improves hardenability of both the core and case, resulting in a deeper and harder case. It can also improve toughness.

- Chromium (Cr): Enhances hardenability, improves corrosion resistance, and contributes to increased wear resistance of the case. However, higher chromium contents can reduce the depth of case hardening. The effects are complex and depend on the overall composition of the steel.

- Molybdenum (Mo): Improves hardenability and high-temperature strength, especially beneficial in applications requiring resistance to creep and deformation at elevated temperatures. It refines the microstructure and also increases the depth of hardening.

- Manganese (Mn): Improves the hardenability of the steel. However, high manganese can negatively impact the depth of the case.

- Silicon (Si): Reduces the depth of hardening and generally does not contribute positively to case hardening. Therefore, its presence is generally undesirable.

The effects of alloying elements are intertwined and complex. Precise control and proper consideration of the desired properties are crucial for optimizing the case hardening process. A metallurgist plays a critical role in determining the ideal alloying composition.

Q 14. How do you troubleshoot issues related to uneven case depth?

Uneven case depth is a significant problem, indicating inconsistencies in the carburizing process. Troubleshooting requires a systematic approach:

- Visual Inspection: Start with a careful visual inspection of the component and the surrounding area in the furnace to identify potential sources of uneven heating or gas flow.

- Hardness Testing: Conduct comprehensive hardness testing across the component’s surface and at different depths to map the hardness variations. This will pinpoint areas with insufficient or excessive case depth.

- Metallographic Examination: A cross-section analysis will reveal the microstructure, including any variations in case depth, and helps to identify the root cause. It can show if there are differences in grain size, presence of decarburization, or other issues.

- Furnace Inspection and Calibration: Examine the furnace for any malfunctions in heating elements, gas flow, or temperature control. Ensure the furnace is properly calibrated and that the control system is working accurately. Temperature gradients within the furnace are a common cause.

- Part Handling and Loading: Assess the loading method in the furnace. Overcrowding, poor positioning, or contact with other components can disrupt uniform heating and carburization. Consider improving loading techniques to ensure uniform gas flow around all components.

- Review of Carburizing Parameters: Review the carburizing parameters (time, temperature, gas composition, etc.) to ensure they’re aligned with specifications for the material and desired case depth. Adjustments may be needed.

Solving uneven case depth issues requires a methodical approach. By carefully examining all aspects of the process, from furnace conditions to component handling, the underlying problems can usually be identified and addressed.

Q 15. Describe the role of atmosphere control in case hardening furnaces.

Atmosphere control in case hardening furnaces is crucial for ensuring the successful and consistent carburization of the workpiece. The furnace atmosphere dictates the carbon potential, which directly influences how much carbon diffuses into the surface of the steel. Think of it like baking a cake – you need the right oven temperature and humidity to get the perfect result. Similarly, in case hardening, we control the atmosphere to achieve the desired carbon concentration in the case-hardened layer.

For example, in gas carburizing, a controlled atmosphere containing hydrocarbons (like methane or propane) and an inert gas (like nitrogen) is used. The hydrocarbons decompose at high temperatures, releasing carbon which diffuses into the steel’s surface. The inert gas helps to maintain a reducing atmosphere and prevents oxidation. Precise control of the gas composition, temperature, and flow rate is critical to achieving the desired carbon concentration and case depth.

Different atmospheres are employed depending on the type of case hardening process. For example, pack carburizing utilizes a solid carbonaceous material, creating its own atmosphere during the process. Precise control of the atmosphere even within these seemingly ‘self-contained’ processes is still critically important.

Career Expert Tips:

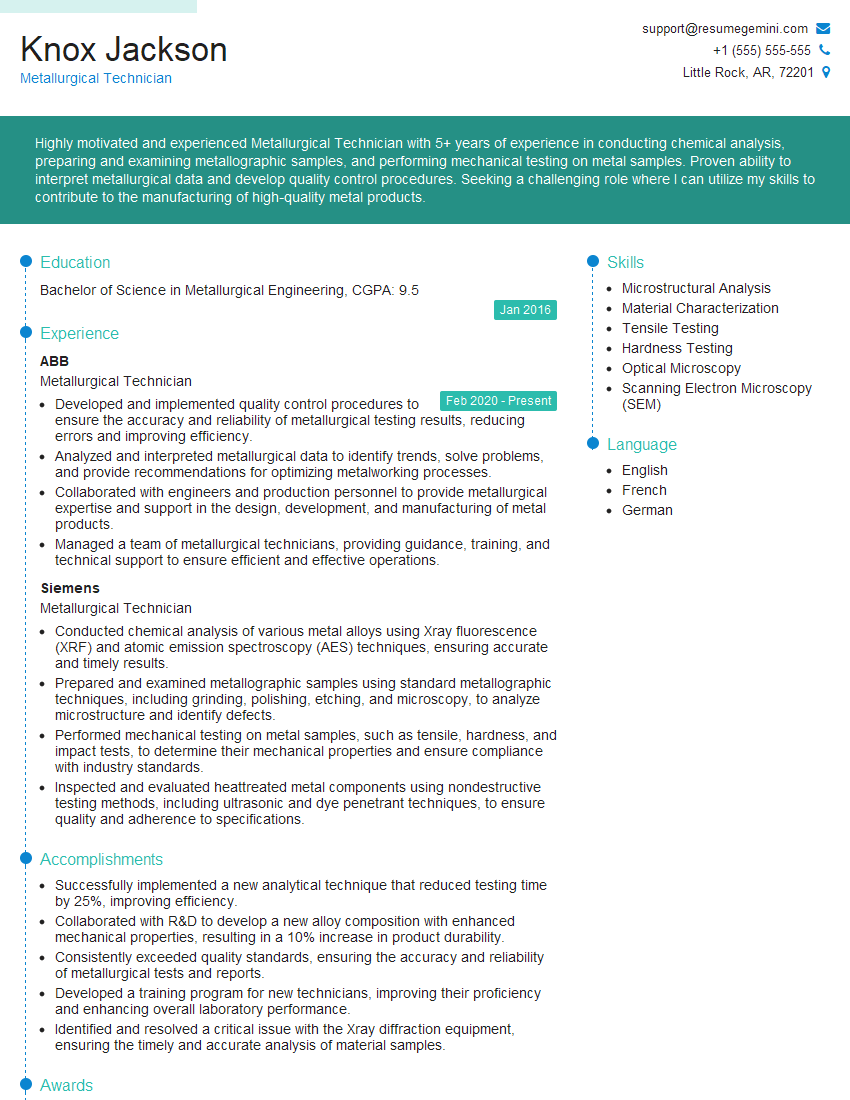

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of proper cleaning and preparation of parts before case hardening.

Proper cleaning and preparation of parts before case hardening is paramount for ensuring consistent and high-quality results. Imagine trying to paint a car without cleaning it first – the paint wouldn’t adhere properly. Similarly, contaminants on the workpiece surface can prevent proper carburization, leading to inconsistencies in the case-hardened layer and potential defects.

The preparation process typically involves several steps: First, parts are degreased to remove oils and greases. This is often done using solvents or alkaline cleaners. Next, any surface oxides or scale (often from prior processing steps) are removed by shot peening, grinding, or chemical etching. This ensures a clean surface for the carbon to diffuse into. Finally, parts are sometimes pre-heated to promote uniform heating during the case hardening process and improve the consistency of the process.

Failure to properly clean and prepare parts can result in uneven case depth, surface cracking, and poor adhesion of the hardened layer, ultimately compromising the component’s performance and lifespan.

Q 17. What are the safety precautions associated with case hardening processes?

Case hardening processes involve high temperatures and potentially hazardous materials, necessitating stringent safety precautions. The key hazards include:

- High Temperatures: Burns from contact with hot parts or furnace components are a significant risk. Proper personal protective equipment (PPE) such as heat-resistant gloves, sleeves, and eye protection is mandatory.

- Hazardous Gases: Some case hardening processes, like gas carburizing, involve the use of flammable and/or toxic gases. Adequate ventilation, leak detection systems, and emergency response plans are essential.

- Chemical Hazards: Cleaning and preparation processes often involve chemicals like solvents and alkaline cleaners which can be irritating or harmful. Appropriate PPE, safe handling procedures, and proper disposal are crucial.

- Quenching Hazards: Quenching, the rapid cooling of parts after carburizing, can involve splashing hot quenching oils or aqueous solutions. Protective barriers and appropriate PPE are needed.

Regular safety training for personnel and adherence to established safety procedures are fundamental to minimize risks associated with case hardening.

Q 18. How do you select the appropriate case hardening process for a given material?

Selecting the appropriate case hardening process hinges on several factors, including the material composition, required case depth, desired surface hardness, and cost considerations. Each process has its strengths and limitations:

- Material: Low-carbon steels are best suited for carburizing, while other materials might require different processes.

- Case Depth: Gas carburizing offers good control over case depth and is suitable for mass production. Pack carburizing is more cost-effective for smaller batches, but controlling case depth can be more challenging.

- Surface Hardness: The choice of process and quenching medium dictates the final surface hardness.

- Cost: Gas carburizing can be capital intensive, but has high throughput. Pack carburizing is often favored for lower volumes.

A thorough material analysis and understanding of the application’s requirements are crucial steps in selecting the optimal case hardening process. Often, a consultation with a materials engineer is beneficial to ensure the best approach is selected.

Q 19. Describe the differences between gas carburizing, liquid carburizing, and pack carburizing.

Gas carburizing, liquid carburizing, and pack carburizing are three common methods of case hardening, each with distinct characteristics:

- Gas Carburizing: This process involves exposing parts to a controlled atmosphere of hydrocarbon gases (e.g., methane, propane) and an inert gas (e.g., nitrogen) at high temperatures (typically 870-950°C). It offers excellent control over case depth and uniformity, and is suitable for mass production. Think of it like gently infusing carbon into the steel’s surface.

- Liquid Carburirizing: This method involves immersing the parts in a molten salt bath containing carbon-containing compounds. It is faster than gas carburizing but can be less precise in controlling case depth, and the salt bath can corrode parts. It is a bit like a quicker carbon bath.

- Pack Carburizing: In this method, the parts are packed in a container with a carbonaceous material (e.g., charcoal, bone, and activators) and heated. Carbon diffuses into the steel from the solid carbonaceous material. This method is suitable for smaller batches and less complex geometries. It is a more cost-effective option for lower volume productions.

The choice among these methods depends on factors such as production volume, required precision in case depth control, and cost constraints.

Q 20. Explain the concept of diffusion in the context of case hardening.

Diffusion is the fundamental principle behind case hardening. It’s the process by which carbon atoms move from a region of high concentration (the carburizing atmosphere or medium) to a region of lower concentration (the steel’s surface and core). Imagine dropping a sugar cube into a glass of water – the sugar molecules slowly spread throughout the water. Similarly, carbon atoms diffuse into the steel’s surface layer, increasing its carbon content.

The rate of diffusion depends on several factors, including temperature, time, and the type of steel. Higher temperatures accelerate diffusion, allowing for deeper case depths in shorter times. The process isn’t instantaneous; the time held at temperature directly dictates how deeply the carbon will penetrate. Understanding diffusion kinetics is crucial to controlling case depth and hardness.

Successful case hardening requires carefully controlling the diffusion process to achieve the desired carbon concentration profile and hence, the desired properties in the final component.

Q 21. What are the environmental regulations related to case hardening?

Environmental regulations governing case hardening processes vary by location, but they generally focus on controlling emissions of pollutants generated during the processes. These include:

- Air Emissions: Regulations often limit the emission of particulate matter, hydrocarbons, and potentially harmful gases produced during heating and carburizing processes. These require the use of efficient exhaust systems and potentially gas scrubbing or filtration technologies.

- Wastewater Treatment: Wastewater from cleaning and quenching processes must be treated before discharge to comply with water quality standards. This may involve filtration, neutralization, and other treatment methods.

- Hazardous Waste Disposal: Used quenching oils and other hazardous materials must be disposed of according to local and national regulations. Proper recycling or specialized waste disposal facilities are necessary.

Compliance with these regulations requires careful monitoring of emissions and waste streams, implementation of appropriate control technologies, and thorough record-keeping. Staying informed about changing regulations in your area is crucial for maintaining compliance.

Q 22. How do you interpret a hardness profile of a case hardened component?

Interpreting a hardness profile of a case-hardened component is crucial for ensuring the part meets its design specifications. The profile shows the variation in hardness from the surface to the core of the component. Ideally, you’ll see a sharp increase in hardness at the surface (the case) followed by a gradual decrease as you move towards the core. This represents the successful diffusion of carbon or other alloying elements into the surface, creating a hard, wear-resistant outer layer while retaining the toughness of the core.

We look for several key characteristics:

- Case Depth: The distance from the surface to the point where the hardness drops to a specified value (e.g., 50 HRC). This is a critical parameter often specified in design drawings.

- Surface Hardness: The maximum hardness achieved at the surface. This indicates the wear resistance of the component.

- Hardness Gradient: The rate at which hardness decreases from the surface to the core. A smooth, gradual gradient is generally preferred to prevent cracking or other issues.

- Core Hardness: The hardness of the component’s core. This needs to be sufficient to provide toughness and prevent catastrophic failure.

Deviations from the expected profile can indicate problems during the case hardening process, such as insufficient carbon penetration, improper cooling, or inconsistent furnace temperature. For instance, a shallow case depth suggests insufficient time at temperature or low carbon potential in the furnace atmosphere. Conversely, a very steep gradient could indicate rapid quenching which might cause cracking.

We often use specialized software to analyze hardness profiles, generating graphs and reports to facilitate interpretation and quality control. The analysis ultimately ensures the component meets its specified performance requirements and is fit for its intended application.

Q 23. Explain the impact of different cooling rates on the microstructure of case hardened steel.

Cooling rate significantly impacts the microstructure and consequently, the hardness and toughness of case-hardened steel. Different cooling methods create different transformations of austenite, the high-temperature phase of steel, leading to varied microstructures.

Slow Cooling: Slow cooling allows for the gradual transformation of austenite into pearlite (a mixture of ferrite and cementite), resulting in a softer, more ductile case. This microstructure might be preferred where impact resistance is prioritized over extreme hardness.

Rapid Cooling (Quenching): Rapid cooling, such as quenching in oil or water, traps the carbon in a supersaturated solid solution (martensite), leading to a very hard, but brittle case. The choice of quenching medium impacts the cooling rate and subsequent microstructure; water provides faster cooling than oil, resulting in a harder but potentially more brittle case. It’s important to select a quenching medium appropriate to the specific steel and application, considering the risk of distortion and cracking.

Martempering/Austempering: These are intermediate cooling approaches that aim to improve toughness while maintaining high hardness. They involve a controlled cooling stage to lessen thermal stresses before final cooling. Martempering uses an isothermal hold at a relatively high temperature, while austempering involves an isothermal hold at a lower temperature.

Think of it like cooking an egg: slow cooking (slow cooling) produces a soft, fully cooked egg (pearlite), while rapid cooking (rapid cooling) leads to a hard-boiled egg (martensite). The ideal cooling rate depends on the required balance between hardness, toughness, and the risk of distortion or cracking.

Q 24. How do you manage and reduce the distortion of parts during case hardening?

Distortion during case hardening is a significant challenge, often resulting from the non-uniform temperature gradients and phase transformations that occur during the process. Several strategies can minimize distortion:

- Preheating: Carefully controlled preheating helps reduce the temperature differential between the surface and core during the case hardening process, minimizing stress development. Think of it like slowly bringing a large metal object to heat before forging, reducing the risk of cracking.

- Fixtures and Jigs: Using robust fixtures and jigs during the heat treatment process helps maintain the part’s shape and minimizes warping. These hold the components in a specific position to counteract warping forces.

- Part Design: Designing parts with symmetrical geometries and avoiding sharp corners can significantly reduce distortion susceptibility. For example, designing a part with uniform wall thickness is less prone to warping than one with varying thicknesses.

- Controlled Cooling: Employing controlled cooling techniques, such as a controlled atmosphere furnace or oil quenching with agitation, ensures uniform cooling and reduces internal stresses that might cause warping. This can be like taking a hot object out of the oven and placing it in a carefully regulated cooling chamber.

- Stress Relieving: Following case hardening, a stress-relieving heat treatment can be employed to reduce residual stresses and minimize distortion. This treatment involves heating the part to a lower temperature and then slowly cooling it.

Selecting the right quenching medium is also crucial. Oil quenching generally offers better dimensional control than water quenching due to slower cooling.

Q 25. What are the different types of furnaces used for case hardening?

Various furnace types are employed for case hardening, each with its strengths and limitations:

- Batch Furnaces: These are traditional furnaces where parts are loaded in batches and heated uniformly. They are versatile but have longer cycle times compared to continuous furnaces.

- Continuous Furnaces: These furnaces provide a continuous flow of parts through a controlled heating zone, leading to higher throughput and consistent heating. They are particularly well-suited for high-volume production.

- Vacuum Furnaces: Vacuum furnaces offer precise control over the atmosphere and minimize oxidation and decarburization. They are particularly useful for high-value components requiring a clean surface finish.

- Salt Bath Furnaces: These furnaces use molten salt as the heating medium, providing rapid and uniform heating. They are well-suited for achieving specific case depths and hardness levels.

The selection of a specific furnace depends on factors such as production volume, part geometry, required case depth, and the desired level of process control. Vacuum furnaces are often used in high-precision applications, while salt bath furnaces are favored for rapid heating.

Q 26. Describe your experience with statistical process control (SPC) in case hardening.

Statistical Process Control (SPC) is essential for maintaining consistent case hardening quality. In my experience, we’ve implemented SPC to monitor critical process parameters like furnace temperature, atmosphere composition, quench temperature, and case depth. Control charts (like X-bar and R charts) are used to track these parameters and identify any deviations from the established control limits.

Data is collected at regular intervals and analyzed to detect trends, patterns, and special causes of variation. We use software like Minitab or JMP for data analysis and chart generation. This helps identify process drift or out-of-control conditions, allowing for timely corrective actions. For example, if the case depth starts trending consistently lower, we investigate the reasons – perhaps a drop in carbon potential in the furnace atmosphere, or changes in the quenching process. This proactive approach minimizes scrap, rework, and improves overall quality. The data-driven nature of SPC helps avoid relying on intuition and leads to evidence-based decision-making in process optimization.

Q 27. Explain your experience with troubleshooting and resolving process issues in case hardening.

Troubleshooting case hardening processes involves a systematic approach. I typically follow these steps:

- Identify the Problem: Clearly define the issue, using data from quality control inspections (e.g., hardness testing, dimensional measurements). This might involve analyzing rejected parts or unusual hardness profiles.

- Gather Data: Collect relevant process data to identify potential root causes. This could include furnace temperature logs, quench parameters, and material properties.

- Analyze the Data: Analyze the collected data, often using statistical methods or process simulation, to pinpoint the likely root cause(s).

- Develop and Implement Solutions: Based on the root cause analysis, implement corrective actions. This could range from adjusting furnace parameters to modifying the quenching process or adjusting the material specification.

- Verify the Solution: Verify the effectiveness of the implemented solution by monitoring the process parameters and product quality. SPC charts are again useful in confirming improvements.

For example, I once encountered a situation where case depth was inconsistent. Through data analysis, we discovered fluctuations in the furnace’s temperature controller, leading to inconsistent heating. Replacing the controller resolved the issue.

Q 28. Describe your experience with implementing process improvements in case hardening.

Implementing process improvements in case hardening focuses on improving efficiency, consistency, and quality. My experience includes several successful implementations:

- Automation: Implementing automated loading and unloading systems for furnaces increased throughput and reduced labor costs while maintaining consistency. It helped minimize human error and variations.

- Process Optimization: We optimized the quenching process by implementing a more effective agitation system, which improved the uniformity of the cooling rate and consequently reduced distortion. This resulted in improved yields and reduced scrap rates.

- New Technologies: I played a role in implementing a new laser-based system for measuring case depth, replacing a slower and less accurate manual method. This improved accuracy, significantly reduced inspection time, and provided more timely feedback to the process.

- Training and Development: I developed and implemented a comprehensive training program for the heat treatment team, improving their understanding of process parameters and troubleshooting techniques. Well-trained operators are key to preventing errors and improving consistency.

In all these cases, rigorous data collection and analysis played a crucial role in evaluating the impact of implemented improvements, demonstrating their effectiveness and justifying investments in process enhancements.

Key Topics to Learn for Case Hardening Interview

- Fundamentals of Case Hardening: Understand the underlying principles – diffusion, phase transformations, and the resulting changes in material properties.

- Types of Case Hardening Processes: Become familiar with carburizing (pack, gas, liquid), nitriding, carbonitriding, and flame hardening. Know their advantages, limitations, and suitability for different applications.

- Process Parameters and Control: Grasp the importance of temperature, time, atmosphere control, and quenching media in achieving desired case depth and hardness.

- Material Selection and Suitability: Learn to select appropriate base materials for various case hardening processes and understand how material composition influences the final product.

- Quality Control and Testing: Familiarize yourself with methods for measuring case depth (e.g., microhardness testing, cross-sectional analysis), surface hardness, and overall quality.

- Practical Applications: Explore real-world examples of case hardening in different industries, such as automotive, aerospace, and tooling. Understand how the chosen process impacts the performance and longevity of components.

- Troubleshooting and Problem Solving: Develop your ability to diagnose common issues encountered during case hardening, such as surface defects, inconsistent case depth, or distortion.

- Heat Treatment Considerations: Understand the relationship between case hardening and other heat treatments, and how they impact the overall microstructure and mechanical properties.

- Safety Procedures and Regulations: Be aware of the safety protocols and industry regulations associated with case hardening processes.

Next Steps

Mastering case hardening opens doors to exciting opportunities in materials engineering and manufacturing. A strong understanding of this crucial process is highly valued by employers. To significantly improve your job prospects, create an ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource for building professional resumes that get noticed. Take advantage of their tools and resources; examples of resumes tailored to Case Hardening are available to help you craft a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.