Cracking a skill-specific interview, like one for Chemical Process Simulation Software (e.g., Aspen Plus), requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Chemical Process Simulation Software (e.g., Aspen Plus) Interview

Q 1. Explain the different types of unit operations available in Aspen Plus.

Aspen Plus boasts a comprehensive library of unit operations, categorized broadly into reactors, separators, heat exchangers, and others. Think of these as the building blocks of your chemical process. Let’s look at some examples:

- Reactors: These simulate chemical reactions. Examples include CSTR (Continuous Stirred Tank Reactor), PFR (Plug Flow Reactor), Gibbs Reactor (for equilibrium reactions), and kinetic reactors where you specify reaction kinetics. In a fertilizer plant, you might model ammonia synthesis in a Gibbs reactor, leveraging Aspen’s thermodynamic capabilities to predict equilibrium conversions.

- Separators: These model the separation of different components. This includes flash units (for separating based on vapor-liquid equilibrium), distillation columns (fractional separation based on volatility), absorption columns (gas-liquid contacting for separating components), and extraction columns (liquid-liquid separation using a solvent).

- Heat Exchangers: These simulate heat transfer between streams. You have various types like shell and tube, plate and frame, and others. Accurate modeling of heat exchangers is crucial for energy efficiency in a refinery.

- Other Unit Operations: Aspen Plus also includes pumps, compressors, valves, mixers, and many more. These are essential for building a complete and realistic process flow diagram.

The selection of the appropriate unit operation depends heavily on the specific process being simulated and the level of detail required. A simplified model might use a single flash drum, while a detailed model of a distillation column might require multiple stages and sophisticated tray models.

Q 2. How do you validate a process simulation model in Aspen Plus?

Validating an Aspen Plus model is crucial to ensure its accuracy and reliability. It involves comparing the simulation results with real-world data or established benchmarks. This often follows a multi-step approach:

- Data Collection: Gather reliable experimental data from the actual process or from literature. This could involve process parameters like temperature, pressure, flow rates, and compositions.

- Model Calibration: Adjust model parameters (e.g., reaction kinetics, efficiency factors in unit operations) to match the experimental data. This often involves iterative adjustments and sensitivity analysis.

- Comparison and Validation: Compare simulation results (key process variables, product yields, energy consumption) to the experimental data. Use statistical methods to quantify the agreement (e.g., calculating Root Mean Squared Error (RMSE)). Significant discrepancies might indicate errors in the model assumptions, data quality, or the chosen thermodynamic package.

- Documentation: Thoroughly document all the steps involved in the validation process, including data sources, model parameters, and validation results. This ensures reproducibility and traceability.

For example, in simulating a distillation column, you might compare the simulated product compositions and purity to lab data obtained from pilot plant studies or an existing industrial unit. A good validation ensures confidence in the model’s predictive capabilities for design and optimization purposes.

Q 3. Describe your experience with Aspen Plus’s property packages.

Aspen Plus offers a range of property packages, which are crucial for accurate thermodynamic calculations. The choice of property package significantly impacts simulation results. My experience includes working with:

- Peng-Robinson (PR): A widely used cubic equation of state, suitable for a broad range of fluids including hydrocarbons. I’ve used this extensively for modeling refinery processes, particularly for vapor-liquid equilibrium calculations in distillation columns and flash drums.

- Soave-Redlich-Kwong (SRK): Another cubic equation of state similar to PR, often preferred for certain specific applications. The choice between PR and SRK often depends on the specific components and their behavior.

- Electrolyte Property Packages: Essential when dealing with aqueous solutions and electrolyte systems. I used these in a project simulating a wastewater treatment plant where modeling the ionic strength and speciation of various salts was critical.

- Activity Coefficient Models: Like NRTL or UNIQUAC, used for liquid-liquid equilibrium calculations, especially in extraction and reactive systems. I applied NRTL while simulating an extraction process of a valuable chemical from an aqueous solution.

The selection of an appropriate property package is not arbitrary; it’s based on the chemical components involved, the process conditions (temperature and pressure), and the accuracy needed. Improper selection can lead to significant errors in predictions.

Q 4. How do you handle convergence issues in Aspen Plus simulations?

Convergence issues in Aspen Plus are common, especially for complex processes. They arise when the solver fails to find a solution that satisfies all the model equations simultaneously. My troubleshooting approach involves:

- Check for Errors: Start by carefully reviewing the model for any obvious errors in the process flow diagram, stream specifications, or unit operation parameters.

- Adjust Convergence Parameters: Aspen Plus allows adjusting convergence parameters for the solver (e.g., tolerance, maximum iterations). Tightening the tolerance might improve accuracy but can hinder convergence. Conversely, loosening it can speed up the process but might compromise accuracy.

- Simplify the Model: Temporarily removing or simplifying parts of the model can help identify the source of the problem. Starting with a simplified model and gradually adding complexity can be an effective strategy.

- Improve Initial Guesses: Providing the solver with better initial guesses for variables can significantly improve convergence. Experience and knowledge of the system’s behavior are helpful here.

- Change Solvers: Aspen Plus has different solvers, each with its own strengths and weaknesses. Experimenting with alternative solvers can sometimes resolve convergence issues.

- Use Convergence Aids: Aspen Plus provides tools like ‘Tear Streams’ and ‘Convergence Promoters’ that can help guide the solver toward a solution.

For instance, if a distillation column refuses to converge, I might first check the feed composition and operating pressure. Then, I might try adjusting the convergence parameters or using a different solver. In extreme cases, I might simplify the column model by reducing the number of stages.

Q 5. Explain the importance of rigorous thermodynamic models in process simulation.

Rigorous thermodynamic models are essential in process simulation because they accurately predict the phase behavior (vapor-liquid, liquid-liquid) and thermodynamic properties (enthalpy, entropy, Gibbs free energy) of the chemical components in the system. This accuracy directly impacts:

- Phase Equilibria: Accurate prediction of vapor-liquid equilibrium is vital in distillation, absorption, and flash calculations. Using a non-rigorous model might lead to significant errors in predicting product compositions and energy requirements.

- Heat and Material Balances: Thermodynamic models determine the enthalpy and entropy changes in processes, crucial for correctly calculating heat duties of heat exchangers, energy consumption, and overall process efficiency.

- Reaction Equilibrium: In reactive systems, rigorous thermodynamic models predict equilibrium conversions, which are essential for designing reactors and determining the optimal operating conditions.

- Process Optimization: Accurate thermodynamic modeling enables effective process optimization for maximizing yield, minimizing energy consumption, and reducing waste.

Imagine designing a new chemical plant. Using simplified thermodynamic assumptions could lead to inaccurate predictions of equipment sizes, energy requirements, and operating costs, potentially resulting in significant financial losses.

Q 6. How do you perform sensitivity analysis in Aspen Plus?

Sensitivity analysis in Aspen Plus helps determine the impact of changes in input parameters on the simulation output. It’s crucial for understanding the robustness of the model and identifying critical parameters. Aspen offers several ways to perform this:

- Manual Parameter Variation: The simplest approach involves manually changing individual parameters and observing the effect on the output. This is time-consuming for numerous parameters but provides a good understanding of individual parameter influence.

- Aspen Plus’s Built-in Sensitivity Analysis Tools: Aspen Plus includes tools that automate the process. These tools systematically vary parameters and quantify their effects on key output variables, often presenting the results graphically.

- Design of Experiments (DOE): For more complex models with numerous parameters, DOE methods (like factorial designs or central composite designs) efficiently explore the parameter space and identify significant interactions between parameters. This is especially beneficial when you have limited time and resources for the study.

For example, in optimizing a reactor design, you might perform sensitivity analysis to determine how changes in temperature, pressure, and reactant concentrations affect the product yield and selectivity. The results will guide the selection of optimal operating conditions.

Q 7. Describe your experience with Aspen Plus Dynamics.

Aspen Plus Dynamics extends the capabilities of Aspen Plus to model the dynamic behavior of chemical processes. It allows simulating transient changes in process variables over time, which is crucial for:

- Process Control Design: Aspen Plus Dynamics is essential for designing and evaluating process control systems. You can simulate different control strategies (e.g., PID control) and assess their effectiveness in maintaining process stability and meeting setpoints.

- Startup and Shutdown Procedures: Simulating startup and shutdown scenarios is vital for optimizing these procedures and preventing potential hazards. It lets you explore the impact of various operational sequences on equipment behavior.

- Process Safety Analysis: Analyzing process responses to disturbances and upsets is crucial for process safety. It helps identify potential hazards and develop strategies for mitigating them (e.g., designing safety relief systems).

- Operator Training Simulators: Aspen Plus Dynamics is often used to build operator training simulators that provide realistic and interactive training environments.

My experience includes building a dynamic model of a distillation column to evaluate its response to feed composition changes and optimize the controller settings to maintain product purity. The dynamic model allowed us to test various scenarios without risking disruptions to the actual process, ultimately improving safety and efficiency.

Q 8. How do you use Aspen Plus to optimize a process for energy efficiency?

Optimizing a process for energy efficiency in Aspen Plus involves a multi-pronged approach leveraging its powerful simulation capabilities. We don’t just look at individual unit operations but rather at the entire process flowsheet.

- Energy Targeting: First, I’d establish energy targets. This might involve analyzing the current energy consumption, identifying major energy consumers (e.g., compressors, reactors, distillation columns), and setting realistic reduction goals. Aspen Plus allows for detailed energy stream analysis.

- Pinch Analysis: This technique helps identify the minimum energy requirement for the process. In Aspen Plus, this can be performed using specialized tools and utilities. By identifying the ‘pinch point’ – the temperature difference limiting further heat recovery – you can strategically place heat exchangers to maximize heat integration.

- Heat Integration Studies: Aspen Plus enables detailed heat exchanger network design. We explore various configurations, optimizing heat exchanger sizes, and minimizing utility consumption (steam, cooling water). This involves iterative simulations, varying exchanger specifications and observing the impact on energy usage and cost. For instance, we might compare shell and tube exchangers versus plate exchangers.

- Process Optimization: Beyond heat integration, we might optimize process parameters (e.g., temperature, pressure, reflux ratio in distillation columns) to reduce energy demand. Aspen Plus allows for parameter sweeps and sensitivity analysis to identify optimal settings. For example, a slightly higher reflux ratio in a distillation column might require more energy but result in improved product purity, a trade-off we can quantify and optimize.

- Advanced Techniques: For complex scenarios, advanced optimization techniques like dynamic simulation and rigorous process optimization algorithms (e.g., NLP solvers) can help find optimal operating conditions while satisfying constraints (e.g., product purity, capacity).

For example, I worked on a project optimizing an ethylene plant. By strategically integrating waste heat streams from various process units, we achieved a 15% reduction in energy consumption without compromising product quality.

Q 9. Explain the concept of recycle streams and how they are handled in Aspen Plus.

Recycle streams are crucial in many chemical processes, allowing for improved yields, better product purity, and more efficient use of raw materials. Essentially, a portion of the process output is fed back to an earlier stage. Think of it as a continuous feedback loop.

Aspen Plus handles recycle streams seamlessly through the use of stream connections and the flowsheet structure. You define the recycle stream as a connection from the downstream unit back to the upstream unit, creating a loop within the flowsheet. Aspen Plus automatically solves the mass and energy balances considering this loop, iteratively converging on a solution. The solver accounts for all components and properties in the recycle stream.

Handling Complex Recycles: Complex processes might involve multiple recycle loops, possibly interconnected. Aspen Plus efficiently manages these through its robust solving algorithms. However, proper convergence behavior depends on the flowsheet structure and the nature of the process itself. If convergence issues arise, you might need to adjust solver settings or manipulate the process flowsheet to aid convergence.

A common example is in a chemical reactor where unconverted reactants are recycled back to improve yield. This is effectively modeled in Aspen Plus by simply connecting the reactor outlet stream to its inlet through a recycle stream object.

Q 10. How do you model reaction kinetics in Aspen Plus?

Modeling reaction kinetics in Aspen Plus involves specifying the reaction stoichiometry and the rate expression. This is typically done within the RGibbs reactor model or similar reactor models.

- Stoichiometry: You define the reactants and products, and their molar ratios in the reaction.

- Rate Expression: This is the heart of kinetic modeling. You need to provide a mathematical equation that describes the reaction rate as a function of temperature, pressure, and reactant concentrations. This could be a simple power-law expression, a more complex Arrhenius-type equation, or a detailed kinetic model derived from experimental data. Aspen Plus allows you to specify rate parameters (activation energy, pre-exponential factor, reaction orders) directly.

- Reaction Data: Accurate kinetic parameters are critical. This often comes from experimental data or from literature values. You can fit experimental data in Aspen Plus to determine or refine rate parameters using regression analysis capabilities.

- Reactor Model Selection: The choice of reactor model (e.g., CSTR, PFR, Gibbs reactor) depends on the type of reactor being simulated. Each model has specific assumptions about mixing, flow patterns, and heat transfer.

For example, modeling a polymerization reaction would require a detailed kinetic model incorporating multiple reaction steps, potentially with propagation, termination, and chain transfer reactions. The rate expressions for each step must be accurately defined using appropriate rate constants and activation energies. Using a more accurate model will certainly provide more insight into the reaction but will take more time to complete.

Q 11. Describe your experience with Aspen Plus’s various solvers.

Aspen Plus offers a range of solvers, each suited to different types of simulations. The choice of solver significantly impacts simulation speed and convergence. My experience spans various solvers, and I understand their strengths and limitations.

- Successive Substitution (SS): This is a simple, relatively fast solver ideal for simple flowsheets with minimal recycle loops or interactions. However, it can struggle with convergence for complex, highly coupled systems.

- Simultaneous Correction (SC): SC is a more robust solver that handles recycle loops and complex interactions more effectively than SS. It solves all equations simultaneously, leading to better convergence, especially in difficult cases. It is commonly used in most chemical engineering problems.

- Equation-Oriented Solvers (e.g., ASPEN’s own): These sophisticated solvers can tackle very complex systems with multiple recycles, reactions, and phase equilibria calculations efficiently. They are computationally more intensive but offer superior convergence performance.

Solver selection depends on the problem’s complexity. For straightforward flowsheets, SS might suffice. For complex situations with many recycle streams, reactions, and phase changes, a more robust solver like SC or the equation-oriented solver is necessary. Troubleshooting involves understanding the solver’s convergence criteria and appropriately adjusting its parameters (e.g., convergence tolerance, maximum iterations).

Q 12. How do you perform economic analysis using Aspen Plus results?

Aspen Plus doesn’t directly conduct economic analysis but provides the fundamental data required for this. I typically use Aspen Plus results (stream compositions, temperatures, pressures, utilities consumption) in conjunction with external spreadsheet software (like Excel) or dedicated economic analysis tools.

- Cost of Raw Materials: Based on Aspen Plus’s mass balances, I can calculate the cost of raw materials consumed.

- Utility Costs: Aspen Plus determines utility consumption (steam, cooling water, electricity), which I can then price using real-world cost data.

- Operating Costs: I’d factor in labor costs, maintenance, and other operational expenses.

- Capital Costs: While Aspen doesn’t directly calculate equipment costs, the simulation provides the necessary design data (e.g., equipment sizes, heat duty) for estimating these costs using cost correlation methods or specialized software.

- Product Value: Aspen Plus defines product output streams, allowing for revenue calculation based on market prices.

The combined analysis – cost of production versus revenue – yields crucial economic indicators such as net present value (NPV), internal rate of return (IRR), and payback period. These indicators help in evaluating the profitability and financial viability of the process.

For example, in optimizing a refinery process, we use Aspen Plus’s results to model the impact of different process configurations on operational costs, capital investment, and product yields, allowing us to recommend the most profitable design option.

Q 13. Explain how you would troubleshoot a simulation error in Aspen Plus.

Troubleshooting simulation errors in Aspen Plus is a systematic process. My approach involves a methodical breakdown of potential issues.

- Check the Input Data: The most common source of errors is incorrect or inconsistent input data (stream compositions, physical property parameters, reaction kinetics, equipment specifications). Carefully review all data and cross-check with reliable sources.

- Examine the Flowsheet: Look for obvious flowsheet errors like incorrect stream connections, missing units, or illogical loops. Visual inspection often identifies simple mistakes.

- Review the Convergence Status: Aspen Plus provides detailed convergence information. Look for messages indicating convergence problems (e.g., slow convergence, non-convergence) and investigate the cause. This often points to problems in the flowsheet or input data.

- Simplify the Model: Sometimes, a complex flowsheet makes it difficult to pinpoint the error. Try simplifying the model by removing less critical elements or temporarily disabling certain features. This helps isolate the problematic area.

- Adjust Solver Settings: Adjusting solver parameters such as tolerance, convergence criteria, and maximum iterations can sometimes improve convergence behavior.

- Utilize Aspen’s Diagnostics: Aspen Plus has built-in diagnostics and debugging tools. Use these features to identify specific errors or inconsistencies within the model.

- Consult Aspen’s Documentation and Support: For persistent problems, I consult Aspen Plus’s comprehensive documentation and user manuals. If needed, I seek assistance from Aspen’s technical support team.

I always keep detailed records of my work, including the simulation settings, input data, and troubleshooting steps. This approach, coupled with experience and understanding of the underlying chemistry and engineering principles, helps resolve most simulation errors effectively.

Q 14. How do you incorporate process constraints into an Aspen Plus model?

Incorporating process constraints into an Aspen Plus model is critical for realistic and accurate simulations. Constraints represent limitations or restrictions imposed on the process, such as production capacity, purity specifications, environmental regulations, or equipment limitations.

Methods for Implementing Constraints:

- Specification Blocks: Aspen Plus provides specification blocks to set constraints on various parameters (e.g., temperature, pressure, flow rate, composition). You can specify a fixed value or a range of acceptable values.

- Design Specifications: For design problems, constraints can be directly specified within the design specifications of the unit operations. For instance, a distillation column might be constrained by a minimum reflux ratio or a maximum tray number.

- Constraint Block Equations: For more complex constraints not directly handled by specification blocks, you can use constraint block equations to define custom constraints. This is useful for non-linear constraints involving multiple variables.

- Optimization Studies: Aspen Plus’s optimization tools enable you to incorporate constraints within optimization problems. This allows you to find the optimal solution that satisfies all constraints simultaneously. Examples include maximizing yield subject to a maximum temperature constraint or minimizing cost subject to product purity constraints.

For example, in designing a chemical reactor, you might impose a constraint on the maximum temperature to avoid thermal runaway or degradation of the catalyst. In a distillation column design, you would specify a minimum product purity constraint. Proper constraint handling is vital for ensuring that the resulting Aspen Plus solution is both feasible and optimal. If constraints are too restrictive, they can prevent the simulation from converging on a solution.

Q 15. Describe your experience using Aspen Plus for heat and mass transfer calculations.

Aspen Plus excels at heat and mass transfer calculations, forming the backbone of many process simulations. I’ve extensively used its capabilities to model everything from simple heat exchangers to complex distillation columns. The software uses rigorous thermodynamic models and numerical methods to solve the governing equations. For example, in modeling a condenser, Aspen Plus would use an energy balance to calculate the heat duty required to condense the vapor stream, considering the latent heat of vaporization and heat transfer coefficients. Simultaneously, a mass balance would track the flow rates of the liquid and vapor phases. My experience includes leveraging different property packages within Aspen Plus (like the Peng-Robinson or NRTL models) depending on the system’s complexity and the accuracy required. I’ve also used the software to analyze the impact of various design parameters, such as heat transfer area and flow rates, on the overall efficiency of heat exchangers and other unit operations. A real-world example was optimizing the design of a multi-stage flash distillation unit for a desalination plant, where accurate heat and mass transfer calculations were critical for determining the optimal energy consumption.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How would you model a flash drum or distillation column in Aspen Plus?

Modeling a flash drum or distillation column in Aspen Plus involves selecting the appropriate unit operation model and specifying the necessary parameters. For a flash drum, I would use the ‘FLASH’ block, defining the feed stream’s composition, temperature, pressure, and the desired pressure in the drum. Aspen Plus then calculates the resulting vapor and liquid compositions and flow rates based on thermodynamic equilibrium. For a distillation column, I’d use the ‘RADFRAC’ or ‘DISTL’ block, specifying the number of stages, reflux ratio, feed location, and other relevant parameters. These models utilize rigorous calculations to simulate the separation process, accounting for vapor-liquid equilibrium and mass and energy balances across each stage. For example, in designing a distillation column to separate a mixture of benzene and toluene, I would specify the desired purity levels of the top and bottom products and use Aspen Plus’s optimization capabilities to determine the optimal number of stages and reflux ratio, minimizing energy consumption and maximizing product purity. The software would then provide detailed information on the composition and temperature profiles along the column.

Q 17. Explain your understanding of different types of reactors (e.g., CSTR, PFR) and their modeling in Aspen Plus.

Aspen Plus offers models for various reactor types, including Continuous Stirred Tank Reactors (CSTRs) and Plug Flow Reactors (PFRs). A CSTR is modeled using the ‘RCSTR’ block, assuming perfect mixing within the reactor. This results in uniform concentration and temperature throughout the reactor volume. In contrast, a PFR, modeled using the ‘RPFR’ block, assumes no mixing in the axial direction; concentration and temperature vary along the reactor length. The choice between CSTR and PFR models depends on the specific reaction kinetics and the mixing characteristics of the actual reactor. For example, a gas-phase reaction with rapid kinetics might be best represented by a PFR, while a liquid-phase reaction with slow kinetics could be modeled as a CSTR. I’ve used Aspen Plus to compare the performance of CSTRs and PFRs for various reaction systems, evaluating factors like conversion, selectivity, and reactor size. Recently, I used this to assess the economic feasibility of two different reactor configurations for a pharmaceutical synthesis. The simulation highlighted the advantages of a CSTR configuration in this case, due to its lower capital cost despite slightly lower conversion.

Q 18. How do you validate and verify Aspen Plus simulation results against experimental data?

Validating and verifying Aspen Plus simulation results are crucial for ensuring accuracy and reliability. Verification focuses on ensuring the simulation model accurately reflects the intended design and equations. This often involves checking the mass and energy balances within the model. Validation, on the other hand, involves comparing simulation results with experimental data. This comparison requires high-quality experimental data obtained under conditions relevant to the simulation. Key metrics for comparison include conversion, selectivity, product purity, and energy consumption. Any significant discrepancies necessitate a review of both the experimental setup and the simulation model. Statistical methods, such as regression analysis, can be used to quantify the agreement between the simulation and experimental results. I’ve used this extensively – for instance, I once used a least-squares regression to refine kinetic parameters in an Aspen Plus model of an enzymatic reaction based on experimental data from lab-scale experiments. The goal is to minimize deviations between model predictions and real-world measurements, ensuring the model is a useful tool for further process design and optimization.

Q 19. Explain how you would use Aspen Plus for process scale-up or scale-down.

Aspen Plus facilitates process scale-up and scale-down through its dimensional analysis capabilities and scaling laws. For scale-up, I would typically start with a well-validated model of a smaller-scale process. Aspen Plus allows me to systematically adjust parameters based on scale-up factors, such as reactor volume, flow rates, and heat transfer areas, while maintaining geometric similarity where appropriate. For scale-down, the same principles apply, but in reverse. However, it’s important to be aware that simple scaling isn’t always sufficient. Factors like heat transfer coefficients and mixing efficiency can change significantly with scale. Therefore, I carefully consider these potential deviations, and may need to adjust parameters or use specialized correlations to capture the scale-dependent phenomena. I once used Aspen Plus to scale-up a batch reactor design from laboratory scale to industrial scale, considering the impact of larger residence times and heat transfer limitations. Through iterative adjustment of parameters and validation with pilot-plant data, I successfully achieved a design that met all performance specifications.

Q 20. Describe your experience with Aspen Plus’s data reconciliation features.

Aspen Plus’s data reconciliation features are invaluable for improving the accuracy of process simulations. These features use optimization techniques to adjust measured data to ensure consistency with the process model’s mass and energy balances. This is particularly useful when dealing with inconsistencies in the raw data due to measurement errors or other uncertainties. The software employs sophisticated algorithms to identify and resolve discrepancies while minimizing adjustments to the measured data. By reconciling the data, I can significantly enhance the reliability of the model predictions, leading to improved process understanding and better decision-making. I frequently utilize these features in projects involving large-scale industrial processes where many different streams and unit operations contribute to uncertainties in data inputs. Reconciling this data allows for a more robust and confident representation of the system as a whole.

Q 21. How do you handle uncertainty in input parameters when performing process simulations?

Uncertainty in input parameters is inherent in many process simulations, and it’s critical to account for this. In Aspen Plus, I employ several strategies to handle this uncertainty. One approach is sensitivity analysis, where I systematically vary individual parameters to determine their impact on the simulation output. This helps identify the most critical parameters that contribute the most to the uncertainty in the overall results. Another strategy is Monte Carlo simulation, a statistical method that samples input parameters randomly from specified probability distributions. This allows for a probabilistic assessment of the model’s output, providing ranges or confidence intervals instead of single point estimates. I may also use error propagation techniques to quantitatively estimate the overall uncertainty in the outputs based on the uncertainty in the inputs. It is critical to thoroughly analyze and understand the various sources of uncertainty to ensure the reported results accurately reflect the range of possible outcomes. This is essential in conveying the level of confidence in the model’s prediction. A recent project involved using Monte Carlo simulation to assess the impact of uncertainty in reaction kinetics and feed composition on the overall yield of a chemical process. The results of this analysis provided a much more realistic assessment of the process risks and uncertainties.

Q 22. Explain the difference between steady-state and dynamic simulation in Aspen Plus.

In Aspen Plus, steady-state and dynamic simulations represent different approaches to modeling a chemical process. A steady-state simulation assumes the process operates under constant conditions – flows, temperatures, pressures, and compositions remain unchanged over time. Think of it like a snapshot of the process at a specific moment. It’s useful for initial design, optimization, and sizing of equipment. A dynamic simulation, on the other hand, accounts for how the process changes over time. It models the process’s response to disturbances or changes in operating conditions, such as a sudden increase in feed flow or a malfunctioning valve. This allows for the analysis of process stability, the design of control systems, and the prediction of process behavior under transient conditions. Imagine it as a movie of the process, showing its behavior over time.

For example, a steady-state simulation might be used to determine the optimal operating temperature and pressure for a reactor to maximize yield. A dynamic simulation would then be used to see how the reactor responds to a sudden loss of cooling, and assess the effectiveness of safety systems.

Q 23. How do you use Aspen Plus to design a control strategy for a process?

Aspen Plus offers powerful tools for designing control strategies. The process begins with building a dynamic model of the process. Once this model is built, you can use Aspen Dynamics, a module within Aspen Plus, to simulate the controller’s behavior. This involves defining the controlled variables (e.g., temperature, pressure, composition), the manipulated variables (e.g., valve positions, flow rates), and the controller type (e.g., PID controller). You then configure the controller parameters (e.g., proportional gain, integral time, derivative time) and simulate the process’s response to various disturbances.

For example, you might design a PID controller to maintain a reactor temperature at a setpoint. The dynamic simulation would then show how effectively the controller maintains the temperature despite changes in feed flow rate or ambient temperature. Aspen Dynamics allows you to test various control strategies and optimize the controller parameters to achieve the desired performance. This often involves analyzing simulation results to assess things like the speed of response, the magnitude of overshoot, and the stability of the system.

Q 24. What are the limitations of using Aspen Plus for process simulation?

While Aspen Plus is a very powerful and widely-used simulation software, it has limitations. One key limitation is the accuracy of the thermodynamic models. The accuracy of the simulation is heavily dependent on the selection of appropriate thermodynamic models for the specific chemicals and conditions involved in the process. An inaccurate model selection can lead to significant errors in predictions.

Another limitation is the complexity of modeling complex chemical reactions. While Aspen Plus can handle many reaction types, accurately modeling complex reactions with multiple phases and kinetic parameters can be challenging and requires significant expertise. Furthermore, Aspen Plus might not be ideal for simulating processes involving highly specialized equipment or unique chemical behaviors that are not adequately represented in the software’s built-in models. Finally, the computational cost of large and complex simulations can be substantial, necessitating high-performance computing resources.

Q 25. Describe your experience with other process simulation software (e.g., PRO/II, ChemCAD).

I have extensive experience with PRO/II and ChemCAD, both of which are leading process simulation software packages. My experience with these tools allows me to effectively compare and contrast their strengths and weaknesses relative to Aspen Plus, depending on the specific application. For example, PRO/II excels in its handling of rigorous physical property calculations, especially important in high-pressure systems. ChemCAD, on the other hand, offers a user-friendly interface and excels in certain specialized areas like reaction kinetics modeling. The key differentiator is often the specific features and functionalities that are best suited for a particular project, as well as the user’s familiarity with the specific software. My ability to leverage the strengths of each package ensures that the most appropriate tool is used for every modeling task.

Q 26. How would you approach modeling a complex process with multiple unit operations in Aspen Plus?

Modeling a complex process with multiple unit operations in Aspen Plus requires a systematic approach. It starts with a clear understanding of the process flow diagram (PFD), including all unit operations, streams, and their interconnections. The next step is to break down the overall process into smaller, manageable blocks, each representing a unit operation or a section of the process. Each block is then individually modeled using the appropriate Aspen Plus unit operation models. Attention should be paid to the proper selection of thermodynamic models and physical property packages, considering the chemical nature of the components involved in each block.

Once the individual blocks are modeled, the interconnection between blocks is established through material and energy balances, ensuring the conservation of mass and energy throughout the entire process. Finally, the entire process model is rigorously simulated and validated against available data, refining the model parameters as needed. This iterative process might necessitate utilizing Aspen Plus’s advanced features for rigorous convergence and data reconciliation to ensure accuracy.

Q 27. Describe a challenging process simulation project you worked on and how you overcame its difficulties.

One challenging project involved simulating a complex refinery process with multiple recycle streams and intricate reaction kinetics. The initial simulations were unstable, showing inconsistent results and failing to converge. The difficulty stemmed from the complex interactions between the various units and the highly nonlinear behavior of the reaction kinetics. The initial thermodynamic model choice wasn’t optimal leading to inconsistencies and convergence issues.

To overcome this, I implemented a systematic troubleshooting strategy: I first reviewed the process flow diagram in detail, focusing on potential bottlenecks and inconsistencies. Secondly, I experimented with different thermodynamic models until I found one that better represented the system’s behavior. Thirdly, I used Aspen Plus’s advanced convergence techniques and gradually tightened the convergence criteria. Finally, I implemented a robust sensitivity analysis to identify the key parameters influencing the stability of the simulation and optimized them. Through this iterative process of refinement and validation, we achieved a stable and reliable simulation, providing accurate predictions of the process performance.

Q 28. What are your plans for continuous learning and development in process simulation software?

My plan for continuous learning involves actively participating in AspenTech training courses and webinars to stay updated on new features and best practices. I also plan to expand my knowledge base by engaging with online communities and professional networks dedicated to process simulation. Furthermore, I aim to actively seek challenging projects that will expose me to new process types and simulation techniques, thus further sharpening my expertise. Lastly, I am exploring opportunities to become involved in research and development to stay at the forefront of this rapidly evolving field.

Key Topics to Learn for Chemical Process Simulation Software (e.g., Aspen Plus) Interview

- Thermodynamics and Phase Equilibria: Understanding vapor-liquid equilibrium, activity coefficients, and equation of state models (e.g., Peng-Robinson, Soave-Redlich-Kwong) is crucial for accurate process modeling.

- Reactor Modeling: Mastering different reactor types (CSTR, PFR, etc.) and their corresponding design equations, including kinetics and reaction mechanisms, is essential for simulating chemical reactions.

- Fluid Dynamics and Heat Transfer: Familiarize yourself with principles of fluid flow, pressure drop calculations, and heat exchanger design, including different types and their performance characteristics.

- Process Design and Optimization: Gain experience in designing and optimizing processes using Aspen Plus, including the use of design specifications, sensitivity analysis, and optimization techniques.

- Data Analysis and Interpretation: Learn to effectively analyze simulation results, identify potential bottlenecks, and interpret the data to make informed decisions regarding process improvements.

- Aspen Plus Specifics: Become proficient in using Aspen Plus’s features, including its different property methods, unit operations, and simulation tools. Practice building and troubleshooting models.

- Case Studies and Practical Applications: Work through examples simulating real-world chemical processes, such as distillation columns, heat exchangers, and reactors. This will solidify your understanding and improve your problem-solving skills.

Next Steps

Mastering chemical process simulation software like Aspen Plus is invaluable for your career growth, opening doors to challenging and rewarding roles in process engineering, research and development, and process optimization. A strong understanding of these tools demonstrates your technical skills and problem-solving abilities – highly sought-after qualities in today’s competitive job market.

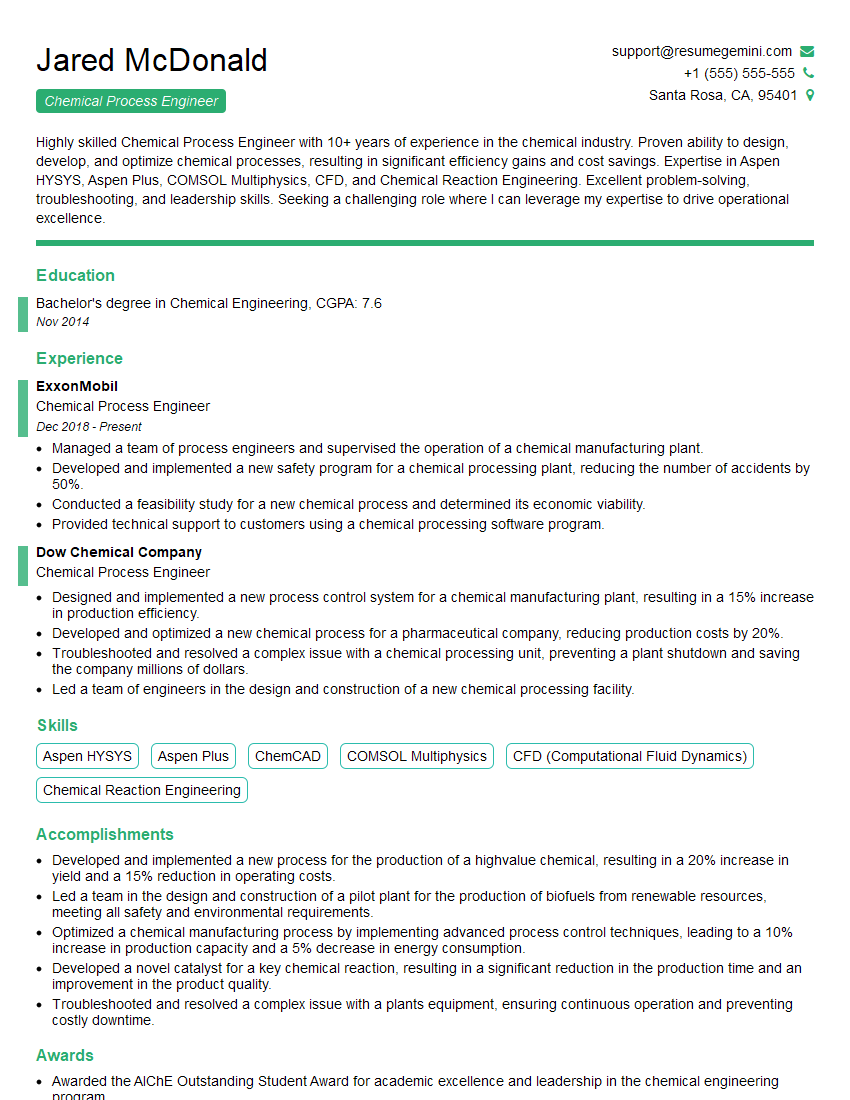

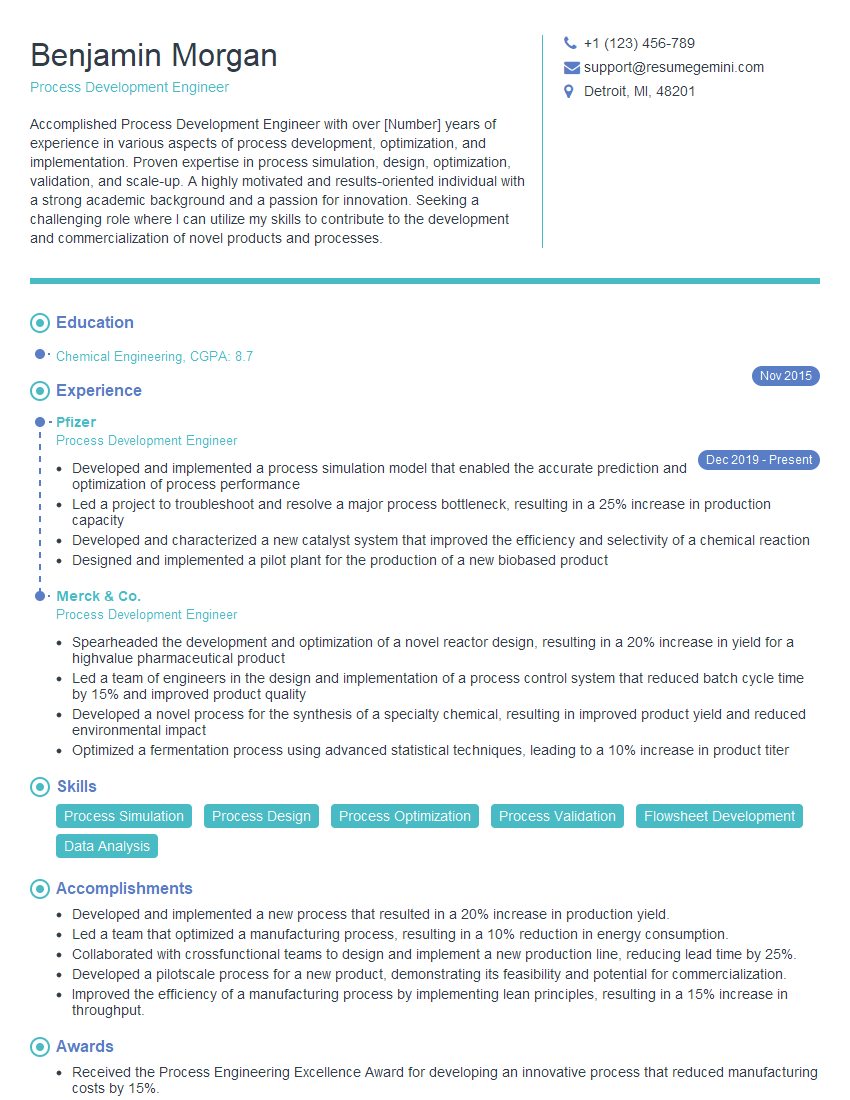

To significantly boost your job prospects, create an ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your specific career goals. We provide examples of resumes specifically designed for candidates with expertise in Chemical Process Simulation Software (e.g., Aspen Plus) to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.