Preparation is the key to success in any interview. In this post, we’ll explore crucial Chemistry and Materials Analysis interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Chemistry and Materials Analysis Interview

Q 1. Explain the principles of gas chromatography-mass spectrometry (GC-MS).

Gas chromatography-mass spectrometry (GC-MS) is a powerful analytical technique used to separate and identify volatile compounds within a sample. Imagine it like a sophisticated detective duo: gas chromatography (GC) acts as the detective separating the components, while mass spectrometry (MS) acts as the forensic scientist identifying each component individually.

Gas Chromatography (GC): The GC works by injecting the sample into a heated column packed with a stationary phase. Different compounds interact differently with this stationary phase, leading to varying speeds of movement through the column. This separation process is based on the different boiling points and polarities of the components. Think of it as a race where each compound runs at its own pace based on its properties. As each compound emerges from the column, it’s detected.

Mass Spectrometry (MS): The separated components then enter the mass spectrometer. Here, the molecules are ionized (charged), and the resulting ions are accelerated through a magnetic or electric field. The degree of deflection depends on the mass-to-charge ratio (m/z) of each ion. This allows for the precise determination of the molecular weight and fragmentation pattern of the components. The fragmentation pattern acts like a fingerprint, allowing for unique identification using databases.

Real-world applications: GC-MS is widely used in various fields, including environmental monitoring (detecting pollutants), forensic science (analyzing drug samples), food safety (identifying contaminants), and clinical chemistry (analyzing metabolites in biological samples).

Q 2. Describe different types of microscopy used in materials analysis (e.g., SEM, TEM, AFM).

Microscopy plays a crucial role in materials analysis, providing high-resolution images at various length scales. Different types of microscopes offer unique capabilities:

- Scanning Electron Microscopy (SEM): SEM uses a focused beam of electrons to scan the surface of a sample. It provides high-resolution images of surface morphology, including topography, texture, and composition. Imagine a tiny electron beam meticulously mapping the surface landscape. It’s excellent for studying the surface features of materials at a relatively large scale.

- Transmission Electron Microscopy (TEM): TEM involves transmitting a beam of electrons through a very thin sample. This technique offers superior resolution compared to SEM, allowing for the visualization of internal structures, such as crystal lattices and grain boundaries. It allows us to ‘see’ inside the material at a much finer scale.

- Atomic Force Microscopy (AFM): AFM employs a sharp tip attached to a cantilever to scan the sample surface. It provides very high-resolution images, even at the atomic level, along with measurements of surface properties like roughness and stiffness. Think of a tiny needle feeling the bumps and valleys of the surface.

Example: In materials science, SEM might be used to characterize the surface roughness of a coating, while TEM could reveal the grain size and structure of a metal alloy, and AFM might be employed to study the morphology of nanoparticles.

Q 3. What are the key differences between XRD and XRF techniques?

Both X-ray diffraction (XRD) and X-ray fluorescence (XRF) are analytical techniques utilizing X-rays, but they provide different types of information:

- X-ray Diffraction (XRD): XRD determines the crystal structure and phase composition of a material. X-rays are diffracted by the crystal lattice, and the resulting diffraction pattern reveals information about the arrangement of atoms within the crystal. It’s like shining a light through a finely structured grating to see the patterns created by the light interacting with the grating’s spacing.

- X-ray Fluorescence (XRF): XRF determines the elemental composition of a material. The sample is irradiated with X-rays, which cause the atoms within the sample to emit characteristic X-rays. By analyzing the energy and intensity of these emitted X-rays, we can identify and quantify the different elements present. It’s akin to using X-rays to excite the atoms, making them glow with a ‘fingerprint’ that identifies the element.

Key Difference: XRD analyzes the arrangement of atoms in a crystal, whereas XRF analyzes the types and amounts of elements present in the sample. One provides structural information, while the other provides compositional information. For example, XRD can be used to differentiate between different polymorphs of the same compound (like graphite and diamond, which are both carbon but have different structures), while XRF can be used to determine the elemental composition of an alloy.

Q 4. How would you determine the crystallinity of a polymer sample?

Determining the crystallinity of a polymer sample involves assessing the degree of order within its molecular structure. A highly crystalline polymer exhibits a well-ordered, repeating arrangement of its chains, whereas an amorphous polymer has a more disordered structure.

Several techniques can determine crystallinity:

- X-ray Diffraction (XRD): Crystalline regions produce sharp diffraction peaks, while amorphous regions produce a broad halo. The ratio of crystalline to amorphous regions can be estimated from the relative intensities of these peaks.

- Differential Scanning Calorimetry (DSC): DSC measures the heat flow associated with phase transitions. The melting enthalpy of crystalline regions provides a measure of the degree of crystallinity.

- Density Measurement: Crystalline polymers generally have higher densities than amorphous polymers due to the more compact packing of their chains. The density difference can be used to estimate crystallinity.

- Wide-Angle X-ray Scattering (WAXS): A more refined XRD technique offering better differentiation between crystalline and amorphous regions.

Example: In quality control of polyethylene packaging, XRD or DSC can be used to ensure the polymer has sufficient crystallinity for required strength and stiffness.

Q 5. Explain the concept of thermal analysis (TGA, DSC).

Thermal analysis encompasses techniques that measure the physical and chemical properties of materials as a function of temperature. Two common methods are Thermogravimetric Analysis (TGA) and Differential Scanning Calorimetry (DSC).

Thermogravimetric Analysis (TGA): TGA monitors the weight change of a sample as it is heated or cooled. This is useful for determining the thermal stability, decomposition temperature, and volatile content of a material. Imagine a tiny scale that weighs the sample as it’s heated, recording any weight loss due to evaporation or decomposition. This helps us understand how the material behaves under heat.

Differential Scanning Calorimetry (DSC): DSC measures the difference in heat flow between a sample and a reference as they are subjected to a controlled temperature program. It detects changes in heat capacity due to phase transitions (like melting or glass transition) and chemical reactions (like curing or oxidation). Think of it as comparing the heat required to heat the sample and a known reference. Any difference in heat flow indicates a change in the sample’s properties, like melting.

Real-world example: TGA might be used to determine the moisture content of a pharmaceutical powder, while DSC might be used to measure the glass transition temperature of a polymer.

Q 6. Describe different methods for surface area determination.

Surface area determination is crucial for materials that have high surface area-to-volume ratios, as their surface properties significantly influence their behaviour. Several methods exist to measure this:

- Gas Adsorption (BET): The Brunauer-Emmett-Teller (BET) method is the most widely used technique. It involves adsorbing a gas (like nitrogen) onto the surface of the material at various pressures. The amount of gas adsorbed is related to the surface area. The method is based on the understanding of how gas molecules interact with a surface and form layers.

- Liquid Adsorption: Similar to gas adsorption, this method uses a liquid instead of a gas, often suitable for materials that don’t easily interact with gases.

- Electron Microscopy: Image analysis from SEM or TEM can provide an estimate of the surface area, though it is often less precise than gas adsorption techniques.

Example: In the development of catalysts, BET surface area measurements are vital as catalytic activity often depends on the available surface area for reactions to occur. High surface area materials are usually required for high catalytic efficiency.

Q 7. What are the common techniques used for elemental analysis?

Elemental analysis aims to identify and quantify the elements present in a sample. Several common techniques are used, each with its strengths and limitations:

- Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES): ICP-OES involves exciting atoms in a plasma and measuring the emitted light to determine the elemental composition. It’s highly sensitive and can analyze a wide range of elements. It’s often used for aqueous samples.

- Inductively Coupled Plasma Mass Spectrometry (ICP-MS): Similar to ICP-OES, but it measures the mass of the ions, offering higher sensitivity and the ability to detect isotopes. It excels at determining trace elements.

- X-ray Fluorescence (XRF): Already described above, XRF is particularly suitable for solid samples and provides rapid qualitative and quantitative elemental analysis. It is non-destructive, meaning the sample is not damaged during analysis.

- Atomic Absorption Spectrometry (AAS): Measures the absorption of light by atoms in a flame or graphite furnace. It’s a sensitive technique for determining specific elements.

- Combustion Analysis: This technique involves combusting the sample and analyzing the resulting gases (CO2, H2O, N2) to determine the carbon, hydrogen, and nitrogen content.

Example: ICP-OES might be used to determine the trace metal content of a drinking water sample, while combustion analysis might be used to determine the elemental composition of an organic compound.

Q 8. Explain the principles of inductively coupled plasma optical emission spectrometry (ICP-OES).

Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES) is a powerful analytical technique used to determine the elemental composition of a sample. It’s based on the principle of atomic emission spectroscopy. The sample, typically dissolved in a suitable solvent, is introduced into an inductively coupled plasma (ICP) torch. This ICP is a high-temperature (around 7000 K) plasma created by passing argon gas through a radio-frequency field. The intense heat causes the atoms in the sample to become excited to higher energy levels. When these excited atoms return to their ground state, they emit light at specific wavelengths characteristic of each element. This emitted light is then passed through a spectrometer that separates the light into its component wavelengths, allowing us to identify and quantify the elements present.

Think of it like a firework display: each element emits a unique ‘color’ (wavelength) of light, and the intensity of that color corresponds to the amount of that element in the sample. The spectrometer acts like a prism separating the different ‘colors’ for accurate identification and quantification. ICP-OES is widely used in environmental monitoring (detecting heavy metals in water), food safety (analyzing trace elements in food), and material characterization (determining the composition of alloys).

Q 9. How do you interpret an FTIR spectrum?

Interpreting an FTIR (Fourier Transform Infrared) spectrum involves identifying the functional groups present in a molecule based on the absorption of infrared (IR) radiation. Each functional group absorbs IR radiation at specific frequencies, creating characteristic peaks in the spectrum. The x-axis represents the wavenumber (cm-1), which is inversely proportional to wavelength, and the y-axis represents the absorbance or transmittance. A strong peak indicates a strong absorption at that wavenumber, while a weak peak signifies a weak absorption.

For example, a broad peak around 3300 cm-1 typically indicates the presence of an O-H stretch (found in alcohols and carboxylic acids), while a sharp peak around 1700 cm-1 suggests a C=O stretch (found in ketones, aldehydes, and carboxylic acids). By comparing the observed peaks with known databases or literature, we can identify the functional groups present in the sample and deduce its structure. The analysis often involves examining the peak positions, intensities, and shapes. It’s a bit like a fingerprint for a molecule, allowing for identification and structural elucidation. This technique is invaluable in polymer analysis, pharmaceutical analysis, and material identification.

Q 10. What are the limitations of Raman spectroscopy?

Raman spectroscopy, while a powerful vibrational spectroscopy technique, does have limitations. One major limitation is the fluorescence effect. Many samples, especially biological samples or those containing aromatic compounds, exhibit strong fluorescence when excited by the laser light used in Raman spectroscopy. This fluorescence signal can overwhelm the much weaker Raman signal, making it difficult or impossible to obtain a useful Raman spectrum. Furthermore, Raman scattering is a relatively weak effect compared to other scattering processes like Rayleigh scattering.

Another limitation is the potential for sample damage. The high-intensity laser light can cause photodegradation or photobleaching of the sample, especially if it is sensitive to light. Finally, Raman spectroscopy is less sensitive than some other techniques, such as ICP-OES, which can detect very low concentrations of elements. While Raman is excellent for structural analysis and identification of materials, these limitations mean that it may not always be the optimal choice for every application. Selecting the appropriate technique for a given analysis requires careful consideration of the sample characteristics and the specific information required.

Q 11. Explain different types of chemical bonding and their influence on material properties.

Chemical bonding significantly influences material properties. There are several main types:

- Ionic Bonding: This involves the electrostatic attraction between oppositely charged ions. For example, in NaCl (sodium chloride), sodium loses an electron to become a positively charged ion (Na+), while chlorine gains an electron to become a negatively charged ion (Cl–). Ionic compounds are typically brittle, have high melting points, and are good insulators in the solid state.

- Covalent Bonding: Here, atoms share electrons to achieve a stable electron configuration. For example, in methane (CH4), carbon shares electrons with four hydrogen atoms. Covalent compounds can have a wide range of properties, depending on the molecule’s structure and the atoms involved. They can be liquids, solids, or gases, and their melting and boiling points vary greatly.

- Metallic Bonding: This occurs in metals, where valence electrons are delocalized and shared amongst a lattice of positive metal ions. This ‘sea’ of electrons allows for good electrical and thermal conductivity, malleability, and ductility.

- Hydrogen Bonding: A special type of dipole-dipole interaction involving hydrogen atoms bonded to highly electronegative atoms (like oxygen or nitrogen). It’s responsible for the relatively high boiling point of water.

The type of bonding present dictates various material properties such as strength, conductivity, melting point, and solubility. For instance, the strong covalent bonds in diamond make it incredibly hard, while the metallic bonding in copper makes it an excellent conductor of electricity.

Q 12. Describe the different types of chemical reactions and their applications.

Chemical reactions are classified in various ways. Some common types include:

- Combination Reactions: Two or more substances combine to form a single product (e.g., 2H2 + O2 → 2H2O).

- Decomposition Reactions: A single compound breaks down into two or more simpler substances (e.g., 2H2O → 2H2 + O2).

- Single Displacement Reactions: One element replaces another in a compound (e.g., Zn + CuSO4 → ZnSO4 + Cu).

- Double Displacement Reactions: Two compounds exchange ions to form two new compounds (e.g., AgNO3 + NaCl → AgCl + NaNO3).

- Acid-Base Reactions: An acid reacts with a base to form salt and water (e.g., HCl + NaOH → NaCl + H2O).

- Redox Reactions: Involve electron transfer between species. One species is oxidized (loses electrons), and another is reduced (gains electrons).

These reactions have diverse applications, from industrial processes like the production of ammonia (Haber-Bosch process) to biological processes like respiration and photosynthesis. Understanding the types of chemical reactions and their mechanisms is crucial for controlling and optimizing various chemical processes.

Q 13. How do you determine the molecular weight of a polymer?

Determining the molecular weight of a polymer is more complex than for small molecules because polymers are not uniform in size. They consist of a distribution of chain lengths. Several techniques are used:

- Number-Average Molecular Weight (Mn): This represents the average molecular weight based on the number of polymer chains. It’s determined using methods like end-group analysis or osmometry.

- Weight-Average Molecular Weight (Mw): This considers the contribution of larger chains more significantly. It’s determined using techniques like light scattering or sedimentation.

- Size Exclusion Chromatography (SEC), also known as Gel Permeation Chromatography (GPC): This separates polymers based on their size. By measuring the elution time and calibrating with known standards, one can obtain a molecular weight distribution and calculate Mn and Mw.

The choice of method depends on the polymer’s properties and the desired information. Often, both Mn and Mw are reported to give a complete picture of the molecular weight distribution. Knowing the molecular weight is essential for determining the polymer’s physical and mechanical properties.

Q 14. Explain the concept of glass transition temperature (Tg).

The glass transition temperature (Tg) is the temperature at which an amorphous solid (like a glass or an amorphous polymer) transitions from a hard, brittle state to a more rubbery or viscous state. Below Tg, the material is rigid and glassy; above Tg, it becomes softer and more flexible. It’s not a true phase transition like melting, but rather a change in molecular mobility. Think of it as the temperature at which the polymer chains gain enough kinetic energy to overcome intermolecular forces and start moving more freely.

Imagine honey: at very low temperatures, it’s a solid; as temperature increases, it becomes less viscous and flows more easily. This change in viscosity is similar to the transition that occurs at Tg. Tg is a critical parameter for the design and application of polymeric materials. For example, if a plastic needs to remain rigid at a certain temperature, its Tg must be above that temperature. The Tg can be determined experimentally using techniques like Differential Scanning Calorimetry (DSC) or Dynamic Mechanical Analysis (DMA).

Q 15. What are the different types of polymers and their applications?

Polymers are large molecules composed of repeating structural units called monomers. They are broadly classified based on their structure, properties, and synthesis methods. Let’s explore some key types and their applications:

- Thermoplastics: These polymers soften when heated and harden when cooled, allowing for repeated molding. Examples include polyethylene (PE) used in plastic bags and bottles, polypropylene (PP) in containers and fibers, and polyethylene terephthalate (PET) in beverage bottles.

- Thermosets: These polymers undergo irreversible chemical changes upon heating, forming a rigid, cross-linked network. They are typically stronger and more heat-resistant than thermoplastics. Examples include epoxy resins used in adhesives and coatings, and vulcanized rubber used in tires.

- Elastomers: These are polymers with high elasticity, meaning they can be stretched significantly and return to their original shape. Examples include natural rubber and silicone rubber used in seals, gaskets, and medical devices.

- Biopolymers: These are polymers produced by living organisms. Examples include proteins (e.g., collagen) and polysaccharides (e.g., cellulose). They find applications in biomedical engineering, food science, and agriculture.

The choice of polymer depends heavily on the required properties, such as strength, flexibility, temperature resistance, and cost. For instance, choosing PET for a beverage bottle is crucial for its recyclability and barrier properties. Similarly, using epoxy resins for aircraft components necessitates their high strength and durability.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the different types of defects in crystalline materials and their effects.

Crystalline materials, while possessing an ordered atomic arrangement, often contain defects that significantly affect their properties. These defects can be broadly classified as:

- Point Defects: These are localized imperfections involving one or a few atoms. Examples include vacancies (missing atoms), interstitial atoms (extra atoms in the interstitial sites), and substitutional atoms (different atoms replacing host atoms). Vacancies can enhance diffusion, while interstitial atoms can cause lattice strain.

- Line Defects (Dislocations): These are one-dimensional defects that disrupt the atomic arrangement along a line. Edge dislocations involve an extra half-plane of atoms, while screw dislocations have a spiral arrangement. Dislocations significantly influence material strength and ductility. For example, the presence of dislocations makes metals malleable.

- Planar Defects: These are two-dimensional defects involving interfaces between regions of different crystallographic orientation or composition. Examples include grain boundaries (boundaries between crystallites), stacking faults (incorrect stacking of atomic planes), and twin boundaries (mirror symmetry across a plane).

- Volume Defects: These are three-dimensional defects involving larger regions of the material. Examples include voids (empty spaces), inclusions (foreign particles within the material), and precipitates (second phase particles). These can significantly weaken the material and reduce its overall properties.

Understanding these defects is crucial in materials science and engineering. For instance, controlling grain size can alter the material strength, and the presence of voids can dramatically reduce the fatigue life.

Q 17. How would you determine the mechanical properties of a material?

Determining the mechanical properties of a material involves subjecting it to various tests to quantify its response to applied forces. Common techniques include:

- Tensile Testing: A specimen is subjected to a uniaxial tensile force, measuring its stress-strain behavior to determine its yield strength, ultimate tensile strength, and elongation. This helps us understand its ability to withstand stretching forces.

- Compression Testing: A specimen is compressed to determine its compressive strength and its ability to resist crushing forces. This is especially relevant for concrete or ceramics.

- Hardness Testing: This measures the material’s resistance to indentation. Common methods include Brinell, Rockwell, and Vickers hardness tests, where a hard indenter is pressed into the surface, and the depth or area of indentation is measured.

- Impact Testing: This assesses the material’s ability to absorb energy upon impact. The Charpy and Izod tests are widely used to evaluate a material’s toughness.

- Fatigue Testing: This involves subjecting a specimen to cyclic loading to determine its fatigue strength – its ability to withstand repeated stresses.

The choice of test depends on the specific application and the properties of interest. For example, designing a bridge requires understanding the tensile and fatigue strengths of the steel used, whereas designing a helmet would necessitate impact testing to evaluate its protective capabilities.

Q 18. Explain the concept of diffusion in materials.

Diffusion is the net movement of atoms or molecules from a region of higher concentration to a region of lower concentration. It’s a fundamental process in many materials phenomena, driven by the tendency to achieve a uniform distribution. Several factors influence diffusion:

- Temperature: Higher temperatures increase atomic mobility and accelerate diffusion. Think of how sugar dissolves faster in hot water.

- Concentration Gradient: The steeper the concentration gradient, the faster the diffusion rate.

- Diffusion Coefficient (D): This material property quantifies the rate of diffusion. It’s temperature-dependent, often following an Arrhenius relationship (

D = D0 exp(-Q/RT), whereD0is the pre-exponential factor,Qis the activation energy,Ris the gas constant, andTis temperature). - Material Structure: Crystalline materials have slower diffusion rates than amorphous materials due to their ordered structure.

Diffusion has numerous practical applications, including doping semiconductors, heat treating metals (for changing their strength and hardness), and sintering ceramics (making them stronger by heat-treating). For example, the doping of silicon with boron in semiconductor manufacturing relies on controlled diffusion to achieve specific electrical properties.

Q 19. What are the different types of corrosion and how can they be prevented?

Corrosion is the deterioration of materials due to chemical or electrochemical reactions with their environment. Several types exist:

- Uniform Corrosion: This involves uniform attack across the entire surface, often due to immersion in a corrosive medium (e.g., rusting of iron in seawater).

- Galvanic Corrosion: This occurs when two dissimilar metals are in contact in an electrolyte, resulting in accelerated corrosion of the more active metal (e.g., steel corroding faster when in contact with copper in a salty environment).

- Pitting Corrosion: This involves localized corrosion forming small pits or holes on the surface, often caused by the breakdown of passive films.

- Crevice Corrosion: This occurs in crevices or gaps where stagnant solutions accumulate, resulting in high concentrations of corrosive species.

- Stress Corrosion Cracking: This involves the combination of tensile stress and a corrosive environment leading to crack propagation.

Corrosion prevention strategies include:

- Protective Coatings: Applying coatings like paint, polymers, or metallic layers to isolate the material from the environment.

- Corrosion Inhibitors: Adding chemicals to the environment that slow down the corrosion process.

- Cathodic Protection: Applying a sacrificial anode to protect a metal structure by making it the cathode.

- Material Selection: Choosing corrosion-resistant materials (e.g., stainless steel).

- Design Modifications: Avoiding crevices and stagnant areas to minimize crevice and pitting corrosion.

For example, pipelines are often protected by cathodic protection to prevent corrosion in the soil.

Q 20. Describe different methods for surface modification of materials.

Surface modification alters the surface properties of a material without significantly changing its bulk properties. Techniques include:

- Physical Vapor Deposition (PVD): Materials are deposited in a vacuum, resulting in thin, uniform coatings with enhanced properties. Examples include titanium nitride coatings for improved hardness and wear resistance.

- Chemical Vapor Deposition (CVD): Chemical reactions on the surface produce a coating. Used for depositing diamond-like carbon films for enhanced hardness and lubricity.

- Plasma Treatment: Using plasma to modify the surface chemistry and energy, enhancing adhesion, wettability, or biocompatibility.

- Ion Implantation: Ions are implanted into the surface to change its composition and properties (e.g., increasing hardness or corrosion resistance).

- Sol-Gel Processing: A sol-gel is deposited and then heated, resulting in a coating with controlled porosity and surface chemistry.

These modifications find wide applications in various fields. For instance, PVD coatings improve the durability of cutting tools, while plasma treatment enhances the biocompatibility of implants.

Q 21. Explain the principles of electrochemical techniques (e.g., cyclic voltammetry).

Electrochemical techniques are used to study electrochemical processes at electrode-electrolyte interfaces. Cyclic voltammetry (CV) is a powerful technique to investigate the redox behavior of electroactive species.

In CV, a potential is applied to the working electrode and cycled linearly between two potential limits. The resulting current is measured as a function of potential. The voltammogram shows characteristic peaks corresponding to oxidation and reduction processes. The peak current and potential provide information on the kinetics and thermodynamics of the redox reaction.

Principles:

- Working Electrode: The electrode where the redox reaction occurs.

- Counter Electrode: Completes the circuit and carries the counter current.

- Reference Electrode: Provides a stable potential reference point.

- Electrolyte: Provides ionic conductivity.

Applications: CV is widely used to study various electrochemical processes such as:

- Redox Reactions: Determining the redox potentials and kinetics of reactions.

- Electrocatalysis: Studying the activity and selectivity of electrocatalysts.

- Battery and Fuel Cell Research: Investigating electrode materials and reactions.

- Biosensors: Detecting biological molecules using electrochemical methods.

Example: A CV experiment might involve cycling the potential of a platinum electrode in a solution containing a redox couple, like Fe2+/Fe3+. The voltammogram will show distinct oxidation and reduction peaks, providing information on the electron transfer kinetics and the formal potential of the couple.

Q 22. How do you interpret a phase diagram?

A phase diagram is a graphical representation of the physical states of a substance (or mixture of substances) as a function of temperature and pressure (or composition). Think of it like a map showing the different ‘landscapes’ a material can exist in. Understanding it allows us to predict phase transitions, like melting or boiling, and the stability of different phases.

For example, a simple water phase diagram shows the coexistence of ice, liquid water, and water vapor under different temperature and pressure conditions. The lines on the diagram represent phase boundaries where two phases are in equilibrium. The triple point indicates the unique condition where all three phases coexist.

Interpreting a phase diagram involves identifying the different phases, understanding the phase boundaries, and determining the stable phase at a given temperature and pressure. More complex diagrams may include multiple components, further enriching the information. For instance, in materials science, phase diagrams are crucial for designing alloys with specific properties, by manipulating the composition and temperature to achieve a desired microstructure.

- Areas represent single phases (solid, liquid, gas).

- Lines represent phase boundaries (equilibrium between two phases).

- Points represent invariant points (triple point, critical point) where three or more phases coexist.

Q 23. What are the different types of analytical techniques used for quality control?

Quality control in chemistry and materials analysis relies on a diverse range of analytical techniques. The choice depends heavily on the material’s properties and the specific quality parameters to be monitored. Common techniques include:

- Spectroscopy: Techniques like UV-Vis, IR, NMR, and mass spectrometry provide information about the molecular structure and composition of a substance. For example, UV-Vis spectroscopy is often used in quality control of pharmaceuticals to ensure purity and concentration.

- Chromatography: Techniques such as HPLC and GC separate components of a mixture, allowing for identification and quantification. This is critical in analyzing the purity of chemicals or identifying contaminants in food products. Imagine checking the purity of a drug using HPLC to ensure no unwanted byproducts are present.

- Thermal Analysis: Techniques such as TGA (Thermogravimetric Analysis) and DSC (Differential Scanning Calorimetry) study the thermal behavior of materials, providing information on decomposition, phase transitions, and heat capacity. These methods can assess the stability and degradation behavior of a polymer over time.

- Electrochemical Methods: Techniques like potentiometry and voltammetry measure the electrical potential or current to determine the concentration of specific ions or molecules. These methods are crucial in environmental monitoring, assessing the concentration of heavy metals, for instance.

- Microscopy: Techniques such as SEM (Scanning Electron Microscopy) and TEM (Transmission Electron Microscopy) provide high-resolution images, revealing the morphology and microstructure of materials. This is vital in materials science to check for defects and ensure homogeneity.

The selection of techniques often involves a combination of methods to obtain a comprehensive quality profile.

Q 24. Explain the concept of standardization in analytical chemistry.

Standardization in analytical chemistry refers to the process of determining the exact concentration or activity of a solution, also known as a standard solution. This is crucial because many analytical techniques rely on comparing the response of an unknown sample to a known standard. A perfectly accurate measurement is impossible without a reliable standard.

Standardization is typically accomplished through titration, where a solution of known concentration (the standard) reacts with a solution of unknown concentration until a stoichiometric equivalence point is reached. Indicators can signal this point. For example, a sodium hydroxide solution can be standardized using a primary standard like potassium hydrogen phthalate (KHP). The precise weight of KHP dissolved in a known volume of water allows us to determine the exact molarity of the sodium hydroxide solution.

The accuracy of analytical measurements hinges on the reliability of the standard solution. A well-standardized solution serves as the bedrock of accurate and reproducible data, which is essential for various applications, including quality control, environmental monitoring, and research.

Q 25. Describe the importance of good laboratory practices (GLP).

Good Laboratory Practices (GLPs) are a set of principles that ensure the quality and reliability of laboratory data. They encompass a broad range of procedures and documentation designed to minimize errors and bias. GLPs are essential not only for ensuring data integrity but also for regulatory compliance, especially in industries like pharmaceuticals and environmental testing.

Key aspects of GLP include:

- Proper record-keeping: Detailed records of experimental procedures, data, and observations are critical for reproducibility and auditing.

- Equipment calibration and maintenance: Regular calibration and maintenance of analytical instruments guarantee accurate and reliable measurements. Imagine using a faulty balance – the results would be unusable.

- Standard operating procedures (SOPs): Standardized procedures for all experiments ensure consistency and reduce variability.

- Personnel training: Well-trained personnel are essential for performing experiments correctly and interpreting data accurately.

- Quality assurance: Regular checks and audits ensure that GLPs are consistently followed and data quality is maintained.

Adherence to GLPs leads to higher data quality, improves reproducibility, and strengthens the credibility of the scientific work.

Q 26. What are the safety precautions you would take when working with hazardous chemicals?

Working with hazardous chemicals necessitates a rigorous approach to safety. My safety practices always prioritize prevention and minimizing risks. They include:

- Risk assessment: Before starting any work, a thorough assessment identifies potential hazards associated with the chemicals involved.

- Personal Protective Equipment (PPE): Appropriate PPE, such as safety goggles, gloves, lab coats, and respirators, is always worn depending on the specific hazard.

- Proper handling and storage: Chemicals are handled carefully, according to the manufacturer’s instructions, and stored appropriately in designated areas, away from incompatible materials.

- Fume hoods: Reactions that generate toxic or volatile compounds are performed within fume hoods to protect against inhalation hazards.

- Emergency procedures: I’m familiar with the location of safety equipment such as eyewash stations, safety showers, and fire extinguishers, and I understand emergency procedures in case of spills or accidents.

- Waste disposal: Chemical waste is disposed of properly, following all relevant regulations.

Regular safety training and adherence to safety protocols are essential to ensure a safe working environment. The mantra is ‘prevention is better than cure’ when handling hazardous materials.

Q 27. How would you troubleshoot a malfunctioning instrument?

Troubleshooting a malfunctioning instrument follows a systematic approach. My strategy involves:

- Identify the problem: First, I pinpoint the exact nature of the malfunction – are there error messages? Is the instrument failing to produce the expected output? Are there unusual readings? This is crucial.

- Check simple issues: I start by checking simple things first – are the power and gas supplies connected? Are there any leaks? Is the sample correctly loaded? Often, simple errors are easily fixed. For example, a spectrometer not functioning might just have a power cable issue.

- Review operational procedures: I carefully review the instrument’s operating manual and check if all procedures have been followed correctly.

- Check calibrations: If the issue might be related to calibration, I verify and perform calibrations as necessary using standard materials.

- Check for maintenance logs: Maintenance records help determine if recent maintenance might be contributing to the problem.

- Consult manuals or documentation: If the problem persists, I refer to the instrument’s troubleshooting guide or contact technical support for assistance.

- Seek expert help: For more complex problems, I wouldn’t hesitate to seek help from qualified engineers or technicians. Sometimes a professional’s knowledge is needed.

A methodical approach increases the chances of resolving instrument issues efficiently and minimizes downtime.

Q 28. Describe your experience with data analysis and interpretation.

I have extensive experience with data analysis and interpretation. My approach involves several key steps:

- Data cleaning and preprocessing: This initial step is vital. It involves identifying and correcting errors, outliers, and inconsistencies in the dataset. This might involve smoothing noisy data or removing spurious readings.

- Exploratory data analysis (EDA): I employ EDA techniques to visualize and summarize the data. This can involve creating histograms, scatter plots, and other visualizations to identify trends, patterns, and relationships between variables. This often reveals unexpected correlations.

- Statistical analysis: I perform appropriate statistical analyses such as hypothesis testing, regression analysis, or ANOVA to test specific hypotheses and draw meaningful inferences from the data.

- Data interpretation and reporting: Finally, I interpret the results of the analysis and communicate the findings clearly and concisely through reports, presentations, or publications. Clear and effective communication is very important to accurately communicate the findings.

I’m proficient in using various statistical software packages, including R and Python, and I’m comfortable working with large and complex datasets. For example, in a recent project involving material characterization, I used multivariate statistical analysis to identify the relationship between the composition of the material and its mechanical properties. This resulted in the development of a better material.

Key Topics to Learn for Chemistry and Materials Analysis Interview

- Spectroscopic Techniques: Understand the principles and applications of techniques like NMR, IR, UV-Vis, and Mass Spectrometry. Be prepared to discuss how these methods are used to characterize materials and elucidate molecular structures.

- Chromatography: Familiarize yourself with various chromatographic methods (e.g., GC, HPLC) and their applications in separating and analyzing complex mixtures. Consider discussing practical aspects like column selection and method optimization.

- Material Characterization: Master techniques like XRD, SEM, TEM, and AFM. Be ready to explain how these methods provide insights into the physical and chemical properties of materials, including crystal structure, morphology, and composition.

- Thermodynamic Principles: Understand fundamental thermodynamic concepts such as enthalpy, entropy, and Gibbs free energy, and their relevance to material properties and phase transitions.

- Chemical Kinetics and Reaction Mechanisms: Demonstrate your understanding of reaction rates, activation energies, and catalytic processes. Be prepared to discuss how these concepts relate to materials synthesis and degradation.

- Polymer Chemistry: If applicable to your target role, brush up on polymer synthesis, characterization, and properties. Understand concepts like polymerization mechanisms, molecular weight distribution, and polymer morphology.

- Problem-Solving and Data Analysis: Practice interpreting experimental data, identifying trends, and drawing conclusions. Develop your ability to troubleshoot experimental problems and propose solutions.

Next Steps

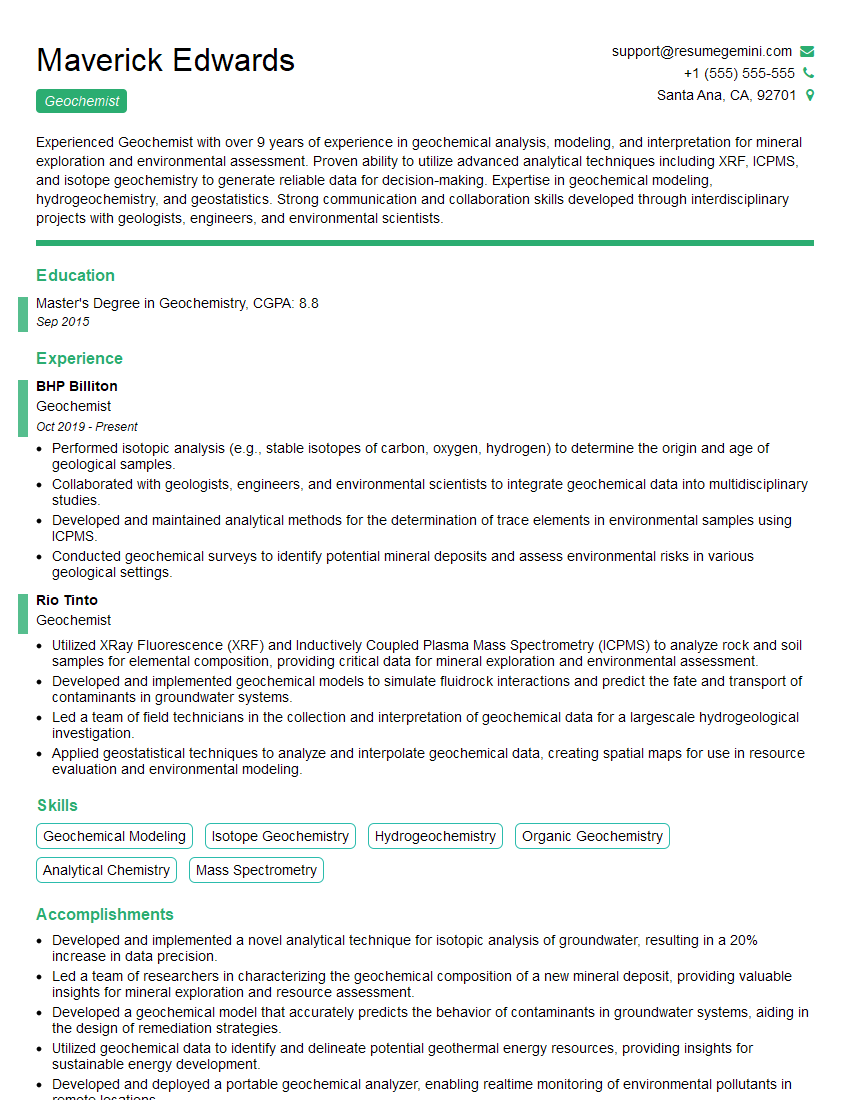

Mastering Chemistry and Materials Analysis opens doors to exciting and impactful careers in research, development, and quality control across various industries. A strong understanding of these principles is crucial for innovation and problem-solving in fields ranging from pharmaceuticals and energy to electronics and advanced materials. To significantly enhance your job prospects, create an ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of Chemistry and Materials Analysis roles. Examples of resumes tailored to this field are available within ResumeGemini to guide you through the process. Invest in crafting a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.