Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Concrete Forms Installation interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Concrete Forms Installation Interview

Q 1. Explain the different types of concrete formwork systems.

Concrete formwork systems are broadly categorized by the material used and their intended application. Choosing the right system depends on factors like the project’s size, complexity, and budget.

- Timber Formwork: This is a traditional and versatile method using lumber, plywood, and other wood products. It’s relatively inexpensive and easily adaptable to complex shapes but requires skilled labor and is susceptible to weather damage. Think of building a simple retaining wall – timber formwork would be perfectly suitable.

- Steel Formwork: Steel forms offer high strength, reusability, and precision. They’re ideal for large-scale projects and repetitive elements like columns and beams, but they are more expensive and require specialized handling equipment. Imagine constructing a multi-story building – steel forms would be more efficient for repetitive elements.

- Aluminum Formwork: Lighter than steel, aluminum forms are easier to handle and maneuver. They’re suitable for various projects, but they’re more expensive than timber. Their lightweight nature makes them useful in projects with limited access or on higher floors.

- Insulating Concrete Forms (ICFs): These forms are made from foam insulation and provide both formwork and insulation in one. They’re energy-efficient and offer faster construction times but are generally more expensive upfront. A great choice for eco-conscious homeowners building a highly energy-efficient house.

- Slipforming: This method uses continuously moving forms to cast long, vertical elements like walls or bridge columns. It’s highly efficient for large projects but requires specialized equipment and expertise. Think of a massive dam or a long highway retaining wall.

Q 2. Describe the process of building a typical column form.

Building a column form involves several crucial steps ensuring a structurally sound and visually appealing final product. Accuracy is paramount. Here’s a breakdown:

- Layout and Measurement: Precisely determine the column’s dimensions and location. Any error here will be amplified in the final concrete structure.

- Formwork Assembly: Assemble the formwork using appropriate materials (e.g., plywood, steel, or aluminum). Ensure proper alignment and bracing for rigidity.

- Plumbing and Alignment: Use levels, plumb bobs, and bracing to ensure the formwork is perfectly vertical and aligned. Any deviation can lead to a structurally unsound column.

- Tie Installation: Securely install form ties to hold the formwork together and prevent it from bulging under the pressure of wet concrete. Ensure proper spacing and tightness.

- Surface Preparation: Apply a release agent to prevent the concrete from sticking to the formwork, making stripping easier.

- Concrete Pouring: Carefully pour the concrete into the formwork, ensuring proper consolidation to eliminate air pockets. Vibration is usually required to achieve the desired density.

- Curing: Allow sufficient time for the concrete to cure before removing the formwork. Maintaining moisture is crucial during the curing process to prevent cracking.

Q 3. How do you ensure proper alignment and plumbness of forms?

Maintaining proper alignment and plumbness is crucial for the structural integrity and aesthetic appeal of concrete structures. We use several techniques to ensure accuracy.

- Laser Levels: These provide highly accurate references for verticality and alignment, particularly useful on larger projects. Imagine building a multi-story building – laser levels are a must.

- Plumb Bobs: Simple yet effective for checking verticality, especially in smaller projects. These are great for quickly checking if a wall section is plumb.

- Levels: Used to check horizontal alignment and ensure forms are level across their surface. Essential for creating flat surfaces.

- String Lines: Establishing string lines at various heights provides visual references during formwork construction. This ensures consistent alignment across larger stretches.

- Bracing and Shoring: Adequate bracing is essential to prevent formwork deflection under the weight of concrete. This is crucial to prevent the form from collapsing under stress.

- Regular Checks: Continuous monitoring and checking are necessary throughout the formwork construction process to address any deviations promptly.

Q 4. What are the common safety hazards associated with concrete formwork?

Concrete formwork poses several safety hazards if proper precautions aren’t taken. These include:

- Falls: Working at heights, often without adequate fall protection.

- Struck-by Hazards: Falling objects (tools, materials) during construction or from adjacent work activities.

- Caught-in/Between Hazards: Workers getting caught in or between formwork components, especially during stripping or movement of forms.

- Electrocution: Contact with exposed electrical wiring or equipment.

- Collapse: Failure of improperly braced or constructed formwork leading to serious injury or fatality. This is especially critical for large structures.

- Repetitive Strain Injuries: Handling heavy materials and repetitive movements can lead to musculoskeletal disorders.

Implementing safety measures like proper scaffolding, personal protective equipment (PPE), regular inspections, and safety training is crucial to mitigate these risks.

Q 5. How do you handle formwork in different weather conditions?

Weather significantly impacts concrete formwork. Effective strategies are vital for success.

- High Temperatures: Rapid drying of concrete can lead to cracking. Techniques such as shading the forms, using evaporation retarders, and keeping the concrete moist are essential.

- Low Temperatures: Freezing temperatures can damage the concrete. Insulating the forms, using antifreeze admixtures, and protecting the concrete from freezing rain are vital steps.

- Rain: Rain can weaken the formwork and compromise the concrete mix. Protecting the forms using tarps or other coverings is crucial. Preventing water from pooling is critical to avoid compromising formwork stability.

- High Winds: Strong winds can damage or even overturn unsecured formwork. Additional bracing and anchoring might be needed to ensure stability.

Proper planning and preparation considering the local weather forecast are crucial before commencing formwork installation.

Q 6. Explain the process of stripping and reusing formwork.

Stripping formwork, the process of removing forms after concrete has cured sufficiently, needs to be done carefully to avoid damage to the concrete. Reusability is a key consideration, both economically and environmentally.

- Visual Inspection: Check the concrete for strength and any signs of cracking or damage that could be exacerbated during stripping.

- Safe Access and Egress: Ensure a safe platform for workers to perform the stripping operation from.

- Systematic Removal: Carefully remove the formwork components in a planned sequence, starting from the least stressed areas. Avoid sudden impacts that could damage the concrete.

- Cleaning: Thoroughly clean the formwork to remove any residual concrete, debris, or release agent. Proper cleaning ensures longevity and facilitates reuse.

- Repair and Maintenance: Inspect the formwork for any damage and repair or replace damaged components before reuse. Regular maintenance improves the longevity of the forms.

- Storage: Store the formwork properly to prevent damage from weather or other hazards.

Proper stripping and reuse significantly reduce costs and environmental impact by minimizing material waste.

Q 7. What are the different types of form ties and their applications?

Form ties are crucial for holding formwork together and ensuring concrete integrity. Different types cater to specific applications:

- Standard Form Ties: These are the most common type, consisting of a threaded rod passing through both sides of the formwork. They are simple and inexpensive.

- Heavy-Duty Form Ties: Designed for thicker walls or higher concrete pressures, offering increased strength and durability.

- Coil Ties: These are made from coiled wire, offering flexibility and ease of removal. Commonly used in curved or complex shapes.

- Adjustable Form Ties: Allow for fine adjustments in formwork spacing, ensuring precise dimensions.

- Snap Ties: These have a break-away mechanism that facilitates easy removal without leaving tie heads protruding from the concrete. This creates a cleaner finish.

- Rebar Ties: Used to connect reinforcing steel (rebar) within the concrete formwork, ensuring the structural integrity of the reinforced concrete.

The selection of form ties depends on the wall thickness, concrete pressure, and desired finish. For instance, snap ties are favoured when a smooth, clean surface is needed after concrete removal.

Q 8. How do you calculate the amount of concrete needed for a specific form?

Calculating the amount of concrete needed for a form involves accurately determining the volume of the space the concrete will fill. Think of it like filling a container – you need to know its capacity. This is done by calculating the cubic volume of the form.

Step-by-step process:

- Determine the dimensions: Carefully measure the length, width, and height of the form in feet (or meters). It’s crucial to be precise here; even small errors can lead to significant discrepancies in concrete ordering.

- Calculate the volume: Multiply the length, width, and height together.

Volume (cubic feet) = Length (ft) x Width (ft) x Height (ft). For example, a form 10ft long, 5ft wide, and 2ft high has a volume of 100 cubic feet (10 x 5 x 2 = 100). - Convert to cubic yards (optional): Concrete is typically ordered in cubic yards. To convert cubic feet to cubic yards, divide the volume in cubic feet by 27 (since there are 27 cubic feet in a cubic yard). In our example, that’s 100 cubic feet / 27 cubic feet/cubic yard ≈ 3.7 cubic yards.

- Add waste factor: Always add a waste factor (typically 5-10%) to account for spillage, consolidation, and unexpected variations. In our example, adding a 10% waste factor would mean needing approximately 4.1 cubic yards (3.7 x 1.1 = 4.07).

- Order the concrete: Order slightly more concrete than calculated to ensure you have enough for the project.

Example: On a recent project involving a retaining wall, I meticulously measured the formwork dimensions – 20ft long, 3ft wide, and 4ft high. After calculating the volume (240 cubic feet) and adding a 10% waste factor, I ordered 9.3 cubic yards of concrete (240/27 * 1.1 ≈ 9.3).

Q 9. Describe your experience with different form materials (e.g., plywood, steel).

My experience spans various form materials, each with its strengths and weaknesses.

- Plywood: Plywood is cost-effective and versatile, ideal for smaller projects and curved forms. However, it requires careful handling to prevent damage, and its lifespan is limited. I’ve used it extensively on residential projects and for creating intricate form designs.

- Steel: Steel forms are reusable, robust, and offer excellent dimensional accuracy, perfect for large-scale commercial projects or repetitive elements. They are more expensive upfront but offer long-term cost savings. I’ve worked with steel forms on high-rise building projects, where precision and durability are paramount.

The choice of material depends on factors such as project size, budget, complexity of the design, and the required level of precision. I always consider the overall cost-effectiveness and the material’s suitability for the specific job.

Q 10. How do you ensure proper bracing and shoring of formwork?

Proper bracing and shoring are crucial for formwork stability and safety, preventing collapse under the weight of wet concrete. Think of it as building a strong skeleton for your concrete structure.

Key aspects:

- Design: The bracing and shoring system should be designed to withstand the lateral pressure exerted by the concrete, taking into account factors like concrete height, formwork material, and soil conditions.

- Placement: Braces and shores should be strategically placed to provide uniform support across the formwork, preventing localized stress points and potential failure.

- Connections: Secure connections between the formwork, bracing, and shoring are vital. This often involves using strong fasteners, adjustable components, and proper anchoring techniques.

- Inspection: Regular inspections during the construction process are essential to ensure the system remains stable and effective.

Example: On a recent foundation project, I used a combination of walers, shores, and rakers to create a robust shoring system capable of handling the significant lateral pressure of the wet concrete. Regular inspections ensured early detection and correction of any potential issues.

Q 11. What are the signs of a failing formwork system?

Recognizing the signs of failing formwork is critical for safety and the quality of the final concrete structure. Ignoring these signs can lead to catastrophic consequences.

Warning signs:

- Visible deflection or bulging: Any noticeable bending or deformation of the formwork indicates excessive pressure or inadequate bracing.

- Loose connections or fasteners: Loose connections compromise the structural integrity of the system.

- Cracking or splitting of formwork: This indicates structural weaknesses within the formwork itself.

- Sagging or uneven surfaces: These indicate inadequate support or uneven distribution of loads.

- Creaking or groaning sounds: These sounds can indicate stress on the formwork, requiring immediate inspection.

Upon observing any of these signs, immediate action, including reinforcement or replacement of the affected sections, is vital.

Q 12. How do you handle formwork adjustments during concrete placement?

Formwork adjustments during concrete placement are sometimes necessary to address minor imperfections or to ensure a smooth, level pour. However, these adjustments must be made carefully and strategically.

Best practices:

- Minimal adjustments: Avoid making major adjustments once concrete placement has begun; this can disrupt the pour and compromise the concrete’s integrity.

- Careful methods: Use gentle methods to make small adjustments, such as tapping or vibrating, to settle the formwork without causing damage or disrupting the concrete.

- Coordination: Ensure proper coordination between the concrete placement crew and the formwork adjustment crew to prevent accidents.

Example: On a recent project, I noticed minor settling in one section of the formwork during concrete placement. By carefully tapping the area, I was able to make a small adjustment without compromising the concrete pour or the integrity of the formwork. This prevented defects in the finished concrete.

Q 13. Describe your experience with oiling and treating formwork.

Oiling and treating formwork is essential to facilitate easy removal and prevent concrete adhesion, ensuring a smooth, clean concrete surface. This is like preparing a baking pan – you want the cake to come out easily and cleanly.

Methods:

- Oil types: Various oils, such as form release agents, are used, each having specific properties and suitability for different formwork materials.

- Application: Oils are applied evenly to all interior surfaces of the forms using brushes, rollers, or sprayers.

- Amount: The correct amount of oil is crucial; too little may result in adhesion, while too much can lead to oil stains on the concrete.

Example: For a recent project involving smooth-faced concrete, I used a specialized silicone-based release agent applied evenly to the plywood formwork, ensuring clean separation and preventing surface imperfections.

Q 14. Explain your process for cleaning and maintaining formwork.

Cleaning and maintaining formwork is vital to extend its lifespan and ensure its reuse on future projects. Proper cleaning also contributes to better concrete finishes.

Process:

- Prompt removal: Remove formwork promptly after the concrete has achieved sufficient strength to avoid damage.

- Thorough cleaning: Remove any adhering concrete remnants using appropriate tools and techniques, minimizing the risk of damage to the formwork.

- Repair and maintenance: Inspect the formwork for damages such as cracks or warping. Repair or replace damaged sections promptly.

- Storage: Store the cleaned and repaired formwork in a protected area, preventing exposure to the elements or damage.

Example: After completing a series of concrete columns, I carefully removed the steel forms, cleaned them thoroughly with high-pressure water jets, and inspected them for any signs of wear. Minor repairs were made, and they were properly stored for future use on similar projects.

Q 15. How do you prevent concrete leakage from formwork?

Preventing concrete leakage from formwork is crucial for ensuring the structural integrity and quality of the final concrete structure. It involves a multi-pronged approach focusing on proper formwork design, material selection, and construction practices.

Proper Sealing: All gaps and joints in the formwork must be meticulously sealed. We use high-quality sealants, ensuring a watertight barrier. Think of it like caulking a bathtub – any gaps will lead to leaks. For example, we might use rubber seals or form ties with sealant applied at their points of contact.

Formwork Material Selection: Choosing the right formwork material is paramount. Plywood, for instance, needs to be properly treated and free from gaps. Metal forms offer better water resistance but require careful handling to prevent damage. Always inspect the formwork material before use, rejecting any damaged or warped pieces.

Adequate Formwork Support: Insufficient bracing and shoring can lead to formwork deflection, creating gaps and causing leaks. We always over-engineer our bracing, ensuring the formwork remains rigid throughout the concrete pour. Imagine a sagging trampoline – that’s what inadequate support creates.

Correct Concrete Placement: Concrete should be poured and vibrated properly to eliminate voids and air pockets which can compromise the seal with the formwork. Proper consolidation is key to a watertight finish. We use vibrators to ensure proper consolidation, avoiding harsh vibrations that could damage the formwork itself.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the formwork is compatible with the design specifications?

Ensuring formwork compatibility with design specifications requires meticulous attention to detail and a thorough understanding of the project drawings and specifications. This involves several steps:

Review of Drawings: We carefully review the architectural, structural, and engineering drawings to understand the exact dimensions, tolerances, and reinforcement details of the concrete structure. We pay close attention to details like angles, curves, and offsets.

Material Selection: The formwork materials (plywood, metal, etc.) and their thickness are chosen based on the concrete pressure, height of the pour, and the required surface finish. The material’s load-bearing capacity should always exceed the anticipated stress.

Formwork Construction: The formwork is built precisely according to the dimensions specified in the drawings. This often involves cutting, assembling, and bracing components to achieve the desired shape and rigidity. Accuracy is paramount here. Even slight deviations can affect the final concrete shape.

Inspection and Approval: Before the concrete pour, a thorough inspection of the erected formwork is carried out to verify compliance with the drawings and specifications. Any discrepancies are addressed immediately. This inspection is crucial to prevent costly rework later.

Q 17. What are some common issues encountered during formwork installation?

Common issues during formwork installation range from minor inconveniences to major setbacks impacting project timelines and budgets. Some frequent problems include:

Dimensional inaccuracies: Errors in cutting or assembling formwork components can lead to misaligned forms and incorrect concrete dimensions. This can be prevented through careful measurement and double-checking.

Inadequate bracing and shoring: Insufficient support can cause formwork deflection or collapse, resulting in concrete imperfections and potential safety hazards. Proper bracing and shoring plans are critical and must be strictly followed.

Leaks and seepage: Gaps in the formwork allow concrete to leak, compromising structural integrity and requiring costly repairs. Careful sealing and proper formwork construction are necessary to prevent this.

Damage to formwork: Improper handling or accidental impacts can damage the formwork, necessitating replacements and delays. The use of protective coverings and careful handling is very important.

Alignment issues: Improper alignment of formwork components can lead to uneven concrete surfaces and structural problems. Using laser levels and plumb bobs is often needed.

Q 18. How do you troubleshoot formwork problems effectively?

Troubleshooting formwork problems effectively requires a systematic approach. We typically follow these steps:

Identify the Problem: Thoroughly assess the nature and extent of the problem. Is it a leak, misalignment, or damage? Taking detailed photographs is always helpful.

Analyze the Cause: Determine the root cause of the problem. Was it due to inadequate design, poor workmanship, or material defects?

Develop a Solution: Based on the analysis, formulate a suitable solution. This might involve resealing leaks, reinforcing the formwork, or replacing damaged components.

Implement the Solution: Carefully implement the chosen solution, adhering to safety regulations and best practices.

Inspect and Verify: After implementing the solution, thoroughly inspect the formwork to ensure the problem has been resolved and that the formwork meets the required specifications.

For example, if we identify a leak, we would first locate its source, then carefully seal it using an appropriate sealant, and subsequently check for further leakage after the concrete pour.

Q 19. What are the relevant building codes and standards for formwork?

Relevant building codes and standards for formwork vary by location but generally align with established international practices. Key standards and codes often include:

ACI 347 (American Concrete Institute): This standard covers recommended practices for formwork for concrete. It provides detailed guidelines on formwork design, construction, and inspection.

Local Building Codes: Local building codes specify requirements for formwork based on regional conditions and specific project needs. Always check the local building codes.

OSHA (Occupational Safety and Health Administration): OSHA regulations address safety requirements for construction activities, including formwork erection and dismantling, emphasizing worker safety and preventing accidents.

Adhering to these codes and standards is crucial for ensuring structural safety, preventing accidents, and meeting project requirements.

Q 20. Explain your understanding of formwork design principles.

Formwork design principles center around ensuring that the formwork can safely and accurately support the wet concrete during the pouring and setting process. Key principles include:

Strength and Stability: The formwork must be strong enough to withstand the lateral pressure exerted by the wet concrete. This requires careful calculations based on concrete pressure, formwork dimensions, and support systems.

Rigidity and Alignment: The formwork must be rigid enough to prevent deflection or movement under load, ensuring accurate dimensions and alignment of the final concrete structure. Bracing and shoring are vital to maintaining rigidity.

Watertightness: The formwork must be watertight to prevent concrete leakage and ensure a high-quality surface finish. Sealants are vital in preventing leakage.

Ease of Construction and Removal: The formwork should be designed for efficient construction and easy removal once the concrete has set, minimizing labor costs and construction time. Design considerations must take this into account.

Surface Finish: The formwork’s surface influences the concrete’s final finish. Smooth formwork yields smoother concrete surfaces. The choice of formwork material directly influences this.

Q 21. How do you ensure the proper curing of concrete after form removal?

Proper concrete curing after form removal is essential for achieving the desired strength and durability of the concrete structure. This involves maintaining adequate moisture and temperature for a sufficient period. Methods include:

Water Curing: Keeping the concrete surface consistently moist by spraying water, covering it with wet burlap, or using curing compounds. This prevents premature drying and cracking.

Membrane Curing: Applying a curing membrane that retains moisture and reduces evaporation. This is particularly useful in hot and dry climates.

Steam Curing: In specialized applications, steam curing accelerates the curing process by raising the temperature and moisture content. This is often used in precast concrete plants.

Protection from Extreme Conditions: Protecting the concrete from direct sunlight, freezing temperatures, and strong winds, particularly during the early stages of curing, is critical to preventing damage.

The duration of curing depends on factors like concrete mix design, ambient temperature, and desired strength. We always follow the concrete supplier’s recommendations for curing duration and methods.

Q 22. Describe your experience with different types of concrete.

My experience encompasses a wide range of concrete types, each with its unique properties and demanding specific formwork considerations. I’m proficient with high-strength concrete, often used in high-rise buildings and demanding structural applications, requiring robust formwork to withstand the immense pressure. I’ve also worked extensively with low-strength concrete, commonly used in pavements and less demanding structures, where the formwork design can be slightly less rigorous but still needs to ensure a smooth, accurate pour. Furthermore, I’ve experience with specialized concrete mixes, including fiber-reinforced concrete and self-consolidating concrete (SCC). SCC, for example, requires specialized formwork considerations, emphasizing airtight seals to prevent leakage and smooth surfaces to allow for proper flow. Understanding the nuances of each concrete type is crucial for selecting the appropriate formwork and ensuring a successful pour.

- High-Strength Concrete: Requires heavy-duty formwork, often with additional bracing and support.

- Low-Strength Concrete: Allows for lighter formwork, but precision is still critical for accurate dimensions.

- Self-Consolidating Concrete (SCC): Demands formwork with tight tolerances and attention to detail to prevent leaks and ensure proper flow.

Q 23. What are your experience with using formwork design software?

I’m highly proficient in using formwork design software, including AutoCAD, Revit, and specialized formwork design programs. These tools are invaluable for creating detailed and accurate formwork plans, optimizing material usage, and ensuring structural integrity. For example, using Revit, I can model complex formwork systems in 3D, accurately calculating the amount of plywood, lumber, and other materials needed. The software also allows for simulations of the concrete pour to identify potential issues before they arise on site. This prevents costly rework and delays. I’m comfortable not only creating designs but also interpreting existing designs to ensure proper execution during installation. I routinely use these tools to create detailed shop drawings, ensuring all team members have a clear understanding of the formwork requirements for each project.

Q 24. Describe your experience with reading and interpreting blueprints.

Reading and interpreting blueprints is fundamental to my work. My experience includes deciphering architectural, structural, and civil engineering drawings to accurately plan and execute formwork installation. I’m adept at identifying key details like dimensions, elevations, reinforcement placement, and tolerances. For example, I can readily identify the required concrete cover for reinforcing steel from the structural drawings, which is crucial for ensuring the structural integrity of the final concrete element. I also understand the importance of coordinating different sections of the drawings – ensuring that the formwork aligns seamlessly with other building components. Misinterpreting even small details in a blueprint can have significant consequences on the overall project, so precision and attention to detail are paramount in this aspect of my work.

Q 25. How do you manage a team of formwork installers?

Managing a team of formwork installers involves effective communication, clear delegation, and maintaining a safe and productive work environment. I emphasize clear instructions, ensuring each team member understands their responsibilities and the overall project goals. I believe in leading by example, actively participating in the work alongside my team. This fosters a sense of collaboration and shared responsibility. Regular toolbox talks are essential for addressing safety concerns, reviewing project plans, and addressing any challenges. Performance monitoring is done regularly, providing both positive reinforcement and constructive feedback to maintain a high level of quality. Conflict resolution is handled promptly and fairly, with the emphasis always on finding solutions that benefit the team and the project.

Q 26. How do you coordinate formwork installation with other trades?

Coordinating formwork installation with other trades is crucial for avoiding delays and conflicts on a construction site. This involves constant communication with other trade supervisors, such as rebar installers, electricians, and plumbers. For instance, I need to coordinate with the rebar installers to ensure that the formwork is built to accommodate the rebar placement accurately. I also need to communicate with the electricians and plumbers to ensure that conduits and pipes are routed properly, avoiding conflicts with the formwork. Regular meetings and collaborative planning are essential for efficient coordination. Using a shared project management system, updated regularly by all trades, helps maintain transparency and ensures everyone is on the same page.

Q 27. Describe a time you had to solve a challenging formwork problem.

On a recent high-rise project, we encountered a complex curved wall section that presented a significant formwork challenge. The standard formwork systems were not suitable for the unique curvature. To solve this, I collaborated with the engineering team and proposed a custom formwork solution using flexible plywood and a series of adjustable supports. We carefully mapped out the curve and created templates to ensure an accurate and consistent form. This required meticulous planning and execution but ultimately resulted in a flawless pour, demonstrating the importance of creative problem-solving and collaboration in overcoming unexpected challenges.

Q 28. What are your salary expectations for this role?

My salary expectations are commensurate with my experience and expertise in concrete formwork installation, and aligned with industry standards for similar roles in this region. I’m open to discussing a competitive compensation package that reflects my contributions to your team.

Key Topics to Learn for Concrete Forms Installation Interview

- Formwork Design and Planning: Understanding drawings, specifications, and material requirements for various concrete structures.

- Formwork Construction: Practical application of building forms using lumber, plywood, and other materials; ensuring proper alignment, bracing, and stability.

- Concrete Placement and Consolidation: Knowledge of proper concrete pouring techniques, vibration methods, and achieving a consistent, void-free pour.

- Formwork Stripping and Removal: Safe and efficient removal of forms, understanding the curing process and minimizing damage to the concrete.

- Safety Procedures and Regulations: OSHA compliance, fall protection, proper handling of materials and equipment, and risk assessment on the job site.

- Troubleshooting and Problem Solving: Identifying and resolving common formwork issues such as leaks, misalignment, and form failure. Developing solutions to unexpected challenges on the jobsite.

- Different Formwork Types: Familiarity with various formwork systems, including slip forming, tilt-up construction, and precast concrete forms.

- Material Selection and Cost Estimation: Understanding the properties of various materials and their suitability for specific applications; ability to estimate material costs and project budgets.

- Quality Control and Inspection: Understanding the importance of quality control measures throughout the formwork process and performing inspections to ensure compliance with specifications.

Next Steps

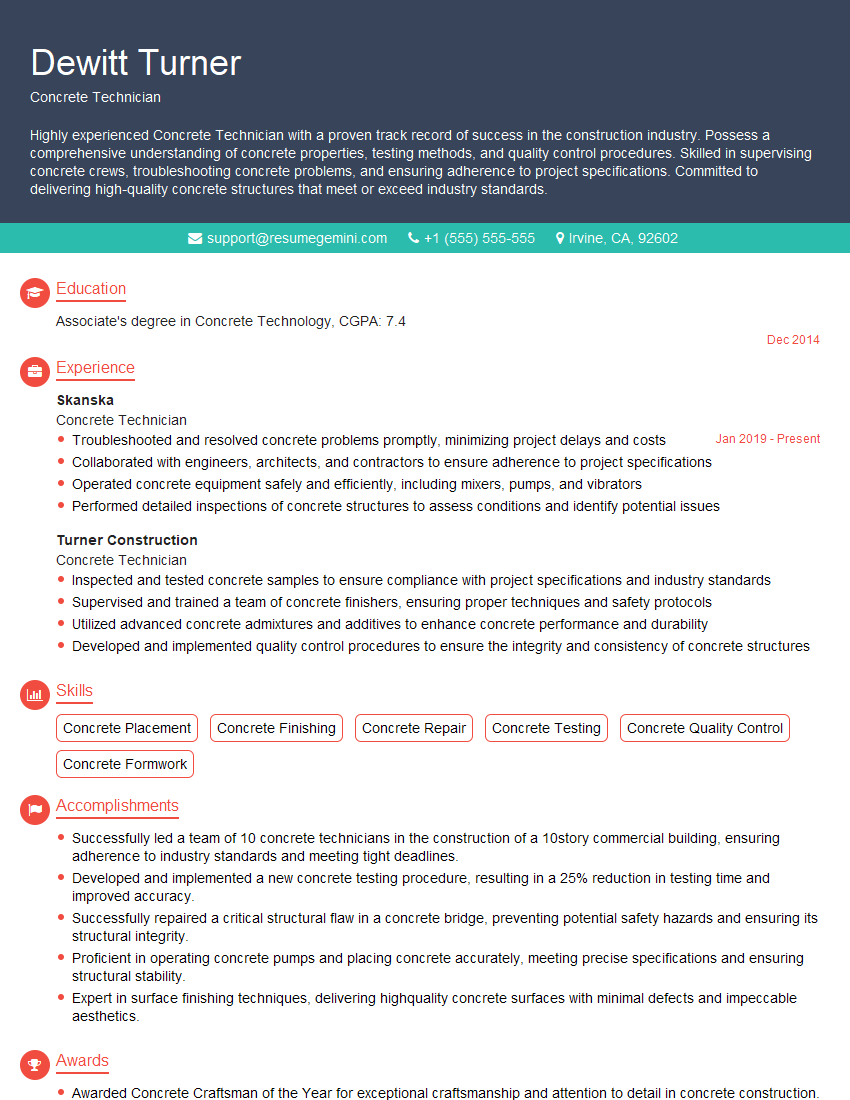

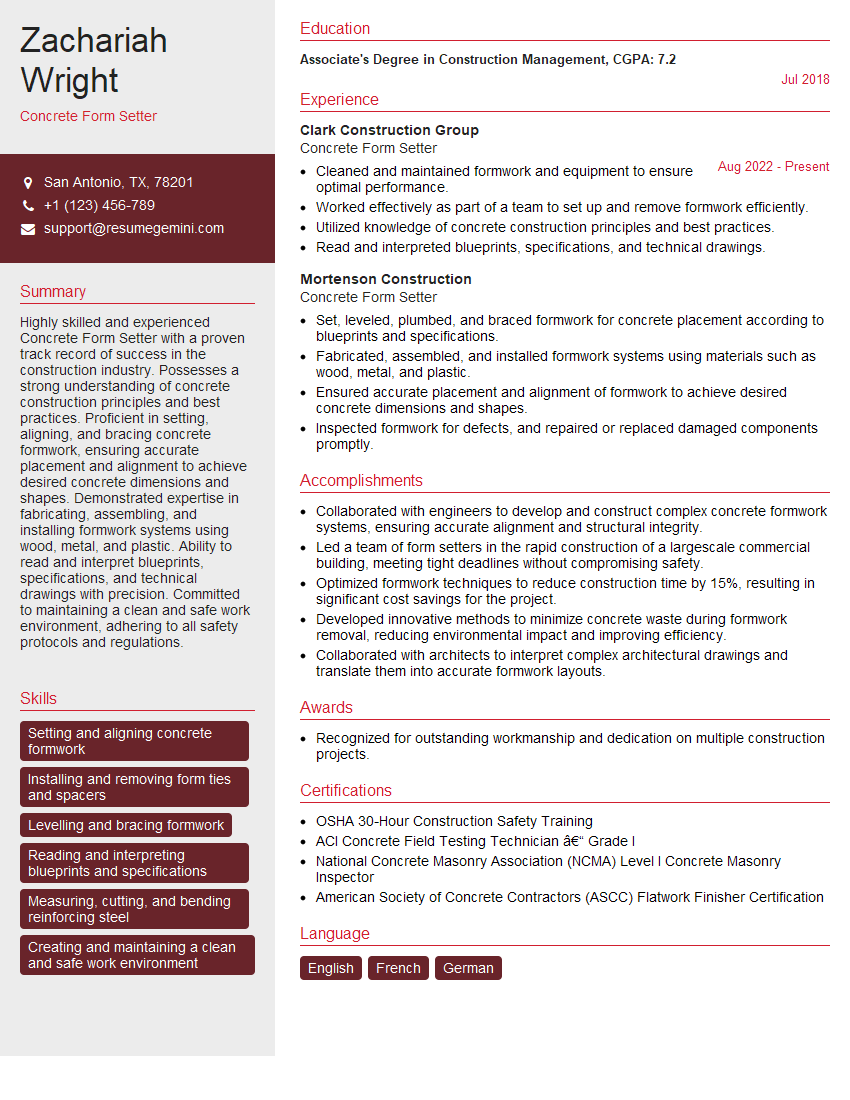

Mastering Concrete Forms Installation opens doors to a rewarding career with excellent growth potential in the construction industry. Your expertise in this crucial area will make you a highly sought-after candidate. To maximize your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume tailored to highlight your skills and experience. Examples of resumes specifically designed for Concrete Forms Installation professionals are available through ResumeGemini to guide you in creating your own compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.