Cracking a skill-specific interview, like one for Concrete Material Testing, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Concrete Material Testing Interview

Q 1. Explain the different types of concrete testing methods.

Concrete testing methods are crucial for ensuring the quality and durability of concrete structures. These methods fall into several categories, broadly covering fresh concrete properties and hardened concrete properties.

- Fresh Concrete Tests: These evaluate the properties of concrete before it sets. Examples include the slump test (measuring workability), air content test (determining air voids), and unit weight test (measuring density).

- Hardened Concrete Tests: These assess the properties of concrete after it has cured. Key tests include compressive strength testing (measuring resistance to crushing), flexural strength testing (measuring resistance to bending), splitting tensile strength testing (measuring tensile strength), and durability tests (like freeze-thaw and chloride penetration resistance) to evaluate long-term performance.

- Other Specialized Tests: Beyond these common tests, there are more specialized methods like rebound hammer testing (a non-destructive test for estimating compressive strength in-situ) and ultrasonic pulse velocity testing (another non-destructive method for evaluating the internal structure and homogeneity of concrete).

The choice of tests depends on the specific application and the properties of interest. For instance, a high-rise building might require extensive compressive strength and durability testing, while a simple sidewalk might necessitate only a slump test and compressive strength testing.

Q 2. Describe the process of conducting a slump test.

The slump test is a simple yet effective method for determining the consistency and workability of fresh concrete. It’s a measure of the concrete’s ability to flow and be placed easily.

- A metal slump cone, typically 12 inches high with a 4-inch diameter base, is placed on a non-absorbent surface.

- The cone is filled in three layers, each compacted with 25 strokes of a standard tamping rod.

- The cone is carefully lifted vertically, leaving the concrete in a slumped shape.

- The slump is measured as the difference between the height of the cone and the height of the slumped concrete. This is measured at the highest point of the slumped concrete.

Slump values indicate the concrete’s workability: a low slump suggests stiff concrete, a high slump indicates very flowable concrete, and a collapse indicates potentially poor mix proportions.

Imagine making a pancake – a low slump is like a thick, stiff pancake, while a high slump is like a very thin, runny one. Each has its place, but the right consistency is crucial for proper placement and finishing.

Q 3. How do you determine the compressive strength of concrete?

Compressive strength is a key indicator of concrete’s durability and load-bearing capacity. It’s determined by testing standard concrete cylinders (typically 6 inches in diameter and 12 inches tall) cured under controlled conditions.

- Specimen Preparation: Cylindrical samples are cast from the fresh concrete mix and cured in a controlled environment (temperature and humidity) for a specified period (often 7, 28, or 90 days).

- Testing: The cured cylinders are placed in a compression testing machine, which applies a gradually increasing compressive load until failure.

- Strength Calculation: The compressive strength is calculated by dividing the maximum load applied at failure by the cross-sectional area of the cylinder. The result is typically expressed in pounds per square inch (psi) or megapascals (MPa).

For example, if a cylinder fails under a load of 500,000 pounds and has a cross-sectional area of 28.27 square inches, its compressive strength is approximately 17,670 psi (500,000/28.27). This strength is then compared to the design specification to ensure the concrete meets the required strength criteria.

Q 4. What are the common causes of low compressive strength in concrete?

Low compressive strength in concrete can result from various factors related to materials, mix proportions, and curing conditions.

- Insufficient Cement Content: A low cement content reduces the binding capacity, resulting in weaker concrete.

- Poor Quality Cement: Cement that is damaged, old, or has been improperly stored can negatively impact strength.

- Inadequate Water-Cement Ratio: Too much water weakens the concrete matrix, even if the cement content is sufficient.

- Poor Mix Proportions: Incorrect ratios of cement, aggregates (sand and gravel), and water can lead to a weak mix.

- Improper Curing: Insufficient curing allows the concrete to dry too quickly, hindering the hydration process and reducing strength.

- Use of Contaminated Aggregates: The presence of clay, organic matter, or other impurities in aggregates reduces bond strength.

- Temperature Effects: Extremely hot or cold temperatures during curing can negatively influence the hydration process and strength gain.

Addressing these issues requires careful attention to material selection, accurate mix design, and proper construction practices. Regular testing and quality control measures throughout the construction process are crucial for ensuring adequate concrete strength.

Q 5. Explain the significance of air entrainment in concrete.

Air entrainment in concrete involves intentionally introducing tiny air bubbles into the concrete mix. These air voids improve the concrete’s resistance to freeze-thaw damage, a significant concern in cold climates.

The air bubbles provide space for water expansion during freezing. Without them, the expanding ice can create internal stresses leading to cracking and deterioration. Air entrainment reduces these stresses and enhances the concrete’s durability.

Think of it like a sponge: a sponge with many small holes can absorb a lot of water without breaking, while a solid block of material might crack under pressure. Similarly, the air bubbles in entrained concrete allow for water expansion without compromising its structural integrity.

The amount of air entrained is carefully controlled to optimize freeze-thaw resistance without significantly sacrificing the concrete’s strength.

Q 6. Describe the different types of concrete admixtures and their functions.

Concrete admixtures are chemical substances added to concrete mixes to modify its properties. They improve workability, strength, durability, or other desirable characteristics.

- Water Reducers: These reduce the amount of water needed to achieve a desired workability, leading to higher strength and durability.

- Superplasticizers: High-range water reducers that significantly increase workability without reducing strength.

- Accelerators: These speed up the setting and hardening process of concrete, useful in cold weather or when rapid construction is needed.

- Retarders: These slow down the setting process, allowing for longer placement times in hot weather or for large pours.

- Air-Entraining Admixtures: These introduce air bubbles into the mix to improve freeze-thaw resistance.

- Waterproofing Admixtures: Enhance the concrete’s resistance to water penetration.

- Corrosion Inhibitors: Reduce corrosion of reinforcing steel in concrete.

Choosing the right admixture is vital for optimizing concrete performance in a given application. The selection depends on factors like the climate, the required strength, and the desired workability.

Q 7. How do you identify and address problems with concrete cracking?

Concrete cracking is a common problem that can significantly affect the durability and structural integrity of concrete structures. Identifying and addressing cracking requires careful investigation.

- Identify the Type and Extent of Cracking: Cracks can be classified by their pattern (e.g., hairline, map, or pattern cracking), location, and severity. This helps determine the cause.

- Determine the Cause: Common causes include shrinkage (drying shrinkage, plastic shrinkage), temperature changes, overloading, foundation settlement, or inadequate curing. Analyzing the crack pattern and surrounding conditions is essential for diagnosis.

- Evaluate the Severity: Minor cracks may not require immediate action, but significant or widening cracks warrant prompt attention.

- Implement Repair Strategies: Repair methods range from simple surface treatments (like sealing cracks) to more complex structural repairs (like epoxy injection or concrete replacement). The choice depends on the cause, severity, and location of the cracks.

For instance, hairline cracks due to drying shrinkage may only need sealing, while significant cracks caused by foundation settlement require more extensive structural repair, possibly involving underpinning or other foundation stabilization measures. Proper diagnosis and targeted repair are crucial to prevent further damage and ensure the long-term performance of the structure.

Q 8. What are the standard procedures for testing concrete’s workability?

Workability in concrete refers to its ability to be mixed, transported, placed, and finished without segregation (separation of the components) or excessive bleeding (water rising to the surface). Several standard tests assess this crucial property.

Slump Test: This is the most common method. A cone-shaped mold is filled with fresh concrete, then carefully removed. The slump, or the difference in height between the original and settled concrete, measures workability. A higher slump indicates higher workability. For example, a slump of 100-150mm might be suitable for many applications, while a lower slump is preferred for less workable mixes.

Flow Test: Used for very fluid mixes, this test measures the spread diameter of concrete after it’s released from a metal container. The wider the spread, the higher the workability.

Compacting Factor Test: This method compares the volume of concrete in a standard measure before and after compaction. A higher compacting factor indicates better workability.

Vee-Bee Test: This test employs a rotating container, measuring the time it takes for the concrete to achieve a specific level of consolidation. It’s particularly useful for assessing the workability of stiff, non-cohesive mixes.

The choice of test depends on the type of concrete and the specific application. Each test provides quantitative data allowing for consistent mix design and quality control.

Q 9. Explain the importance of curing concrete properly.

Proper curing of concrete is essential for achieving its designed strength, durability, and overall performance. Curing involves maintaining adequate moisture and temperature conditions for a specific period after placement. Without proper curing, concrete will not fully hydrate, resulting in reduced strength, increased porosity, and susceptibility to cracking and damage.

Think of it like baking a cake: you need the right temperature and time for the ingredients to react and create the desired texture and taste. Similarly, concrete needs proper curing for the cement hydration process to complete effectively.

Importance:

Strength Development: Curing ensures the cement hydrates fully, leading to higher compressive strength.

Durability: It minimizes the formation of microcracks, reducing permeability and enhancing resistance to freeze-thaw cycles, chemical attack, and abrasion.

Reduced Shrinkage: Proper curing controls shrinkage cracking by maintaining adequate moisture content.

Methods: Curing techniques include water curing (ponding, spraying, immersion), membrane curing (using plastic sheets), and steam curing (used in precast concrete plants). The optimal curing method depends on factors such as the project scale, climate, and concrete type.

Q 10. Describe the different types of concrete durability tests.

Concrete durability tests evaluate its ability to withstand various environmental factors over its service life. These tests assess resistance to deterioration mechanisms such as freeze-thaw cycles, chemical attack, abrasion, and alkali-aggregate reaction.

Freeze-thaw tests: These tests subject concrete specimens to repeated cycles of freezing and thawing to determine their resistance to damage caused by ice formation. Methods like the Rapid Freeze-Thaw test are commonly used.

Chemical attack tests: Assess resistance to chemicals like sulfates, chlorides, and acids found in aggressive environments. These tests may involve immersion of specimens in specific chemical solutions for extended periods.

Abrasion resistance tests: Evaluate concrete’s resistance to surface wear due to traffic or other abrasive actions. Tests like the Los Angeles abrasion test are frequently employed.

Alkali-aggregate reaction tests: Determine the potential for expansion due to a chemical reaction between the cement’s alkaline components and certain aggregates. Tests may include petrographic examination and accelerated mortar bar tests.

Permeability tests: Measure the ease with which water or other fluids can penetrate the concrete. High permeability increases susceptibility to damage. Methods include air permeability and water absorption tests.

The specific tests selected depend on the anticipated environmental conditions and the intended application of the concrete. Results guide the selection of appropriate concrete mixes and construction techniques to ensure long-term performance.

Q 11. How do you interpret the results of a concrete cylinder test?

Concrete cylinder tests, also known as compressive strength tests, are crucial for assessing the strength of hardened concrete. Cylindrical specimens are cast from the fresh concrete mix, cured under controlled conditions, and then subjected to a compressive load until failure. The maximum load at failure is used to calculate the compressive strength in units of megapascals (MPa) or pounds per square inch (psi).

Interpretation:

Strength Value: The primary result is the compressive strength. A higher value indicates stronger concrete, capable of withstanding greater loads. This value is compared to the specified strength requirements in the project specifications.

Failure Mode: Observing how the cylinder fails (e.g., sudden crushing, splitting) provides insight into the concrete’s quality. An uneven failure might indicate defects in the concrete or flaws in the testing procedure.

Consistency: Multiple cylinder tests are conducted to ensure consistency and reliability of the results. Variations between the test results should be within an acceptable range.

Example: If a project requires a minimum compressive strength of 30 MPa, and the average of three cylinder tests is 35 MPa, the concrete meets the specification. Conversely, if the average is below 30 MPa, it may require remedial actions.

Q 12. What are the common defects found in concrete and their causes?

Several defects can occur in concrete, compromising its performance and durability. These defects often stem from improper materials, poor mixing, inadequate placement, or insufficient curing.

Cracking: Shrinkage (due to water loss), temperature changes, overloading, and settlement can cause cracking. Cracks reduce the structural integrity and permeability of the concrete.

Plastic shrinkage cracking: This occurs when water evaporates from the surface of the fresh concrete faster than it can be replenished from the interior.

Scaling: This surface deterioration is often caused by freeze-thaw cycles in concrete that is not sufficiently air-entrained or properly cured.

Honeycombing: This is the presence of voids or air pockets within the concrete, reducing its strength and durability. It’s often due to improper consolidation or inadequate vibration during placement.

Segregation: This refers to the separation of the components (aggregates, cement, water) of the concrete mix, resulting in weakened areas.

Bleeding: The excess water in the mix rising to the surface, which can weaken the concrete surface and increase permeability.

Understanding the causes of these defects is crucial for implementing preventive measures during concrete design, mixing, placement, and curing.

Q 13. Explain the role of quality control in concrete construction.

Quality control (QC) in concrete construction is vital for ensuring that the final product meets the specified requirements and provides the intended performance. It involves a systematic approach to monitoring and verifying every stage of the concrete process, from materials selection to final testing.

Role of QC:

Material Testing: Ensuring that aggregates, cement, and admixtures meet the required specifications.

Mix Design: Developing an appropriate mix design based on project requirements and site conditions.

Batching and Mixing: Verifying the accuracy of the batching process and the quality of the mixing.

Placement and Consolidation: Overseeing the proper placement, compaction, and finishing of the concrete.

Curing: Ensuring that adequate curing procedures are followed.

Strength Testing: Conducting compressive strength tests and other relevant tests to verify that the hardened concrete meets the required standards.

A robust QC program minimizes defects, reduces rework, and enhances the overall durability and safety of the structure. It’s essential to have a well-defined QC plan tailored to each project, defining responsibilities and procedures for different aspects of concrete construction.

Q 14. How do you ensure the accuracy and reliability of concrete testing results?

Ensuring the accuracy and reliability of concrete testing results is paramount for ensuring the structural integrity and safety of any concrete structure. This requires careful attention to every stage of the testing process.

Measures for Accuracy and Reliability:

Calibration and Maintenance: Regular calibration and maintenance of testing equipment (e.g., compressive testing machines, slump cones) are crucial to eliminate systematic errors.

Proper Sampling: Representative samples of concrete must be obtained and handled carefully to avoid any alteration of their properties.

Standard Procedures: Adhering strictly to established standard test methods (e.g., ASTM, ACI) to ensure consistency and comparability of results.

Quality Control of Personnel: Technicians conducting the tests need to be well-trained and experienced to ensure proper execution of test procedures.

Environmental Control: Maintaining consistent temperature and humidity conditions during curing of specimens to minimize variations in strength development.

Data Analysis: Proper statistical analysis of test data to identify outliers, calculate average strengths, and assess variability between results.

Documentation: Meticulous documentation of every step of the testing process, including sample identification, test methods used, and results obtained. This allows for traceability and validation of the results.

By implementing these rigorous measures, we can have confidence in the accuracy and reliability of concrete testing results, which are critical for making informed decisions regarding mix design, construction practices, and project acceptance criteria.

Q 15. What are the safety precautions to be followed during concrete testing?

Safety is paramount in concrete testing. We must always prioritize personal protective equipment (PPE). This includes safety glasses to protect against flying debris during sample preparation, gloves to prevent skin irritation from cement and chemicals, and steel-toed boots to protect feet from dropped objects. Work areas must be well-lit and free of obstacles to prevent trips and falls. When working with heavy equipment, like compressive testing machines, proper training and adherence to manufacturer guidelines are crucial to prevent accidents. Furthermore, proper ventilation is necessary to mitigate exposure to cement dust, especially in confined spaces. Finally, handling potentially hazardous materials like chemical admixtures requires careful reading and adherence to the manufacturer’s safety data sheets (SDS).

For example, during a slump test, a sudden, uncontrolled drop of the concrete cone could lead to splashing and injury. Using a smooth, controlled lowering technique prevents this. Similarly, during core sampling, the core drill generates significant heat and vibrations; the use of proper safety equipment minimizes the risk of injury.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of concrete testing equipment.

My experience encompasses a wide range of concrete testing equipment, from basic tools to sophisticated automated systems. I’m proficient in using equipment for determining slump, air content (using the pressure method and the air meter), unit weight, and compressive strength. I have extensive experience with compressive testing machines, both manual and automated, ranging from smaller capacity machines for testing smaller specimens to larger machines capable of testing larger cylinders and cubes. I’ve also worked with equipment for measuring the flexural strength of concrete beams, and I’m familiar with the operation and maintenance of various types of mixers used for preparing test specimens. Furthermore, I have experience using rebound hammers (Schmidt hammer) for in-situ concrete strength assessment. I’m comfortable using data acquisition systems to automate data logging and analysis.

For instance, I once had to troubleshoot a malfunctioning compressive testing machine. Through systematic diagnosis, I identified a faulty load cell and replaced it, ensuring accurate and reliable test results. Another example involved using a precision balance to accurately measure the mass of aggregate samples for grading analysis, highlighting the importance of meticulous measurement in accurate results.

Q 17. How do you handle non-conforming concrete results?

Non-conforming concrete results necessitate a thorough investigation to identify the root cause. My approach is systematic and involves several steps. First, I meticulously review the testing procedures to ensure they adhered strictly to the relevant standards (ASTM, ACI, etc.). Second, I examine the testing equipment for any potential malfunctions or calibration issues. Third, I look into the concrete mix design and its preparation, including the quality of the materials used (cement, aggregates, admixtures, water). Fourth, I investigate the placement, curing, and handling of the concrete. Depending on the nature of the non-conformity, I may conduct further testing to verify the initial findings.

For example, if compressive strength is below the specified value, I might investigate the water-cement ratio, the curing process, or the presence of deleterious materials in the aggregates. Once the cause is determined, corrective actions are implemented, including modifications to the mix design, improved quality control measures, or retraining of personnel. Finally, documentation of the entire process, including the non-conformance, investigation, corrective action, and verification, is meticulously maintained.

Q 18. Explain the use of statistical analysis in concrete testing data.

Statistical analysis is indispensable for interpreting concrete testing data. It helps in moving beyond individual test results to understand the overall variability and reliability of the concrete. We use descriptive statistics (mean, standard deviation, etc.) to summarize the data. Inferential statistics (t-tests, ANOVA, etc.) are employed to compare different samples or assess the significance of variations. Control charts are frequently used to monitor the consistency of concrete properties over time. Statistical analysis also helps in determining the appropriate sample size needed for reliable conclusions.

For instance, analyzing compressive strength data from multiple batches of concrete allows us to determine the average strength and its variability, giving a clearer picture of the concrete’s overall performance. A control chart would allow us to track trends in strength and identify potential problems before they escalate. By applying statistical analysis, we can confidently assess if the concrete meets the specified quality standards and make informed decisions about the project.

Q 19. Describe your experience with different concrete standards (e.g., ASTM, ACI).

My experience spans various concrete standards, including ASTM (American Society for Testing and Materials) and ACI (American Concrete Institute) standards. I’m thoroughly familiar with the relevant test methods outlined in these standards, such as ASTM C192 (making and curing concrete specimens), ASTM C39 (compressive strength), ASTM C173 (slump), ASTM C138 (air content), and many others. I understand the nuances and differences between various standards and their applicability to different types of concrete and project requirements. I can readily adapt testing procedures and interpret results according to the specific requirements of a given project. Knowing which standard applies is crucial for ensuring consistent quality and fair assessment of the concrete.

For example, the requirements for concrete mix proportions or acceptance criteria might differ slightly between ASTM and ACI standards. I’ve had to navigate these subtle differences to provide the most appropriate and reliable test reports. The standards are regularly updated, so staying current with these changes is critical for maintaining proficiency in the field.

Q 20. How do you ensure the quality of concrete aggregates?

Ensuring the quality of concrete aggregates involves a multi-stage process. It starts with careful selection of the aggregate source, followed by thorough testing and evaluation of the physical properties of the aggregates. These tests cover aspects like gradation (particle size distribution), unit weight, absorption, soundness (resistance to weathering), and strength. We use sieves to determine gradation, and we perform tests to assess the presence of deleterious materials (e.g., clay, organic matter) that might negatively affect concrete quality. Testing for soundness uses methods like the sodium sulfate soundness test to determine the aggregates’ susceptibility to damage due to weathering.

For instance, poorly graded aggregates could lead to weak concrete, and the presence of clay in aggregates can significantly reduce the strength and durability of the final product. Regular quality control checks and the meticulous maintenance of proper documentation throughout the selection and testing process are essential to ensuring the aggregates conform to the project’s specifications.

Q 21. What are the effects of different water-cement ratios on concrete properties?

The water-cement ratio is a critical factor influencing concrete properties. It’s the ratio of the weight of water to the weight of cement in a concrete mix. A lower water-cement ratio generally leads to higher strength, durability, and lower permeability. This is because a lower water content results in a denser concrete matrix with fewer pores. Conversely, a higher water-cement ratio leads to lower strength, reduced durability, increased permeability, and potentially higher shrinkage. This is due to increased porosity in the concrete. The increased porosity makes the concrete more vulnerable to the ingress of water, leading to freeze-thaw damage, chemical attack, and reduced durability.

However, a very low water-cement ratio can lead to workability issues, making it difficult to place and finish the concrete. Finding the optimal water-cement ratio is a balance between achieving the desired strength and durability while maintaining good workability. This is often achieved by adjusting the mix design to include different types of cement, admixtures, or additional fine aggregates.

Q 22. Explain the different types of concrete mixes and their applications.

Concrete mixes are categorized based on their intended use and performance requirements. The primary types include:

- Normal Strength Concrete: This is the most common type, used for general construction applications like foundations, slabs, and walls. Its compressive strength typically ranges from 25 to 40 MPa (Megapascals). Think of it as the ‘all-purpose’ concrete for everyday construction.

- High-Strength Concrete (HSC): HSC boasts compressive strengths exceeding 50 MPa, offering enhanced durability and load-bearing capacity. It’s frequently employed in high-rise buildings, bridges, and specialized structures where strength and longevity are paramount. Imagine it as the ‘muscle’ in the construction world.

- High-Performance Concrete (HPC): HPC goes beyond high strength, incorporating advanced materials and mix designs to achieve superior durability, workability, and other properties such as reduced permeability and increased resistance to chemicals. It’s typically used in demanding environments or for critical structural elements where exceptional performance is critical.

- Lightweight Concrete: This type uses lightweight aggregates (like expanded clay or shale) to reduce the overall density, making it ideal for applications where weight is a concern, such as precast elements, roof slabs, and in situations needing reduced dead loads.

- Fiber-Reinforced Concrete (FRC): This type includes fibers (steel, synthetic, or natural) to improve tensile strength, crack resistance, and overall durability. It’s frequently utilized in pavement applications, overlays, and structures subjected to impact or dynamic loads. Think of it as adding tiny ‘reinforcements’ to give extra toughness.

- Self-Consolidating Concrete (SCC): SCC flows easily under its own weight and fills complex formwork without needing vibration. This reduces labor costs and improves the final product’s quality. It’s used extensively in situations where vibration is difficult or impossible, and achieving a uniform, high-quality finish is vital.

The choice of concrete mix depends heavily on the specific project requirements, including strength demands, environmental conditions, and budget constraints.

Q 23. How do you determine the appropriate mix design for a specific application?

Determining the appropriate mix design is a crucial step in ensuring successful concrete construction. It’s a multi-faceted process involving several key considerations:

- Strength Requirements: The desired compressive strength of the concrete is determined based on structural design calculations and codes.

- Durability Requirements: Environmental factors such as exposure to chlorides (de-icing salts), sulfates (in soil), or freezing and thawing cycles influence the required durability of the concrete. Choosing appropriate cement type, admixtures and aggregates is key here.

- Workability Requirements: The desired consistency of the fresh concrete (slump) must be considered, impacting the ease of placement and finishing.

- Economic Considerations: The cost of different materials (cement, aggregates, admixtures) needs to be balanced against the desired performance characteristics.

The mix design process typically involves using established guidelines like ACI (American Concrete Institute) or similar standards. These guidelines provide detailed procedures and recommendations for different concrete types and applications. Often, specialized software is used to optimize the mix design, considering all of these factors and providing the best mix proportions.

For instance, if I’m designing a mix for a bridge deck exposed to de-icing salts, I would choose a mix with a high cement content, low water-cement ratio, and potentially incorporate air-entraining admixtures to enhance freeze-thaw resistance. The mix design would be meticulously tested and verified to ensure it meets the specified performance requirements.

Q 24. What are the environmental considerations for concrete production and testing?

Environmental considerations in concrete production and testing are increasingly important due to the industry’s significant environmental footprint. Key aspects include:

- Cement Production: Cement manufacturing is a significant source of greenhouse gas emissions (primarily CO2). Using supplementary cementitious materials (SCMs) like fly ash, slag, or silica fume can reduce the carbon footprint significantly. These materials partially replace Portland cement and possess their own unique properties that can also benefit concrete performance.

- Aggregate Sourcing: Aggregates should be sustainably sourced to minimize environmental impact on the land from quarrying and transportation. Recycled aggregates from demolition waste can be a valuable sustainable alternative.

- Water Usage: Concrete production requires substantial amounts of water. Implementing water-efficient mixing techniques and using recycled water can conserve resources.

- Waste Management: Proper disposal of concrete waste is crucial to minimize landfill space and potential environmental contamination. Recycling and reuse of concrete debris should be prioritized.

- Testing Practices: Minimizing the environmental impact of testing involves using eco-friendly testing methodologies, choosing durable and reusable test equipment, reducing waste produced during testing, and adhering to appropriate safety and waste disposal protocols.

Implementing environmentally conscious practices throughout the lifecycle of concrete – from production to disposal – is crucial for sustainable infrastructure development.

Q 25. Describe your experience with concrete repair and rehabilitation methods.

My experience with concrete repair and rehabilitation encompasses various methods tailored to the specific damage type and location. These include:

- Crack Repair: Small cracks can be repaired using epoxy injection or surface patching. Larger cracks may require more extensive techniques, including stitching or the use of specialized repair mortars.

- Spalling Repair: Spalling (the breaking or flaking of concrete) often necessitates the removal of the damaged concrete followed by careful cleaning and patching using a compatible repair mortar.

- Corrosion Repair: Repairing corrosion damage in reinforced concrete usually involves removing the corroded steel, cleaning the affected area, and replacing the steel with new reinforcing bars (rebar) embedded in a suitable repair mortar.

- Carbonation Repair: Carbonation (the reaction of carbon dioxide with concrete) weakens the concrete. Rehabilitation may involve applying protective coatings or applying specialized materials to improve the alkalinity of the concrete.

I’ve worked on various projects involving these methods, ranging from repairing minor cracks in residential structures to large-scale rehabilitation of bridges and industrial facilities. Successful repair requires a thorough understanding of the cause of the damage, careful selection of appropriate materials, and strict adherence to established repair procedures.

For example, I once worked on a project where significant spalling occurred on a bridge deck due to freeze-thaw cycles. We implemented a multi-step repair process involving careful removal of the damaged concrete, cleaning the surface, applying a protective coating to prevent further damage, and finally, patching the concrete with a high-durability, freeze-thaw-resistant repair mortar. The resulting repair extended the service life of the bridge significantly.

Q 26. How do you maintain and calibrate concrete testing equipment?

Maintaining and calibrating concrete testing equipment is essential for obtaining accurate and reliable results. This involves regular inspections, cleaning, and calibration using traceable standards:

- Regular Inspections: Daily or weekly inspections are performed to check for any damage, wear and tear, or signs of malfunction. This ensures the equipment is functioning properly and safety protocols are in place.

- Cleaning: Equipment should be thoroughly cleaned after each use to remove any residual concrete, debris, or chemicals. This prevents cross-contamination and ensures the accuracy of subsequent tests.

- Calibration: Concrete testing equipment, such as compressive strength testing machines, must be regularly calibrated against traceable standards. This typically involves using certified weights or other reference materials to verify the accuracy of the equipment. Calibration frequency varies depending on the equipment type and usage frequency, but it should be done according to manufacturer’s recommendations or accredited standards.

- Maintenance Records: Detailed maintenance and calibration records should be maintained to track the equipment’s performance and ensure compliance with relevant standards.

Proper maintenance and calibration ensure the reliability of test results, crucial for making informed decisions about concrete quality and structural integrity. A malfunctioning machine can lead to inaccurate results, potentially compromising safety and structural performance.

Q 27. Describe your experience with concrete testing in different climatic conditions.

My experience includes concrete testing in diverse climatic conditions, ranging from extreme heat and arid environments to cold, snowy winters. These conditions significantly affect concrete properties and the testing process itself:

- Temperature Effects: Extreme temperatures influence the setting and hardening of concrete, as well as the strength development. Testing needs to account for these effects, potentially requiring adjustments to procedures or corrections to measured strength values. This may involve temperature-compensated curing or specialized testing techniques.

- Moisture Content: High humidity can accelerate the curing process while dry conditions can lead to premature drying shrinkage. Properly controlling the moisture content during curing and testing is therefore vital for accurate results.

- Freezing and Thawing: Freeze-thaw cycles can significantly affect the durability of concrete. Specialized tests are employed to assess resistance to these cycles, evaluating how the concrete performs in repeated freeze-thaw conditions.

- Equipment Considerations: Extreme temperatures can impact the performance of testing equipment. Equipment might need to be adapted or special considerations need to be made during testing in extreme conditions to prevent damage and ensure accurate results. For example, equipment may need to be shielded from extreme sunlight in high heat conditions or insulated during cold weather.

I have developed expertise in adapting testing protocols to various climatic conditions, ensuring the accuracy and reliability of the results, regardless of the ambient environment.

Q 28. What are your strengths and weaknesses in relation to concrete material testing?

My strengths in concrete material testing lie in my comprehensive understanding of relevant standards, my meticulous attention to detail during testing, and my ability to adapt to different situations and testing requirements. I possess excellent problem-solving skills and a proven track record of delivering accurate and reliable results. I’m also proficient in using various testing equipment and software, and I’m able to effectively communicate technical information to both technical and non-technical audiences.

A potential area for improvement is expanding my experience with some specialized testing methods such as advanced non-destructive evaluation (NDE) techniques. While I have a foundational understanding of these methods, gaining more practical experience in this area would enhance my skill set further.

Key Topics to Learn for Concrete Material Testing Interview

- Mix Design and Proportioning: Understanding the fundamental principles behind concrete mix design, including the selection of aggregates, cement type, and water-cement ratio. Practical application: Calculating the required quantities of each ingredient for a specific strength requirement.

- Strength Testing (Compressive, Tensile, Flexural): Mastering the procedures and interpretation of results for various strength tests. Practical application: Analyzing test data to determine if concrete meets specified strength requirements and identifying potential issues.

- Durability Testing: Understanding tests for assessing concrete’s resistance to factors like freeze-thaw cycles, chloride penetration, and sulfate attack. Practical application: Specifying appropriate concrete mixes and construction practices to enhance durability in specific environments.

- Non-Destructive Testing (NDT): Familiarizing yourself with techniques like rebound hammer, ultrasonic pulse velocity, and cover meter testing. Practical application: Evaluating the in-situ strength and quality of existing concrete structures without causing damage.

- Quality Control and Assurance: Understanding the role of quality control procedures in concrete production and construction. Practical application: Implementing and monitoring quality control measures to ensure consistent concrete quality throughout a project.

- Data Analysis and Reporting: Developing skills in interpreting test results, identifying trends, and preparing clear and concise reports. Practical application: Communicating findings to engineers and stakeholders in a professional and effective manner.

- Relevant Standards and Codes: Familiarity with ASTM, ACI, or other relevant standards and codes related to concrete testing. Practical application: Ensuring compliance with industry best practices and regulations.

Next Steps

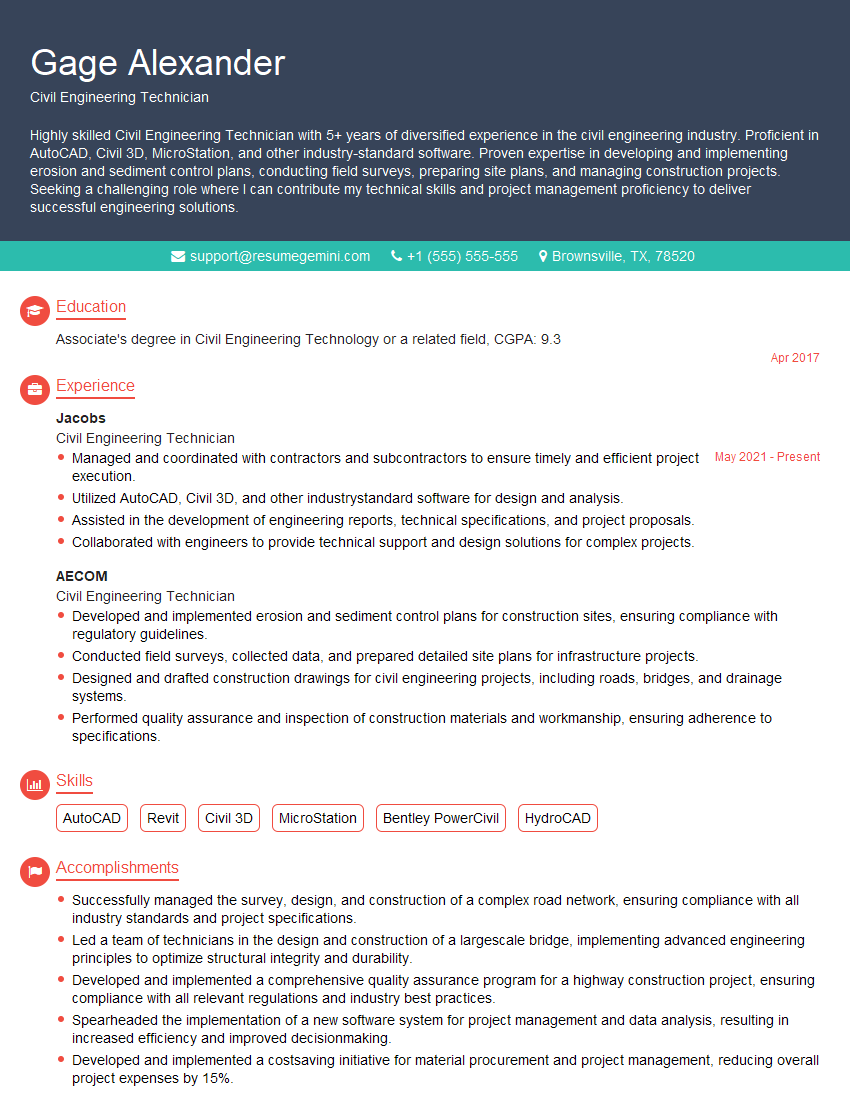

Mastering concrete material testing is crucial for career advancement in the construction and civil engineering industries. A strong understanding of these principles opens doors to specialized roles and higher earning potential. To enhance your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a compelling and effective resume tailored to the concrete testing field. Examples of resumes specifically designed for Concrete Material Testing professionals are available to guide you through the process. Invest time in crafting a professional resume; it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.