The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Concrete Materials Characterization and Research interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Concrete Materials Characterization and Research Interview

Q 1. Explain the different methods used for determining the compressive strength of concrete.

Determining the compressive strength of concrete is crucial for ensuring the structural integrity of any concrete structure. It’s essentially a measure of how much force the concrete can withstand before it crumbles. This is typically done using a compression testing machine.

Standard Cylinder Compression Test: This is the most common method. Cylindrical concrete specimens (typically 6 inches in diameter and 12 inches high) are cast from the fresh concrete mix and cured under controlled conditions (temperature and humidity). After a specified curing time (often 7, 28, or 90 days), these cylinders are placed in a compression testing machine. The machine applies a gradually increasing compressive load until the cylinder fails. The maximum load applied just before failure, divided by the cross-sectional area of the cylinder, gives the compressive strength in units of PSI (pounds per square inch) or MPa (megapascals).

Cube Compression Test: Similar to the cylinder test, but uses cubic specimens (typically 6-inch cubes). Cubes are also commonly used, particularly in some regions and specifications.

In-situ Testing: Methods like the Schmidt hammer test or ultrasonic pulse velocity testing provide estimates of compressive strength without destroying the concrete structure. These are useful for evaluating existing concrete structures but are generally less precise than laboratory testing.

The results from these tests are vital for quality control and ensuring that the concrete meets the required specifications for the project. For example, a bridge might require a minimum compressive strength of 5000 psi, and these tests would verify this.

Q 2. Describe the procedures for conducting slump tests and their significance.

The slump test is a simple and widely used method for assessing the workability of fresh concrete. Workability refers to how easily the concrete can be placed, consolidated, and finished without segregation (separation of components). A slump cone, a truncated metal cone with specific dimensions, is filled with fresh concrete in three layers, each compacted with 25 strokes of a standard tamping rod. After removing the cone, the slump (the vertical distance the concrete settles) is measured.

Procedure: The slump cone is placed on a flat, non-absorbent surface. The concrete is carefully placed in three layers, each compacted with 25 strokes. The cone is then carefully lifted vertically, and the slump is measured immediately using a ruler. The slump is categorized as low (0-2 inches), medium (2-4 inches), or high (4-6 inches). Slumps exceeding 6 inches often indicate excessive water content.

Significance: The slump test provides an indication of the consistency and workability of the concrete. A low slump suggests stiff, less workable concrete, while a high slump indicates a very workable but potentially weak mix. The ideal slump is project-specific, depending on factors like the placement method and the desired finish. For example, a high slump might be suitable for pumping concrete into tall structures but could cause segregation in a simple slab pour.

It’s important to note that the slump test is an empirical measure and may not be sufficient to fully characterize workability in all cases. Other tests are also important, as described in the next answer.

Q 3. What are the common methods for assessing the workability of concrete?

Assessing concrete workability involves evaluating how easily the concrete can be handled and placed without losing its integrity. The slump test is just one method; several others provide a more complete picture.

Slump Test (already discussed): Measures the consistency of the concrete.

Flow Table Test: This method measures the flow or spreading of concrete on a circular flow table. The table is subjected to a number of impacts, and the diameter of the spread concrete is measured. It’s particularly useful for assessing very fluid concrete mixes.

Compacting Factor Test: This measures the degree of compaction achieved in a standard volume of concrete. It is a better indicator of workability for harsh and high strength concrete mixtures.

Vebe Test: This test utilizes a vibrating table to assess workability; it measures the time it takes for the concrete to consolidate to a certain level.

Kelly Ball Test: This method utilizes a standardized ball penetrating into the concrete, its penetration depth measuring workability.

The choice of test depends on the type of concrete and the specific application. A combination of tests is often preferable to obtain a comprehensive understanding of workability.

Q 4. How do you determine the air content of concrete, and why is it important?

Air content in concrete is determined primarily through the pressure method using a pressure meter. This method involves placing a small sample of fresh concrete in a chamber and pressurizing it to measure the air volume within the sample. The air voids are important in several aspects.

Pressure Method: This is the most accurate method for determining air content. A sample of concrete is placed in a pressure chamber, and air pressure is applied. The change in volume due to the trapped air is measured, and the air content is calculated.

Importance of Air Content: Air entrained in concrete improves its durability, particularly in freeze-thaw cycles. Small, well-distributed air bubbles create space for water to expand during freezing, preventing the damaging internal pressures that can lead to cracking and deterioration. It also improves workability and reduces segregation of the mix ingredients. However, excessive air content can reduce the strength of the concrete.

Air content is controlled through the use of air-entraining admixtures which are chemical additives specifically designed to incorporate air bubbles in the concrete mix, creating this beneficial effect. The optimal air content depends on the exposure conditions and other concrete properties.

Q 5. Explain the significance of the water-cement ratio in concrete mix design.

The water-cement ratio is a crucial factor in concrete mix design, significantly influencing the strength and durability of the hardened concrete. It’s simply the ratio of the weight of water to the weight of cement in a concrete mix. A lower water-cement ratio generally results in higher strength and durability.

Significance: Water is necessary for the hydration process, where cement reacts with water to form a hardened cement paste. However, excess water weakens the concrete by creating more porosity. The excess water leaves behind pores when it evaporates during curing; these pores make the concrete more vulnerable to cracking, freeze-thaw damage, and chemical attack. A lower water-cement ratio leads to less porosity, resulting in denser, stronger, and more durable concrete. This is often expressed as a relationship: Strength is inversely proportional to the water-cement ratio.

Practical Application: Concrete mix designers carefully control the water-cement ratio to achieve the desired strength and durability for a particular application. For instance, high-strength concrete used in structures demanding greater load-bearing capacity would have a lower water-cement ratio compared to a normal-strength concrete used in pavements.

It’s important to note that while a low water-cement ratio is beneficial, it can also make the concrete less workable. This necessitates finding the optimal balance between strength, durability and workability through careful mix design.

Q 6. Discuss the different types of cement and their properties.

Cement is the binding agent in concrete, responsible for its hardening and strength. Various types exist, each with unique properties:

Ordinary Portland Cement (OPC): This is the most common type, a finely ground powder made from a mixture of limestone and clay. It’s known for its relatively high strength and versatile use. It is widely used in all types of structures.

Portland Blast Furnace Slag Cement: This is a blend of OPC and blast furnace slag (a byproduct of iron production). It offers improved durability and resistance to sulfate attack compared to OPC. It is commonly used for marine and other aggressive environments.

Portland Pozzolana Cement: This is a blend of OPC and pozzolana (a siliceous or aluminosiliceous material). Pozzolana reacts with calcium hydroxide (released during cement hydration) to form additional binding products, enhancing strength and durability over time. It’s used where durability is a key factor.

Rapid-Hardening Cement: This type of cement sets and hardens faster than OPC, making it suitable for projects where rapid construction is necessary. However, early-age properties can be slightly compromised.

Low-Heat Cement: Used in massive concrete structures where the heat generated during hydration needs to be controlled to prevent cracking. The hydration process in low-heat cement releases less heat than in ordinary Portland Cement.

The selection of cement type depends on the specific requirements of the project, including the desired strength, durability, setting time, and environmental conditions.

Q 7. Describe the impact of aggregate properties on concrete performance.

Aggregates (sand, gravel, crushed stone) constitute a significant portion of concrete’s volume and significantly influence its properties. Their quality and characteristics directly impact the overall performance of the concrete.

Influence on Strength: The strength and durability of aggregates affect the overall strength of the concrete. Strong, durable aggregates contribute to stronger concrete, and vice versa. Weak or fractured aggregates can lead to weakness or early deterioration.

Influence on Durability: The durability of the aggregates plays a crucial role in resisting various forms of deterioration, including freeze-thaw damage, chemical attack, and abrasion. Aggregates that are porous or chemically reactive can compromise the long-term durability of the concrete.

Influence on Workability: The shape, size distribution, and surface texture of aggregates impact the workability of the fresh concrete mix. Well-graded aggregates (a mix of various sizes) typically result in better workability.

Influence on Volume Changes: Some aggregates can undergo volume changes due to temperature fluctuations or moisture variations. These changes can cause stresses in the concrete, leading to cracking. It is important to test for alkali aggregate reactivity.

Therefore, careful selection and testing of aggregates are crucial for producing high-quality, durable concrete. The quality of aggregates is often as important as the quality of the cement used.

Q 8. Explain the concept of chloride penetration in concrete and its implications.

Chloride penetration in concrete is a significant durability issue. Chloride ions, often present in de-icing salts or marine environments, can ingress into the concrete pore structure. These ions migrate through the porous concrete, driven by diffusion and capillary suction. The implications are severe because chloride ions can initiate corrosion of the embedded steel reinforcement, leading to cracking, spalling, and ultimately, structural failure. Imagine it like rusting from the inside out – a hidden threat that weakens the structure over time.

The rate of chloride penetration depends on factors such as concrete mix design (water-cement ratio, cement type, aggregate type), environmental conditions (temperature, humidity, chloride concentration), and the presence of cracks or other defects. A high water-cement ratio, for instance, results in a more porous concrete, making it more susceptible to chloride ingress. Similarly, a marine environment with high chloride concentrations will accelerate the penetration process.

Q 9. How do you assess the durability of concrete structures?

Assessing the durability of concrete structures is a multifaceted process that involves considering various factors and employing a range of testing methods. We need to evaluate the resistance to factors like chloride attack, freeze-thaw cycles, sulfate attack, and alkali-aggregate reaction. The assessment often begins with a thorough visual inspection to identify any visible signs of distress, such as cracking, spalling, or efflorescence. This is followed by more advanced testing depending on the specific concerns.

- Material characterization: This involves laboratory testing of concrete samples to determine properties like compressive strength, water absorption, air void characteristics, and chloride permeability.

- Non-destructive testing (NDT): Methods like rebound hammer testing, ultrasonic pulse velocity testing, and ground-penetrating radar are employed to assess the in-situ condition of the concrete without causing damage.

- Service life prediction models: Sophisticated models incorporating material properties, environmental exposure, and load conditions are used to predict the remaining service life of the structure.

For example, in a coastal bridge, we would pay particular attention to chloride penetration resistance and evaluate the concrete’s performance using techniques like rapid chloride permeability test (RCPT) and assessing the chloride content in the concrete.

Q 10. What are the different types of concrete admixtures and their functions?

Concrete admixtures are chemical substances added to the concrete mix to modify its properties. They play a vital role in enhancing various aspects of concrete performance. They can be broadly categorized as follows:

- Water reducers: Reduce the amount of mixing water needed without compromising strength, leading to higher strength and durability.

- Superplasticizers: These are high-range water reducers, significantly increasing workability while maintaining strength. Think of them as making the concrete ‘flow’ better.

- Accelerators: Speed up the setting and hardening process, allowing for faster construction.

- Retarders: Slow down the setting and hardening process, beneficial in hot weather or for large pours.

- Air-entraining admixtures: Incorporate microscopic air bubbles into the concrete mix, improving freeze-thaw resistance and reducing permeability.

- Corrosion inhibitors: Help protect the reinforcement from corrosion by reducing the ingress of chloride ions or mitigating the effects of corrosion.

The choice of admixture depends on the specific requirements of the project and the desired concrete properties. For example, in a cold climate, air-entraining admixtures are essential to improve freeze-thaw resistance.

Q 11. Describe the methods for evaluating the freeze-thaw resistance of concrete.

Evaluating the freeze-thaw resistance of concrete typically involves laboratory testing. The most common method is the ASTM C666 test, which subjects concrete specimens to repeated cycles of freezing and thawing while immersed in water or subjected to other controlled conditions. The mass loss, strength loss, and visual examination of the specimens after a specified number of cycles are used to assess the resistance to freeze-thaw damage. Other methods may include using a more rapid freeze-thaw testing method (e.g., using liquid nitrogen for rapid freezing).

The results are usually expressed as a percentage of mass loss or strength reduction. Lower values indicate better freeze-thaw resistance. The test simulates the effects of repeated freezing and thawing in real-world conditions, particularly important for structures exposed to harsh winter climates. For instance, pavements in cold regions must exhibit excellent freeze-thaw resistance to prevent damage.

Q 12. Explain the principles behind non-destructive testing (NDT) methods for concrete.

Non-destructive testing (NDT) methods for concrete provide a way to evaluate the condition of concrete structures without causing damage. These methods utilize various principles of physics, such as the propagation of sound waves, electromagnetic waves, or other physical phenomena, to infer properties of the material without extracting core samples. The underlying principle is that variations in the concrete’s properties – such as density, stiffness, or presence of voids – will influence how these waves propagate through the material.

For example, if a concrete structure contains a void, the sound waves will travel differently around that void compared to areas with solid concrete. Analyzing the response enables engineers to assess the condition, detect defects, or evaluate the structural integrity.

Q 13. What are the common NDT methods used for evaluating concrete structures?

Several common NDT methods are used for evaluating concrete structures, each with its own advantages and limitations:

- Rebound hammer testing: Measures the surface hardness of the concrete. A higher rebound number generally indicates higher strength.

- Ultrasonic pulse velocity testing: Measures the speed of sound waves traveling through the concrete. Lower velocity typically suggests lower strength or the presence of cracks.

- Ground-penetrating radar (GPR): Uses electromagnetic waves to detect subsurface anomalies, such as voids, rebar, or cracks.

- Cover meter testing: Measures the depth of reinforcement bars in concrete.

- Infrared thermography: Detects temperature differences on the concrete surface, which can indicate internal defects or moisture problems.

The selection of the appropriate NDT method depends on the specific objective of the evaluation and the type of concrete structure being inspected. For example, GPR is often used to locate rebar before drilling, while rebound hammer tests are quick and easy to determine the relative surface strength.

Q 14. How do you interpret the results of concrete testing data?

Interpreting concrete testing data requires careful consideration of the specific tests performed, the obtained values, and relevant standards. The data should be analyzed within the context of the project requirements and the expected performance of the concrete. For example, comparing the compressive strength results to the specified design strength is critical for determining whether the concrete meets the design requirements. Similarly, a high chloride content might indicate an increased risk of corrosion, even if other properties appear satisfactory.

Statistical analysis might be needed to assess the variability in the test results and ensure the reliability of the conclusions drawn. Comparing the data to acceptance criteria defined by relevant codes and standards (like ASTM or ACI standards) is essential to make informed decisions. An experienced engineer or materials scientist is crucial to interpret the data correctly and make appropriate recommendations.

For example, if chloride penetration tests show high chloride ion concentrations near the reinforcement, it warrants further investigation and potentially remedial actions, such as cathodic protection.

Q 15. Discuss the importance of quality control in concrete production.

Quality control in concrete production is paramount to ensuring the structural integrity and longevity of any concrete structure. Think of it like baking a cake – if you don’t measure your ingredients precisely or follow the recipe carefully, the outcome will be compromised. Similarly, variations in the mix design, improper handling, or inadequate curing can lead to significant defects in concrete.

A robust quality control program involves several key aspects:

- Material Testing: Regular testing of aggregates, cement, and admixtures to ensure they meet specified requirements. This includes assessing factors like compressive strength, gradation, and chemical composition.

- Mix Design Control: Precise measurement and consistent mixing of ingredients according to the approved mix design. This minimizes variations in the final product.

- In-Place Testing: Performing tests on the freshly placed concrete, such as slump tests to check workability and air content tests to ensure proper air entrainment.

- Curing Control: Maintaining appropriate moisture and temperature conditions during the curing process to allow the concrete to gain sufficient strength and durability.

- Documentation: Meticulous record-keeping of all materials used, tests conducted, and observations made throughout the production process. This allows for traceability and identification of potential issues.

Ignoring quality control can result in costly repairs, structural failures, and even safety hazards. For example, insufficient curing can lead to premature cracking and reduced lifespan, while using substandard aggregates can compromise the strength and durability of the structure. A well-defined quality control plan is essential to ensure that the finished concrete meets the required specifications and performs as intended.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different concrete mix designs.

My experience encompasses a wide range of concrete mix designs, from high-performance concrete for specialized applications to conventional concrete for general construction. I’ve worked with designs tailored for specific performance criteria, such as high strength, durability, or resistance to chemicals. Each design involves careful consideration of several factors:

- Strength Requirements: Determining the desired compressive strength based on the structural demands of the project.

- Durability Needs: Considering factors such as exposure conditions (e.g., freeze-thaw cycles, aggressive environments), and selecting appropriate admixtures to enhance durability.

- Workability: Optimizing the mix design to achieve the desired workability for efficient placement and consolidation.

- Economic Considerations: Balancing performance requirements with material costs to develop a cost-effective mix design.

For instance, I was involved in a project requiring high-strength concrete for a bridge deck. We used a mix design incorporating high-strength cement and optimized aggregate grading to achieve the necessary compressive strength while maintaining adequate workability. In another project involving a marine structure exposed to harsh saltwater, a special mix design was employed that included corrosion inhibitors and specialized admixtures to ensure long-term durability.

My approach to mix design always involves thorough testing and evaluation to ensure the final product meets the specified requirements and performs as intended. I frequently utilize statistical methods to analyze test data and refine mix proportions for optimal results.

Q 17. Explain the significance of curing in concrete.

Curing is a critical post-placement process that allows concrete to achieve its designed strength and durability. It involves maintaining adequate moisture and temperature conditions for a specific period. Think of it as allowing the concrete to properly ‘set’ and ‘harden’. Without proper curing, the concrete will be weak, prone to cracking, and have a significantly reduced lifespan.

The hydration process, which is the chemical reaction between cement and water, is crucial for strength development. This process requires sufficient moisture, and inadequate moisture during curing can lead to incomplete hydration and reduced strength. Temperature also plays a role; extreme temperatures can either accelerate or retard the hydration process, potentially affecting the final properties of the concrete.

Common curing methods include:

- Water Curing: Keeping the concrete surface continuously moist by ponding, spraying, or covering with wet burlap.

- Membrane Curing: Applying a curing membrane to retain moisture within the concrete.

- Steam Curing: Using steam to accelerate the hydration process, typically used for precast concrete elements.

The duration of curing depends on several factors, including the type of cement, ambient temperature, and desired strength. Insufficient curing is a major cause of concrete deterioration, leading to reduced service life and potential structural problems. Therefore, proper curing procedures are indispensable for ensuring the long-term performance of any concrete structure.

Q 18. What are the common causes of concrete cracking and how can they be prevented?

Concrete cracking is a common problem that can significantly affect the durability and serviceability of concrete structures. Several factors contribute to cracking:

- Shrinkage Cracking: Caused by the loss of moisture during drying, leading to shrinkage stresses that exceed the tensile strength of the concrete.

- Thermal Cracking: Resulting from temperature changes, which induce thermal stresses in the concrete. Rapid temperature fluctuations, such as those occurring during hot weather concreting, are particularly problematic.

- Plastic Cracking: Occurs in freshly placed concrete due to early drying, inadequate consolidation, or excessive vibration.

- Load-Induced Cracking: Develops due to excessive loads or stresses imposed on the concrete structure.

- Corrosion Cracking: Caused by the corrosion of reinforcing steel, which expands and exerts pressure on the surrounding concrete.

Preventing concrete cracking involves a multi-pronged approach:

- Proper Mix Design: Using appropriate cement content, aggregate grading, and admixtures to minimize shrinkage and improve tensile strength.

- Effective Curing: Maintaining adequate moisture and temperature conditions during curing to reduce shrinkage stresses.

- Control of Temperature Variations: Employing strategies to control temperature fluctuations during placement and curing.

- Proper Construction Practices: Ensuring proper consolidation and placement techniques to avoid plastic cracking.

- Reinforcement Design: Including sufficient reinforcement to handle anticipated loads and stresses.

- Control Joints: Incorporating control joints to relieve stresses and guide cracking in predetermined locations.

Ignoring these preventative measures can lead to significant repair costs and compromised structural integrity.

Q 19. How do you assess the carbonation of concrete and its effects?

Carbonation is a chemical reaction where carbon dioxide from the atmosphere reacts with the calcium hydroxide in concrete, forming calcium carbonate. This process reduces the pH of the concrete, making it less alkaline. This is significant because the alkalinity of concrete provides protection to the embedded steel reinforcement against corrosion. When carbonation occurs, this protective layer is compromised, leading to corrosion of the steel.

Assessing carbonation involves using phenolphthalein indicator, which is a chemical that changes color when it comes into contact with an alkaline substance. By applying phenolphthalein to a concrete surface, the depth of carbonation can be determined visually. The depth at which the color change occurs represents the depth of carbonation. Deeper penetration indicates more significant carbonation and greater risk of corrosion.

The effects of carbonation include:

- Corrosion of Reinforcement: The most significant consequence of carbonation is the initiation and progression of corrosion of the embedded steel reinforcement, weakening the structure.

- Reduced Durability: Carbonation can also lead to a decrease in the concrete’s overall durability and resistance to other deterioration mechanisms.

- Reduced Strength: In severe cases, carbonation can lead to a reduction in concrete strength.

Mitigation strategies include using low-permeability concrete, reducing exposure to carbon dioxide, and incorporating corrosion inhibitors into the mix design. Regular inspections and monitoring are essential to identify and address carbonation before it causes significant damage.

Q 20. Describe the different types of concrete deterioration mechanisms.

Concrete deterioration is a complex process influenced by various environmental factors and material properties. Several mechanisms contribute to the degradation of concrete:

- Chemical Attack: This includes reactions with aggressive chemicals such as sulfates, chlorides, and acids, which can lead to expansion, cracking, and strength loss. Sulfate attack, for instance, is common in areas with high sulfate content in the soil or groundwater.

- Physical Deterioration: This involves processes like freeze-thaw damage, where the expansion of ice within the pores of the concrete causes cracking and spalling. Abrasion and erosion are other examples, often seen in pavements or structures exposed to flowing water.

- Biological Attack: Certain microorganisms can colonize concrete, leading to damage. This is often associated with increased moisture content and nutrient availability.

- Alkaline-Aggregate Reaction (AAR): This is a chemical reaction between certain reactive aggregates and the alkaline components of cement paste. This can lead to expansion and cracking.

- Corrosion of Reinforcement: As discussed earlier, the corrosion of steel reinforcement is a major cause of concrete deterioration, causing expansion and cracking.

Understanding these deterioration mechanisms is crucial for developing effective strategies for preventing and mitigating damage. This often involves material selection, appropriate mix design, protection from aggressive environments, and regular inspections and maintenance.

Q 21. What is the role of statistical analysis in concrete testing and research?

Statistical analysis plays a vital role in concrete testing and research, allowing for objective evaluation of test results and informed decision-making. Concrete properties exhibit natural variability, and statistical methods are essential for quantifying this variability and drawing meaningful conclusions.

Common statistical applications include:

- Descriptive Statistics: Calculating measures like mean, standard deviation, and coefficient of variation to summarize test data and understand the variability of concrete properties.

- Inferential Statistics: Using techniques like hypothesis testing and confidence intervals to make inferences about the population of concrete based on a sample of test results.

- Regression Analysis: Developing models to understand the relationships between different factors (e.g., mix proportions, curing conditions) and concrete properties.

- Analysis of Variance (ANOVA): Comparing the means of different groups (e.g., concrete produced with different admixtures) to determine if there are statistically significant differences.

- Reliability Analysis: Assessing the probability of concrete structures performing as intended over their service life.

For example, in a study assessing the effect of different curing methods on concrete strength, ANOVA would be used to compare the average strengths achieved under various curing regimes. Regression analysis might be used to model the relationship between curing duration and compressive strength. Statistical analysis ensures that conclusions drawn from concrete testing are scientifically sound and reliable, informing design decisions and improving the overall quality of concrete structures.

Q 22. Explain your experience with different types of concrete microscopy techniques.

Concrete microscopy is crucial for understanding the internal structure and properties of concrete at a micro-level. My experience encompasses several techniques, each offering unique insights.

- Optical Microscopy: This is a fundamental technique used for examining the overall microstructure, including aggregate distribution, paste morphology, and the presence of cracks or voids. I’ve used it extensively for quality control, identifying potential defects like poor aggregate bonding or excessive porosity. For example, I once used optical microscopy to identify a batch of concrete with unusually high porosity, leading to a revision of the mixing process.

- Scanning Electron Microscopy (SEM): SEM provides much higher magnification and resolution, allowing detailed examination of the cement paste microstructure, hydration products, and the interface between aggregates and paste. This is invaluable for studying the effects of different admixtures or curing regimes on the concrete’s microstructure. I’ve used SEM to analyze the effectiveness of various superplasticizers on the pore structure of high-performance concrete.

- Transmission Electron Microscopy (TEM): TEM offers even higher resolution, allowing the study of crystal structures and the identification of individual phases within the cement paste. It’s essential for understanding the hydration process at a fundamental level. I’ve utilized TEM in research projects to investigate the effects of nano-materials on cement hydration.

- Confocal Laser Scanning Microscopy (CLSM): This technique provides 3D images of the internal structure, particularly useful for studying the pore network and permeability of concrete. It’s been instrumental in evaluating the efficacy of various water-reducing admixtures on reducing porosity.

The choice of microscopy technique depends on the specific research question or quality control objective. I’m proficient in all these techniques and adept at interpreting the results to draw meaningful conclusions about the concrete’s properties and performance.

Q 23. Discuss your experience with advanced testing methods for concrete, such as resonant frequency testing.

Advanced testing methods like resonant frequency testing are essential for assessing the dynamic properties of concrete, offering insights beyond traditional static tests. Resonant frequency testing measures the natural frequencies of vibration of a concrete specimen. These frequencies are directly related to the elastic modulus and density of the concrete.

My experience includes using this technique to:

- Assess the early-age strength development of concrete: Resonant frequency testing provides a rapid and non-destructive method for monitoring the strength gain during the curing process.

- Evaluate the effects of various admixtures and curing methods on concrete properties: I’ve used this to compare the performance of different concrete mixes under varying conditions.

- Detect damage in concrete structures: Changes in the resonant frequency can indicate the presence of micro-cracks or other damage mechanisms.

Beyond resonant frequency, my experience also encompasses other advanced techniques such as ultrasonic pulse velocity testing (to assess the integrity and homogeneity of concrete), and nuclear magnetic resonance (NMR) spectroscopy (to study pore size distribution).

Q 24. How do you ensure the accuracy and reliability of concrete testing results?

Ensuring the accuracy and reliability of concrete testing results is paramount. My approach involves a multi-faceted strategy:

- Calibration and Verification of Equipment: All testing equipment is regularly calibrated and verified using certified standards to ensure accuracy and traceability. I maintain meticulous records of calibration procedures.

- Strict Adherence to Standards: I rigorously follow established testing standards (e.g., ASTM, ACI) to ensure consistent and reliable results. This involves carefully controlling variables like temperature and humidity.

- Proper Sample Preparation: The quality of test results is critically dependent on proper sample preparation. This includes careful selection of representative samples, accurate dimensions, and appropriate curing conditions.

- Quality Control Procedures: Implementing quality control checks at each stage of the testing process minimizes errors. This might involve running duplicate tests or using different methods to validate results.

- Data Analysis and Interpretation: Data analysis is not just about numbers; it’s about understanding the context. I meticulously analyze data, taking into account potential sources of error and variations. For instance, statistical methods help identify outliers and assess the variability of results.

- Maintaining a Chain of Custody: Proper documentation and sample tracking are essential to maintain the integrity and traceability of the testing process.

Through these rigorous procedures, I ensure that the results are accurate, reliable, and can be confidently used for decision-making in concrete design and construction.

Q 25. Explain your understanding of concrete rheology.

Concrete rheology is the study of the flow and deformation behavior of fresh concrete. Understanding rheology is crucial for optimizing concrete mix design and ensuring proper placement and consolidation. It encompasses several key aspects:

- Yield Stress: The minimum stress required to initiate flow. A higher yield stress indicates a stiffer mix.

- Plastic Viscosity: A measure of the resistance to flow once flow has begun. Lower viscosity indicates easier flow.

- Thixotropy: The time-dependent change in viscosity, often observed as a decrease in viscosity with time under shear.

I have extensive experience characterizing the rheological properties of concrete using various methods, such as:

- Rotational Rheometry: This involves measuring the torque required to rotate a spindle immersed in fresh concrete. This determines parameters like yield stress and plastic viscosity.

- Falling Head Viscometry: Measures the flow rate of concrete through a calibrated tube.

- Slump Test: While not a direct rheological measure, it provides a simple, practical assessment of workability.

Understanding concrete rheology allows me to design mixes with optimal workability for different applications, from self-consolidating concrete to high-performance concrete. For example, in one project, we optimized the rheological properties to achieve proper placement in heavily reinforced sections.

Q 26. Describe your experience with using software for concrete mix design and analysis.

I’m proficient in several software packages used for concrete mix design and analysis. My experience includes using:

- Mix Design Software: These packages incorporate algorithms and databases to optimize concrete mix proportions based on specified strength requirements, workability, and durability targets. I use these to efficiently generate multiple mix designs and compare their properties.

- Finite Element Analysis (FEA) Software: FEA allows for the simulation of the structural behavior of concrete structures under various loading conditions. I use this to validate designs, predict the long-term performance of concrete, and evaluate the impact of material properties.

- Data Analysis Software: Statistical software (e.g., R, SPSS) is indispensable for analyzing experimental data, validating mix designs, and identifying trends in concrete behavior.

These software tools are invaluable for optimizing concrete mix designs, reducing material costs, improving the durability and performance of concrete structures, and providing strong evidence for engineering decision-making.

Q 27. How do you stay current with the latest advancements in concrete materials and technology?

Staying current in the rapidly evolving field of concrete materials and technology requires a multifaceted approach:

- Professional Organizations: Active membership in professional organizations like ACI (American Concrete Institute) and RILEM (International Union of Laboratories and Experts in Construction Materials, Systems and Structures) provides access to the latest research, publications, and industry events.

- Conferences and Workshops: Attending conferences and workshops allows me to learn about cutting-edge research and network with leading experts in the field.

- Peer-Reviewed Publications: I regularly review scientific journals and technical publications to stay informed on new developments in concrete science and technology.

- Online Resources: Utilizing online databases and platforms dedicated to concrete research ensures access to the latest information.

- Continuing Education: Participating in continuing education courses and training programs enhances my knowledge and skills.

This commitment to continuous learning ensures that my work is informed by the most up-to-date advancements, leading to innovative solutions and improvements in concrete design and construction.

Q 28. Describe a challenging concrete-related problem you solved and how you approached it.

One challenging project involved a high-rise building where the concrete in the columns exhibited unexpected cracking during construction. Initial investigations suggested that the problem was linked to the high temperature rise during hydration (the heat released by cement as it hardens). The high temperature caused excessive thermal stresses, leading to cracking.

My approach involved a multi-step process:

- Thorough investigation: We conducted detailed analysis of the concrete mix design, including the cement type, aggregate properties, and admixtures.

- Laboratory testing: We performed various tests on concrete samples to characterize its thermal properties and investigate the extent of cracking.

- Numerical modeling: We used FEA to simulate the temperature rise and stress distribution within the columns, identifying the critical areas prone to cracking.

- Mitigation strategies: Based on the findings, we developed a mitigation strategy including a reduction in cement content, incorporation of supplementary cementitious materials with lower heat of hydration, and the use of cooling techniques during placement.

- Implementation and monitoring: The revised mix design and mitigation strategies were implemented in subsequent concrete pours, with close monitoring of the temperature rise and crack formation.

This project highlighted the importance of considering the complex interactions between material properties and construction practices. Through systematic investigation, modeling, and implementation of mitigation measures, we successfully resolved the cracking problem and ensured the structural integrity of the building.

Key Topics to Learn for Concrete Materials Characterization and Research Interview

- Microstructure and Composition: Understanding the relationship between concrete’s microscopic structure (e.g., cement hydration products, pore structure) and its macroscopic properties (strength, durability). Consider techniques like SEM and XRD analysis.

- Mechanical Properties: Comprehending the various mechanical tests used to characterize concrete (compressive strength, tensile strength, flexural strength, elastic modulus) and their practical applications in structural design and quality control. Explore the influence of mix design and curing conditions.

- Durability and Degradation: Investigating the mechanisms of concrete deterioration (e.g., chloride ingress, alkali-aggregate reaction, freeze-thaw cycles) and methods for enhancing durability (e.g., using admixtures, incorporating supplementary cementitious materials). This includes understanding relevant testing standards.

- Rheology and Fresh Concrete Properties: Analyzing the flow and workability characteristics of fresh concrete, and their impact on placing and finishing. Explore different rheological models and their applications.

- Non-Destructive Testing (NDT) Techniques: Familiarize yourself with various NDT methods used to assess the condition and properties of hardened concrete in situ, such as ultrasonic pulse velocity testing, rebound hammer testing, and ground penetrating radar. Understand their limitations and applications.

- Sustainable Concrete Materials: Explore the use of alternative cementitious materials (e.g., fly ash, slag, geopolymers) and strategies for reducing the environmental impact of concrete production. This includes understanding life cycle assessment principles.

- Data Analysis and Interpretation: Mastering statistical analysis techniques for interpreting experimental data obtained from various characterization methods, including regression analysis and hypothesis testing.

Next Steps

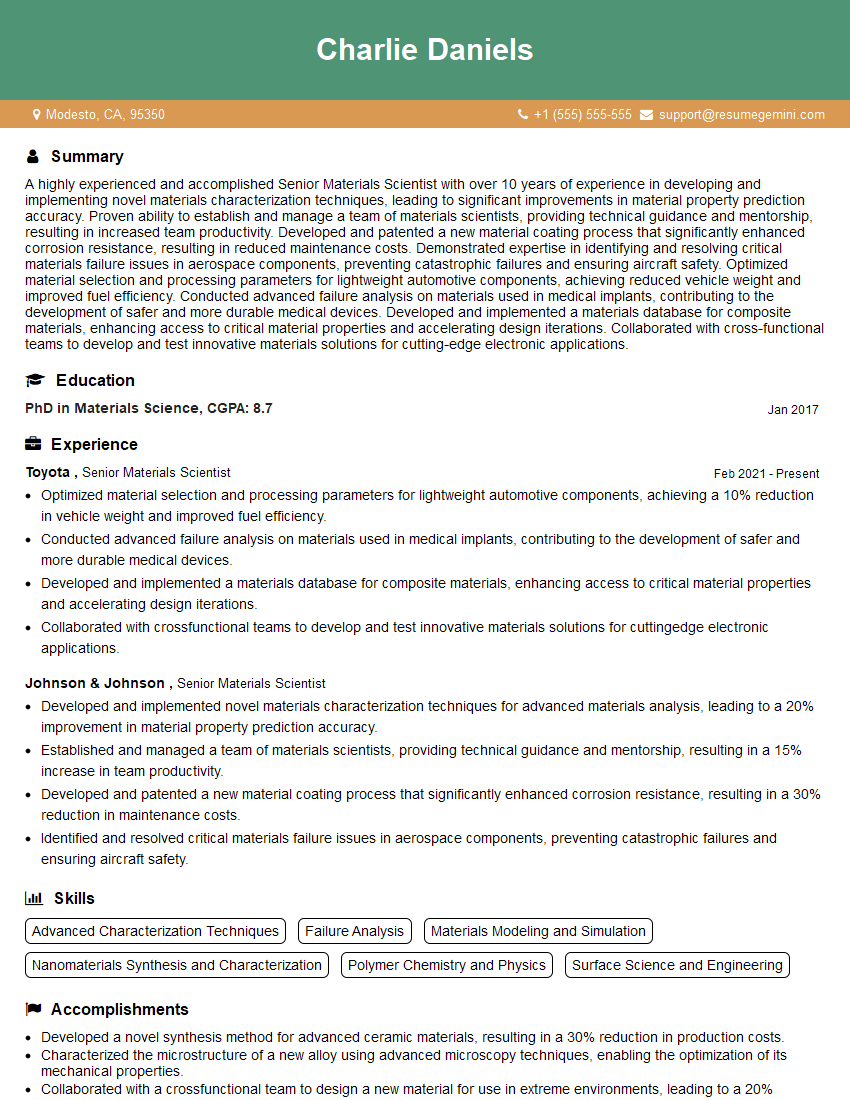

Mastering Concrete Materials Characterization and Research opens doors to exciting career opportunities in research, construction materials testing, and structural engineering. A strong understanding of these concepts will significantly enhance your interview performance and overall career prospects. To further boost your job search, focus on creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your qualifications stand out. Examples of resumes tailored to Concrete Materials Characterization and Research are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.