Cracking a skill-specific interview, like one for Concrete Structural Analysis, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Concrete Structural Analysis Interview

Q 1. Explain the different types of concrete mix designs and their applications.

Concrete mix design involves specifying the proportions of cement, aggregates (sand and gravel), water, and sometimes admixtures to achieve desired properties. Different mixes cater to specific needs.

- Normal Strength Concrete (NSC): This is the most common type, used for general construction like foundations and slabs. It has a compressive strength typically ranging from 25 to 40 MPa. Think of it as the ‘everyday’ concrete for most building projects.

- High-Strength Concrete (HSC): Achieves higher compressive strengths (above 50 MPa) due to a higher cement content and optimized mix proportions. Used where high strength and durability are critical, like in high-rise buildings, bridges, and structures exposed to aggressive environments. Imagine needing concrete that can withstand immense pressure – HSC fits the bill.

- Lightweight Concrete: Uses lightweight aggregates like expanded clay or shale to reduce the overall weight. Commonly used in high-rise buildings to decrease dead loads on the structure, resulting in cost savings and a smaller overall structure.

- High-Performance Concrete (HPC): A broad term encompassing concrete with enhanced properties like high strength, durability, and workability. This might include specialized admixtures to improve its properties even further beyond what HSC offers. It’s often employed in demanding applications, such as offshore structures or nuclear power plants.

- Self-Consolidating Concrete (SCC): Flows easily under its own weight, filling even complex formwork without vibration. Useful for congested reinforcement and difficult-to-access areas, minimizing labor costs and improving quality of placement. It’s like pouring concrete that self-levels, making the placement process simpler and faster.

The choice of mix design depends on factors like the structural requirements, exposure conditions, cost, and availability of materials. A structural engineer would perform calculations to ensure the concrete’s strength and durability meet the project’s specifications.

Q 2. Describe the process of designing a reinforced concrete beam.

Designing a reinforced concrete beam involves several steps:

- Determine Loads: Calculate all loads acting on the beam, including dead loads (self-weight of the beam and any permanent elements it supports) and live loads (temporary loads, like people, furniture, or snow). The load will determine the shear force and bending moment diagram across the span. A proper load assessment is absolutely crucial.

- Select Material Properties: Specify the compressive strength of concrete (fc‘) and the yield strength of steel reinforcement (fy). These properties are obtained from material testing reports.

- Determine Bending Moment and Shear Force: Using structural analysis methods (like statics or a software package), determine the maximum bending moment (Mu) and shear force (Vu) along the beam’s length. This will dictate the beam’s necessary dimensions and reinforcement requirements.

- Design the Section: Choose a suitable beam cross-section (rectangular, T-beam, I-beam, etc.) and dimensions based on architectural constraints, construction feasibility, and preliminary calculations. Aim for an efficient design that minimizes the use of materials.

- Calculate Reinforcement: Using appropriate design codes (like ACI 318 or Eurocode 2), calculate the required area of tensile reinforcement (As) to resist the bending moment. The area of shear reinforcement (Av) is determined similarly to resist shear forces. This step often involves iterative calculations to find an optimal design.

- Check for Deflections: Ensure the beam’s deflection under load meets serviceability limit state requirements. Excessive deflection can cause cracking or damage to non-structural elements.

- Detailing: Create detailed drawings showing the arrangement of reinforcement, including bar sizes, spacing, and placement. This is crucial for accurate construction and structural integrity.

Designing a reinforced concrete beam is an iterative process, requiring engineers to balance strength, stiffness, and cost-effectiveness. Software is widely used to perform these calculations and optimize the designs.

Q 3. How do you account for shrinkage and creep in concrete design?

Shrinkage and creep are time-dependent deformations in concrete that must be considered in design to avoid cracking and excessive deflections.

- Shrinkage: The reduction in volume of concrete due to the loss of moisture during hardening. It’s like a sponge drying out and shrinking. It causes tensile stresses in the concrete, potentially leading to cracking, particularly in restrained members.

- Creep: The slow and continuous deformation of concrete under sustained load. It’s analogous to a piece of rubber slowly deforming under constant pressure. It causes additional deflection, especially in long-term loading situations.

We account for these effects through various methods:

- Using design codes: Building codes (like ACI 318) provide simplified methods to estimate shrinkage and creep based on concrete properties, environmental conditions, and member size. This is often the most practical approach.

- Finite Element Analysis (FEA): More sophisticated analysis can incorporate time-dependent material properties and predict shrinkage and creep effects more accurately. FEA is commonly used in the design of complex structures.

- Modifying the design: Engineers might adjust the beam dimensions, reinforcement layout, or introduce control joints to mitigate cracking caused by shrinkage. Control joints intentionally create pre-determined cracks to reduce stresses caused by drying shrinkage.

- Using shrinkage-reducing admixtures: These chemical additives reduce the amount of shrinkage during the concrete hardening process.

Ignoring shrinkage and creep can lead to significant structural problems. For instance, a simply supported beam might experience excessive long-term deflection causing damage.

Q 4. Explain the concept of ultimate and serviceability limit states.

Limit states define the boundary conditions that a structure must satisfy throughout its design life. We have two main categories:

- Ultimate Limit States (ULS): These represent the failure conditions of the structure. They describe the point at which the structure will collapse or experience significant damage. Examples include collapse due to overloading, material failure (e.g., concrete crushing, steel yielding), or instability (e.g., buckling).

- Serviceability Limit States (SLS): These deal with the structure’s ability to perform its intended function without unacceptable deformations or vibrations. They encompass issues that affect the user’s comfort and the longevity of the structure. Examples include excessive deflection, cracking, excessive vibration, and water leakage.

The design must ensure that the structure satisfies both ULS and SLS. While ULS focus on safety and preventing collapse, SLS focus on the long-term functionality and user comfort. A design that’s perfectly safe under ULS but excessively deflects under SLS is not considered a good design.

Example: A bridge must not collapse under the design loads (ULS) and must also have acceptable deflection and cracking to permit safe and comfortable passage of vehicles (SLS).

Q 5. What are the different types of concrete failure modes?

Concrete failure modes depend on the type of loading and the member’s reinforcement. Here are some common ones:

- Crushing of Concrete in Compression: The most common mode for concrete members under compressive stress. It occurs when the concrete’s compressive strength is exceeded.

- Tensile Failure of Concrete: Concrete is weak in tension, causing cracking before significant tensile stress is reached. Reinforcement is typically used to handle tensile forces.

- Flexural Failure: A combination of tensile and compressive failure, typically in beams. Tensile failure may occur in the bottom fibers of the beam, while compressive failure may happen in the top fibers. Reinforcement is provided in the tensile zone.

- Bond Failure: A lack of adequate bond between the concrete and steel reinforcement. This can lead to slip of the rebar, and is avoided by proper detailing and using hooked or deformed bars.

- Punching Shear Failure: This occurs around columns where concentrated loads from the slab or beams are applied. It leads to a cone-shaped failure zone and typically needs specialized reinforcement.

Understanding failure modes is crucial in designing structures to prevent catastrophic failures.

Q 6. How do you determine the required reinforcement for a concrete column?

Determining the required reinforcement for a concrete column involves a similar process to beam design, but focuses on axial loads and moment capacity. The design process generally involves:

- Determine Loads: Calculate all axial loads (dead and live) and moments acting on the column.

- Select Material Properties: Specify concrete compressive strength (fc‘) and steel yield strength (fy).

- Choose a Column Section: Select a suitable column cross-section (rectangular, circular, etc.). Usually, you need to consider building aesthetics and construction feasibility.

- Interaction Diagrams: Interaction diagrams graphically represent the capacity of a column section under various combinations of axial loads and moments. These diagrams are often generated using structural analysis software.

- Check Capacity: Compare the calculated axial load and moment combinations (from step 1) against the column’s capacity shown in the interaction diagram. The column must have enough capacity to handle the applied loads with sufficient safety margin.

- Design Reinforcement: If the column’s capacity is insufficient, adjust the reinforcement area (adding more longitudinal steel bars and/or ties) until it satisfies the required capacity.

- Check Stability: Ensure the column is stable and does not buckle under the applied load. This typically involves checking slenderness ratios and using stability formulas provided in relevant design codes.

Designing columns requires careful consideration of interaction between axial loads and bending moments. This is why interaction diagrams are essential in the design process, as they allow for a complete evaluation of the column’s capacity.

Q 7. Explain the principles of prestressed concrete design.

Prestressed concrete involves introducing intentional compressive stresses into the concrete member before it is subjected to service loads. This compression counteracts tensile stresses induced by external loads, significantly improving the member’s strength and reducing cracking.

Principles:

- Introducing Compressive Stresses: High-strength steel tendons are tensioned within the concrete member. When the tendons are released, they exert a compressive force on the surrounding concrete.

- Stress Distribution: The compressive stress is distributed throughout the cross-section of the member, effectively reducing the tensile stresses that would otherwise be generated under service loads.

- Reduced Cracking: By keeping the concrete primarily in compression, the possibility of tensile cracking is significantly minimized, enhancing durability and improving performance.

- Improved Deflection Control: The initial compressive stress reduces deflections and creep under sustained loading.

Types:

- Pre-tensioning: Tendons are tensioned before the concrete is placed around them. Once the concrete hardens, the tendons are released, transferring the compressive stress to the concrete.

- Post-tensioning: Tendons are tensioned after the concrete has hardened. Ducts are embedded in the concrete to allow for the placement and tensioning of the tendons, and the tendons are anchored at the ends.

Prestressed concrete is widely used in bridges, buildings, and other structures requiring high strength, durability, and slender members.

Q 8. What are the factors influencing the durability of concrete structures?

The durability of concrete structures is a critical aspect of their design and lifespan. It’s influenced by a complex interplay of factors, broadly categorized into material properties, environmental exposure, and design considerations.

- Material Properties: The quality of the cement, aggregates (sand and gravel), and water significantly impacts durability. Using high-quality materials, proper mixing ratios, and adequate curing are crucial. The presence of impurities or deleterious materials in aggregates can lead to premature deterioration. For instance, reactive aggregates can react with alkalis in cement, causing expansion and cracking.

- Environmental Exposure: Concrete’s exposure to aggressive environments like de-icing salts (chlorides), sulfates in soil or groundwater, and freeze-thaw cycles significantly affects its durability. Coastal structures face the additional challenge of chloride ingress, leading to corrosion of reinforcing steel. Similarly, structures in areas with high sulfate content in the soil can experience sulfate attack, which weakens the concrete matrix.

- Design Considerations: Proper detailing of reinforcement, ensuring adequate concrete cover to protect steel from corrosion, and designing for crack control are vital for durability. Over-reinforced sections can experience brittle failure, while under-reinforced sections might exhibit excessive cracking. Careful design to minimize cracking reduces ingress paths for damaging agents. Drainage design also plays a key role. Proper drainage prevents water ponding, minimizing freeze-thaw damage and reducing the chances of chemical attack.

Imagine a bridge exposed to harsh winters: if the concrete isn’t designed with sufficient freeze-thaw resistance, it could experience significant damage, leading to costly repairs or even structural failure. Conversely, a well-designed structure, using durable materials and incorporating appropriate protective measures, will have a longer lifespan with reduced maintenance needs.

Q 9. Describe different methods for concrete strength testing.

Concrete strength testing is essential to verify the quality of the concrete and ensure it meets design requirements. Several methods are commonly used:

- Compressive Strength Test: This is the most common method, where standard cylindrical specimens (typically 6×12 inches) are cured under controlled conditions and then tested to failure in a compression machine. The maximum load before failure is used to calculate the compressive strength in psi or MPa. This test provides a measure of the concrete’s overall strength.

- Flexural Strength Test (Split Cylinder Test): This test determines the concrete’s tensile strength, which is usually lower than its compressive strength. A cylindrical specimen is loaded diametrically until failure, and the tensile strength is calculated based on the load and dimensions.

- Non-Destructive Testing (NDT): These methods evaluate the strength without damaging the concrete. Examples include rebound hammer tests, ultrasonic pulse velocity tests, and nuclear density gauges. These tests are particularly useful for assessing the in-situ strength of existing structures. They are less precise than the destructive methods but are convenient and suitable for large structures.

For example, a construction project might require compressive strength tests on multiple batches of concrete to ensure consistency and compliance with specifications. NDT methods could be employed to evaluate the condition of a bridge deck without interrupting traffic.

Q 10. How do you design for seismic loads in concrete structures?

Designing concrete structures for seismic loads requires careful consideration of several factors. The goal is to ensure the structure can withstand ground shaking without collapsing or suffering significant damage.

- Ductility: Concrete structures should be designed to exhibit ductile behavior under seismic loads. This means they can deform significantly without losing strength, allowing them to absorb seismic energy and dissipate it. Ductility is achieved through proper detailing of reinforcement, ensuring adequate confinement of columns, and employing ductile detailing techniques.

- Strength: Sufficient strength is necessary to resist inertial forces during an earthquake. The design should account for both gravity and seismic loads. Reinforcement detailing is crucial for ensuring strength.

- Seismic Codes: Adherence to relevant seismic codes and standards is mandatory. These codes specify design requirements based on the seismic zone, soil conditions, and structural system. They include provisions for detailing, analysis procedures, and strength requirements.

- Structural Systems: Selecting appropriate structural systems that are inherently more resistant to seismic loads is important. For example, moment-resisting frames or shear walls can be designed to provide better lateral strength and stiffness.

A common strategy is to use strong columns and weak beams; this ensures that in the event of an earthquake, the beams will yield before the columns, preventing collapse. Proper detailing, such as using confinement reinforcement around columns and ensuring adequate lap splices in reinforcement bars, is also critical for achieving ductile behavior.

Q 11. Explain the use of finite element analysis in concrete design.

Finite Element Analysis (FEA) is a powerful computational technique used to simulate the behavior of concrete structures under various loading conditions. It’s particularly useful in complex scenarios where analytical methods are insufficient or impractical.

- Modeling: FEA involves dividing the structure into numerous small elements interconnected at nodes. The material properties and loading conditions are then defined for each element. This allows for more accurate representation of the structure’s actual behavior than simple analytical methods.

- Analysis: The software solves a system of equations to determine the stresses, strains, and displacements at each node. This provides a detailed picture of the structure’s response under different loads, including seismic loads, dead loads, and live loads.

- Nonlinear Behavior: FEA can effectively model the nonlinear behavior of concrete, including cracking, crushing, and material degradation. This is crucial for accurate assessment of the structure’s capacity and behavior in ultimate load conditions.

- Applications: FEA is extensively used for detailed stress analysis, crack prediction, assessing the influence of openings and discontinuities, and optimizing the design of reinforced concrete structures. It allows engineers to investigate the behavior under complex loading conditions before construction begins. It’s also used to analyze existing structures to assess their condition and remaining life.

For example, FEA can be used to optimize the placement of reinforcement in a complex structure to effectively manage cracking under various load combinations. It can also analyze the structural performance of an existing building after being subjected to a seismic event, facilitating effective retrofitting strategies.

Q 12. What are the key considerations in detailing reinforced concrete?

Detailing reinforced concrete involves specifying the location, size, and arrangement of reinforcement bars to ensure the structure’s strength, serviceability, and durability. Key considerations include:

- Concrete Cover: Sufficient concrete cover is essential to protect the reinforcement from corrosion. The minimum cover is specified in codes and depends on the environmental exposure conditions. Insufficient cover can lead to rapid corrosion and significant deterioration of the structure.

- Spacing and Placement: Bars must be spaced adequately to ensure proper concrete compaction and bond. Overcrowding can hinder compaction, leading to weaknesses in the concrete. The placement of bars should also be carefully planned to ensure they are in the most effective positions to resist stresses.

- Lap Splices: When reinforcement bars need to be spliced, lap splices are commonly used. The length of the lap splice needs to be carefully determined to ensure adequate strength and to avoid bond failure.

- Development Length: Reinforcement bars need sufficient development length to transfer stresses effectively to the surrounding concrete. The required development length depends on the bar size, concrete strength, and stress levels. Insufficient development length can result in pull-out failures.

- Anchorage: Proper anchorage is vital to prevent reinforcement from pulling out of the concrete. Hooks and other anchorage devices can help ensure adequate anchorage.

For example, in a column, the reinforcement must be adequately confined to prevent buckling under compression. Proper detailing involving stirrups (closed ties or spirals) is crucial for this purpose. Poor detailing can lead to premature failure, even under normal loading conditions.

Q 13. Describe the different types of concrete foundations.

Concrete foundations are essential for transferring structural loads to the underlying soil. Different types are selected based on soil conditions, load magnitude, and project requirements:

- Spread Footings: These are used for individual columns or walls, distributing the load over a larger area to reduce the soil pressure. They are suitable for relatively strong soils with sufficient bearing capacity.

- Strip Footings: Continuous footings used for supporting walls or rows of columns. They are economical for long walls.

- Combined Footings: Used when two or more columns are close together, sharing a single footing.

- Mat Foundations (Raft Foundations): Used when the soil has low bearing capacity or when numerous columns require support. It covers the entire structure’s footprint, distributing the loads effectively.

- Pile Foundations: Used when the soil is weak or when deep foundations are needed. Piles are driven or bored into the ground to transfer the load to a stronger soil stratum below.

- Pier Foundations: Similar to piles but typically larger in diameter and constructed of reinforced concrete.

For instance, a high-rise building in an area with soft soil might require pile foundations to reach deeper, stronger soil layers, while a small residential building on firm soil might be adequately supported by spread footings.

Q 14. How do you account for cracking in concrete design?

Cracking is inevitable in concrete structures due to shrinkage, thermal effects, and applied loads. However, the goal is to control the extent and width of cracks to ensure structural integrity and serviceability.

- Crack Control Design: This involves using design strategies to minimize the amount and width of cracks. This includes proper detailing of reinforcement, using concrete with low shrinkage properties, and controlling temperature gradients during construction.

- Crack Width Limits: Codes provide limits on permissible crack widths to prevent corrosion of reinforcement and ensure acceptable levels of serviceability. Exceeding these limits can lead to premature deterioration of the structure.

- Crack Modeling: Advanced analysis techniques, like FEA, can be used to predict crack patterns and widths under various loading conditions. This helps in optimizing the reinforcement detailing and improving the crack control design.

- Crack Monitoring: For critical structures, crack monitoring might be employed to track crack development over time. This provides insight into the structure’s long-term behavior and allows for timely interventions if necessary.

For example, in a long span beam, proper detailing of flexural reinforcement helps control the width of tensile cracks. Designing for minimum reinforcement to control cracking ensures acceptable serviceability, whereas using high strength concrete reduces cracking. Ignoring crack control can lead to early deterioration and reduced structural life.

Q 15. Explain the concept of moment redistribution in concrete structures.

Moment redistribution in concrete structures refers to the shifting of moments within a structural member due to the ductile behavior of concrete and reinforcement. Imagine a simply supported beam with a concentrated load in the middle. Initially, the maximum bending moment occurs at the mid-span. However, if the concrete starts to crack in the tension zone, the reinforcement takes over, and the moment is no longer solely resisted at the mid-span. The load is redistributed to adjacent sections, reducing the peak moment and increasing the load-carrying capacity. This redistribution is possible because concrete, although brittle in tension, exhibits a degree of ductility due to the presence of steel reinforcement.

This phenomenon is particularly significant in statically indeterminate structures (like continuous beams or frames), where the redistribution can significantly alter the moment distribution compared to elastic analysis assumptions. Design codes often account for moment redistribution to allow for more economical designs. The amount of redistribution allowed is governed by factors like the reinforcement ratio, concrete strength, and the level of cracking.

Practical Example: Consider a continuous beam. If a mid-span support settles slightly, a pure elastic analysis would predict large negative moments at the support. However, thanks to moment redistribution, a portion of this moment is transferred to the spans, resulting in a less severe moment concentration at the support and therefore a less demanding design.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common defects found in concrete structures and their causes?

Concrete structures are susceptible to various defects, many stemming from issues during design, material selection, construction, or inadequate maintenance. Some common defects include:

- Cracking: This can be caused by shrinkage (due to drying), temperature changes, overloading, inadequate reinforcement, or poor workmanship. Different types of cracks (e.g., fine hairline cracks, wide cracks, map cracking) reveal different causes.

- Corrosion of Reinforcement: Insufficient concrete cover, ingress of chlorides (from de-icing salts or seawater), and carbonation (reaction with CO2 in the air) can lead to steel corrosion, causing expansion and cracking.

- Durability Issues: Freeze-thaw damage in cold climates, alkali-aggregate reaction (chemical reaction between certain aggregates and alkalis in cement), and sulfate attack (reaction with sulfates in the environment) can weaken concrete and impair its serviceability.

- Deflection and Sagging: Overloading, inadequate design, or shrinkage can cause excessive deflection, compromising aesthetic appeal and functionality.

- Spalling: This refers to the breaking off of fragments of concrete, usually due to fire exposure, corrosion of embedded steel, or freeze-thaw cycles.

- Poor Workmanship: Insufficient compaction, honeycombing (voids within the concrete), segregation (separation of cement paste from aggregates), and incorrect placement of reinforcement are all examples of workmanship issues.

Causes are multifaceted and often interconnected. For instance, insufficient concrete cover increases the risk of corrosion and reduces the structure’s durability. Careful design, quality control during construction, and regular maintenance are crucial to minimize defects.

Q 17. How do you select appropriate concrete cover for reinforcement?

Selecting appropriate concrete cover for reinforcement is crucial for ensuring the durability and longevity of the structure. Concrete cover acts as a protective layer for the embedded steel, shielding it from environmental hazards like corrosion.

The required cover is influenced by several factors:

- Environmental exposure conditions: Structures exposed to aggressive environments (e.g., marine environments, de-icing salts) require significantly larger covers than those in less severe environments.

- Concrete strength: Higher strength concrete generally offers better protection against cracking, allowing for slightly reduced cover.

- Fire resistance requirements: Structures needing higher fire resistance require increased concrete cover to protect the reinforcement from high temperatures.

- Type of reinforcement: Different types of reinforcement may need varying covers (e.g., prestressed concrete may require different cover than standard reinforcing bars).

- Code requirements: Building codes specify minimum concrete covers based on environmental conditions and concrete strength.

Design Process: To determine the appropriate cover, engineers consider the environmental category, the concrete strength class, the fire resistance class, and then consult relevant design codes to ascertain the minimum cover requirements. For example, in a marine environment, a significantly larger cover than in an inland environment would be necessary.

Q 18. Explain the principles of bond between concrete and reinforcement.

The bond between concrete and reinforcement is crucial for the structural integrity of reinforced concrete elements. It ensures that the steel reinforcement and the concrete act as a composite unit, sharing stresses effectively. This bond is not a simple physical ‘gluing’ but a complex interaction involving several mechanisms.

Key Principles:

- Mechanical Interlock: The steel rebars’ surface roughness creates mechanical interlock with the surrounding concrete. The ribs and deformations on the rebars enhance this effect.

- Chemical Adhesion: A chemical bond forms between the steel surface and the cement paste. This is especially important for smooth bars, but still plays a role for deformed bars.

- Frictional Resistance: The compressive stress in the concrete contributes to frictional resistance between the concrete and the steel.

Factors affecting bond strength: Concrete strength, the type and spacing of reinforcement, the surface texture of the rebars, the concrete mix design, and the level of curing all influence bond strength. Poor workmanship (e.g., improper consolidation of concrete around the rebars) can significantly weaken the bond.

Practical Significance: Understanding the principles of bond is vital for designing structures to withstand tension, shear, and other loads. Insufficient bond leads to slippage of the reinforcement relative to the concrete, reducing the overall strength and stiffness of the element. Adequate bond is key to ensuring that the steel effectively transfers tensile forces to the surrounding concrete.

Q 19. Describe different types of concrete admixtures and their functions.

Concrete admixtures are materials added to the concrete mix to modify its properties, enhancing its workability, strength, durability, or other characteristics. They are crucial for optimizing the concrete mix for specific applications.

Types and Functions:

- Water reducers (superplasticizers): Reduce the water content required for a given workability, leading to higher strength and durability. They are like a lubricant making the concrete flow easier.

- Air-entraining admixtures: Incorporate small air bubbles into the concrete, enhancing its freeze-thaw resistance. These tiny bubbles create space for water expansion during freezing, preventing damage.

- Accelerators: Speed up the setting and hardening process of concrete, beneficial in cold weather or when faster construction is needed.

- Retarders: Slow down the setting and hardening process, useful in hot weather or when large pours require extended working time.

- Corrosion inhibitors: Reduce the risk of steel corrosion by reducing chloride permeability or improving the alkalinity of the concrete.

- Pozzolans: Supplementary cementitious materials that react with calcium hydroxide to enhance long-term strength and durability.

Example: A superplasticizer might be used in a high-rise building to allow pumping of the concrete to upper floors, while an air-entraining admixture would be essential in a pavement exposed to freeze-thaw cycles.

Selecting admixtures requires careful consideration of the concrete mix design, environmental conditions, and the desired properties of the hardened concrete. Properly chosen admixtures can significantly improve the quality and performance of concrete structures.

Q 20. How do you design for fire resistance in concrete structures?

Designing for fire resistance in concrete structures is crucial for ensuring the safety of occupants and the structural integrity of the building in the event of a fire. The main goal is to protect the reinforcement from excessive heat to prevent loss of strength and bond failure.

Strategies:

- Sufficient concrete cover: Increased concrete cover acts as a thermal barrier, delaying the temperature rise at the reinforcement level. The thickness of the cover is directly related to the required fire resistance period.

- High-performance concrete: Using high-strength and low-permeability concrete reduces the rate at which heat penetrates the section.

- Reinforcement protection: Using special fire-resistant coatings or intumescent materials provides added thermal protection to the reinforcement.

- Fireproofing systems: External fireproofing systems (such as sprayed fire-resistant material) may be employed to enhance the fire resistance of structural members.

- Computational fire modelling: Advanced computer modelling techniques simulate fire behavior and assess the temperature distribution within the concrete element, allowing for more accurate design.

Code Compliance: Building codes specify fire resistance requirements for various structural elements based on occupancy type and building use. Designers must adhere to these codes to ensure adequate fire protection.

Example: A column in a high-rise building requiring a 2-hour fire resistance rating would need a significantly larger concrete cover than a similar column in a less critical building. The choice of concrete mix design and the use of fire-resistant coatings may also be dictated by the fire resistance requirement.

Q 21. What are the different methods for evaluating the serviceability of concrete structures?

Evaluating the serviceability of concrete structures ensures they perform satisfactorily under normal service conditions. Serviceability is concerned with factors like deflection, cracking, vibration, and durability, rather than ultimate collapse. Several methods are used for evaluation:

- Visual inspection: A visual inspection is often the first step, checking for visible cracks, spalling, corrosion signs, and other defects. This gives a qualitative assessment of the structure’s condition.

- Non-destructive testing (NDT): Methods such as ultrasonic pulse velocity, rebound hammer tests, and cover meter measurements provide information about the concrete’s strength, homogeneity, and the location of reinforcement. These tests do not damage the structure.

- Deflection measurements: Deflection measurements assess whether the structure’s deformation under load is within acceptable limits. Excessive deflection can affect aesthetics and functionality.

- Crack width measurements: Crack width measurements are crucial for evaluating the structural integrity and durability of the structure. Excessive cracking can lead to corrosion and reduced serviceability.

- Finite Element Analysis (FEA): FEA can be used to simulate the behavior of the structure under various load conditions, allowing for a quantitative assessment of deflections, stresses, and crack widths.

- In-situ testing: Load tests on structural elements or the whole structure can provide a comprehensive assessment of the structure’s performance.

The choice of methods depends on the specific structure, its condition, and the available resources. A combination of methods often provides the most comprehensive assessment of the structure’s serviceability.

Q 22. Explain the concept of effective depth in reinforced concrete design.

Effective depth in reinforced concrete design refers to the distance between the extreme compression fiber and the centroid of the tensile reinforcement. Think of it like this: imagine a simple concrete beam with steel bars at the bottom. The effective depth is the distance from the top of the beam (where the concrete is compressed) to the center of those steel bars (where the concrete is in tension). It’s crucial because it directly influences the beam’s flexural capacity – its ability to resist bending forces.

The accurate determination of effective depth is paramount in structural design. Using an incorrect value can lead to significant errors in calculating the bending moment capacity. For instance, underestimating the effective depth might lead to under-designed beams that are prone to failure. Conversely, overestimating could lead to uneconomical designs with excessive concrete and steel. Design codes provide specific guidelines on how to calculate the effective depth, considering factors like the cover of reinforcement and the size of the reinforcing bars. For example, if we have a 10-inch deep beam with 1-inch concrete cover and #4 bars (diameter approximately 0.5 inches), the effective depth would be 10 – 1 – 0.5/2 = 8.75 inches.

Q 23. How do you address the effects of temperature changes on concrete structures?

Temperature changes significantly impact concrete structures, causing expansion and contraction. These movements can induce stresses, leading to cracking and potentially structural failure. We address these effects through several strategies.

- Construction Joints: These are strategically placed gaps in the concrete that allow for thermal movement without causing excessive stress. Think of them like expansion joints in roads. They’re essential for large structures.

- Reinforcement: Steel reinforcement helps to mitigate cracking by accommodating the thermal strains. The steel’s flexibility absorbs some of the movement.

- Control of Concrete Properties: Using concrete mixes with lower coefficients of thermal expansion can help minimize the extent of expansion and contraction.

- Design Considerations: The design process must explicitly account for temperature-induced stresses. Calculations consider the temperature range and material properties to ensure sufficient structural capacity.

- Crack Control: Minimizing the width and spacing of cracks is critical for durability. We achieve this through detailing reinforcement effectively, employing shrinkage-reducing admixtures, and selecting appropriate concrete mix designs.

For instance, in a long bridge deck, temperature changes throughout the year can cause significant expansion and contraction. The presence of construction joints and sufficient reinforcement are crucial to prevent cracking and maintain the structural integrity of the bridge.

Q 24. Describe the process of designing a concrete slab.

Designing a concrete slab involves a systematic process:

- Determine Loads: This crucial step involves calculating all anticipated loads on the slab – dead loads (self-weight of the slab, finishes, etc.), live loads (occupancy loads, furniture, equipment), and any superimposed dead loads (partitions, mechanical equipment).

- Select Material Properties: This includes choosing the concrete compressive strength and selecting the appropriate type and amount of reinforcement (steel bars or fibers) based on the loads and desired serviceability requirements (e.g., deflection limitations).

- Determine Thickness: The slab thickness is determined considering strength and deflection requirements. Deflection is a critical aspect; we want to ensure the slab doesn’t sag excessively under load.

- Design Reinforcement: This step involves calculating the area of reinforcement needed to resist bending moments and shear forces. The reinforcement layout and spacing are carefully designed to meet the structural requirements. Detailed drawings are critical to ensure proper placement.

- Check for Shear and Punching Shear: Shear failure is a mode of failure that needs careful consideration. We must ensure the slab has sufficient shear capacity to resist the shear forces developed.

- Detailing: Creating detailed drawings of the reinforcement layout showing bar sizes, spacing, and placement is essential for successful construction. Accurate detailing ensures the slab is built to the design specifications.

For instance, designing a warehouse slab requires considering heavy storage loads, which necessitates a thicker slab with substantial reinforcement. A residential slab has far less stringent requirements. Each slab design is unique and tailored to specific conditions.

Q 25. What are the different types of concrete shear walls?

Concrete shear walls are structural elements designed to resist lateral forces (like those from wind or earthquakes). They are broadly classified into several types:

- Plain Shear Walls: These are simply reinforced concrete walls without any openings.

- Coupled Shear Walls: These consist of two or more shear walls connected by beams or cross-walls, providing greater lateral stiffness and strength.

- Openings in Shear Walls: Frequently, shear walls need openings for doors, windows, etc. The design of such openings requires careful consideration to maintain the structural integrity of the wall.

- Reinforced Concrete Shear Walls: This is a general term, encompassing all shear walls that use reinforcement to enhance strength and ductility.

- Hollow-Core Shear Walls: These consist of two reinforced concrete faces separated by a hollow core, reducing weight while maintaining strength.

The choice of shear wall type depends on factors like the building’s height, occupancy, seismic zone, and architectural requirements. For example, a high-rise building in a high-seismic zone would require robust coupled shear walls with careful detailing of openings to resist lateral forces effectively.

Q 26. Explain the principles of composite concrete construction.

Composite concrete construction involves combining concrete with other materials like steel to create a structural system with enhanced performance. The key principle is to utilize the strengths of each material while mitigating their weaknesses. Steel provides high tensile strength and stiffness, while concrete offers compressive strength and fire resistance. By integrating them efficiently, we obtain structures that are lighter, stronger, and more economical than using either material alone.

Common examples include composite beams (concrete slab integrated with steel beams), composite columns (concrete core enclosed by steel sections), and composite floors. The interaction between the concrete and steel is crucial and involves proper connection mechanisms to ensure they work together effectively. The design considers the composite action, where both materials share the load and deform together. This is achieved through shear connectors, which are mechanical devices that bond the concrete to the steel. Without these connectors, the concrete and steel would act independently, negating the benefits of composite action.

One prominent example of composite concrete construction is in modern high-rise buildings where composite columns and beams provide the structure’s main load-bearing elements, resulting in lighter structures and efficient space utilization.

Q 27. How do you design for fatigue loading in concrete structures?

Designing for fatigue loading in concrete structures is critical because repeated cyclic stresses can lead to cracking and ultimately failure, even if the stress levels are below the concrete’s ultimate strength. Concrete, unlike steel, has limited fatigue resistance.

The design process focuses on several key aspects:

- Accurate Load Prediction: Precisely defining the cyclic loading pattern is essential. This involves identifying the frequency, amplitude, and number of loading cycles. Traffic loading on bridges, for example, needs accurate prediction.

- Stress Analysis: Detailed stress analysis is performed to determine the stress range experienced by the concrete elements under fatigue loading. Finite element analysis is frequently employed for complex geometries and loading conditions.

- Material Properties: Considering the material properties, including the concrete’s fatigue strength, is crucial. Experimental data and material models can help estimate fatigue resistance.

- Crack Control: Designing for adequate crack control, using sufficient reinforcement and detailing, is vital to prevent the propagation of fatigue cracks. This slows down fatigue failure.

- Detailing: Sharp corners and stress concentrations need careful attention during detailing to avoid premature fatigue cracking.

A practical example is designing a bridge deck subjected to repeated traffic loading. The design must ensure that the concrete slab can withstand millions of loading cycles without significant fatigue damage. This involves detailed fatigue analysis, proper reinforcement detailing, and selection of high-quality, durable concrete.

Q 28. What software are you proficient in for concrete structural analysis?

I am proficient in several software packages for concrete structural analysis. My expertise includes:

- SAP2000: A widely used finite element analysis program capable of modeling complex structures and performing linear and nonlinear analyses.

- ETABS: Another popular software package specializing in the analysis and design of buildings, particularly efficient for seismic analysis.

- ABAQUS: A powerful finite element analysis program suitable for highly specialized and complex simulations, such as those involving fracture mechanics and fatigue.

- Autodesk Robot Structural Analysis Professional: A robust tool commonly used for detailed structural analysis and design of reinforced concrete structures.

My proficiency extends beyond simply running analyses; I am adept at creating accurate models, interpreting results, and translating those results into practical design decisions. Selecting the right software depends on the project’s complexity and specific needs. For instance, a simple beam design might use a simpler program, whereas a complex bridge design would benefit from the power of a program like ABAQUS.

Key Topics to Learn for Concrete Structural Analysis Interview

- Material Properties of Concrete: Understanding compressive strength, tensile strength, modulus of elasticity, and creep behavior is crucial for accurate analysis.

- Stress and Strain Analysis: Applying fundamental principles of stress and strain to concrete members, including bending, shear, and axial loading. Practical application includes designing beams and columns to withstand expected loads.

- Reinforced Concrete Design: Mastering the design principles of reinforced concrete elements, including detailing and placement of reinforcement to effectively resist stresses.

- Finite Element Analysis (FEA): Familiarity with FEA software and its application in analyzing complex concrete structures. This allows for efficient and accurate modeling of real-world scenarios.

- Design Codes and Standards: Thorough understanding of relevant building codes (e.g., ACI, Eurocode) and their application in structural design. This demonstrates adherence to safety regulations and best practices.

- Crack Analysis and Control: Understanding crack formation mechanisms and methods to control cracking in concrete structures to ensure serviceability and durability.

- Serviceability Limit States: Knowledge of deflection, cracking, and vibration limits to ensure the structure performs satisfactorily under service loads.

- Ultimate Limit States: Understanding the collapse mechanisms and capacity design principles to ensure the structure’s safety under ultimate loads.

- Shear Design of Concrete Members: Analyzing and designing concrete members to resist shear forces, considering factors like shear reinforcement and concrete’s shear capacity.

- Prestressed Concrete: Understanding the principles of prestressed concrete and its advantages in structural design. This involves familiarity with tendon design and stress calculations.

Next Steps

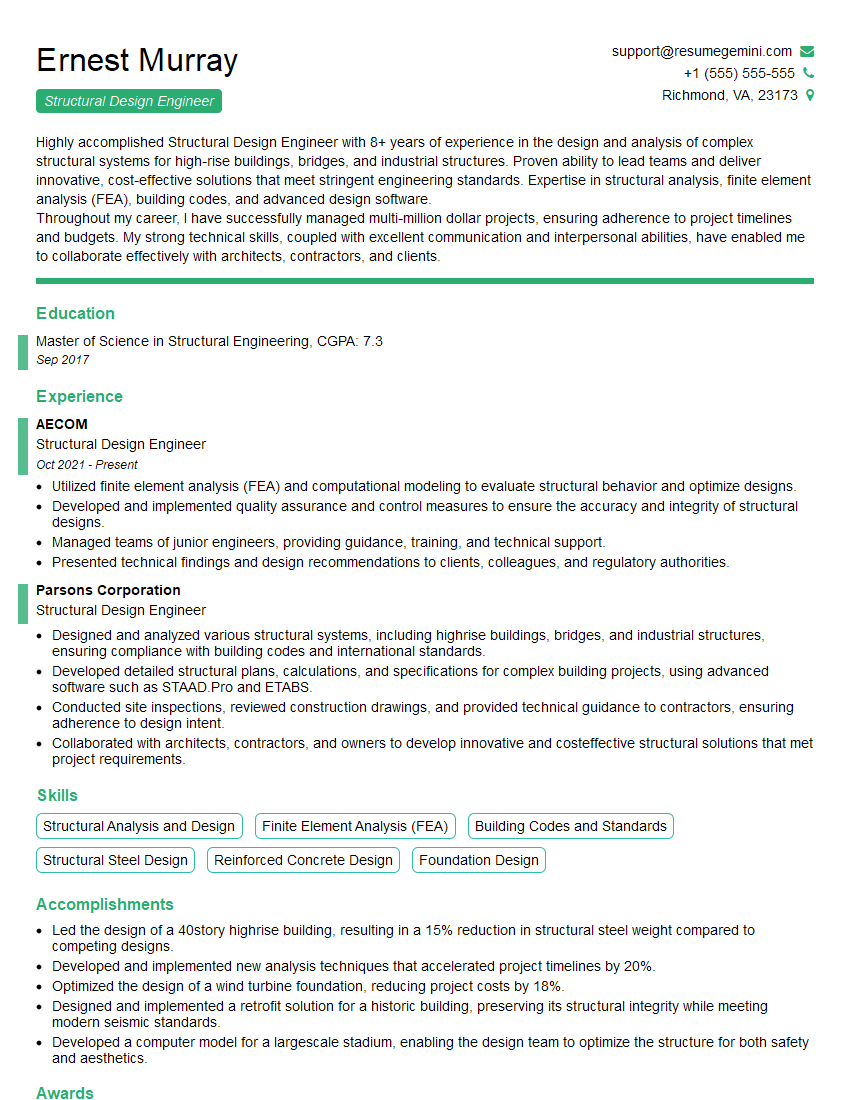

Mastering Concrete Structural Analysis is vital for career advancement in the civil engineering field, opening doors to exciting opportunities and higher earning potential. To significantly boost your job prospects, focus on creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. They provide examples of resumes tailored to Concrete Structural Analysis, ensuring your qualifications are presented clearly and concisely to potential employers. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.