Cracking a skill-specific interview, like one for Crystallizer Process HAZOP, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Crystallizer Process HAZOP Interview

Q 1. Describe the purpose of a HAZOP study in a crystallization process.

A HAZOP (Hazard and Operability Study) for a crystallization process aims to systematically identify and evaluate potential hazards and operability problems that could occur during design, operation, or maintenance. It’s a proactive risk assessment technique ensuring the safety and efficient operation of the crystallization unit. Think of it as a rigorous brainstorming session with a structured approach, going beyond simply listing potential problems to examining the underlying causes and consequences.

Q 2. What are the common hazards associated with crystallization processes?

Crystallization processes present several hazards. These can be broadly categorized into:

- Process Hazards: These involve the inherent risks of the crystallization process itself. Examples include runaway reactions (exothermic crystallization), dust explosions (if the crystal product is finely divided and flammable), and the potential for hazardous chemical reactions during the process.

- Equipment Hazards: These relate to the equipment used in the process. Examples include pressure vessel failures, leaks of hazardous materials, blockages leading to over-pressurization, and rotating equipment hazards (e.g., impellers in agitators).

- Human Factors Hazards: These are related to human error or actions. Examples include incorrect operation procedures, inadequate training, and poor maintenance practices.

- Environmental Hazards: These focus on potential environmental impacts. Examples include spills of hazardous materials, emissions of volatile organic compounds (VOCs), and the disposal of waste streams.

The specific hazards will vary depending on the particular chemicals involved, the process parameters (temperature, pressure, concentration), and the type of crystallization equipment used.

Q 3. Explain the different types of crystallization equipment and their associated HAZOP considerations.

Various types of crystallizers exist, each with unique HAZOP considerations:

- Evaporative Crystallizers: These rely on evaporation to increase solute concentration. HAZOP should focus on potential scaling issues, overheating, and vacuum system failures. A vacuum leak, for instance, could lead to a rapid pressure drop, potentially damaging the equipment or releasing hazardous materials.

- Drowned Crystallizers (also known as MSMPR): These operate with a constant slurry level. HAZOP should consider pump failures (affecting slurry circulation and temperature control), mixing issues (leading to uneven crystal growth and potential blockages), and level control issues (resulting in overflow or insufficient slurry).

- Cooling Crystallizers: These rely on cooling to induce crystallization. HAZOP should evaluate cooling system failures, potential freezing hazards, and the handling of cold solutions.

- Forced Circulation Crystallizers: These use a pump to circulate the slurry. HAZOP concerns here would include pump failures, impeller erosion, and potential for slurry channeling resulting in uneven crystallization.

In all cases, HAZOP should thoroughly consider material compatibility, potential for corrosion, and the safe handling of the crystal product and any associated byproducts.

Q 4. How would you identify and evaluate potential hazards during a Crystallizer HAZOP?

Identifying and evaluating potential hazards during a crystallizer HAZOP involves a structured approach. We use the HAZOP guide words (e.g., ‘no,’ ‘more,’ ‘less,’ ‘part of,’ ‘reverse,’ ‘other than’) to systematically deviate from the design or operating parameters. For example:

- Guide Word: ‘No’: What if the cooling system fails? (Consequence: overheating, potential runaway reaction)

- Guide Word: ‘More’: What if the feed rate is higher than expected? (Consequence: supersaturation increase, potential for uncontrolled nucleation and crystal growth)

- Guide Word: ‘Less’: What if the agitation is less than required? (Consequence: uneven crystal growth, potential for fouling and blockages)

For each deviation identified, the team assesses the likelihood, severity, and detectability of the consequence. A risk matrix is used to prioritize the findings based on the risk level (likelihood x severity). This helps in determining the appropriate mitigation measures.

Q 5. What are some common deviations and consequences identified during a crystallizer HAZOP?

Common deviations and their consequences identified during a crystallizer HAZOP might include:

- Deviation: Loss of vacuum in an evaporative crystallizer. Consequence: Sudden pressure increase, potential equipment damage, release of hazardous vapors.

- Deviation: Failure of the cooling system in a cooling crystallizer. Consequence: Product degradation, loss of crystallization, and potential for hazardous exothermic reactions if the process is exothermic.

- Deviation: Blockage in the crystallizer discharge line. Consequence: Build-up of pressure, potential equipment failure, and interruption of production.

- Deviation: Incorrect addition of seed crystals. Consequence: Poor crystal quality, size distribution problems, and reduced yield.

These examples highlight the importance of considering all aspects of the process and equipment, from the feed preparation to product handling and disposal. The specific deviations and consequences will depend on the individual characteristics of each crystallization process.

Q 6. Describe your experience in facilitating a HAZOP study.

In my previous role at a pharmaceutical manufacturing company, I led a HAZOP study for a new continuous crystallization process producing an active pharmaceutical ingredient. The team comprised process engineers, safety engineers, and operational staff. We used a structured approach, reviewing process flow diagrams and P&IDs. One critical finding highlighted the potential for a dust explosion in the dryer section if the product wasn’t adequately deagglomerated before drying. We were able to identify alternative drying methods with an inert gas purge to mitigate this risk. The HAZOP report led to design modifications improving the safety and efficiency of the unit.

Q 7. How do you manage and document HAZOP findings?

HAZOP findings are managed and documented meticulously. A HAZOP report is produced, which includes:

- A description of the process: Including process flow diagrams and P&IDs

- A list of identified deviations: Detailed descriptions of each deviation, the guide word used, and the potential consequences.

- Risk assessment: For each deviation and consequence, the likelihood and severity are assessed, and a risk level is assigned.

- Recommended actions/mitigation measures: These could include design changes, operational procedures, or safety systems.

- Responsibility and timelines: Clear assignment of responsibility for implementing the recommendations and deadlines for completion.

The report is then reviewed and approved by relevant stakeholders. Implementation of the recommendations is tracked, and a follow-up review is often conducted to ensure effectiveness.

Q 8. Explain the role of process flow diagrams (PFDs) and piping and instrumentation diagrams (P&IDs) in a HAZOP study.

Process flow diagrams (PFDs) and piping and instrumentation diagrams (P&IDs) are crucial visual aids in a HAZOP (Hazard and Operability) study. They provide a detailed representation of the crystallization process, allowing the HAZOP team to systematically analyze each stage and component.

PFDs offer a simplified overview of the process, showing the main equipment and flow streams. They are helpful for establishing the overall process context. Think of them as a roadmap highlighting the major arteries of the system.

P&IDs, on the other hand, are much more detailed. They include instrumentation, valves, control loops, and safety devices. They’re the detailed street map, revealing every intersection and potential hazard. For a crystallizer, this includes details on pumps, agitators, heaters, coolers, filters, and associated safety systems like pressure relief valves (PRVs).

During a HAZOP, the team will use these diagrams to identify potential deviations from normal operating parameters (e.g., high pressure, low flow, temperature excursions) for each element in the system. The diagrams allow for a guided discussion to explore how such deviations can lead to hazards and then determine what safeguards are already in place and what additional measures are necessary.

Q 9. What are the key safety instrumented systems (SIS) related to crystallization processes?

Key safety instrumented systems (SIS) in crystallization processes are designed to mitigate major hazards. These systems are typically triggered by deviations from normal operating parameters and are designed to bring the process to a safe state. Examples include:

- High-level alarms and shutdowns for crystallizers: Prevents overflowing and potential release of hazardous materials.

- High-pressure safety relief valves (PRVs) on crystallizers and associated vessels: Protects against overpressure events that could cause vessel rupture.

- Low-flow alarms and interlocks on feed streams: Prevents crystallization from proceeding without adequate feed, which could lead to damage or reduced product quality.

- Temperature control systems with high/low temperature alarms and interlocks: Maintains optimal crystallization temperature and prevents overheating or freezing, both of which could cause equipment failure or product degradation.

- Emergency shutdown systems (ESD): These encompass multiple systems, including those listed above, working in concert to quickly stop the process in case of a critical event. These often incorporate multiple layers of protection.

- Inerting systems: For hazardous materials, inerting with nitrogen or other non-reactive gases prevents fire and explosion hazards.

It’s crucial that these SIS are regularly tested and maintained according to stringent protocols to ensure their reliability when needed.

Q 10. How do you assess the risk associated with identified hazards?

Risk assessment in a Crystallizer HAZOP involves a qualitative approach that considers the likelihood and severity of consequences. This often employs a risk matrix.

Likelihood: This refers to how probable it is that a particular hazard will occur. We may estimate likelihood using descriptive terms like ‘frequent,’ ‘likely,’ ‘possible,’ ‘unlikely,’ or ‘rare,’ potentially supported by historical data, statistical models, or expert judgment.

Severity: This reflects the potential consequences of the hazard, considering factors like environmental damage, injuries, fatalities, equipment damage, and production downtime. Similar to likelihood, we might use descriptions like ‘catastrophic,’ ‘major,’ ‘moderate,’ ‘minor,’ or ‘negligible’.

Risk Calculation (Qualitative): A risk matrix combines likelihood and severity to provide a qualitative assessment of risk. For example, a ‘likely’ likelihood combined with ‘catastrophic’ severity yields a ‘high’ or ‘intolerable’ risk level, requiring immediate attention. A ‘rare’ likelihood with ‘minor’ severity might be deemed ‘low’ or ‘tolerable’.

Examples: The likelihood of a pump failure might be considered ‘possible,’ while the severity of a resulting chemical spill might be ‘major,’ leading to a ‘moderate’ risk level. Conversely, the likelihood of a fire might be ‘unlikely’, but the severity ‘catastrophic,’ still indicating a potentially ‘high’ risk that needs mitigation.

Q 11. What are the ALARP principles and how do they apply to Crystallizer HAZOP?

ALARP stands for ‘As Low As Reasonably Practicable.’ This principle guides risk management by aiming to reduce risks to a level that is as low as reasonably achievable, considering the costs and benefits of further risk reduction. In a Crystallizer HAZOP, the ALARP principle is applied by evaluating the cost-effectiveness of implementing safety recommendations.

Application in Crystallizer HAZOP:

- Identify Hazards and Risks: The HAZOP team identifies potential hazards and assesses the associated risks using a risk matrix.

- Evaluate Control Measures: For each hazard, control measures (inherent safety, engineering controls, administrative controls, personal protective equipment) are evaluated.

- Cost-Benefit Analysis: The cost of implementing each control measure (engineering, maintenance, training) is weighed against the potential reduction in risk. A detailed cost-benefit analysis might be required for significant investments.

- ALARP Decision: Based on the cost-benefit analysis, the team decides whether the residual risk after implementing the control measures is ALARP. If the residual risk is considered unacceptably high, additional measures must be considered.

- Documentation: The entire process, including justifications for ALARP decisions, must be meticulously documented.

Example: Suppose a hazard is identified as a possible equipment failure leading to a minor spill. Installing a more robust pump might significantly reduce the risk, but it would be expensive. The team might decide this additional expense isn’t justified to achieve a minor risk reduction, concluding the residual risk is ALARP.

Q 12. Explain your understanding of consequence analysis in the context of crystallization HAZOP.

Consequence analysis in a crystallization HAZOP study involves determining the potential effects of a hazard. It goes beyond simply identifying the hazard; it aims to quantify and qualify the impact on people, the environment, equipment, and production.

Elements of Consequence Analysis:

- Human Health: Potential for injuries (burns, chemical exposure), illness, or fatalities.

- Environmental Impact: Potential for air, water, or soil pollution; release of hazardous materials.

- Equipment Damage: Extent of damage to equipment (minor repair, major replacement).

- Production Losses: Downtime, loss of product, reduced efficiency.

- Economic Costs: Repair costs, cleanup costs, fines, insurance claims, production losses.

Techniques: Consequence analysis may involve qualitative estimations (e.g., ‘minor damage,’ ‘significant environmental impact’) or quantitative calculations (e.g., modeling the extent of a potential spill using dispersion models; estimating financial losses from production downtime).

Example: A high-pressure rupture of a crystallizer could result in severe injuries to personnel nearby, release of toxic chemicals causing environmental damage, and substantial equipment damage, leading to significant production losses and hefty economic costs.

Q 13. Describe different types of risk matrices used in HAZOP studies.

Various risk matrices are employed in HAZOP studies, typically differing in the granularity of their scales and the specific criteria used. The choice depends on the complexity of the process and the specific regulatory requirements. Some common types include:

- Simple 2×2 Matrix: This basic matrix uses a simple categorization for both likelihood (e.g., High/Low) and severity (e.g., High/Low), generating four risk categories (High, Medium, Low, Negligible).

- Numerical Risk Matrix: This uses numerical scales (e.g., 1-5 for likelihood and 1-5 for severity) for a more precise risk quantification. The risk level is usually the product of the two numerical ratings. This can be further categorized into risk levels (Low, Medium, High, Very High).

- Color-Coded Risk Matrix: This enhances visual representation using colors to denote different risk levels. The color coding generally corresponds to the numerical scores or qualitative descriptions.

- Bow-tie Analysis: While not strictly a matrix, it’s a popular tool. It visually represents the hazard (the ‘node’ in the middle of the bow-tie), the initiating events (top of the bow tie), the consequences (bottom of the bow tie), and preventive and mitigative safeguards (the sides of the bowtie).

Regardless of the type used, consistency and clear definition of terms for likelihood and severity are crucial for meaningful risk assessment.

Q 14. How do you ensure the effectiveness of implemented safety recommendations?

Ensuring the effectiveness of implemented safety recommendations requires a multi-faceted approach that extends beyond simply implementing the recommendations themselves. This includes:

- Verification: After implementation, verification checks that the recommendations were correctly implemented and that the intended improvements were achieved. This might involve inspection, testing, and review of operational procedures.

- Validation: Validation demonstrates that the implemented safeguards effectively reduce the risks to an acceptable level (ALARP). This might require performance monitoring, data analysis, and simulation studies.

- Training: Operators and maintenance personnel must be adequately trained on the new procedures and safety systems. Regular refresher training is also essential.

- Monitoring and Review: Ongoing monitoring tracks the effectiveness of implemented recommendations. Regular reviews (e.g., HAZOP re-validation, safety audits) assess their continued adequacy and identify potential shortcomings. This also incorporates lessons learned from other facilities or incidents.

- Documentation: All aspects of the process, including the identification of hazards, risk assessment, implemented recommendations, verification, validation, training, and monitoring, should be meticulously documented.

- Management of Change (MOC): A formal MOC process ensures that any future changes to the process are properly assessed for their impact on safety and that appropriate measures are implemented to maintain safety.

By adhering to a robust process of verification, validation, and ongoing monitoring, we can be confident in the efficacy of implemented safety recommendations, providing continued protection against potential hazards.

Q 15. Explain your experience in using HAZOP software.

My experience with HAZOP software spans several years and various projects. I’m proficient in using industry-standard software like PHAST and other specialized tools for conducting HAZOP studies. These tools are crucial for managing the complexity of a large-scale HAZOP, particularly for a process as intricate as crystallization. They facilitate the systematic recording of deviations, causes, consequences, safeguards, and recommendations. For example, in a recent project involving a continuous vacuum crystallizer, the software allowed us to easily link potential hazards, such as a vacuum pump failure, with the corresponding process parameters and safety instrumentation, generating a comprehensive database for analysis and reporting. The software’s reporting capabilities were also invaluable in presenting our findings clearly and concisely to stakeholders.

Beyond data management, I utilize the software’s functionalities for advanced analysis. This includes generating ‘what-if’ scenarios, performing sensitivity analyses, and integrating with other process simulation software for a holistic risk assessment. This holistic approach has proven vital in identifying subtle risks that might be missed during a manual HAZOP.

Career Expert Tips:

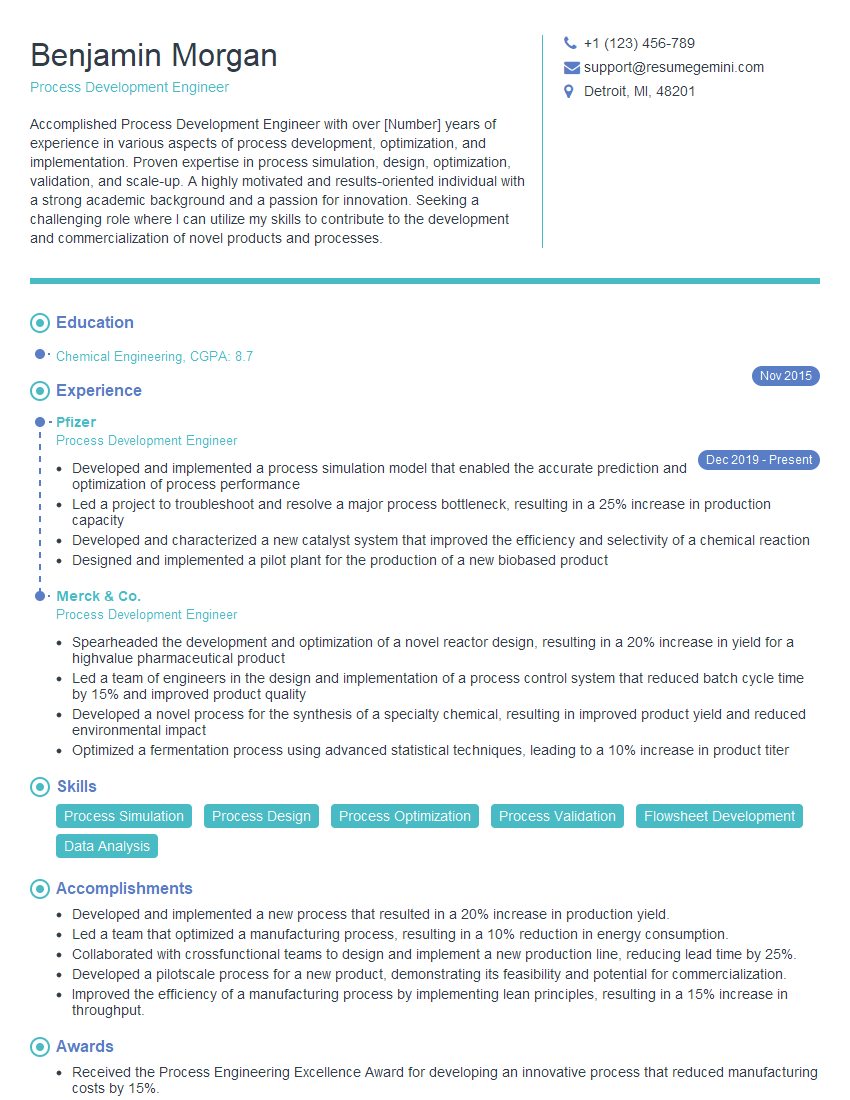

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common causes of scale formation in crystallizers and their HAZOP implications?

Scale formation in crystallizers is a common operational problem with significant HAZOP implications. It typically arises due to the supersaturation of dissolved salts or other components within the solution, leading to their precipitation on heat transfer surfaces and internal components. This can cause reduced heat transfer efficiency, leading to increased energy consumption or process upsets.

- Causes: Common causes include exceeding solubility limits due to temperature changes (in cooling crystallizers), evaporation rate (in evaporative crystallizers), or insufficient mixing. Impurities in the feedstock can also act as nucleation sites, exacerbating scale formation. Changes in process parameters, such as flow rate or residence time, can unexpectedly increase the supersaturation leading to scaling.

- HAZOP Implications: Scale buildup can restrict flow, leading to blockages and potentially causing pressure build-up within the crystallizer. This pressure build-up could lead to vessel rupture or equipment failure. Reduced heat transfer efficiency can cause temperature runaway, overheating, or other process deviations. Moreover, the accumulation of scale can compromise the crystal quality, impacting product purity and yield. Furthermore, cleaning or maintenance operations required to remove scale pose inherent safety risks, particularly when working in confined spaces or dealing with hazardous chemicals used for cleaning.

In a HAZOP study, we meticulously identify these causes and analyze their potential consequences, implementing safeguards like regular cleaning protocols, improved process control strategies (e.g., precise temperature control and optimized mixing), and appropriate safety systems (e.g., pressure relief valves, temperature sensors with alarms). The analysis also extends to risk mitigation strategies during maintenance and cleaning operations.

Q 17. How do you handle unforeseen hazards or deviations during a HAZOP session?

Unforeseen hazards or deviations during a HAZOP session are not uncommon. The key is a flexible and collaborative approach. When something unexpected arises, I initiate a structured investigation, immediately documenting the deviation. We then utilize brainstorming techniques to systematically explore potential root causes and consequences. The team leverages its collective experience to develop potential mitigation strategies. If the team lacks specific expertise, we might consult external resources or experts.

For instance, during a HAZOP on a specific crystallizer design, we encountered a potential hazard related to a novel type of impeller. Our initial risk assessment was incomplete due to limited understanding of the impeller’s behavior under certain conditions. We paused the session, consulted the impeller’s manufacturer, and incorporated their insights into our analysis. This collaborative and iterative approach allowed us to adequately assess and mitigate the risk. The key is to not ignore these deviations but to thoroughly investigate, document them, and integrate learnings to refine the process risk assessment.

Q 18. What is your experience with different types of crystallizers (e.g., evaporative, cooling, etc.)?

My experience encompasses various crystallizer types, including evaporative, cooling, and mixed-suspension mixed-product removal (MSMPR) crystallizers. Each type presents unique operational challenges and safety considerations.

- Evaporative Crystallizers: These involve the evaporation of solvent to achieve supersaturation. HAZOPs for these focus on vacuum system failures (leading to potential in-rush of air and process upset), overheating, and potential for solvent emissions.

- Cooling Crystallizers: In these, cooling causes supersaturation. HAZOP studies focus on cooling system malfunctions (leading to uncontrolled temperature increases), potential freezing hazards if temperatures drop below safe limits, and issues related to cooling water management.

- MSMPR Crystallizers: These are continuous systems requiring careful control of supersaturation, residence time and crystal size distribution. HAZOPs emphasize flow control issues, pump failures, and maintaining consistent product quality.

Understanding the specific operating principles and inherent risks associated with each type is crucial for a thorough HAZOP analysis. Each study must be tailored to the specific design and operating parameters of the crystallizer to ensure accurate and effective risk assessment.

Q 19. How do you ensure that the HAZOP team has the necessary expertise?

Ensuring the HAZOP team has the necessary expertise is paramount. I approach this in a multi-faceted way. First, I carefully select team members with diverse backgrounds and relevant process knowledge. This includes process engineers, instrumentation and control specialists, safety engineers, operations personnel, and, critically, those with direct experience operating the specific crystallizer.

Secondly, I provide comprehensive pre-HAZOP training materials to ensure everyone is familiar with the process, the HAZOP methodology, and relevant safety standards. This helps establish a common understanding and fosters efficient teamwork. Prior to the study, we have a kickoff meeting to clarify roles, objectives, and expectations. Finally, if a gap in expertise arises during the HAZOP session, I don’t hesitate to bring in external consultants or specialists to augment the team’s knowledge. This proactive approach guarantees a robust and thorough risk assessment.

Q 20. What are the regulatory requirements for HAZOP studies in your industry?

Regulatory requirements for HAZOP studies vary depending on the industry and geographic location. However, in many sectors, including the pharmaceutical and chemical industries where crystallizers are commonly used, HAZOP studies are often mandated by regulatory bodies such as OSHA (in the US) or equivalent agencies globally. These regulations typically specify the frequency of HAZOPs, the required documentation, and the level of detail needed in the study.

Furthermore, industry best practices and internal company standards often add layers of requirements beyond the legal minimums. For example, our company demands detailed documentation of the HAZOP process, including the team’s composition, the methodology used, the identification of hazards, recommended safeguards, and the assigned responsibilities for implementing and verifying the recommendations. Regular audits and reviews of the HAZOP process itself are also integral to maintain compliance and continuously improve its effectiveness. Adherence to these regulatory requirements and best practices is essential for maintaining safety, protecting personnel, and preventing environmental damage.

Q 21. Explain your understanding of layer of protection analysis (LOPA) and its relation to HAZOP.

Layer of Protection Analysis (LOPA) is a quantitative risk assessment technique used to determine the required safety integrity levels (SIL) for safety instrumented systems (SIS). It’s often employed in conjunction with HAZOP. While HAZOP identifies potential hazards and recommends safeguards, LOPA quantifies the residual risk after implementing these safeguards.

Specifically, HAZOP identifies the hazards and proposes preventative and mitigating measures. LOPA takes the output of the HAZOP study and performs a quantitative assessment to determine if the proposed layers of protection are sufficient to reduce the risk to an acceptable level. LOPA considers factors like the frequency of initiating events, the probability of failure of each layer of protection, and the severity of the consequences. The result of the LOPA analysis determines the required SIL for the SIS, guiding the selection and design of safety instruments. In simpler terms, HAZOP helps us figure out *what* could go wrong and *how* to prevent it, while LOPA tells us *how safe* the preventative measures make the process and whether additional safeguards are necessary.

Q 22. How do you incorporate operational experience and lessons learned into the HAZOP process?

Incorporating operational experience and lessons learned is crucial for a robust HAZOP study. It’s not just about theoretical analysis; it’s about grounding the process in the realities of the crystallization process. We achieve this through several key methods:

- Pre-HAZOP Documentation Review: Before the HAZOP meeting, we thoroughly review past incident reports, maintenance logs, and operating procedures. This provides a baseline understanding of previous issues and near misses.

- Expert Panel Inclusion: We ensure the HAZOP team includes operators, maintenance personnel, and engineers with extensive experience in similar crystallization processes. Their firsthand knowledge is invaluable in identifying potential hazards that might be overlooked by those with only design experience.

- Interactive Session: During the HAZOP meeting itself, we actively encourage participants to share their anecdotes and insights. A casual ‘what-if’ scenario based on past experience can often unearth critical hazards that might not be obvious from the P&IDs alone.

- Post-HAZOP Action Tracking: We rigorously track the implementation of recommended mitigations. If a particular hazard keeps recurring, it highlights areas where our understanding or mitigation strategies need refinement, feeding back into future HAZOPs.

For example, in one study, an operator’s anecdote about a previous pump failure leading to a slurry buildup in a pipe section, which was nearly overlooked in the initial design review, led to the identification of a significant blockage hazard and the implementation of improved alarm systems and emergency shutdown procedures.

Q 23. Describe your experience with reviewing and approving HAZOP reports.

My experience in reviewing and approving HAZOP reports involves a multi-step process focused on thoroughness and rigor. I look beyond simply verifying that the HAZOP was conducted; I critically assess the quality and effectiveness of the process and its outcomes.

- Completeness and Accuracy: I check for completeness in hazard identification, thoroughness of consequence analysis, and the justification behind proposed mitigations. Inaccurate data or assumptions are a significant concern.

- Mitigation Effectiveness: I evaluate the feasibility, effectiveness, and practicality of the recommended mitigation strategies. Are they truly effective in preventing or mitigating the identified hazards? Are they cost-effective and operationally sound?

- Action Item Tracking: I review the action plan to ensure it contains clear responsibilities, deadlines, and a mechanism for tracking progress and closure of action items. I insist on a robust follow-up system to ensure recommendations aren’t just documented but actually implemented.

- Documentation Quality: The report itself must be clear, concise, and well-organized, making it easily understandable for a wide range of stakeholders, including management, operations, and maintenance personnel.

In instances where I find deficiencies, I provide detailed feedback to the HAZOP team, specifying the areas requiring improvement and explaining the reasons. This often involves clarifying certain points or requesting additional information before approving the report.

Q 24. What are the challenges you have faced during HAZOP studies?

Conducting HAZOP studies for crystallization processes presents unique challenges. Some of the most prominent ones I’ve faced include:

- Complexity of Crystallization: The process is inherently complex, involving multiple parameters (temperature, concentration, agitation, seeding) that interact in intricate ways. Identifying all possible deviation scenarios can be demanding.

- Scale-Up Issues: Hazards identified during lab-scale or pilot plant studies might not fully translate to industrial-scale operations, requiring careful scaling considerations.

- Data Availability: Sufficient and reliable process data is essential for effective hazard analysis. Sometimes data is limited or inconsistent, hindering accurate risk assessment.

- Team Dynamics: Ensuring effective communication and collaboration among participants with diverse backgrounds (process engineers, operators, safety specialists) can be challenging.

- Time Constraints: HAZOP studies can be time-consuming, especially for complex processes. Balancing thoroughness with deadlines can be a significant pressure.

For instance, in one project, obtaining consistent data on slurry rheology (flow behavior) proved challenging, impacting the accuracy of our predictions for potential blockages and pressure buildup scenarios.

Q 25. How do you prioritize identified hazards and recommend mitigation strategies?

Prioritizing hazards and recommending mitigation strategies involves a systematic approach. We typically employ a risk matrix based on the likelihood and severity of the consequences.

- Risk Matrix: We use a qualitative or quantitative risk matrix to score each identified hazard based on the likelihood of occurrence (frequent, occasional, rare) and the severity of consequences (catastrophic, major, minor). This generates a risk level for each hazard.

- Severity Categorization: We define severity levels with clear criteria, such as potential for injuries, environmental damage, production losses, or equipment damage.

- Likelihood Assessment: This involves considering historical data, process knowledge, and expert judgment. We use techniques like Failure Mode and Effects Analysis (FMEA) to estimate the likelihood of specific deviations.

- Mitigation Prioritization: Hazards with the highest risk scores (likelihood x severity) are prioritized for mitigation. We then develop and evaluate mitigation options based on their effectiveness, cost-effectiveness, and feasibility.

For example, a high-risk hazard like a runaway reaction in a crystallizer would be given top priority, potentially requiring sophisticated safety instrumented systems (SIS) as a mitigation strategy. Conversely, a low-risk hazard might only require improved operating procedures or additional training.

Q 26. How do you ensure effective communication and collaboration within a HAZOP team?

Effective communication and collaboration are paramount to a successful HAZOP. Here’s how we ensure this:

- Clearly Defined Roles: Each team member has a clearly defined role (Chairperson, Scribe, Process Expert, Safety Expert, etc.) to ensure clear responsibilities and efficient progress.

- Facilitated Discussion: A skilled facilitator guides the discussion, ensuring all perspectives are considered and preventing the conversation from deviating from the defined scope.

- Structured Approach: Using a structured HAZOP methodology (e.g., using predefined guidewords) helps maintain focus and consistency.

- Open Communication: We encourage open and respectful discussion, fostering a culture of collaboration where everyone feels comfortable expressing their opinions and concerns.

- Visual Aids: Process flow diagrams (P&IDs), process data, and other visual aids are utilized to facilitate understanding and communication within the team.

For instance, using a shared digital whiteboard during virtual HAZOP meetings allows all participants to contribute and visualize the discussions concurrently, fostering better participation and collaboration.

Q 27. What are the key performance indicators (KPIs) for a successful HAZOP study?

Key performance indicators (KPIs) for a successful HAZOP study are multifaceted and go beyond simply completing the study. They indicate the effectiveness of the process and its impact on safety and operational performance.

- Number of Hazards Identified: A high number doesn’t automatically mean success; it might indicate overlooked hazards in previous designs or operations. However, a reasonable number, combined with other indicators, suggests a thorough analysis.

- Risk Reduction Achieved: This is a crucial KPI, quantifying the reduction in risk levels after implementing recommended mitigations. This might involve reduction in risk scores from the risk matrix.

- Action Item Closure Rate: Tracking the closure of action items indicates the effectiveness of the follow-up process and commitment to implementation.

- Team Satisfaction: A positive team experience contributes to the quality and acceptance of the findings.

- Time and Cost Efficiency: Balancing thoroughness with time and cost constraints is vital. An efficient study delivers high-quality results within reasonable limits.

Ultimately, the success of a HAZOP is measured by its demonstrable contribution to reducing the risk of incidents and improving overall process safety.

Key Topics to Learn for Crystallizer Process HAZOP Interview

Ace your Crystallizer Process HAZOP interview by mastering these key areas. Remember, understanding the underlying principles and their practical application is key to demonstrating your expertise.

- Crystallizer Fundamentals: Understand the various types of crystallizers (e.g., evaporative, cooling, etc.), their operating principles, and the factors influencing crystal size and quality. Consider the impact of different process parameters on crystal growth and morphology.

- HAZOP Methodology in Crystallization: Deeply understand the HAZOP process itself – how to define nodes, identify deviations, and develop preventative and mitigative measures within the context of a crystallizer. Practice applying the HAZOP technique systematically.

- Safety Considerations in Crystallization: Explore potential hazards specific to crystallizers, such as dust explosions, runaway reactions, and equipment failures. Learn how to identify and assess these hazards using qualitative and quantitative risk assessment methods.

- Process Control and Instrumentation: Understand the role of instrumentation and control systems in maintaining safe and efficient crystallizer operation. This includes analyzing process variables, alarm systems, and safety interlocks.

- Material Handling and Storage: Analyze the potential hazards associated with the handling and storage of crystallized materials, focusing on issues like dust control, segregation, and potential reactivity.

- Case Studies and Practical Applications: Review real-world examples of HAZOP studies conducted on crystallizers. This will help you understand how theoretical concepts are applied in practice and will strengthen your problem-solving abilities.

- Troubleshooting and Root Cause Analysis: Develop your skills in identifying the root causes of incidents or near misses in crystallizer processes. Understanding common failure modes and their consequences is crucial.

Next Steps

Mastering Crystallizer Process HAZOP significantly enhances your career prospects in the chemical process industries, opening doors to advanced roles and increased responsibilities. To maximize your job search success, it’s crucial to present your skills effectively. Crafting an ATS-friendly resume is key to getting your application noticed by recruiters.

We highly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini offers a streamlined process and provides access to examples of resumes tailored to Crystallizer Process HAZOP roles, giving you a head start in showcasing your expertise.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.