Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Crystallizer Process Instrumentation interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Crystallizer Process Instrumentation Interview

Q 1. Explain the principle of operation of a typical crystallizer.

Crystallization is a separation process where a solid crystalline substance is formed from a solution. A typical crystallizer works on the principle of supersaturation. This means creating a solution that contains more solute (the substance to be crystallized) than it can normally dissolve at a given temperature and pressure. This excess solute, driven by the inherent instability of the supersaturated state, then precipitates out of the solution in the form of crystals.

Think of it like this: imagine a glass of iced tea that’s so sweet you can barely stir it. The sugar (solute) is beyond its saturation point. As the ice melts or the temperature changes slightly, the sugar starts to come out of solution, forming sugar crystals. This is analogous to how a crystallizer works, though it’s a much more controlled and efficient process.

The process involves three main steps: (1) Supersaturation: creating a solution beyond its solubility limit. (2) Nucleation: the formation of tiny seed crystals from the supersaturated solution. (3) Crystal growth: the enlargement of these seed crystals through the addition of solute molecules.

Q 2. Describe different types of crystallizers and their applications.

Various crystallizer types exist, each suited to different applications based on factors like crystal size, desired purity, and throughput. Some common types include:

- Batch Crystallizers: These operate in discrete batches. They’re simple to operate but less efficient for large-scale production. Think of making rock candy at home – a batch process.

- Mixed-Suspension, Mixed-Product Removal (MSMPR) Crystallizers: These maintain a consistent crystal size distribution by continuously mixing crystals and removing product. They’re commonly used in industrial settings due to their efficient operation and ability to produce consistent crystal quality.

- Fluidized Bed Crystallizers: Crystals are suspended in a fluidized state by an upward flow of liquid, leading to uniform crystal growth. Excellent for fine crystal production.

- Draft Tube Baffle (DTB) Crystallizers: These create a high degree of mixing within a relatively small volume, improving the control over crystal size distribution and leading to higher production rates. Frequently used in large-scale operations.

- Evaporative Crystallizers: These increase supersaturation by evaporating the solvent, leaving behind a higher concentration of solute to crystallize. Useful for solutions where solubility is strongly affected by temperature.

The choice depends on specific needs. For example, pharmaceutical applications might necessitate extremely pure and precisely sized crystals, demanding tighter control and potentially employing a DTB or MSMPR crystallizer. Industrial salt production might favour the higher throughput of an evaporative crystallizer.

Q 3. What are the key process parameters monitored in a crystallizer?

Monitoring key parameters is crucial for efficient and consistent crystal production. These parameters include:

- Temperature: Directly impacts solubility and thus supersaturation.

- Pressure: Particularly important in evaporative crystallizers, influencing the boiling point of the solvent.

- Supersaturation: The driving force behind crystallization, measured indirectly through temperature, concentration and other parameters.

- Concentration: Directly reflects the amount of solute available for crystallization.

- Crystal Size Distribution (CSD): Critical for product quality and downstream processing, typically assessed using image analysis techniques.

- pH: Influences solubility in many systems.

- Flow rate: Influences residence time and mixing within the crystallizer.

Sophisticated process control systems integrate these measurements to optimize the process in real-time.

Q 4. How do you measure and control supersaturation in a crystallizer?

Supersaturation is rarely measured directly, but indirectly via other parameters. The most common approach involves using online sensors to measure temperature and concentration. These values, along with solubility data for the specific system (obtained via laboratory analysis), are used to calculate supersaturation.

Supersaturation = Actual Concentration - Solubility at a given Temperature

Controlling supersaturation involves manipulating parameters such as temperature, concentration, and flow rates. For instance, in an evaporative crystallizer, we control the rate of evaporation to achieve the desired supersaturation. In a cooling crystallizer, cooling rate is carefully adjusted. Advanced control systems, often utilizing feedback loops, automatically adjust these parameters to maintain the optimal supersaturation level for consistent crystal growth and minimize secondary nucleation (undesired nucleation events).

Q 5. Explain the importance of nucleation and crystal growth in crystallization.

Nucleation and crystal growth are the two fundamental stages of crystallization. They govern the final crystal size distribution and quality.

- Nucleation: This is the initial formation of tiny crystalline nuclei from the supersaturated solution. It’s a crucial step, as the number of nuclei largely dictates the number of crystals formed. Too many nuclei lead to many small crystals, while too few result in fewer, larger crystals. Nucleation can be either primary (spontaneous formation) or secondary (formation on existing crystals or impurities).

- Crystal Growth: Once nuclei have formed, solute molecules from the solution attach to their surfaces, leading to crystal growth. The rate of growth is influenced by supersaturation, temperature, and fluid dynamics. Uniform growth leads to well-formed crystals.

Think of it like building a sandcastle: nucleation is laying the foundation (many small seeds), and crystal growth is building the castle bigger (one grain at a time). Controlling both processes is essential for building the desired ‘castle’ – or crystal.

Q 6. Describe common methods for controlling crystal size distribution.

Controlling crystal size distribution (CSD) is critical for downstream processing and product quality. Techniques include:

- Controlling Supersaturation: Maintaining a controlled supersaturation level prevents excessive nucleation and promotes uniform crystal growth.

- Seeding: Introducing pre-formed seed crystals into the crystallizer promotes growth on these existing crystals, reducing the number of new nuclei formed and leading to a more uniform CSD. This is analogous to introducing a few large sandcastle forms into our sand-building example.

- Agitation/Mixing: Proper mixing prevents localized supersaturation and ensures uniform mass and heat transfer, resulting in a more homogeneous CSD.

- Classifying and Recycling: Separating crystals by size and recycling undersized crystals back to the crystallizer leads to a more homogenous and narrower CSD.

The specific approach depends on the crystallizer type and the desired CSD. Often, a combination of these methods is used.

Q 7. What are the different types of sensors used in crystallizer process instrumentation?

Crystallizer process instrumentation relies on a variety of sensors to monitor key process parameters. These include:

- Temperature Sensors (Thermocouples, RTDs): Measure temperature throughout the crystallizer for precise control.

- Pressure Sensors: Monitor pressure, particularly important for evaporative crystallizers.

- Level Sensors (Ultrasonic, Capacitive): Maintain the desired liquid level within the crystallizer.

- Flow Sensors (Coriolis, Magnetic): Measure and control feed and product flow rates.

- Concentration Sensors (In-line refractometers, NIR spectroscopy): Determine solute concentration in real-time.

- Particle Size Analyzers (Laser Diffraction, Image Analysis): Measure crystal size distribution online.

- pH Sensors: Monitor and control pH if relevant to the system.

The specific sensor selection depends on the process requirements and budget. Online measurements are becoming increasingly important for advanced process control and automation.

Q 8. How do you troubleshoot common issues such as fouling and scaling in a crystallizer?

Fouling and scaling in crystallizers are common operational challenges stemming from the deposition of impurities onto heat transfer surfaces or crystal surfaces. Troubleshooting involves a systematic approach. First, we identify the type of fouling (e.g., organic, inorganic). This often involves analyzing the fouled material. For inorganic scaling, we might see calcium carbonate or sulfate deposits, common in evaporative crystallizers processing solutions with high hardness. Organic fouling is usually more complex and can require advanced analytical techniques.

Once the type is identified, we address the root cause. For inorganic scaling, we can adjust process parameters such as temperature, pH, or supersaturation to reduce the driving force for precipitation. We may also use antiscalants – chemicals that inhibit crystal growth on surfaces. Cleaning might involve acid washing (carefully!), followed by thorough rinsing. For organic fouling, cleaning might involve solvent cleaning or enzymatic treatments. Preventive measures include pre-treatment of the feed solution (e.g., filtration), optimized process control to minimize supersaturation, and regular cleaning cycles based on fouling rates.

Example: In a potash crystallizer, scaling caused by potassium chloride can be mitigated by carefully controlling the temperature and concentration of the solution to avoid exceeding the solubility limits. Regular cleaning with hot water may be sufficient, but more aggressive cleaning may be needed if scaling is severe.

Q 9. Explain the role of process control systems (e.g., DCS, PLC) in crystallizer operation.

Process Control Systems (PCS), such as Distributed Control Systems (DCS) and Programmable Logic Controllers (PLCs), are the brains of a crystallizer operation. They monitor and control various process parameters crucial for consistent crystal quality and yield. This includes temperature, pressure, flow rates of feed and product streams, agitation speed, and level in the crystallizer vessel.

A DCS or PLC continuously collects data from numerous sensors – thermocouples, pressure transmitters, flow meters, level sensors. This data is then used by control algorithms to precisely manipulate actuators like valves, pumps, and variable-speed drives, ensuring the crystallizer operates within optimal conditions. For example, a PLC might adjust the feed rate based on real-time measurements of supersaturation, ensuring that crystal growth remains controlled and uniform. The PCS also provides a comprehensive monitoring and alarming system to alert operators to deviations from setpoints or abnormal conditions, enabling timely intervention.

Example: A DCS could automatically adjust the cooling rate in a cooling crystallizer based on real-time measurements of the product temperature and supersaturation. This prevents uncontrolled nucleation and crystal growth, resulting in better crystal size distribution.

Q 10. Describe different control strategies used in crystallizers (e.g., feedback, feedforward).

Crystallizers employ various control strategies to achieve consistent crystal size and shape. Feedback control is the most common; it involves measuring a process variable (e.g., temperature, supersaturation) and adjusting the manipulated variable (e.g., cooling rate, feed rate) to maintain the desired setpoint. This is a closed-loop system constantly correcting deviations.

Feedforward control anticipates changes and adjusts the manipulated variable proactively. For example, if the feed solution’s temperature is expected to fluctuate, the cooling rate can be adjusted in advance to compensate, minimizing deviations from the setpoint. This strategy requires a good understanding of the process dynamics.

Cascade control involves using two or more control loops where the output of one loop becomes the setpoint of the other. This is often used to control temperature in a crystallizer, where an outer loop controls the overall temperature and an inner loop controls the cooling water flow rate. Ratio control is employed to maintain a consistent ratio between two or more process variables. This is crucial for maintaining a specific concentration ratio in the feed stream. These control strategies are often implemented through a combination of PID (Proportional-Integral-Derivative) control algorithms.

Q 11. How do you calibrate and maintain instruments used in crystallizer operations?

Calibration and maintenance of instruments in crystallizers are crucial for accurate process control and reliable operation. The frequency depends on the instrument type and manufacturer’s recommendations, but regular checks are essential. Calibration involves comparing the instrument’s readings to known standards using traceable standards. This ensures accuracy and consistency.

Examples: Thermocouples are calibrated using a temperature calibrator, while pressure transmitters are calibrated using a deadweight tester. Flow meters are typically calibrated using a flow calibrator. Maintenance might include cleaning sensors, replacing worn parts (e.g., seals in valves), or inspecting for any signs of damage or malfunction. Regular preventative maintenance can reduce downtime and increase the lifespan of the instruments. Maintaining accurate calibration records is crucial for compliance and troubleshooting.

Example: A regular calibration schedule for a temperature sensor in a crystallizer might involve checking against a certified thermometer monthly and a full recalibration annually. A regular inspection would check for damage to the sensor or its wiring.

Q 12. What are the safety considerations related to crystallizer process instrumentation?

Safety considerations in crystallizer process instrumentation are paramount. The systems must be designed to prevent hazardous conditions. This involves incorporating safety instrumented systems (SIS) to shut down the process if abnormal conditions occur. These might include high temperature, high pressure, or low level in the vessel. Redundant instrumentation and automated emergency shutdown systems are crucial.

Examples: High-temperature alarms and automatic shutdowns prevent overheating and potential runaway reactions. Pressure relief valves (PRVs) protect the system from over-pressurization. Level sensors prevent overflows and potential spills. Instruments must be intrinsically safe to prevent ignition of flammable materials in the process. Regular safety inspections and training programs for operators are essential.

Example: A high-temperature limit switch on a heating jacket coupled to a shut-off valve protects against excessive temperature excursions in the crystallizer. Regular testing of these safety devices is critical.

Q 13. Explain the importance of data logging and analysis in crystallizer operation.

Data logging and analysis are crucial for optimizing crystallizer operation and ensuring consistent product quality. Modern PCS automatically record process data, including temperature, pressure, flow rates, and other relevant parameters. This historical data provides valuable insights into the process behavior and helps identify trends, potential problems, and areas for improvement.

Example: Analyzing historical data can reveal a correlation between feed temperature fluctuations and crystal size distribution. This information can be used to optimize the feed pre-treatment process or adjust the control strategy to mitigate these fluctuations and improve product quality. Statistical Process Control (SPC) techniques can help identify patterns and detect deviations from normal operating conditions early on.

Example: Regular analysis of logged data allows for better understanding of the relationship between process parameters and final product quality parameters such as crystal size distribution, purity, and yield. This can lead to adjustments in operating conditions to improve overall performance.

Q 14. Describe the different types of agitators used in crystallizers and their impact on crystal quality.

Different types of agitators are used in crystallizers, each impacting crystal quality differently. The choice depends on factors like crystal size, shape, and susceptibility to breakage.

Axial flow impellers create a strong axial flow, suitable for mixing large volumes with minimal shear. This prevents crystal breakage but may lead to less uniform mixing compared to other designs. Radial flow impellers produce a strong radial flow promoting better mixing, but may also increase crystal breakage. Helical ribbon impellers are efficient in viscous fluids and provide good mixing, but may also induce significant shear. Anchor impellers are used for highly viscous fluids and scrape the walls preventing fouling, but may not provide sufficient mixing in large vessels.

The selection of the agitator and its operating parameters (speed, power) are critical in determining crystal quality. Excessive agitation can lead to excessive crystal breakage, resulting in smaller crystals, while insufficient agitation can cause non-uniform supersaturation and poor crystal growth. Careful design and operation are therefore crucial.

Example: In a crystallizer producing large, high-quality crystals, an axial-flow impeller operating at a low speed might be preferred to minimize crystal breakage. Conversely, a radial-flow impeller might be chosen for a process that is less sensitive to crystal breakage and requires more thorough mixing.

Q 15. How do you determine the optimal operating conditions for a crystallizer (temperature, pressure, etc.)?

Determining optimal operating conditions for a crystallizer involves a delicate balance between achieving high product yield and purity while maintaining consistent crystal size and morphology. It’s not a simple equation, but rather an iterative process combining theoretical understanding with practical experimentation.

We start by considering the solubility curve of the target compound. This curve shows the relationship between solubility and temperature. Operating at a temperature that gives a supersaturation within the metastable zone is crucial. Too little supersaturation, and nucleation – the formation of new crystals – is slow and leads to large crystals, potentially increasing the risk of agglomeration. Too much, and you get uncontrolled nucleation leading to a slurry of tiny crystals, making downstream processing difficult.

Pressure plays a lesser role in many crystallizations, primarily influencing solubility in some systems and the gas-liquid equilibrium in the case of gas-antisolvent crystallization. Other crucial factors include the feed concentration, the cooling rate, and the level of agitation. We often use sophisticated process simulators, like Aspen Crystallizer, to model the system and predict the impact of various operating parameters. This modeling is then validated and refined through experimental runs using pilot-scale crystallizers.

Example: In the crystallization of paracetamol, the optimal temperature profile might involve a slow cooling rate from the saturation point to maintain a controlled supersaturation, preventing excessive nucleation. Careful agitation ensures uniform supersaturation preventing crystal defects.

Career Expert Tips:

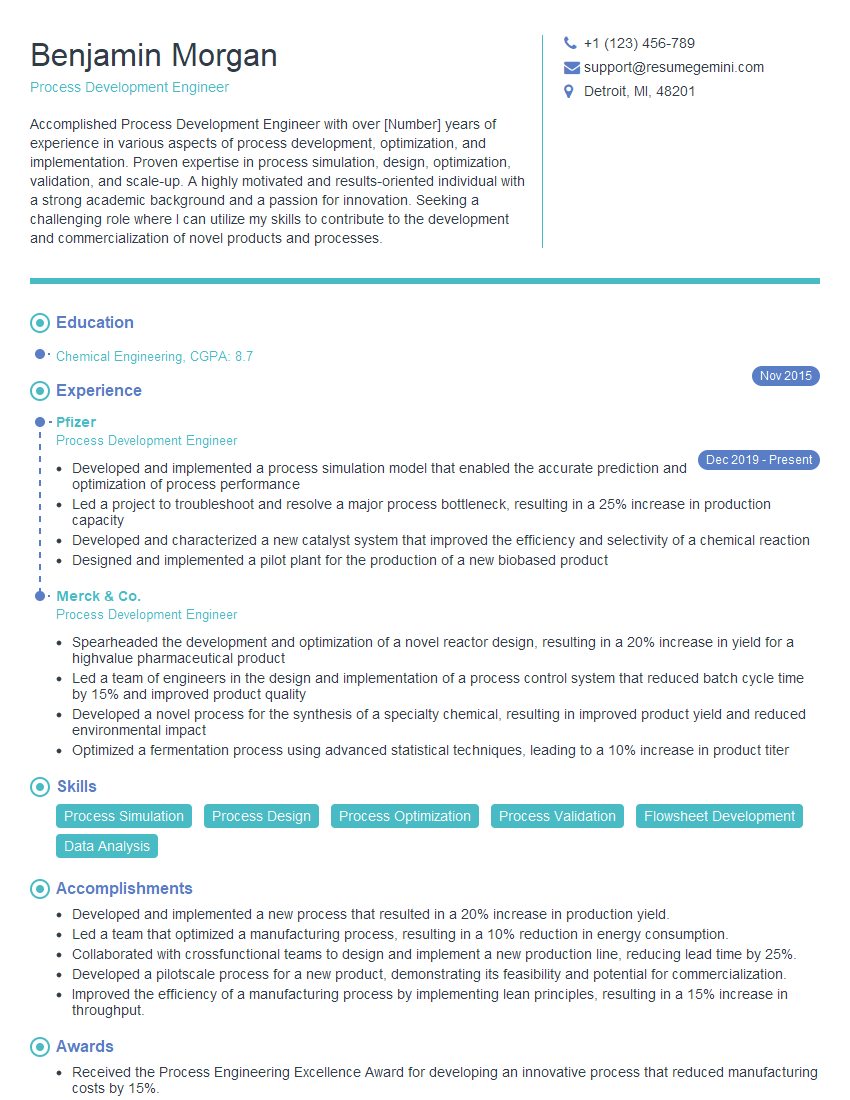

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of residence time distribution (RTD) in a crystallizer.

Residence Time Distribution (RTD) describes how long different fluid elements spend inside the crystallizer. Understanding RTD is vital because the time spent in the supersaturated environment directly impacts crystal growth and size distribution. A perfectly mixed crystallizer would have an ideal RTD, indicating all fluid elements spend the same amount of time inside. In reality, however, flow patterns within the crystallizer are seldom perfect.

We analyze RTD using tracer experiments: A non-reactive tracer (e.g., dye) is introduced into the crystallizer, and its concentration at the outlet is monitored over time. The RTD curve is then used to calculate parameters such as the mean residence time and the variance, which quantify the degree of mixing. A broad RTD indicates poor mixing with uneven crystal growth. A narrow RTD shows more consistent growth conditions, leading to a more uniform product.

Practical Application: By analyzing the RTD, we can optimize the crystallizer design and operating parameters to ensure uniform residence time and ultimately, consistent crystal size and shape. For example, improved mixing through better impeller design or strategic baffles can significantly narrow the RTD.

Q 17. How do you prevent product degradation during the crystallization process?

Preventing product degradation during crystallization requires careful control of several factors. Heat, light, oxygen, and even mechanical stress can trigger degradation. Our strategies involve minimizing exposure to these factors:

- Temperature Control: Maintaining the crystallizer at the optimal temperature prevents thermal degradation. This might involve using efficient heat exchangers and precise temperature controllers.

- Inert Atmosphere: For oxygen-sensitive compounds, we use an inert atmosphere (e.g., nitrogen) to prevent oxidation.

- Light Protection: If light sensitivity is a concern, we use opaque tanks or limit exposure to light.

- Minimizing Shear Stress: Excessive agitation can cause crystal breakage and degradation. Careful impeller selection and control of agitation speed help to prevent this.

- Addition of Stabilizers: In some cases, adding stabilizers to the solution can help prevent degradation during the process.

- Short Processing Times: Minimizing the overall crystallization time reduces the total exposure to potentially degrading conditions.

Example: In the crystallization of aspirin, it’s crucial to avoid high temperatures as they can induce hydrolysis and decomposition. Low temperature operation and the use of an inert atmosphere are therefore critical.

Q 18. What are the common causes of crystal breakage in a crystallizer?

Crystal breakage is a significant challenge that affects product quality and downstream processing. The main causes include:

- High Shear Forces: Excessive agitation or improper impeller design can generate high shear forces, leading to attrition and breakage.

- Crystal-Crystal Collisions: High crystal concentrations and vigorous agitation lead to frequent collisions, resulting in breakage.

- Crystal Growth Defects: Crystals with internal defects are more prone to breakage.

- Improper Handling during Discharge: Rough handling during crystal removal can damage the crystals.

Mitigation Strategies: We address these issues through careful design and operation. For example, optimized impeller design, controlled agitation speeds, and the use of specialized crystallizers that minimize shear are key to preventing breakage.

Example: In a continuous crystallizer producing pharmaceutical products, even minor crystal breakage can compromise the purity and uniformity of the product, possibly causing defects that will need to be dealt with in a downstream operation. Minimizing breakage is paramount.

Q 19. How do you optimize crystal yield and purity?

Optimizing crystal yield and purity relies on a multi-faceted approach focusing on process control and design:

- Nucleation Control: Carefully managing supersaturation to promote a controlled number of nuclei helps to increase the average crystal size and reduce fines (small, unwanted crystals). Techniques include seeding and controlled cooling rates.

- Growth Optimization: Maintaining stable supersaturation and gentle agitation allows crystals to grow to their optimal size and shape, enhancing yield and purity. Consistent residence time further optimizes this.

- Impurity Removal: Using techniques like washing or recrystallization helps to increase the purity of the crystals. Careful selection of solvents and additives can further improve this.

- Process Monitoring and Control: Advanced instrumentation and control systems, such as online particle size analyzers and advanced process control (APC) software, are crucial in maintaining consistent operating conditions and ensuring optimal yield and purity.

Example: In the production of high-purity chemicals, even small amounts of impurities can significantly impact product quality. We typically implement multi-stage crystallization processes with intermediate purification steps to achieve the desired purity.

Q 20. Describe your experience with different types of crystallizer process control software.

My experience encompasses a range of crystallizer process control software, including:

- Aspen Crystallizer: A sophisticated process simulator capable of predicting crystal size distribution, yield, and purity under various operating conditions.

- DeltaV (Emerson): A distributed control system (DCS) widely used in the process industries for monitoring and controlling crystallizer parameters such as temperature, pressure, and agitation speed.

- Siemens SIMATIC PCS 7: Another widely used DCS providing similar functionality to DeltaV.

- In-house developed software solutions: In some specialized applications, custom software has been developed to precisely control certain crystallization parameters and integrate with online analytical sensors.

These platforms allow us to implement sophisticated control strategies, such as model predictive control (MPC) for optimizing crystallization processes in real-time, maximizing efficiency, yield, and product quality.

Q 21. How do you handle process upsets and deviations in a crystallizer?

Handling process upsets and deviations in a crystallizer requires a structured approach and a deep understanding of the process dynamics. The first step is always to ensure the safety of personnel and equipment. Then, a systematic investigation is needed:

- Identify the Root Cause: Use data from process sensors, alarm logs, and operator observations to pinpoint the source of the upset. This might involve analyzing deviations in temperature, supersaturation, or agitation.

- Implement Corrective Actions: Based on the root cause, implement immediate corrective actions to stabilize the process. This might include adjusting temperature, flow rates, or agitation speed.

- Prevent Recurrence: Investigate if there are any underlying issues contributing to the upset and implement preventative measures. This might involve refining control strategies, improving process monitoring, or implementing alarm settings.

- Data Analysis: Thorough analysis of the event using process historians is essential for understanding the dynamics of the upset and optimizing process control strategies for the future.

Example: A sudden loss of cooling water in a cooling crystallizer can lead to a rapid increase in temperature, resulting in excessive nucleation and a product with poor quality. The immediate corrective action would be to isolate the crystallizer and initiate emergency cooling procedures, while simultaneously investigating the root cause of the cooling water failure.

Q 22. Describe your experience with troubleshooting and resolving instrument malfunctions in a crystallizer.

Troubleshooting instrument malfunctions in a crystallizer requires a systematic approach. I begin by carefully reviewing the instrument’s alarm logs and historical data to identify the nature and timing of the malfunction. This often involves checking for unusual trends in temperature, pressure, or flow rate preceding the failure. For example, a sudden drop in temperature recorded by a thermocouple might indicate a heating element failure or a leak in the system. Then, I visually inspect the instrument itself for signs of physical damage, loose connections, or corrosion.

Next, I employ a process of elimination. If the problem is with a temperature sensor, I might first check the calibration and then substitute it with a known good sensor to isolate the fault. Similarly, problems with flow meters often involve checking for blockages or air pockets in the lines. If the issue remains unresolved after these basic checks, more advanced diagnostic tools and techniques such as loop testing, signal tracing, and calibration verification may be required. Finally, I meticulously document all troubleshooting steps, the root cause of the malfunction, and the corrective actions taken, ensuring compliance with safety regulations and GMP guidelines.

For example, during one project, a faulty conductivity sensor consistently yielded inaccurate readings, leading to inconsistent crystal size distribution. After verifying the sensor’s calibration and replacing the sensor with a spare, the issue was resolved. This highlighted the importance of regular calibration and having redundant instrumentation in place. My experience handling these situations emphasizes the need for quick, effective responses to minimize downtime and maintain product quality.

Q 23. How do you ensure the accuracy and reliability of process measurements in a crystallizer?

Ensuring accurate and reliable process measurements in a crystallizer is paramount for consistent product quality and efficient operation. This involves a multi-pronged approach. First, we select appropriate instruments for the specific measurement required, considering factors like accuracy, range, and environmental conditions. For instance, a robust, high-precision temperature sensor is crucial for monitoring the precise temperature changes during crystallization.

Regular calibration and verification are also key. We establish a rigorous calibration schedule using traceable standards and maintain detailed calibration records. This ensures that the instruments remain accurate and provide reliable data. In addition, we utilize redundant sensors and instrumentation whenever possible. Having backup systems minimizes downtime in case of a sensor failure. Regular preventive maintenance helps detect and address potential issues before they escalate into major problems. This can include cleaning sensors, checking for leaks, and verifying the integrity of the wiring.

Furthermore, advanced techniques like data reconciliation and statistical process control (SPC) are implemented to detect and correct systematic errors in the measurements and identify potential process drifts. Think of it like a quality control check for the measurements themselves. By implementing these strategies, we can maintain the highest levels of confidence in the accuracy of our process measurements and create a more stable and efficient crystallizer operation.

Q 24. What are the key performance indicators (KPIs) used to evaluate crystallizer performance?

Key Performance Indicators (KPIs) for evaluating crystallizer performance are crucial for optimization and process control. These KPIs typically focus on aspects of crystal quality, process efficiency, and overall production yield. Common KPIs include:

- Crystal Size Distribution (CSD): This describes the range and distribution of crystal sizes. A narrow CSD is generally desirable for improved filtration and product consistency.

- Yield: The percentage of desired product obtained relative to the input material. Higher yield indicates more efficient use of resources.

- Purity: The concentration of the desired crystal product relative to impurities. High purity is essential for meeting product specifications.

- Production Rate: The mass of crystals produced per unit time. A higher production rate indicates greater efficiency.

- Energy Consumption: The amount of energy used per unit mass of product. Lower energy consumption improves process sustainability and reduces operating costs.

- Downtime: The amount of time the crystallizer is not operating due to maintenance, cleaning, or malfunctions. Minimizing downtime maximizes productivity.

Analyzing these KPIs allows us to identify areas for improvement and make data-driven decisions to optimize the crystallizer’s performance. For instance, a consistently low yield might indicate problems with the seeding process or supersaturation control, prompting investigation and corrective actions.

Q 25. Explain your experience with different types of crystal size analyzers.

My experience encompasses various crystal size analyzers, each with its own strengths and limitations. These include:

- Laser Diffraction: This technique uses the diffraction pattern of a laser beam passing through a crystal suspension to determine particle size distribution. It’s widely used due to its speed and ability to analyze a wide range of sizes. However, it assumes spherical particles, which may not always be the case.

- Image Analysis: This method involves taking microscopic images of the crystals and using software to analyze their size and shape. It provides detailed information about crystal morphology, but is more time-consuming than laser diffraction.

- Dynamic Light Scattering (DLS): DLS measures the Brownian motion of particles in suspension to determine their size. It’s particularly useful for analyzing smaller crystals, but is sensitive to the presence of aggregates or other particles in the sample.

- Sieve Analysis: A traditional method that uses a set of sieves with decreasing mesh size to separate crystals based on their size. It’s simple and relatively inexpensive, but less accurate than more modern techniques, particularly for smaller particles.

The choice of analyzer depends on the specific application and the level of detail required. For example, for rapid online monitoring of CSD, laser diffraction might be preferred, whereas image analysis would be suitable for detailed offline characterization of crystal morphology.

Q 26. Describe your understanding of good manufacturing practices (GMP) in the context of crystallization.

Good Manufacturing Practices (GMP) in crystallization encompass a wide range of regulations and guidelines to ensure product quality, safety, and consistency. In the context of crystallization, GMP mandates meticulous attention to every stage of the process, from raw material handling to final product packaging.

This includes stringent documentation practices, maintaining detailed records of all process parameters (temperatures, pressures, flow rates, etc.), and having a robust cleaning validation procedure for equipment to prevent cross-contamination. It’s also imperative to perform regular instrument calibration and verification, implement effective quality control measures, and ensure that all personnel involved are properly trained and knowledgeable about GMP principles. We must also adhere to strict safety protocols to protect operators and the environment. For instance, proper handling of potentially hazardous chemicals and the use of appropriate personal protective equipment (PPE) are essential. Non-compliance with GMP guidelines can lead to product recalls, regulatory sanctions, and reputational damage.

A key aspect of GMP is traceability. Every step of the process should be thoroughly documented to allow for full tracking of materials and products throughout their lifecycle. This ensures that in case of any quality issues, the source of the problem can be quickly identified and addressed.

Q 27. How do you contribute to continuous improvement initiatives in a crystallizer process?

Contributing to continuous improvement initiatives in a crystallizer process involves proactively identifying opportunities for optimization and implementing changes to enhance efficiency, product quality, and safety. This involves several key strategies.

Firstly, we actively participate in process reviews and data analysis, using statistical process control (SPC) charts and other tools to identify trends and deviations from optimal operating conditions. This allows for early detection of potential problems and prompt corrective actions. Secondly, we explore new technologies and techniques to improve process performance. This can include evaluating new sensor technologies, advanced control strategies (like model predictive control), or novel crystallization methods. For example, introducing inline particle size analyzers can provide real-time feedback enabling faster process adjustments.

Furthermore, we actively seek out and share best practices both within the company and through professional networks. Attending industry conferences and workshops keeps us abreast of the latest advancements in crystallization technology. Finally, we emphasize training and development for our team members to improve their understanding of the crystallizer process and the importance of continuous improvement. By fostering a culture of continuous learning and improvement, we can continuously optimize our crystallizer operation and maintain a competitive edge.

Key Topics to Learn for Crystallizer Process Instrumentation Interview

- Crystallizer Types and Operation: Understand the different types of crystallizers (e.g., MSMPR, DTB, etc.) and their operational principles. Be prepared to discuss their advantages and disadvantages in various applications.

- Instrumentation for Process Control: Master the principles and applications of key instruments used in crystallizer processes, including temperature sensors, level transmitters, flow meters, and particle size analyzers. Know how these instruments contribute to effective process control.

- Process Monitoring and Data Acquisition: Familiarize yourself with data acquisition systems and their role in monitoring critical process parameters. Understand how to interpret data trends and identify potential issues.

- Advanced Process Control Strategies: Explore advanced control techniques like PID control, model predictive control (MPC), and their application in optimizing crystal size distribution and yield.

- Troubleshooting and Problem Solving: Practice identifying and resolving common problems in crystallizer processes. Be ready to discuss your approach to diagnosing issues based on process data and instrumentation readings.

- Safety and Operational Procedures: Understand the safety protocols and operational procedures specific to crystallizer processes. This includes handling hazardous materials and ensuring safe operation of equipment.

- Crystallization Kinetics and Thermodynamics: Develop a strong understanding of the fundamental principles governing crystallization processes. This includes nucleation, growth, and the influence of process parameters on crystal properties.

- Data Analysis and Interpretation: Be prepared to discuss your experience with analyzing process data, identifying trends, and using this information to improve process efficiency and product quality.

Next Steps

Mastering Crystallizer Process Instrumentation is crucial for advancement in process engineering and related fields. A strong understanding of these principles opens doors to exciting career opportunities and higher earning potential. To maximize your chances of landing your dream role, crafting an ATS-friendly resume is essential. This ensures your qualifications are effectively communicated to recruiters and hiring managers. We highly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides valuable tools and resources to help you create a compelling document that showcases your skills and experience. Examples of resumes tailored to Crystallizer Process Instrumentation are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.