Cracking a skill-specific interview, like one for Diesel Generators and UPS Systems, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Diesel Generators and UPS Systems Interview

Q 1. Explain the principle of operation of a diesel generator.

A diesel generator operates on the principle of converting the chemical energy stored in diesel fuel into mechanical energy, which is then used to generate electricity. This process involves four key strokes in a four-stroke engine: intake, compression, combustion, and exhaust.

Intake: The piston moves downward, drawing in a mixture of air into the cylinder.

Compression: The piston moves upward, compressing the air to a high pressure and temperature.

Combustion: Fuel is injected into the compressed air, igniting and causing a rapid expansion of gases, pushing the piston downward.

Exhaust: The piston moves upward again, expelling the burned gases from the cylinder.

This cyclical process drives a crankshaft, which rotates and turns a generator (alternator) to produce electricity. Think of it like a highly efficient internal combustion engine powering a giant electric motor in reverse.

The electricity generated is typically alternating current (AC), and a control system regulates the generator’s speed and output voltage to maintain a stable power supply. Larger generators often incorporate sophisticated monitoring and control systems to ensure optimal performance and prevent damage.

Q 2. Describe the different types of UPS systems and their applications.

UPS (Uninterruptible Power Supply) systems are categorized primarily by their architecture and the type of power they provide. The three main types are:

Online UPS: These systems continuously convert AC power to DC power and then back to AC power, providing constant, clean power. They offer the best protection against power disturbances, including brownouts and surges, and are ideal for critical applications like servers and medical equipment. Think of it as a constant buffer between the mains power and your load.

Offline (Standby) UPS: These systems only activate when the mains power fails. They are less expensive but provide less protection against power disturbances and have a longer switching time. They are suitable for less critical loads like home computers or basic office equipment. Think of it like a backup battery, only kicking in when the primary power source fails.

Line-Interactive UPS: These systems offer a compromise between online and offline UPS. They continuously regulate the voltage, providing protection against brownouts and surges, and switch to battery power when the mains power fails. They are more affordable than online UPS but offer better protection than offline UPS, and are a good choice for small businesses or home offices with moderately critical equipment. They act as a voltage regulator with a battery backup.

The choice of UPS depends heavily on the sensitivity of the equipment being protected, the frequency and severity of power outages in the area, and the budget.

Q 3. What are the key components of a diesel generator, and what are their functions?

A diesel generator comprises several critical components:

Diesel Engine: The heart of the system, responsible for converting fuel into mechanical energy. This includes the cylinders, pistons, crankshaft, and connecting rods.

Alternator: A rotating electrical machine that converts mechanical energy (from the engine) into electrical energy (AC power).

Control Panel: Houses the monitoring and control system, providing information on engine parameters (speed, temperature, pressure), load status, and allowing for start/stop operations and fault diagnosis.

Fuel Tank: Stores the diesel fuel needed for operation.

Exhaust System: Directs the exhaust gases away from the generator safely.

Cooling System: Keeps the engine at the optimal operating temperature, typically using either air or liquid cooling.

Starting System: Initiates the engine operation, often utilizing a battery and starter motor.

Battery: Provides power for starting the engine and often for some auxiliary functions.

Each component plays a crucial role in the overall function of the generator. Failure of any single component can lead to a malfunction or complete failure of the system.

Q 4. How does a UPS system provide uninterrupted power?

A UPS system provides uninterrupted power by using a battery to supply power to the connected equipment during a power outage or voltage fluctuation. When mains power is available, the UPS charges its battery and provides power directly to the load. However, when the mains power fails, the UPS instantly switches to battery power, ensuring that the connected equipment continues to operate without interruption. This switch is seamless in online UPS systems, while there is a short delay (a few milliseconds to several seconds) in offline and line-interactive UPS systems.

The battery’s capacity dictates the duration of the uninterrupted power. Once the battery is depleted, the UPS will shut down gracefully, giving the connected devices sufficient time to save data and shut down properly. Some UPS systems can be connected to external generators to extend the runtime even further.

Q 5. Explain the process of performing a routine maintenance check on a diesel generator.

Routine maintenance on a diesel generator is crucial for ensuring its reliability and longevity. A typical check includes:

Visual Inspection: Check for any leaks (fuel, oil, coolant), loose connections, or visible damage to components.

Fluid Levels: Inspect and top off engine oil, coolant, and fuel levels as needed.

Battery Check: Test battery voltage and ensure proper charging.

Air Filter Inspection/Replacement: A clogged air filter restricts airflow and reduces engine performance. Replace if necessary.

Belt Tension Check: Proper belt tension is essential for efficient power transfer. Adjust or replace belts as needed.

Load Test: Run the generator under a controlled load to assess its performance and identify any potential issues.

Exhaust System Check: Inspect for leaks or blockages.

Record Keeping: Meticulously document all maintenance activities, including dates, readings, and any repairs or replacements performed.

The frequency of these checks depends on the generator’s size, usage, and operating environment. Manufacturers usually provide detailed maintenance schedules.

Q 6. Describe the safety procedures you would follow when working on a diesel generator.

Safety is paramount when working on a diesel generator. Always follow these procedures:

Lockout/Tagout: Before performing any maintenance, ensure the generator is completely shut down and locked out to prevent accidental startup. Use appropriate lockout/tagout devices.

Personal Protective Equipment (PPE): Wear safety glasses, gloves, and sturdy footwear. If working in confined spaces, use appropriate respiratory protection.

Ventilation: Diesel generators produce exhaust gases, which are toxic. Ensure adequate ventilation to prevent carbon monoxide poisoning.

Hot Surfaces: Many components become very hot during operation. Allow sufficient cooling time before touching any part of the generator.

Electrical Safety: When working on electrical components, disconnect the power and use insulated tools.

Grounding: Ensure proper grounding to prevent electrical shocks.

Fire Safety: Keep a fire extinguisher nearby and be aware of potential fire hazards associated with fuel and electrical systems.

Consult Manuals: Refer to the manufacturer’s manuals for specific safety procedures and precautions for your particular model.

Ignoring safety procedures can lead to serious injuries or even fatalities.

Q 7. How do you troubleshoot a diesel generator that fails to start?

Troubleshooting a diesel generator that fails to start is a systematic process. Here’s a step-by-step approach:

Check the Battery: Test the battery voltage. If low, charge or replace the battery.

Fuel Supply: Verify that there is sufficient fuel in the tank and that the fuel lines are not clogged or damaged.

Starting System: Check the starter motor and its connections. Listen for any unusual noises during cranking. A weak cranking sound suggests a battery or starter motor issue.

Control Panel Checks: Review any fault codes or error messages displayed on the control panel. These often provide valuable clues.

Fuel Pump: Ensure the fuel pump is working correctly and supplying fuel to the engine.

Air Intake: Check the air filter for blockages. A clogged filter can prevent the engine from starting.

Engine Oil: Confirm that the engine has sufficient oil and the oil level is within the correct range.

Glow Plugs (for cold starting): If the engine is cold, ensure that the glow plugs are functioning and preheating the cylinders adequately before cranking.

Emergency Stop Switch: Ensure that the emergency stop switch is not engaged.

If none of these steps resolve the problem, it’s best to consult a qualified technician to diagnose and repair the issue. Improper repair attempts could worsen the problem or create safety hazards.

Q 8. What are the common causes of UPS system failures?

UPS system failures can stem from various sources, broadly categorized into battery issues, power problems, and system malfunctions. Let’s break it down:

- Battery Problems: This is the most common cause. Aging batteries lose capacity and can fail to deliver power during outages. Internal shorts or cell imbalances can also lead to failure. Think of a car battery – eventually, it needs replacing.

- Power Problems: Overloads on the UPS input can damage internal components. Similarly, prolonged brownouts (low voltage) can stress the system, reducing its lifespan and potentially causing failure. Imagine trying to run a powerful appliance on a weak power source – it’s not going to work well.

- System Malfunctions: These can range from faulty circuit breakers and fuses to problems with the inverter (which converts DC from the battery to AC for your devices), or the charging circuitry. It’s like a car needing a new alternator or starter motor – a vital part has failed.

- Environmental Factors: Extreme temperatures (too hot or too cold) can negatively impact battery life and system performance. Excessive dust or humidity can also cause malfunctions.

Regular maintenance, including battery testing and inspections, is crucial to prevent these issues.

Q 9. How do you troubleshoot a UPS system that is not providing power?

Troubleshooting a UPS that’s not providing power requires a systematic approach. Safety first! Always disconnect the UPS from the mains power before beginning any internal inspection.

- Check the obvious: Ensure the UPS is switched on and plugged into a functioning power outlet. Confirm the circuit breaker hasn’t tripped. It sounds simple, but it’s often overlooked.

- Inspect the input power: Use a multimeter to check if the mains power is present and within the correct voltage range. This rules out a problem with the building’s electricity.

- Examine the load: Is the load connected correctly and within the UPS’s capacity? An overload will shut down the system for protection.

- Check the battery: Measure the battery voltage. A low voltage indicates the batteries need replacing or charging. Listen for unusual noises – hissing or bubbling could indicate a serious problem.

- Inspect the UPS displays and alarms: Many UPS systems have indicators that show fault codes or error messages. Refer to the manual to understand what these mean.

- Consult the manual: The manual provides troubleshooting steps, diagrams, and specifications specific to your UPS model.

- Call a qualified technician: If you cannot identify and fix the problem, it’s best to call a qualified technician to avoid further damage or injury.

Q 10. Explain the concept of load sharing in a parallel diesel generator system.

Load sharing in a parallel diesel generator system means distributing the electrical load equally across multiple generators. This increases reliability, efficiency, and redundancy. Imagine a building needing a massive 1000kW of power. Rather than having one enormous generator, several smaller generators (e.g., three 350kW units) can be connected in parallel.

A sophisticated control system manages the load distribution, ensuring each generator carries its fair share. If one generator fails, the others automatically take over the extra load. This seamless transition ensures uninterrupted power supply. Key components involved include synchronizing panels, load sharing controllers, and protective relays, all working together to balance the load and safeguard the system.

The benefits are clear: increased uptime, reduced wear and tear on individual generators (as they’re not constantly running at maximum capacity), and improved fuel efficiency.

Q 11. What are the different types of diesel generator fuel systems?

Diesel generator fuel systems vary depending on size and application, but some common types include:

- Mechanical Fuel Injection Systems: These use a mechanical pump to deliver precisely metered fuel to the engine’s cylinders. They’re robust and reliable but can be less precise than electronic systems.

- Electronic Unit Injectors (EUI): These combine the fuel pump and injector into a single unit. They offer greater precision and fuel efficiency compared to mechanical systems. Think of them as a more sophisticated, computer-controlled version of mechanical systems.

- Common Rail Systems: Fuel is delivered to a common rail under high pressure, and electronically controlled injectors precisely time the fuel injection into each cylinder. This is the most advanced and efficient type, offering excellent control and emission reduction.

The choice of fuel system depends on factors like engine size, required performance, and emission regulations. Each system requires different levels of maintenance and expertise.

Q 12. How do you select the appropriate size UPS system for a particular load?

Selecting the right UPS size involves calculating the total power consumption of your critical load (the equipment requiring backup power).

- Determine the load’s power consumption: Check the nameplate of each device to find its wattage (W) or kilowatts (kW) rating. Add up all the power requirements to obtain the total load.

- Consider the power factor: The power factor represents the efficiency of the equipment’s use of power. A lower power factor means the actual power consumed is less than the apparent power. It’s important to factor this in for accurate sizing.

- Calculate the VA rating: The Volt-Ampere (VA) rating is the apparent power. To obtain the VA rating, divide the total power (Watts) by the power factor. (VA = Watts / Power Factor). UPS systems are typically rated in VA.

- Select a UPS with a suitable VA rating: Choose a UPS with a VA rating that’s higher than the calculated VA rating of the load. This ensures there’s enough capacity to handle surges and peak demands. As a general rule, allow for a 20-30% safety margin.

- Consider runtime requirements: How long do you need the UPS to power your equipment during an outage? This will determine the required battery capacity.

For example, if your total load is 1000W and the power factor is 0.8, the required VA rating would be 1250VA (1000W / 0.8 = 1250VA). You should choose a UPS with a higher VA rating, possibly 1500VA or more.

Q 13. Describe the importance of regular battery maintenance in a UPS system.

Regular battery maintenance is crucial for UPS system reliability and longevity. Neglecting this can lead to premature failure and leave you without backup power when you need it most. It’s like not changing your car’s oil; eventually, it will cause problems.

- Regular cleaning: Keep the battery terminals clean and free from corrosion using a wire brush and baking soda solution.

- Periodic voltage and load testing: Use a multimeter or load tester to check the battery voltage and capacity. This helps identify failing batteries before they cause complete failure.

- Visual inspections: Regularly check for any signs of damage, swelling, or leakage. A cracked or bulging battery is a serious safety hazard.

- Temperature monitoring: Ensure the battery environment is properly ventilated and within the manufacturer’s recommended temperature range.

- Environmental control: Protect batteries from excessive dust, moisture, or extreme temperatures.

- Scheduled replacements: Batteries have a limited lifespan and need to be replaced periodically, even if they appear to be working. Consult the manufacturer’s recommendations.

Proper battery maintenance reduces the risk of unexpected UPS failures, ensuring the continued protection of your critical equipment.

Q 14. What are the environmental considerations when operating a diesel generator?

Operating diesel generators involves significant environmental considerations due to their emissions. It’s crucial to minimize their impact:

- Emissions control: Modern generators employ various emission control technologies, including exhaust gas recirculation (EGR), selective catalytic reduction (SCR), and diesel particulate filters (DPF). Regular maintenance of these systems is vital to ensure effective emission reduction.

- Fuel efficiency: Properly maintained generators operate more efficiently, reducing fuel consumption and emissions.

- Noise reduction: Diesel generators can be noisy. Enclosures and mufflers can significantly reduce noise pollution.

- Air quality: Exhaust fumes contain harmful pollutants. Generators should be operated in well-ventilated areas or equipped with exhaust extraction systems.

- Fuel storage and handling: Proper fuel storage and handling practices prevent spills and leaks, which can contaminate soil and water.

- Compliance with regulations: Operating diesel generators requires adherence to local, regional, and national environmental regulations.

Choosing low-emission generators and implementing appropriate mitigation strategies are essential for responsible operation.

Q 15. Explain the concept of generator synchronization.

Generator synchronization is the process of connecting two or more generators to operate in parallel, supplying power to a common load. This is crucial for larger power systems or situations requiring redundancy. It ensures a stable and continuous power supply, preventing outages and load imbalances. Imagine it like adding another engine to a train – both engines need to be running at the same speed and in perfect alignment to pull the train smoothly.

Successful synchronization requires matching several parameters: voltage (magnitude and phase), frequency, and phase sequence. Any discrepancies can lead to significant damage to the generators and the electrical system. Specialized equipment like synchronizing panels or automatic synchronizers are used to ensure these parameters match before connecting the generators. These devices monitor the generators’ outputs and provide signals to initiate the connection only when the parameters are within acceptable tolerances.

- Voltage Matching: The voltage magnitude and phase angle of all generators must be nearly identical to prevent voltage surges or dips.

- Frequency Matching: The frequency of all generators needs to be within a very narrow tolerance (typically a fraction of a Hertz) to prevent large current flows during connection.

- Phase Sequence Matching: The order in which the voltage phases (A, B, C) reach their peak values must be identical for all generators.

Failure to properly synchronize generators can result in severe consequences, including generator damage, electrical equipment failure, and potential safety hazards. Therefore, meticulous synchronization procedures are essential for safe and reliable parallel operation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of UPS topologies?

Uninterruptible Power Supply (UPS) systems utilize various topologies, each with its strengths and weaknesses regarding efficiency, cost, and performance. The primary types are:

- Off-line (Passive Standby): This is the simplest and most cost-effective topology. The UPS only activates when the main power fails, switching to battery power. There’s a brief interruption in power during the transfer, making it unsuitable for critical applications requiring zero downtime. Think of it as a backup generator kicking in when the main power goes out.

- Line-Interactive: This topology offers improved performance over off-line UPS. It uses a voltage regulator to condition the incoming AC power, extending battery life and providing some protection against minor voltage fluctuations. However, it still relies on a transfer switch during outages, causing some power disruption.

- On-line (Double Conversion): This is the most reliable and expensive topology. It continuously converts AC power to DC and then back to AC, providing clean, uninterrupted power even during mains failures. The battery is always connected and ready to supply power instantly, ensuring zero downtime. This is the preferred choice for mission-critical applications, such as servers and data centers.

- Delta Conversion (Online UPS): A sophisticated topology that features higher efficiency than traditional online UPS systems while maintaining high-quality power delivery.

The choice of UPS topology depends heavily on the application’s criticality and budget constraints. For applications with tolerance for brief interruptions, an off-line or line-interactive UPS might suffice. However, for critical applications requiring zero downtime, an online or delta conversion UPS is essential.

Q 17. What are the safety regulations related to the operation of diesel generators?

Safety regulations related to diesel generator operation are stringent and vary by location, but common themes include:

- Exhaust Emission Control: Regulations limit harmful exhaust emissions, often requiring the use of catalytic converters or exhaust gas recirculation systems. Proper ventilation is crucial to prevent carbon monoxide poisoning.

- Fuel Handling: Safe storage and handling of diesel fuel are paramount. This includes preventing spills, ensuring adequate ventilation in fuel storage areas, and complying with fire safety regulations.

- Electrical Safety: Proper grounding, bonding, and isolation of electrical components are vital to prevent electric shock. Regular inspections and maintenance of electrical systems are necessary.

- Mechanical Safety: Rotating parts of the generator pose significant risks. Guards and safety interlocks are required to prevent accidental contact. Regular inspections and maintenance are crucial to ensure safe operation.

- Noise Control: Diesel generators can be noisy; regulations often specify noise limits. Soundproofing measures and proper installation location are critical.

- Fire Safety: Diesel fuel is flammable. Fire suppression systems, fire extinguishers, and clear fire evacuation plans must be in place.

- Personal Protective Equipment (PPE): Operators should always wear appropriate PPE such as safety glasses, gloves, and hearing protection.

Regular training for operators on safe operating procedures and emergency response is essential. Failure to comply with these regulations can result in accidents, fines, and legal repercussions.

Q 18. How do you interpret a diesel generator’s performance data?

Interpreting diesel generator performance data involves analyzing various parameters to assess its efficiency, reliability, and overall health. Key data points include:

- Fuel Consumption: Tracks the amount of fuel consumed per hour or kilowatt-hour. High fuel consumption can indicate mechanical problems or inefficiencies.

- Engine Oil Pressure and Temperature: Critical indicators of engine health. Low oil pressure or high temperatures suggest potential problems that need immediate attention.

- Coolant Temperature: Elevated coolant temperature can point to issues with the cooling system or engine overheating.

- Voltage and Frequency: Monitor the output voltage and frequency to ensure they stay within acceptable limits. Deviations can indicate problems with the alternator or control system.

- Load Current: Measures the electrical load on the generator. High load can overload the system.

- Exhaust Gas Temperature: Helps assess combustion efficiency and identify potential problems.

- Battery Voltage: Monitors the battery’s health and ensures its readiness for starting the engine.

Analyzing trends in this data over time is crucial. Sudden changes or consistent deviations from normal operating parameters often indicate developing problems that may be addressed before major failures occur. Data logging and remote monitoring systems can assist in this analysis, providing real-time insights into the generator’s performance.

Q 19. Describe the process of installing a new diesel generator.

Installing a new diesel generator is a complex process involving several stages:

- Site Assessment: This includes evaluating the site’s suitability, considering factors such as space requirements, access for delivery and maintenance, fuel storage, and exhaust ventilation.

- Foundation Preparation: A robust foundation is vital to support the generator’s weight and vibrations. This might involve concrete pouring and reinforcement.

- Generator Placement and Installation: The generator is carefully placed on the foundation, ensuring proper leveling and alignment.

- Fuel System Installation: This involves connecting the fuel tank, fuel lines, and fuel filters, ensuring proper flow and safety.

- Exhaust System Installation: The exhaust system needs to be appropriately sized and routed to safely vent exhaust gases away from the building. This often involves using appropriate silencers to reduce noise levels.

- Electrical System Installation: Connecting the generator to the electrical system involves wiring the generator to the ATS, load panel, and other components according to electrical codes and regulations. This is a crucial step requiring skilled electricians.

- Testing and Commissioning: Rigorous testing is conducted to ensure that the generator functions correctly, including load testing to assess its performance under varying conditions. Once all testing is complete, the generator is commissioned.

- Documentation and Training: Detailed documentation of the installation process and operation instructions is essential. Operator training is needed to cover safe operation and maintenance procedures.

The entire process requires strict adherence to safety regulations and best practices, with proper permits and inspections at each stage. It is best handled by experienced professionals.

Q 20. Explain the different types of generator controllers.

Generator controllers are sophisticated systems that monitor and regulate the operation of diesel generators. Various types exist, each offering different levels of functionality:

- Basic Controllers: These controllers provide essential functions such as starting, stopping, and monitoring basic parameters like voltage and frequency. They often feature simple displays and limited control capabilities.

- Advanced Controllers: These controllers offer more comprehensive monitoring and control capabilities, including load management, data logging, and remote monitoring. They can incorporate sophisticated algorithms for optimizing generator performance and fuel efficiency.

- Programmable Logic Controllers (PLCs): PLCs are used in large-scale power generation systems, offering highly flexible control and monitoring capabilities. They can integrate with other systems, providing automated control and sophisticated data analysis.

- Networked Controllers: These controllers can communicate with other devices and systems over a network, enabling remote monitoring, control, and diagnostics. This improves system management and facilitates proactive maintenance.

The choice of controller depends on the size and complexity of the generator system and the required level of control and monitoring. More sophisticated controllers offer greater flexibility, optimization potential, and enhanced system management capabilities.

Q 21. What is the role of automatic transfer switches (ATS) in power systems?

Automatic Transfer Switches (ATS) are crucial components in power systems that automatically switch the load between the normal power source (utility grid) and a backup power source, such as a diesel generator, in case of a power failure. They are safety devices designed to ensure uninterrupted power supply to critical loads. Think of it as a sophisticated light switch that automatically redirects the power when one source fails.

The ATS typically monitors the main power source. When a power outage is detected, it automatically disconnects the load from the utility grid and connects it to the backup generator. Once the main power is restored, the ATS seamlessly switches the load back to the utility grid. This process minimizes downtime and prevents power interruptions to sensitive equipment.

ATS configurations vary depending on the needs of the application, including single-source or multi-source configurations with different priorities. They are essential for ensuring business continuity in critical applications such as hospitals, data centers, and manufacturing plants where power outages could have significant consequences.

Q 22. How do you perform load testing on a UPS system?

Load testing a UPS system involves gradually increasing the load on the UPS until it reaches its maximum capacity or the battery begins to deplete. This helps to verify the UPS’s rated power output and runtime under various load conditions. It’s like stress-testing a car engine to see how it performs under duress.

The process typically involves using calibrated load banks—essentially resistive loads that mimic the actual equipment the UPS will power—to simulate different load profiles. You’d start with a small load and incrementally increase it, monitoring key parameters such as output voltage, current, frequency, and battery voltage. Any deviations from the specified parameters indicate potential issues.

For example, a UPS rated for 10kVA might be tested with 2kVA initially, then increased in increments of 2kVA or more, depending on the testing procedure and the UPS’s specifications. The test continues until the UPS hits its rated capacity or the battery voltage drops below the manufacturer’s specified threshold, indicating the system’s limit has been reached. Detailed logging of all parameters is crucial for accurate analysis and reporting.

Q 23. Explain the concept of runtime in a UPS system.

Runtime in a UPS system refers to the length of time the UPS can supply power to the connected load during a power outage, using its stored battery energy. Think of it as the endurance of a backup power source. It’s dependent on several factors, the most significant being the battery capacity and the load being drawn from the UPS. A larger battery capacity generally translates to a longer runtime, while a larger load will deplete the battery faster, reducing the runtime.

Manufacturers typically specify runtime at various load levels. For instance, a UPS might be advertised with a 10-minute runtime at full load and a 30-minute runtime at half load. This is because the same battery will power a smaller load for a much longer time than a larger one. Runtime is a crucial specification to consider when selecting a UPS for critical equipment, as it dictates how long your systems remain operational during power interruptions.

Q 24. What are the common causes of overheating in a diesel generator?

Overheating in a diesel generator can stem from several issues, all ultimately leading to reduced efficiency and potential damage. It’s like a car engine overheating – you need to address the underlying cause, not just the symptom.

- Insufficient Cooling: This is perhaps the most common cause. Problems with the radiator, cooling fan, or clogged air filters can restrict airflow and prevent efficient heat dissipation.

- Low Coolant Levels: A lack of coolant (usually water or a mixture of water and antifreeze) reduces heat transfer efficiency, leading to overheating.

- Faulty Thermostat: A malfunctioning thermostat may fail to regulate coolant flow appropriately, resulting in inadequate cooling.

- Fuel System Issues: Problems with fuel injection or excessive fuel can lead to incomplete combustion, generating excessive heat.

- Overloading: Running the generator at or above its rated capacity for extended periods places undue stress on the engine and can result in overheating.

- Lubrication Problems: Insufficient or degraded engine oil limits the lubrication of critical moving parts, leading to friction and heat generation.

Regular maintenance, including checking coolant levels, inspecting the cooling system, and replacing filters as scheduled, is vital to prevent overheating. Ignoring these issues can lead to significant engine damage and costly repairs.

Q 25. How do you calculate the required capacity of a UPS system?

Calculating the required capacity of a UPS involves several steps. You need to determine the total power consumption (in VA or Watts) of all the equipment you intend to protect. Think of it like calculating the total weight you need a truck to carry—you need to add up the weights of everything you’re transporting.

- List all critical loads: Identify all equipment that requires uninterrupted power and determine its power consumption (usually found on the equipment’s nameplate). Note whether the power rating is in Watts (real power) or VA (apparent power – which includes reactive power). VA is generally the more conservative value to use for UPS sizing.

- Sum the power consumption: Add up the power consumption of all identified loads. Ensure consistency in units (VA or Watts).

- Apply a safety factor: Add a safety factor (typically 10-20%, but can be higher depending on the criticality of the application) to account for future growth and unexpected power demands. This is like adding extra capacity to the truck to account for unforeseen items.

- Choose a UPS with sufficient capacity: Select a UPS with a rated power capacity greater than or equal to the calculated total power consumption plus the safety factor.

Example: If your total load is 5000 VA, and you apply a 20% safety factor, you’d need a UPS with a minimum capacity of 6000 VA (5000 VA + (5000 VA * 0.20)).

Q 26. Describe the different types of battery used in UPS systems.

UPS systems employ various battery types, each with its strengths and weaknesses. The choice depends on factors like runtime requirements, cost, and environmental considerations.

- Lead-Acid Batteries: The most common type, further categorized into flooded lead-acid (FLA), valve-regulated lead-acid (VRLA), and gel cell batteries. FLA batteries are cost-effective but require maintenance. VRLA and gel cell batteries are sealed, maintenance-free, and offer better performance in various environments but are generally more expensive.

- Lithium-ion Batteries: These batteries offer longer lifespans, higher energy density (more power for the same size), and faster charging times compared to lead-acid. However, they are significantly more expensive and may require more sophisticated battery management systems.

- Nickel-Cadmium (NiCd) Batteries: These are durable and have a long lifespan, but are expensive, heavy, and contain toxic materials, limiting their use.

The selection process often involves a trade-off between cost, performance, and environmental impact. Lead-acid remains dominant due to its relatively low cost, while lithium-ion is gaining traction for its superior performance characteristics in high-end applications.

Q 27. What are the advantages and disadvantages of using diesel generators versus other power sources?

Diesel generators offer a reliable, high-power backup solution, but they also come with drawbacks compared to other power sources.

Advantages:

- High Power Output: Diesel generators can provide significant power capacity, suitable for large facilities or critical applications.

- Relatively Low Fuel Cost (Compared to Gas): Diesel fuel is often cheaper than gasoline, resulting in lower operating costs over time.

- Long Runtime: Diesel generators can operate for extended periods, ideal for situations requiring long-term backup power.

Disadvantages:

- High Initial Cost: The upfront investment for a diesel generator is substantially higher than for smaller UPS systems or alternative solutions.

- Maintenance Requirements: Diesel generators require regular maintenance, including oil changes, filter replacements, and periodic servicing, which can add to the overall cost of ownership.

- Noise and Emissions: Diesel generators produce noise and exhaust emissions, requiring careful consideration of their location and environmental impact.

- Fuel Storage: Requires secure fuel storage, posing safety and environmental considerations.

The best choice depends on the specific application. Small businesses might find UPS systems sufficient, while large industrial facilities or hospitals may need the higher power capacity and longer runtime of diesel generators.

Q 28. Explain the importance of proper grounding in a power system.

Proper grounding in a power system is crucial for safety and equipment protection. It provides a low-resistance path for fault currents to flow back to the source, preventing dangerous voltage buildup and minimizing the risk of electric shock. Imagine it as a safety valve for the electrical system.

Grounding helps to:

- Prevent electric shock: If a fault occurs, grounding diverts the current to the ground, preventing it from flowing through a person touching the equipment.

- Protect equipment: Grounding helps to neutralize voltage surges and protect sensitive equipment from damage.

- Reduce noise and interference: Grounding minimizes electrical noise and interference that can affect sensitive electronic equipment.

- Ensure proper operation: Some equipment requires a proper ground connection to operate correctly.

Improper grounding can lead to serious hazards, including electrical fires, equipment damage, and potential fatalities. Regular inspection and maintenance of the grounding system are essential to ensure its effectiveness and safety.

Key Topics to Learn for Diesel Generators and UPS Systems Interview

- Diesel Generator Fundamentals: Understanding engine operation (4-stroke cycle, fuel injection, lubrication), generator principles (electromagnetism, voltage regulation), and maintenance schedules.

- UPS System Principles: Differentiating between different UPS topologies (online, offline, line-interactive), battery technologies and their characteristics, and understanding power factor correction.

- Practical Applications: Analyzing system sizing and load calculations for both diesel generators and UPS systems in various applications (e.g., hospitals, data centers, industrial facilities).

- Troubleshooting and Diagnostics: Familiarizing yourself with common malfunctions and their solutions, including fault finding techniques and safety protocols.

- Control Systems and Automation: Understanding the role of automatic transfer switches (ATS), SCADA systems, and remote monitoring capabilities for improved efficiency and reliability.

- Safety Regulations and Compliance: Knowledge of relevant safety standards and regulations related to the operation and maintenance of diesel generators and UPS systems.

- Economic Considerations: Analyzing lifecycle costs, fuel consumption, and maintenance strategies for optimal cost-effectiveness.

- Environmental Impact: Understanding emission control technologies and their importance in minimizing the environmental footprint of diesel generators.

Next Steps

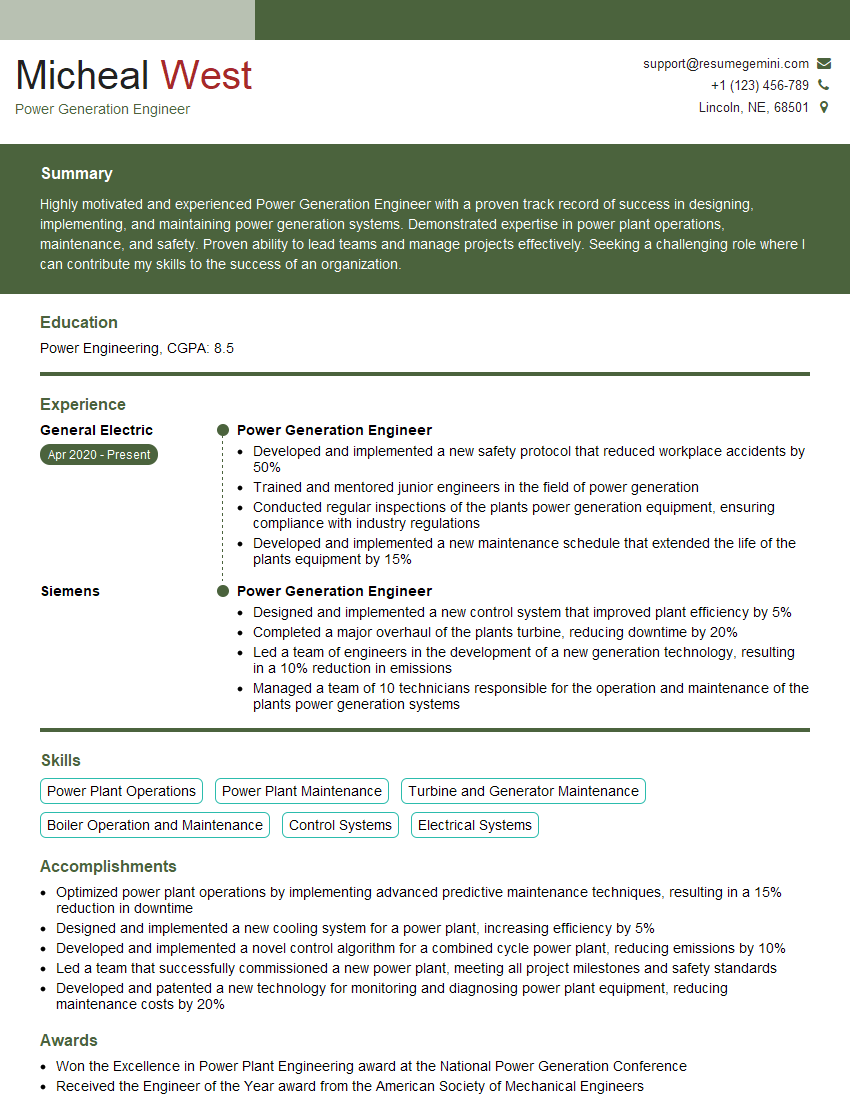

Mastering Diesel Generators and UPS Systems opens doors to exciting career opportunities in critical infrastructure management, energy solutions, and industrial automation. These skills are highly sought after, leading to competitive salaries and challenging roles. To maximize your job prospects, creating an ATS-friendly resume is crucial. ResumeGemini can help you craft a professional and impactful resume that highlights your expertise. We provide examples of resumes tailored to the Diesel Generators and UPS Systems field to guide you in building a winning application. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.