Are you ready to stand out in your next interview? Understanding and preparing for Effluent and Wastewater Treatment interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Effluent and Wastewater Treatment Interview

Q 1. Explain the different stages of a typical wastewater treatment process.

Wastewater treatment is a multi-stage process aiming to remove pollutants and make the water safe for discharge or reuse. A typical process can be broken down into the following stages:

- Preliminary Treatment: This initial step involves removing large debris like sticks, rags, and grit using screens, bar screens, and grit chambers. Think of it like pre-washing your clothes before putting them in the machine. This protects downstream equipment.

- Primary Treatment: Here, we use gravity to separate settleable solids from the wastewater. This is done in sedimentation tanks where heavier particles sink to the bottom, forming sludge, while lighter materials remain in the supernatant (the liquid on top). This is similar to letting sand settle at the bottom of a glass of water.

- Secondary Treatment: This is the core of the treatment process, where biological processes break down dissolved organic matter. The most common method is activated sludge, which uses microorganisms to consume pollutants. We’ll discuss this in more detail in the next answer. Other secondary treatment options include trickling filters and constructed wetlands.

- Tertiary Treatment (Advanced Treatment): This optional step removes remaining pollutants like nitrogen and phosphorus, and further improves water quality. Methods include filtration (sand, membrane), disinfection, and advanced oxidation processes.

- Sludge Treatment and Disposal: The sludge collected during primary and secondary treatment undergoes further processing, including thickening, digestion (anaerobic or aerobic), dewatering, and ultimately disposal or beneficial reuse (e.g., land application, incineration).

The specific stages and their intensity will depend on the characteristics of the wastewater, local regulations, and the desired level of treatment.

Q 2. Describe the principles of activated sludge treatment.

Activated sludge treatment leverages the power of microorganisms to break down organic matter in wastewater. It’s a biological process that relies on aerobic (oxygen-rich) conditions. Think of it as a tiny, highly efficient ecosystem within a tank.

The process involves:

- Aeration: Air is pumped into the aeration tank to provide dissolved oxygen for the microorganisms (primarily bacteria). This oxygen is crucial for their metabolic processes to break down organic matter.

- Microbial Growth: The bacteria consume the dissolved organic matter in the wastewater, using it as food and energy. This process converts the organic pollutants into biomass (more bacteria and other microorganisms) and carbon dioxide.

- Clarification: After aeration, the mixture is transferred to a clarifier (settling tank). The heavier biomass settles at the bottom, forming activated sludge. The clarified effluent (treated water) flows out from the top.

- Sludge Return: A portion of the settled activated sludge is recycled back to the aeration tank to maintain a healthy microbial population. This ‘seed’ ensures consistent treatment.

The activated sludge process is highly efficient at removing BOD (Biochemical Oxygen Demand) and suspended solids. It’s widely used in municipal and industrial wastewater treatment plants worldwide.

Q 3. What are the key parameters monitored in wastewater treatment, and why?

Monitoring key parameters is essential for ensuring the effectiveness and safety of wastewater treatment. Regular monitoring allows operators to identify potential problems early and make necessary adjustments.

Key parameters include:

- BOD (Biochemical Oxygen Demand): Measures the amount of dissolved oxygen consumed by microorganisms while decomposing organic matter. High BOD indicates a high level of organic pollution.

- COD (Chemical Oxygen Demand): Measures the total amount of oxygen required to oxidize all organic and inorganic matter in wastewater. Provides a broader picture of organic pollution than BOD.

- Suspended Solids (SS): Measures the total amount of solid particles in the wastewater. High SS indicates poor settling and potentially high turbidity.

- pH: Measures the acidity or alkalinity of the wastewater. Maintaining a suitable pH range (typically 6.5-8.5) is crucial for microbial activity.

- Nitrogen and Phosphorus: These nutrients can cause eutrophication (excessive algae growth) in receiving water bodies. Monitoring levels is important for nutrient removal efficiency.

- Disinfectants (e.g., Chlorine Residual): Monitoring ensures adequate disinfection after treatment to eliminate pathogens.

- Turbidity: Measures the clarity of the water; high turbidity indicates the presence of suspended solids.

Regular monitoring and analysis of these parameters allow for real-time process control and optimization, ensuring the treated effluent meets regulatory standards and environmental protection goals.

Q 4. Explain the role of aeration in wastewater treatment.

Aeration plays a vital role in wastewater treatment, particularly in biological processes like activated sludge. It’s the process of introducing air into the wastewater to provide dissolved oxygen (DO) for aerobic microorganisms.

The importance of aeration stems from the fact that these microorganisms need oxygen to effectively break down organic matter. Without sufficient DO, the aerobic bacteria die off, leading to anaerobic conditions (lack of oxygen) which can produce odorous and harmful by-products. Aeration ensures:

- Optimal Microbial Activity: Sufficient DO promotes vigorous growth and activity of aerobic bacteria, maximizing the breakdown of organic pollutants.

- Odor Control: Aerobic conditions prevent the formation of foul-smelling gases produced under anaerobic conditions.

- Efficient Pollutant Removal: Aerobic processes are much more efficient at removing pollutants compared to anaerobic processes.

- Sludge Stabilization: Aeration also plays a role in stabilizing the sludge, reducing its tendency to putrefy (decay) and generate foul odors.

Different aeration methods exist, such as diffused aeration (using air diffusers), surface aeration (using mechanical aerators), and others. The choice of method depends on factors like the size of the treatment plant, the characteristics of the wastewater, and operational costs.

Q 5. How do you control sludge production and disposal?

Controlling sludge production and disposal is a critical aspect of wastewater treatment. Sludge, a byproduct of the treatment process, needs careful management due to its potential environmental impact.

Strategies for sludge control include:

- Sludge Reduction Techniques: Optimizing the activated sludge process, using advanced treatment technologies (membrane bioreactors), and employing strategies like pre-treatment to reduce the amount of incoming solids can minimize sludge production.

- Sludge Thickening: Before further processing, sludge is thickened to increase its solids concentration, reducing transportation and disposal costs.

- Sludge Digestion: Anaerobic digestion is widely used, where microorganisms break down organic matter in the absence of oxygen, producing biogas (methane and carbon dioxide) which can be used for energy generation.

- Sludge Dewatering: Reducing the water content of sludge using methods like belt presses or centrifuges makes it easier to handle and transport.

- Sludge Disposal: Disposal methods include land application (after stringent testing), incineration, landfill disposal, and beneficial reuse in construction materials.

The best approach to sludge management depends on various factors such as local regulations, available technologies, and economic considerations. Careful planning and monitoring are vital to ensure environmentally sound and cost-effective sludge management.

Q 6. What are the different types of wastewater treatment membranes and their applications?

Membrane technology plays an increasingly important role in wastewater treatment, providing advanced treatment capabilities. Various membrane types exist, each with specific applications:

- Microfiltration (MF): Removes suspended solids and large colloids (particles larger than 0.1 µm). Often used as a pre-treatment step for other membrane processes or for polishing the effluent.

- Ultrafiltration (UF): Removes smaller particles (0.01-0.1 µm), including bacteria and viruses. Used for enhancing the quality of secondary effluent or treating specific industrial wastewaters.

- Nanofiltration (NF): Removes dissolved salts, organic molecules, and multivalent ions. It is suitable for softening water, desalination and advanced treatment of industrial effluents.

- Reverse Osmosis (RO): Removes dissolved salts, organic matter, and virtually all other substances, producing high-quality permeate. Used extensively for desalination, water reuse, and producing highly purified water.

Membrane bioreactors (MBRs) integrate membrane separation with biological treatment. MBRs combine the advantages of both activated sludge and membrane filtration, resulting in high-quality treated effluent with reduced sludge production. The choice of membrane depends on the desired level of treatment, the characteristics of the wastewater, and the overall cost-benefit analysis.

Q 7. Describe the process of disinfection in wastewater treatment.

Disinfection is the final stage in most wastewater treatment processes, aimed at eliminating harmful pathogens (bacteria, viruses, and protozoa) to protect public health and the environment.

Common disinfection methods include:

- Chlorination: Uses chlorine gas or hypochlorite to kill pathogens. It’s effective, relatively inexpensive, and widely used, but chlorine can form disinfection byproducts (DBPs) which may be harmful at high concentrations.

- UV Disinfection: Utilizes ultraviolet light to damage the DNA of microorganisms, rendering them inactive. It’s environmentally friendly, doesn’t produce DBPs, but requires careful design and operation to ensure effective treatment.

- Ozone Disinfection: Ozone is a powerful oxidant that kills pathogens quickly. It’s effective, doesn’t leave residual chemicals, but it’s more expensive than chlorine and requires on-site generation.

- Chloramine Disinfection: Chloramine is a compound formed by the reaction of chlorine with ammonia. It provides a longer-lasting disinfection residual than chlorine.

The choice of disinfection method depends on factors such as the effluent quality, cost, energy requirements, and regulatory standards. Effective disinfection is crucial to protect the health of people and ecosystems receiving the treated wastewater.

Q 8. Explain the importance of nutrient removal (nitrogen and phosphorus) in wastewater treatment.

Nutrient removal, specifically nitrogen and phosphorus, is crucial in wastewater treatment because these elements contribute significantly to water pollution. Excess nutrients cause eutrophication in receiving water bodies like lakes and rivers. This process leads to excessive algal growth, depleting oxygen levels and creating ‘dead zones’ where aquatic life cannot survive. Think of it like over-fertilizing a garden – too much nutrients leads to uncontrolled growth and ultimately harms the ecosystem.

Removing nitrogen and phosphorus is essential for protecting aquatic ecosystems, maintaining water quality for drinking and recreational purposes, and complying with environmental regulations. The methods used for nutrient removal typically involve biological processes, such as nitrification and denitrification for nitrogen and enhanced biological phosphorus removal (EBPR) for phosphorus, often integrated into advanced wastewater treatment plants.

Q 9. What are the common effluent discharge standards and regulations?

Effluent discharge standards and regulations vary significantly depending on the location (national, regional, or local) and the type of wastewater being discharged. Generally, these regulations set limits on various parameters to protect receiving water bodies. Commonly regulated parameters include:

- Biochemical Oxygen Demand (BOD): Measures the amount of oxygen consumed by microorganisms as they decompose organic matter. Lower BOD indicates less pollution.

- Chemical Oxygen Demand (COD): Measures the amount of oxygen required to chemically oxidize organic and inorganic matter. Provides a broader measure of pollution than BOD.

- Suspended Solids (SS): Represents the total amount of solid particles in the wastewater. High SS leads to turbidity and can harm aquatic life.

- Nitrogen (Nitrate and Ammonia): As discussed earlier, limits on nitrogen are crucial for preventing eutrophication.

- Phosphorus: Limits on phosphorus are also critical for preventing eutrophication.

- pH: The wastewater must have a pH within a specific range to avoid harming aquatic life.

- Specific Pollutants: Depending on the source of wastewater (e.g., industrial discharge), specific pollutants like heavy metals or organic chemicals might also be regulated.

Regulatory bodies, such as the Environmental Protection Agency (EPA) in the US or equivalent agencies in other countries, establish these standards and enforce compliance through regular monitoring and potential penalties for non-compliance. The specific limits will depend on factors such as the receiving water body’s sensitivity and designated use.

Q 10. How do you troubleshoot problems in a wastewater treatment plant?

Troubleshooting in a wastewater treatment plant requires a systematic approach. I typically follow these steps:

- Identify the problem: What is not working as expected? Are there changes in effluent quality, process performance indicators (e.g., BOD, SS), or operational parameters (e.g., flow, dissolved oxygen)?

- Gather data: Collect data from various sources, including SCADA systems, laboratory analyses, process monitoring instruments, and operational logs. This data helps pinpoint the source of the problem.

- Analyze the data: Look for patterns and correlations in the data. Are there any unusual trends or deviations from normal operating conditions? This step often involves using statistical process control (SPC) techniques.

- Develop hypotheses: Based on the data analysis, formulate potential causes for the problem. This might involve considering equipment malfunctions, process upsets, or changes in influent characteristics.

- Test hypotheses: Conduct experiments or make adjustments to the process to test the hypotheses. For example, if you suspect a problem with aeration, you might increase the air flow to see if it improves the situation. Careful documentation is crucial during this step.

- Implement corrective actions: Once the root cause is identified, implement the necessary corrective actions. This may involve repairing equipment, adjusting process parameters, or modifying the treatment process itself.

- Monitor the results: After implementing the corrective actions, closely monitor the system to ensure the problem is resolved and the plant is operating efficiently.

For example, if the effluent BOD is consistently high, I might investigate the performance of the activated sludge process by checking the mixed liquor suspended solids (MLSS), dissolved oxygen levels, and the sludge age. Low dissolved oxygen could indicate a problem with aeration, while low MLSS might indicate sludge wasting issues.

Q 11. Describe your experience with SCADA systems in wastewater treatment.

I have extensive experience with SCADA (Supervisory Control and Data Acquisition) systems in wastewater treatment plants. These systems play a vital role in monitoring and controlling various aspects of plant operations. In my previous roles, I used SCADA systems to:

- Monitor process parameters: Real-time monitoring of key parameters like flow rates, levels, pH, dissolved oxygen, and effluent quality.

- Control process equipment: Automated control of pumps, blowers, valves, and other equipment based on predefined setpoints or alarm conditions.

- Generate reports and alarms: Automated generation of operational reports and alerts for deviations from normal operating conditions.

- Analyze historical data: Access and analyze historical data to identify trends, optimize process performance, and troubleshoot problems.

- Remote access and control: Remote access to the plant’s SCADA system for monitoring and control, even when not physically present at the site.

I’m proficient in using various SCADA platforms, including GE iFIX, Wonderware InTouch, and Siemens WinCC. My experience includes designing, implementing, and maintaining SCADA systems for both new and existing wastewater treatment plants. I also have experience in integrating SCADA with laboratory information management systems (LIMS) for seamless data exchange and analysis. For instance, I once used SCADA data to identify a recurring pattern of high ammonia levels during periods of peak flow, leading to a successful upgrade of the nitrification process.

Q 12. What are the different types of filtration used in wastewater treatment?

Several filtration methods are used in wastewater treatment, each suited for specific purposes. These include:

- Screening: The initial step, removing large debris using bar screens or screens with varying mesh sizes. Think of it as a large sieve cleaning out twigs and larger items.

- Sedimentation: Allows suspended solids to settle out by gravity. Commonly used in clarifiers and settling tanks.

- Filtration: Can range from simple media filters (e.g., sand, gravel, anthracite) to more advanced membrane filtration techniques.

- Media filtration: Uses granular media to remove suspended solids and some dissolved pollutants. Similar to a coffee filter, but on a much larger scale.

- Membrane filtration: Includes microfiltration, ultrafiltration, nanofiltration, and reverse osmosis. These techniques can remove a much wider range of pollutants, including bacteria and viruses.

The choice of filtration method depends on several factors, including the type of wastewater, the desired effluent quality, and cost considerations. For example, membrane filtration is highly effective but can be more expensive than media filtration. In a typical municipal treatment plant, you might find screening, sedimentation, and media filtration, while advanced treatment facilities might also include membrane filtration.

Q 13. Explain the concept of biological nutrient removal.

Biological nutrient removal (BNR) relies on microbial processes to remove nitrogen and phosphorus from wastewater. It’s a cornerstone of advanced wastewater treatment. The process generally involves two main stages:

- Biological Phosphorus Removal (BPR): Certain microorganisms, known as polyphosphate-accumulating organisms (PAOs), uptake and store phosphorus during anaerobic conditions (low oxygen) and release it during aerobic conditions (high oxygen). This allows for efficient removal of phosphorus.

- Nitrification and Denitrification: Nitrification is the conversion of ammonia to nitrate by aerobic bacteria, while denitrification is the conversion of nitrate to nitrogen gas by anaerobic bacteria. This removes nitrogen from the wastewater. These processes often take place in separate tanks to optimize conditions for each bacterial group.

The effectiveness of BNR depends on careful control of several factors, including dissolved oxygen levels, the ratio of aerobic to anaerobic conditions, and the concentration of organic carbon. These processes are carefully orchestrated in a treatment plant to achieve optimal nutrient removal.

Think of it as a microbial community working together; some consume phosphorus under one set of conditions, and others consume nitrogen under different conditions. This biological dance effectively cleans the water.

Q 14. How do you manage and handle industrial wastewater?

Managing industrial wastewater requires a tailored approach based on the specific characteristics of the wastewater stream. This often involves a multi-step process:

- Characterization: Thorough analysis of the wastewater’s composition, including pH, BOD, COD, suspended solids, specific pollutants (heavy metals, organic chemicals), and flow rate. This is like understanding the patient’s symptoms before diagnosing them.

- Pre-treatment: This may involve equalization (to even out flow variations), pH adjustment, and removal of large debris or specific pollutants using methods like chemical precipitation or coagulation. This prepares the wastewater for further treatment.

- Treatment: Depending on the wastewater characteristics, various treatment methods can be used, including biological treatment (activated sludge, membrane bioreactors), chemical treatment (oxidation, coagulation), and physical treatment (filtration, sedimentation). The selection of the optimal method depends on the pollutants present and the required effluent quality.

- Effluent Monitoring: Continuous monitoring of effluent quality to ensure compliance with regulatory standards. Regular testing is vital to ensure the treatment is working effectively.

- Disposal or Reuse: Treated effluent might be discharged to a municipal wastewater treatment plant, reused within the industry, or disposed of through other means, such as deep well injection. The choice depends on regulatory requirements and cost-effectiveness.

For example, a textile mill might generate wastewater containing dyes and heavy metals. This would require specific pre-treatment steps such as coagulation to remove dyes and chemical precipitation to remove heavy metals before further treatment can occur. Effective industrial wastewater management protects both the environment and public health.

Q 15. Describe your experience with various types of pumps and blowers used in WWTPs.

Pumps and blowers are the workhorses of any wastewater treatment plant (WWTP), each crucial for different stages of the treatment process. My experience encompasses a wide range, including centrifugal pumps for moving large volumes of wastewater, submersible pumps for handling sludge and other solids, and positive displacement pumps for precise dosing of chemicals. Blowers, on the other hand, are essential for aeration in activated sludge processes. I’ve worked with various types, including rotary lobe blowers for high-pressure applications and centrifugal blowers for larger volumes at lower pressure. For example, in one project, we optimized the pump selection for a new wastewater treatment facility by conducting a hydraulic analysis to ensure efficient energy consumption and prevent cavitation. This involved modeling the flow rates and head pressures for different pump types and selecting the most cost-effective and energy-efficient option. In another project, we upgraded aging blowers in an existing WWTP, resulting in improved aeration efficiency and reduced energy costs.

Specific examples include experience with:

- Centrifugal pumps (e.g., end-suction, multi-stage)

- Submersible pumps (e.g., for sludge pumping)

- Positive displacement pumps (e.g., diaphragm pumps for chemical dosing)

- Rotary lobe blowers (for aeration systems)

- Centrifugal blowers (for aeration systems)

The selection of the right pump or blower is crucial. Factors considered include flow rate, head pressure, liquid characteristics (viscosity, abrasiveness), energy efficiency, maintenance requirements, and overall cost.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of anaerobic digestion.

Anaerobic digestion is a crucial biological process in wastewater treatment that breaks down organic matter in the absence of oxygen. This process is carried out by microorganisms which produce biogas – a mixture primarily of methane and carbon dioxide – as a byproduct. This biogas can be captured and used as a renewable energy source, significantly reducing the plant’s carbon footprint. The process typically occurs in a sealed digester where organic matter is broken down in stages, starting with the hydrolysis of complex organic molecules followed by acidogenesis, acetogenesis, and finally methanogenesis. The end products are biogas, digestate (a nutrient-rich fertilizer), and treated wastewater.

Think of it like a controlled composting process on a large scale. However, unlike composting, anaerobic digestion occurs in an oxygen-free environment. The process is significantly influenced by parameters like temperature (mesophilic or thermophilic), pH, and the composition of the feedstock. Effective monitoring of these parameters is vital for efficient anaerobic digestion. For example, I’ve been involved in projects where optimizing the feedstock composition improved biogas production by 15% by ensuring a balanced C:N ratio. We also implemented improved temperature control to maintain optimal digester performance. I’ve also had experiences resolving issues with digester foaming and acidification through adjustments of the feedstock and the implementation of corrective measures.

Q 17. What are the different types of wastewater treatment plants?

Wastewater treatment plants vary in size and complexity, depending on the volume and characteristics of wastewater they process. They can be broadly categorized as:

- Conventional Treatment Plants: These plants utilize a combination of primary, secondary, and tertiary treatment processes. Primary treatment involves physical removal of solids through screening and sedimentation. Secondary treatment employs biological processes like activated sludge or trickling filters to remove dissolved organic matter. Tertiary treatment involves advanced processes for nutrient removal (nitrogen and phosphorus) and disinfection.

- Waste Stabilization Ponds: These are natural systems that use sunlight and microorganisms to treat wastewater. They are cost-effective and energy-efficient but require large land areas and are not suitable for all wastewater types.

- Membrane Bioreactors (MBRs): These plants combine membrane filtration with biological treatment to achieve high effluent quality. MBRs are highly efficient and compact, producing a superior effluent quality compared to conventional systems, but they are more expensive to operate and maintain.

- Constructed Wetlands: These utilize natural processes involving plants and microorganisms to treat wastewater. They are environmentally friendly and relatively low maintenance but require a significant land area.

The choice of treatment plant type depends on factors such as the volume and quality of wastewater, available land area, budget constraints, and environmental regulations. I’ve worked with all of these types and understand their strengths and weaknesses in different contexts.

Q 18. What are the environmental impacts of poorly treated wastewater?

Poorly treated wastewater poses a significant threat to both human health and the environment. Untreated or inadequately treated effluent can lead to:

- Water pollution: Contamination of surface and groundwater with pathogens (bacteria, viruses), nutrients (nitrogen, phosphorus), and toxic substances. This can lead to eutrophication (algal blooms), oxygen depletion (leading to fish kills), and contamination of drinking water sources.

- Public health risks: Exposure to untreated wastewater can cause waterborne diseases such as cholera, typhoid, and gastroenteritis.

- Ecosystem damage: Pollution can harm aquatic life, disrupt ecological balance, and destroy sensitive habitats.

- Soil contamination: Irrigation with contaminated wastewater can lead to soil degradation and contaminate food crops.

- Air pollution: The release of odorous gases from inadequately treated wastewater can affect air quality and cause nuisance.

For example, I once worked on a project investigating a case of river pollution traced back to a poorly maintained WWTP. The lack of proper disinfection led to a significant increase in waterborne illnesses in the downstream community. The solution involved upgrading the disinfection system and implementing a stricter maintenance schedule.

Q 19. How do you ensure compliance with environmental regulations?

Ensuring compliance with environmental regulations is paramount in wastewater treatment. This involves several key steps:

- Regular monitoring and testing: Conducting routine analysis of wastewater influent and effluent to ensure parameters such as BOD, COD, TSS, nutrients, and pathogens are within regulatory limits.

- Record keeping: Maintaining detailed records of all monitoring data, treatment processes, and maintenance activities. This is vital for demonstrating compliance to regulatory authorities.

- Operational optimization: Regularly reviewing and optimizing treatment processes to maximize efficiency and minimize pollutant discharge.

- Permitting and reporting: Obtaining necessary permits and submitting regular reports to regulatory bodies.

- Emergency response planning: Developing and implementing plans to address unexpected events such as equipment failures or spills.

- Staying updated: Keeping abreast of changes in environmental regulations and best management practices.

In my experience, proactive compliance is key. This involves anticipating potential issues and taking preventative measures rather than reacting to problems after they occur. We use a robust data management system that automates reporting and analysis, allowing for immediate detection of deviations from regulatory limits. This allows for quick corrective actions to be implemented before non-compliance occurs.

Q 20. Explain the process of solids handling and disposal in wastewater treatment.

Solids handling and disposal are critical aspects of wastewater treatment. The process begins with the removal of solids through screening and sedimentation in the primary treatment stage. The resulting sludge undergoes further treatment, which may include:

- Thickening: Reducing the volume of sludge by concentrating the solids.

- Anaerobic digestion: Breaking down organic matter in the sludge to produce biogas and digestate.

- Stabilization: Reducing the putrescibility of sludge to prevent odor and health risks.

- Dewatering: Removing water from the sludge to reduce its volume and facilitate disposal.

Disposal methods depend on local regulations and environmental considerations. Common methods include:

- Land application (landfilling): Applying dewatered sludge to land as a soil amendment. This is only feasible with appropriately stabilized sludge.

- Incineration: Burning sludge to reduce its volume and produce energy (in some cases).

- Landfill disposal: Disposing of sludge in designated landfills that meet specific requirements.

I’ve worked on projects involving optimizing sludge thickening processes to reduce transportation costs and improving anaerobic digestion efficiency to maximize biogas recovery. A successful project involved the implementation of a new centrifuge dewatering system resulting in a significant reduction in the volume of sludge requiring disposal, leading to substantial cost savings.

Q 21. What are your experiences with different types of wastewater treatment chemicals?

My experience includes working with a variety of chemicals used in wastewater treatment, each with its specific function. These include:

- Coagulants and flocculants: Chemicals used to enhance the settling of suspended solids in primary and secondary treatment (e.g., alum, ferric chloride, polymers).

- Disinfectants: Chemicals used to kill pathogens in the final effluent (e.g., chlorine, ozone, UV radiation).

- pH adjusters: Chemicals used to adjust the pH of wastewater to optimize biological processes (e.g., lime, sulfuric acid).

- Nutrient removal chemicals: Chemicals used to remove excess nitrogen and phosphorus (e.g., ferric chloride, alum, activated carbon).

- Corrosion inhibitors: Chemicals used to protect equipment from corrosion (e.g., various phosphates).

The safe and efficient use of these chemicals requires careful consideration of dosage, handling procedures, and potential environmental impacts. For example, I’ve been involved in selecting and optimizing the use of polymer coagulants in an activated sludge plant, resulting in improved sludge settling and reduced sludge production. Safe handling of chemicals, such as chlorine, involves adhering to strict safety protocols to prevent health risks. Responsible chemical management is critical to environmental protection.

Q 22. Describe your experience with troubleshooting and repairing wastewater treatment equipment.

Troubleshooting wastewater treatment equipment requires a systematic approach combining practical experience with a deep understanding of the underlying processes. My experience involves diagnosing malfunctions in various components, from pumps and blowers to clarifiers and aeration systems. For instance, I once addressed a significant reduction in dissolved oxygen (DO) levels in an activated sludge process. After systematically checking flow rates, aeration system performance, and inspecting the aeration diffusers for clogging, I discovered a malfunctioning air compressor. Replacing the compressor quickly restored the DO levels and prevented a potential process failure. Other common issues I’ve handled include pump seal failures, which I addressed using preventative maintenance schedules and proper lubrication; and issues with sludge thickening, often solved by optimizing polymer dosage and flocculation.

My approach typically involves:

- Careful observation: Assessing the overall system performance and identifying any unusual indicators (e.g., unusual noises, odors, or changes in effluent quality).

- Data analysis: Examining historical data (e.g., flow rates, DO levels, pH, sludge volume index) to identify trends and pinpoint the source of the problem.

- Systematic troubleshooting: Using a methodical approach to eliminate potential causes, often working my way from the simplest to the most complex possibilities.

- Component testing: Conducting tests on individual components (e.g., checking pump performance, evaluating blower efficiency) to confirm their functionality.

- Repair or replacement: Implementing the necessary repairs or replacing faulty components.

Q 23. How do you optimize energy efficiency in wastewater treatment?

Optimizing energy efficiency in wastewater treatment plants is crucial for both environmental and economic reasons. It involves a multi-pronged strategy focusing on process optimization and equipment upgrades. For example, optimizing aeration systems – a significant energy consumer – can yield substantial savings. This can involve implementing techniques like using dissolved oxygen (DO) control strategies to avoid over-aeration or utilizing advanced aeration equipment with higher oxygen transfer efficiency. I’ve successfully implemented variable frequency drives (VFDs) on numerous blower systems, leading to energy savings of up to 30% by adjusting the blower speed according to the actual oxygen demand.

Other strategies include:

- Energy-efficient equipment: Utilizing high-efficiency pumps, motors, and other equipment.

- Process optimization: Fine-tuning process parameters to minimize energy consumption while maintaining treatment efficiency (e.g., optimizing sludge retention time, optimizing the aeration process).

- Waste heat recovery: Utilizing waste heat from processes (e.g., digesters) to pre-heat incoming water or for other purposes.

- Renewable energy sources: Integrating renewable energy sources, such as solar or wind power, into the plant’s energy supply.

- Data analytics: Using data analytics tools to monitor energy consumption and identify areas for improvement.

Q 24. Describe your experience with designing or upgrading wastewater treatment systems.

My experience encompasses the complete lifecycle of wastewater treatment system design and upgrades, from conceptual design to commissioning and start-up. This includes specifying equipment, managing budgets, overseeing construction, and ensuring compliance with environmental regulations. For instance, I was involved in a project to upgrade an outdated activated sludge plant to improve its treatment efficiency and reduce its energy footprint. This involved designing a new aeration system with improved oxygen transfer efficiency, installing a new sludge thickening system, and upgrading the plant’s control system to incorporate advanced process monitoring and control capabilities. This resulted in a 20% increase in treatment efficiency and a 15% reduction in energy consumption.

My design process emphasizes a holistic approach, considering factors such as:

- Hydraulic design: Ensuring adequate flow capacity throughout the system.

- Process design: Selecting the appropriate treatment processes to meet the specific requirements of the wastewater.

- Equipment selection: Specifying cost-effective, energy-efficient equipment.

- Instrumentation and control: Designing a robust control system to monitor and control the plant’s operation.

- Environmental compliance: Ensuring compliance with all relevant environmental regulations.

Q 25. What are some common challenges encountered in wastewater treatment and how do you address them?

Wastewater treatment faces numerous challenges, many stemming from variations in influent characteristics and technological limitations. One common challenge is dealing with high levels of toxic substances or fluctuating influent flows. High concentrations of toxic substances can inhibit biological processes, whereas variable flow rates can stress the system’s capacity and lead to effluent quality issues. To address these, we might implement pretreatment processes to remove or neutralize the toxins or install equalization basins to even out flow fluctuations. Another frequent issue involves managing sludge production and disposal. Optimizing sludge dewatering processes and exploring beneficial reuse options for the sludge (e.g., as a soil amendment or in energy generation) are vital solutions.

Other challenges include:

- Funding limitations: Securing adequate funding for plant upgrades and maintenance.

- Regulatory compliance: Meeting increasingly stringent environmental regulations.

- Operator training: Ensuring that plant operators have the skills and knowledge to run the plant efficiently and effectively.

- Emerging contaminants: Dealing with the presence of emerging contaminants (e.g., pharmaceuticals, personal care products) in wastewater.

Q 26. Explain your understanding of advanced oxidation processes (AOPs).

Advanced Oxidation Processes (AOPs) are a suite of chemical oxidation technologies used to remove recalcitrant pollutants from wastewater that are difficult to remove by conventional treatment methods. These processes involve the generation of highly reactive hydroxyl radicals (•OH), which are potent oxidants capable of degrading a wide range of organic and inorganic contaminants. Different AOPs utilize various methods for •OH generation, such as UV/H2O2, O3/H2O2, and Fenton’s reagent (Fe2+/H2O2).

For example, UV/H2O2 utilizes ultraviolet (UV) light to photolyze hydrogen peroxide (H2O2), generating •OH radicals. This is effective for removing various micropollutants such as pesticides and pharmaceuticals. The choice of AOP depends on factors such as the nature of the contaminants present, the desired treatment level, and the cost-effectiveness of the process. AOPs are often integrated into existing treatment plants as a polishing step to further enhance the effluent quality.

Q 27. What software or tools are you proficient in for wastewater treatment processes?

Proficiency in various software and tools is essential for effective wastewater treatment management. I am highly proficient in using several industry-standard software packages such as:

- SCADA (Supervisory Control and Data Acquisition) systems: These systems allow for real-time monitoring and control of wastewater treatment processes. My experience includes working with various SCADA platforms, including Siemens WinCC and Rockwell Automation RSView.

- Process simulation software: Software like GPS-X and BioWin helps model and optimize wastewater treatment processes, enabling better design and operation.

- Data analysis software: I utilize statistical software packages (like R or SPSS) and spreadsheet software (like Excel) for analyzing process data to identify trends, optimize processes, and troubleshoot issues.

- CAD software: Autodesk AutoCAD and similar software are used for the design and drafting of wastewater treatment plant layouts and piping diagrams.

In addition to these, I’m comfortable using various data logging devices and analytical instruments common in wastewater labs to collect and analyze samples.

Q 28. Describe your experience with developing and implementing a wastewater treatment plant operations and maintenance plan.

Developing and implementing a comprehensive operations and maintenance (O&M) plan is crucial for ensuring the long-term efficiency and reliability of a wastewater treatment plant. This plan is not merely a document; it’s a living strategy that guides daily operations, preventative maintenance, and emergency response. Creating such a plan involves meticulous attention to detail and a deep understanding of the plant’s specific processes and equipment. It typically includes:

- Detailed equipment descriptions: Including specifications, schematics, and operational parameters.

- Preventative maintenance schedules: Specifying regular inspections, cleaning, and repairs for each piece of equipment.

- Spare parts inventory: Maintaining a sufficient inventory of essential spare parts to minimize downtime.

- Operator training programs: Providing operators with the skills and knowledge to safely and efficiently operate and maintain the plant.

- Emergency response procedures: Establishing clear protocols for responding to equipment failures, spills, or other emergencies.

- Performance monitoring and reporting: Tracking key performance indicators (KPIs) and generating regular reports to evaluate the plant’s performance.

Implementing this plan involves regular review and updates based on plant performance and technological advancements. The plan is instrumental in minimizing operational costs, maximizing the lifespan of equipment, and ensuring the consistent delivery of high-quality effluent.

Key Topics to Learn for Effluent and Wastewater Treatment Interview

- Wastewater Characteristics: Understanding the physical, chemical, and biological properties of wastewater influent, including suspended solids, BOD, COD, nitrogen, phosphorus, and pathogens.

- Pretreatment Processes: Familiarize yourself with screening, grit removal, and flow equalization, and their impact on downstream processes.

- Primary Treatment: Grasp the principles and applications of sedimentation and its role in removing settleable solids.

- Secondary Treatment: Master the concepts of activated sludge, trickling filters, and rotating biological contactors, including their operational parameters and limitations.

- Tertiary Treatment: Explore advanced treatment technologies such as filtration, disinfection (UV, chlorine), and nutrient removal (nitrification/denitrification, phosphorus removal).

- Sludge Treatment and Disposal: Learn about thickening, digestion (aerobic and anaerobic), dewatering, and land application or incineration of sludge.

- Effluent Discharge Standards and Regulations: Understand the legal framework governing effluent discharge and compliance monitoring.

- Instrumentation and Process Control: Become familiar with the various sensors, meters, and control systems used in wastewater treatment plants.

- Troubleshooting and Problem-Solving: Develop your ability to analyze operational issues, identify causes, and implement effective solutions. This includes understanding process upsets and their remediation.

- Sustainability and Energy Efficiency in Wastewater Treatment: Explore the latest advancements in energy-efficient technologies and sustainable practices.

Next Steps

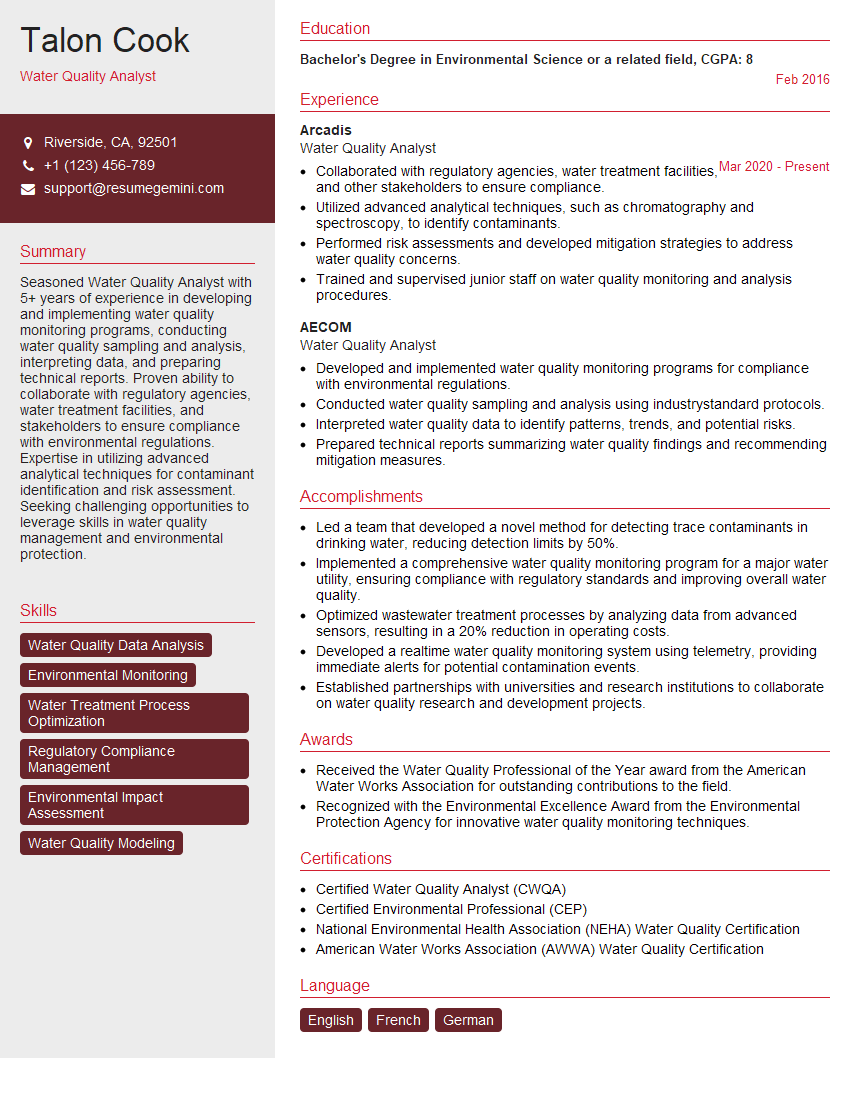

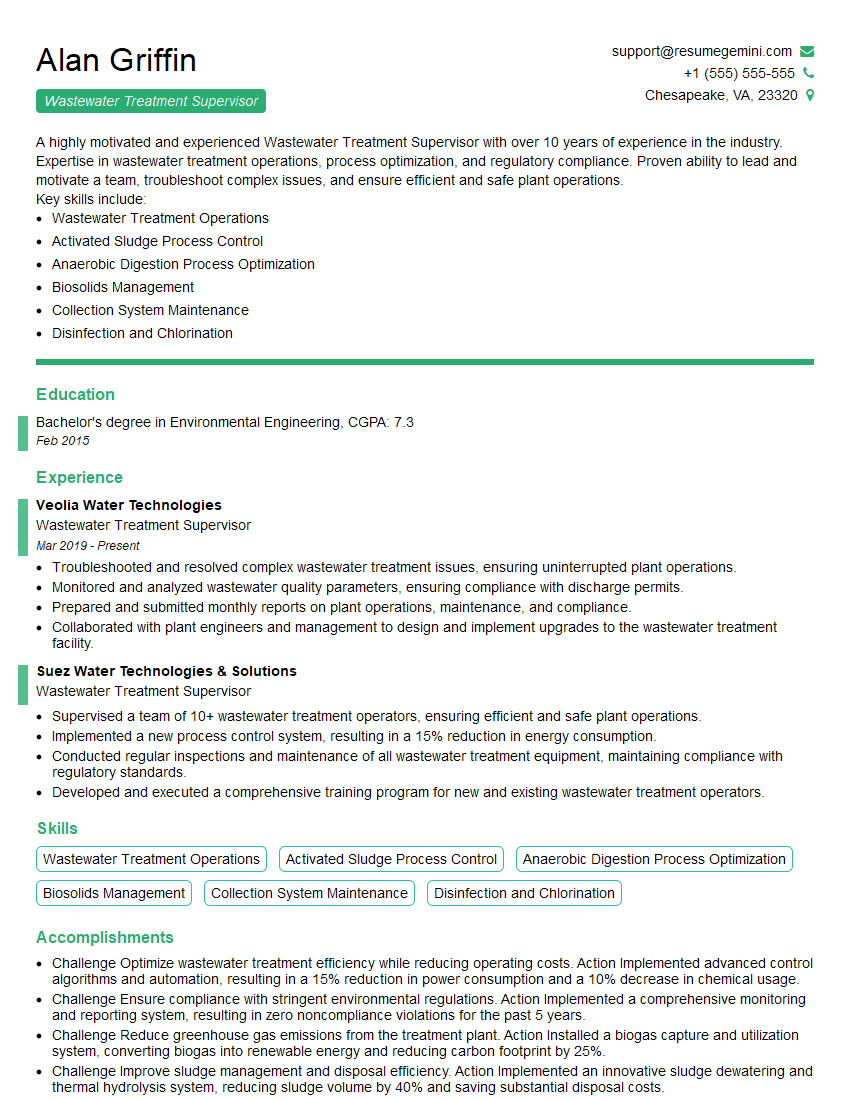

Mastering Effluent and Wastewater Treatment opens doors to a rewarding career with diverse opportunities for growth and specialization. A strong understanding of these processes is highly sought after in the environmental sector, leading to positions with increasing responsibility and impact. To significantly boost your job prospects, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and effective resume that highlights your skills and experience. ResumeGemini provides examples of resumes tailored to the Effluent and Wastewater Treatment field to guide you in crafting the perfect application. Take advantage of these resources to present yourself as a strong and qualified candidate.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.